In the world of material cutting, two powerful contenders stand tall: Nd:YAG laser cutters and rotary cutters. Like two skilled warriors, these cutting tools fiercely compete for the title of efficiency champion.

Imagine a battle between a swift and precise laser beam and a rotating, razor-sharp blade. Who will emerge victorious? Which cutting method will reign supreme?

In this article, we delve into the epic clash between Nd:YAG laser cutters and rotary cutters, meticulously evaluating their performance, precision, versatility, and efficiency. By analyzing their cutting capabilities, we uncover the strengths and weaknesses of each contender.

We also explore the factors influencing their overall effectiveness, such as speed, cost, and adaptability.

Prepare to immerse yourself in a technical and precise analysis as we uncover the truth behind these cutting solutions. Join us on this journey as we determine whether the mighty Nd:YAG laser cutter or the formidable rotary cutter will claim the coveted title of the most efficient cutting tool.

Key Takeaways

- Nd:YAG laser cutters are limited to metals and ceramics, while rotary cutters can cut a wide range of materials including fabrics, paper, and plastics.

- Nd:YAG laser cutters offer high precision and accuracy, making them ideal for intricate designs and delicate materials.

- Rotary cutters are more cost-effective with lower upfront costs and maintenance, making them suitable for low-volume production runs.

- The choice between Nd:YAG laser cutters and rotary cutters depends on factors such as material type, desired cutting speed, and budget, and should be based on the specific requirements and priorities of the user.

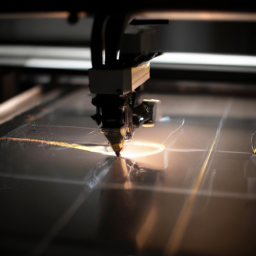

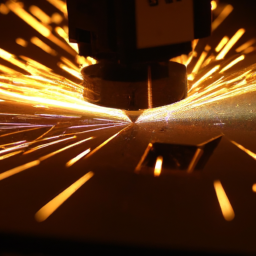

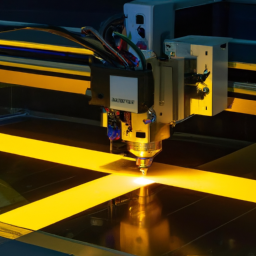

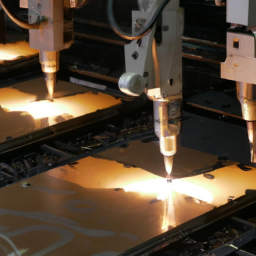

Performance Comparison of Nd:YAG Laser Cutters and Rotary Cutters

When comparing the performance of Nd:YAG laser cutters and rotary cutters, it’s important to consider which one is more efficient. Rotary cutters have several advantages over Nd:YAG laser cutters.

Firstly, rotary cutters are capable of cutting a wide range of materials, including fabrics, paper, and plastics, whereas Nd:YAG laser cutters are limited to certain materials like metals and ceramics.

Additionally, rotary cutters can handle thicker materials and are not affected by heat distortion, while Nd:YAG laser cutters may cause warping or melting.

Moreover, rotary cutters are faster and more cost-effective, as they don’t require the use of expensive laser technology.

Considering these advantages of rotary cutters and the limitations of Nd:YAG laser cutters, it becomes evident that rotary cutters offer superior efficiency in various cutting applications.

Moving forward, precision and accuracy in evaluating cutting capabilities will be discussed.

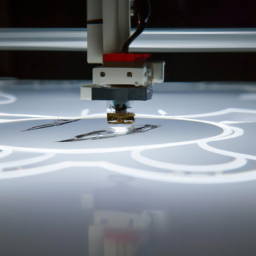

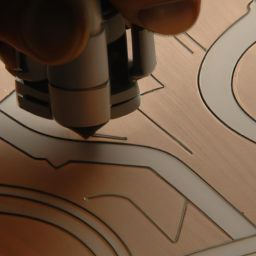

Precision and Accuracy: Evaluating the Cutting Capabilities

To truly experience the remarkable precision and mind-blowing accuracy of this cutting technology, you need to try it for yourself. Evaluating the cutting capabilities of Nd:YAG laser cutters and rotary cutters requires careful consideration of various evaluation methods.

