Are you ready to cut through the competition and take your business to the next level? It’s time to harness the power of Nd:YAG laser cutters. These cutting-edge machines utilize the latest in laser technology to deliver precision and efficiency like never before.

But before you make a purchase, it’s crucial to have a comprehensive guide at your disposal. That’s where we come in. In this article, we will take you on a journey through the world of Nd:YAG laser cutters, equipping you with the knowledge and expertise needed to make an informed decision.

From understanding the technology to considering performance and cost, choosing the right size and type, and researching brands and models, we’ve got you covered. Get ready to become a laser-cutting aficionado and revolutionize your business. Let’s dive in!

Key Takeaways

- Nd:YAG laser cutters utilize the latest laser technology for precision and efficiency in cutting, welding, and engraving.

- They have a longer lifespan and can operate in harsh environments, making them suitable for industries like automotive, aerospace, and jewelry manufacturing.

- Factors to consider when buying a Nd:YAG laser cutter include price, maintenance, and technical support.

- Informed decisions can be made by conducting thorough research, comparing brands and models, and considering factors such as price comparison, user reviews, and technical specifications.

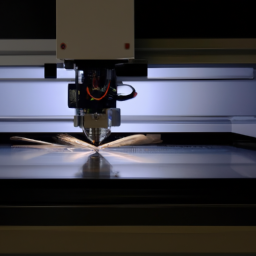

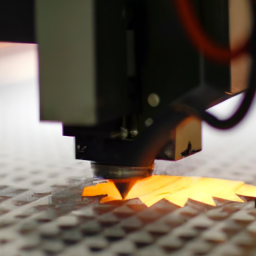

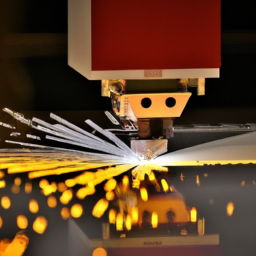

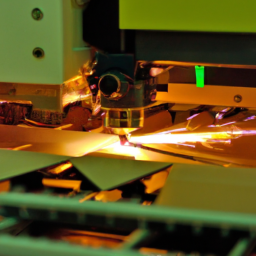

Nd:YAG Laser Technology Explained

If you’re looking to understand how Nd:YAG laser technology works, you’re in the right place! Nd:YAG, short for neodymium-doped yttrium aluminum garnet, is a solid-state laser that uses a crystal as its medium.

The crystal is doped with neodymium ions, which when excited by a flash lamp or diode laser, emit light at a wavelength of 1064 nanometers. This specific wavelength makes Nd:YAG lasers ideal for various applications, including laser cutting, welding, and engraving.

One of the advantages of Nd:YAG lasers is their ability to deliver high energy pulses, making them perfect for cutting through thick materials like metals and ceramics. They also have a longer lifespan compared to other laser types and can operate in harsh environments. Nd:YAG laser technology is widely used in industries such as automotive, aerospace, and jewelry manufacturing.

Now that you have a good understanding of Nd:YAG laser technology, let’s move on to the next section where we will discuss the factors to consider when buying a Nd:YAG laser cutter.

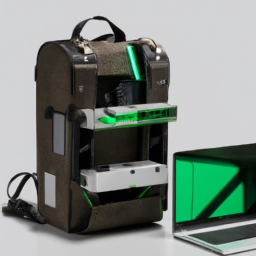

Factors to Consider When Buying a Nd:YAG Laser Cutter

When purchasing an Nd:YAG laser cutter, it’s important to consider various factors. Firstly, laser cutter prices vary depending on the brand, power, and functionality. It’s crucial to set a budget and compare prices from different suppliers to ensure you get the best deal.

Secondly, laser cutter maintenance is another important consideration. Look for a machine that is easy to maintain and has readily available spare parts. Regular maintenance is necessary to ensure optimal performance and longevity of the laser cutter. Additionally, consider the cost and availability of technical support and training.

Understanding performance and cost go hand in hand when choosing the right Nd:YAG laser cutter for your needs. Transitioning into the next section, let’s delve into the factors that affect performance and cost in more detail.

Understanding Performance and Cost

When considering the performance and cost of a Nd:YAG laser cutter, there are several key points to keep in mind.

Firstly, cutting speed and precision are crucial factors that can greatly impact the efficiency and quality of your laser cutting operations.

Secondly, operating costs and consumables, such as laser gas and lenses, should be carefully assessed to ensure long-term affordability.

Lastly, the warranty and customer support provided by the manufacturer can provide peace of mind and assurance of a reliable and responsive service.