Technological advancements have greatly improved the precision and accuracy of both types of cutters, making it challenging to determine which one is more efficient. Laser cutters utilize high-powered lasers to melt or vaporize the material, resulting in incredibly precise cuts. On the other hand, rotary cutters employ a rotating blade to slice through the material with exceptional accuracy.

Both methods offer their own advantages and limitations, making it essential to understand your specific application requirements.

In the subsequent section about versatility and applications: which cutter fits your needs?, we will explore the different factors to consider when choosing between Nd:YAG laser cutters and rotary cutters.

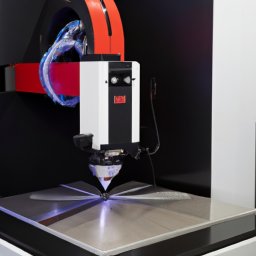

Versatility and Applications: Which Cutter Fits Your Needs?

If you’re looking for a cutting solution that can handle a wide range of applications, it’s important to consider the versatility and suitability of each option. When evaluating cutting techniques, it’s crucial to assess their material compatibility and ability to meet your specific needs. While both the Nd:YAG laser cutters and rotary cutters have their advantages, they differ in terms of their versatility.

A comparison of the two cutting methods reveals that Nd:YAG laser cutters excel in precision and accuracy, making them ideal for intricate designs and delicate materials such as electronics and jewelry. On the other hand, rotary cutters offer more versatility in terms of material compatibility, as they can handle a broader range of materials, including fabrics, plastics, and metals.

To further illustrate this point, consider the following table:

| Nd:YAG Laser Cutters | Rotary Cutters | |

|---|---|---|

| Precision and Accuracy | High | Moderate |

| Material Compatibility | Limited | Wide Range |

As you can see, Nd:YAG laser cutters are more precise and accurate, but their material compatibility is limited compared to rotary cutters. However, it’s important to note that efficiency in production is not solely determined by versatility. In the next section, we will delve into the analysis of efficiency in production, including time and cost considerations.

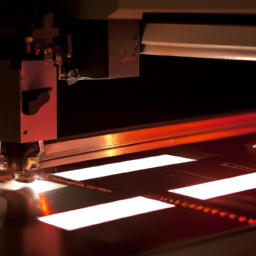

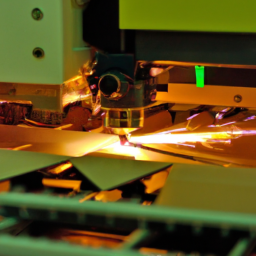

Efficiency in Production: Time and Cost Analysis

Efficiency in production can be analyzed by considering the factors of time and cost. When comparing nd:yag laser cutters and rotary cutters, it’s important to evaluate their cost effectiveness and production optimization.

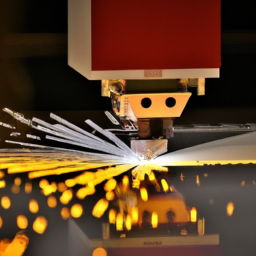

Nd:yag laser cutters are known for their high precision and speed, allowing for faster cutting times and increased productivity. Additionally, they have the advantage of being able to cut through a wide range of materials with minimal heat-affected zones.

On the other hand, rotary cutters are more cost effective for certain applications as they have lower upfront costs and require less maintenance. However, their cutting speed is typically slower compared to laser cutters.

Ultimately, the choice between these two cutting tools will depend on the specific needs and priorities of the production process. Factors such as material type, desired cutting speed, and budget will influence the overall effectiveness of the chosen tool.

Transitioning into the subsequent section, it’s essential to consider these factors to make an informed decision.

Factors Influencing Overall Effectiveness of Cutting Tools

Factors such as material type, desired cutting speed, and budget play a crucial role in determining the overall effectiveness of the chosen cutting tool. When considering laser cutting advancements, it’s important to assess the material compatibility with the Nd:YAG laser cutter. This type of laser cutter is highly efficient for cutting metals, especially stainless steel and aluminum, but may not be as effective for cutting certain organic materials or plastics.

On the other hand, rotary cutters offer versatility in cutting a wide range of materials, including fabrics, plastics, and woods. Additionally, rotary cutters are often more cost-effective for low-volume production runs. Therefore, when deciding on the most efficient cutting solution, it’s essential to consider the specific material requirements, desired cutting speed, and available budget.

Transitioning into the subsequent section, the final verdict will analyze these factors to determine the most efficient cutting solution.