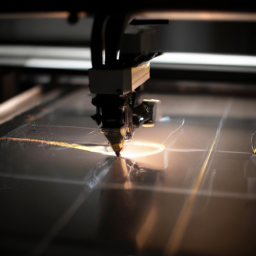

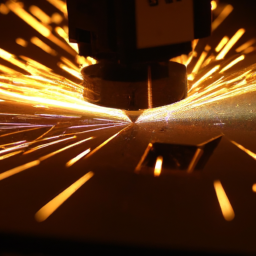

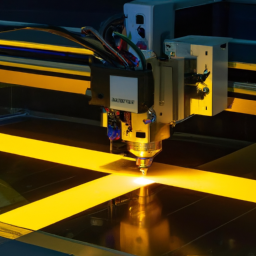

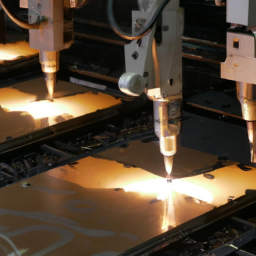

Cutting Speed and Precision

To achieve precise and fast cutting, you should consider that a high-quality ND:YAG laser cutter can cut through materials at speeds of up to 500 inches per minute. These cutting techniques require a laser beam with a high power density to vaporize or melt the material in the desired pattern.

The cutting precision is determined by the spot size of the laser beam, which can be adjusted to achieve different levels of accuracy. Additionally, the maintenance requirements of the laser cutter also play a crucial role in maintaining cutting speed and precision. Regular cleaning and calibration of the laser optics and focusing lens are essential to ensure optimal performance.

Moving forward, let’s delve into the next section about operating costs and consumables, which will further enhance your understanding of the ND:YAG laser cutter.

Operating Costs and Consumables

Operating an ND:YAG laser cutter involves considering the operating costs and consumables, which are crucial factors to keep in mind as they directly impact the overall efficiency and profitability of your cutting operations. Conducting an operating cost analysis is essential to understand the financial implications of running the machine. This analysis should include factors such as electricity consumption, gas usage, and maintenance and upkeep expenses. It is important to choose a laser cutter that has low operating costs and requires minimal consumables to maximize your profitability. To further emphasize this point, consider the following table:

| Operating Costs | Consumables |

|---|---|

| Electricity | Gas |

| Maintenance | Optics |

| Upkeep | Filters |

By carefully considering these operating costs and consumables, you can make informed decisions that will optimize your laser cutting operations. Moving forward, it is crucial to also take into account the warranty and customer support provided by the manufacturer. This ensures that you have the necessary support in case any issues arise during operation.

Warranty and Customer Support

Having reliable warranty and customer support is crucial for peace of mind and ensuring smooth operation of your laser cutter. When purchasing an ND:YAG laser cutter, it’s important to consider the warranty options offered by the manufacturer. Look for extended warranty plans that cover both parts and labor to protect your investment for a longer period of time.

In addition, a manufacturer that provides excellent customer support can save you time and money in the long run. Make sure they offer troubleshooting tips and assistance over the phone or through email to quickly resolve any issues that may arise.

By choosing a laser cutter with a comprehensive warranty and reliable customer support, you can have confidence in the performance and longevity of your machine.

Now, let’s move on to choosing the right size and type of laser cutter.

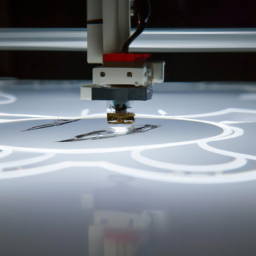

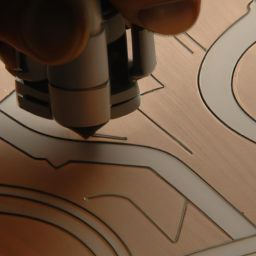

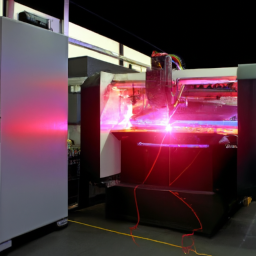

Choosing the Right Size and Type of Laser Cutter

When selecting the perfect size and type of laser cutter, it’s crucial to consider your specific needs and the various options available in order to make an informed decision.

To avoid common mistakes, it is important to assess your production requirements accurately. Overestimating or underestimating the size of the laser cutter can lead to inefficiencies or limitations in your workflow. Consider the maximum material size you will be working with and leave room for growth.

Additionally, think about the type of materials you will be cutting. Some laser cutters are better suited for certain materials than others. For example, if you plan to work with metals, a fiber laser cutter would be a better choice than a CO2 laser cutter.

By carefully analyzing your needs and doing thorough research, you can select the right size and type of laser cutter that aligns with your specific requirements and budget.

Next, let’s delve into researching and comparing brands and models to ensure you make a well-informed decision.

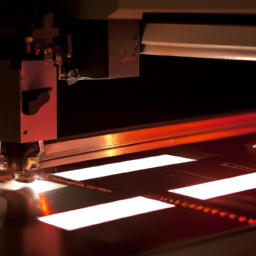

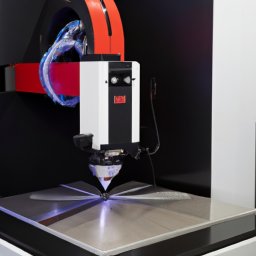

Researching and Comparing Brands and Models

Researching and comparing brands and models is essential to finding the right laser cutter for your needs. With over 200 different laser cutter models available on the market, there is a wide range of options to choose from.