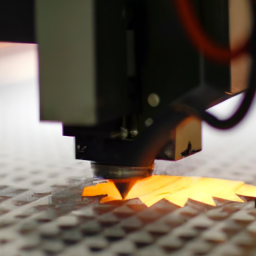

Final Verdict: Determining the Most Efficient Cutting Solution

In the final analysis, when it comes to choosing the most efficient cutting solution, it’s like finding the perfect pair of scissors that effortlessly glides through any material, making the job easier and more enjoyable.

To determine the most efficient cutting solution between ND:YAG laser cutters and rotary cutters, a thorough cost effectiveness and speed analysis is essential.

Cost effectiveness considers the initial investment, maintenance costs, and operating expenses associated with each cutting tool.

Speed analysis evaluates the time taken to complete a cutting task with each tool.

It’s important to consider the specific requirements of the project and the materials being cut.

While ND:YAG laser cutters offer high precision and versatility, rotary cutters excel in speed and cost effectiveness for certain applications.

Ultimately, the most efficient cutting solution depends on the unique needs and priorities of the user.

Frequently Asked Questions

What is the difference between a Nd:YAG laser cutter and a rotary cutter?

The main difference between an Nd:YAG laser cutter and a rotary cutter lies in their cutting methods. An Nd:YAG laser cutter utilizes a high-powered laser beam to cut materials with precision and speed, offering various advantages. These include the ability to cut intricate designs, minimal material wastage, and a clean cutting edge.

In contrast, rotary cutters rely on a rotating blade to cut materials, which can be limiting due to the risk of imprecise cuts, limited design options, and increased material wastage.

Can both Nd:YAG laser cutters and rotary cutters be used on all types of materials?

When considering the use of nd:yag laser cutters and rotary cutters on different materials, it’s important to weigh the pros and cons. Nd:yag laser cutters offer precise and clean cuts on a wide range of materials, including metals and plastics. However, they may not be suitable for highly reflective or transparent materials.

On the other hand, rotary cutters excel at cutting fabrics and textiles, but may struggle with harder materials. Understanding these limitations will help you make an informed decision.

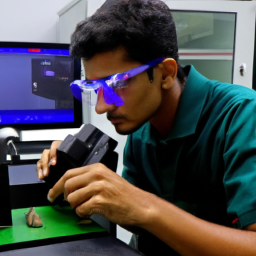

Are there any safety concerns associated with using Nd:YAG laser cutters?

When using nd:YAG laser cutters, it’s important to take safety precautions and implement protective measures. The high power laser beam can pose a risk to the eyes and skin, so wearing appropriate safety goggles and gloves is crucial.

Proper ventilation should be in place to prevent the inhalation of fumes and dust. It’s also important to follow manufacturer guidelines and receive proper training to ensure safe operation of the laser cutter.

How do Nd:YAG laser cutters and rotary cutters compare in terms of maintenance and upkeep?

In terms of maintenance and upkeep, nd:YAG laser cutters and rotary cutters differ significantly.

Nd:YAG laser cutters require regular cleaning and calibration to ensure optimal performance, which can be time-consuming and costly.

On the other hand, rotary cutters have minimal maintenance needs and are relatively low-cost to maintain.

Additionally, when it comes to speed comparison, nd:YAG laser cutters outshine rotary cutters with their lightning-fast cutting capabilities.

However, it’s important to consider the cost comparison between the two options before making a decision.

Which cutter is more suitable for small-scale or hobbyist use?

For small-scale or hobbyist use, small scale laser cutters are more suitable compared to rotary cutters.nnSmall scale laser cutters offer several advantages such as precise cutting, versatility in materials, and the ability to create intricate designs.nnOn the other hand, rotary cutters have their disadvantages: they require manual operation, are limited in the type of materials they can cut, and may not provide the same level of precision as laser cutters.

Conclusion

After evaluating the performance, precision, versatility, and efficiency of Nd:YAG laser cutters and rotary cutters, it’s clear that Nd:YAG laser cutters are the more efficient cutting solution.

Although some may argue that rotary cutters are more cost-effective, the superior precision and versatility of Nd:YAG laser cutters outweigh any minor cost differences.

By investing in Nd:YAG laser cutters, you can significantly enhance the quality and productivity of your cutting processes. This ultimately leads to greater success and satisfaction.

Make the smart choice and opt for Nd:YAG laser cutters for optimal efficiency.