To help you in your decision-making process, here are three important factors to consider:

-

Price comparison: Take the time to compare prices from different brands and models. Look for the best value for your budget, considering both the initial cost and long-term maintenance expenses.

-

User reviews and ratings: Read reviews from other customers who’ve purchased and used the laser cutters you’re considering. Pay attention to their experiences, positive or negative, as they can provide valuable insights into the quality and reliability of the machines.

-

Technical specifications: Carefully examine the technical specifications of each laser cutter. Look for features that align with your specific requirements, such as cutting speed, power output, and compatibility with different materials.

By considering these factors and conducting thorough research, you’ll be able to make an informed decision and finalize your purchase, ensuring that you choose the best laser cutter for your needs.

Making an Informed Decision and Finalizing Your Purchase

Once you’ve gathered all the necessary information, it’s time to make an informed decision and seal the deal on your ideal laser cutter. To ensure you are getting the best value for your money, it’s important to negotiate the price and explore financing options. Use the table below to compare different options and make a well-informed decision:

| Brand/Model | Price | Financing Options |

|---|---|---|

| Brand A | $10,000 | 0% interest for 12 months |

| Brand B | $12,000 | 5% interest for 24 months |

| Brand C | $15,000 | Lease-to-own option available |

Consider your budget and financial situation before making a decision. If you have limited funds upfront, a financing option with low or no interest may be ideal. On the other hand, if you can afford to pay more upfront, a lower-priced model with no financing may be the best choice. Take your time to analyze the options and choose the one that aligns with your needs and budget.

Frequently Asked Questions

How long does it take to learn how to operate a Nd:YAG laser cutter?

Learning to operate a nd:YAG laser cutter varies depending on individual aptitude and previous experience. However, as the adage goes, ‘practice makes perfect.’

The learning curve for operating a nd:YAG laser cutter can range from a few weeks to several months. Training requirements typically include understanding laser safety protocols, machine calibration, and material settings.

With dedication and proper guidance, you can quickly gain the technical expertise needed to operate this precision tool.

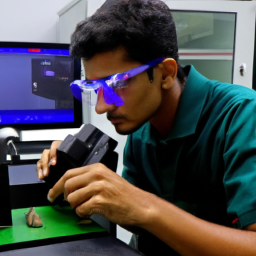

Are there any safety precautions that need to be taken when using a Nd:YAG laser cutter?

When using an nd:yag laser cutter, it’s crucial to follow safety measures to protect yourself and others. Always wear laser safety goggles to shield your eyes from the intense laser beam.

Additionally, ensure that the work area is well-ventilated and free of flammable materials. Familiarize yourself with the emergency shut-off procedure and always keep a fire extinguisher nearby.

By adhering to these precautions, you can safely operate an nd:yag laser cutter.

Can a Nd:YAG laser cutter be used on all types of materials?

Yes, a Nd:YAG laser cutter can be used on a wide range of materials. Its applications include cutting and engraving metals, plastics, ceramics, and even some organic materials. However, there are pros and cons to using a Nd:YAG laser cutter.

On the positive side, it offers high precision and can handle thicker materials. On the negative side, it has a slower cutting speed compared to other laser cutters and may not be suitable for all materials due to its wavelength limitations.

Are there any ongoing maintenance costs associated with owning a Nd:YAG laser cutter?

Maintenance costs for owning a nd:YAG laser cutter depend on factors like the machine’s usage and quality. Regular maintenance tasks, such as cleaning the optics and replacing consumables like filters and lamps, are essential to ensure optimal performance.

Additionally, it’s crucial to factor in training costs for operators to ensure safe and efficient operation. The duration of training can vary depending on the complexity of the machine, but it’s necessary to minimize the risk of accidents and maximize productivity.

Are there any restrictions or regulations for owning and operating a Nd:YAG laser cutter in certain areas or countries?

There may be restrictions and regulations in certain areas or countries regarding the ownership and operation of an Nd:YAG laser cutter. It’s important to be aware of the legal requirements and ensure compliance with any applicable laws.

These restrictions and regulations may vary, but they usually focus on safety measures, certification, and proper training for operators. It’s crucial to research and understand these requirements before purchasing and using an Nd:YAG laser cutter to avoid any legal issues.

Conclusion

Congratulations! You’ve reached the end of this comprehensive guide to buying Nd:YAG laser cutters. By now, you’re well-equipped with the knowledge and expertise needed to make an informed decision. Remember to carefully consider the factors that affect performance and cost, choose the right size and type of laser cutter, and thoroughly research and compare brands and models.

With all these steps completed, you can confidently finalize your purchase. Happy laser cutting!