Are you ready to witness the clash of the laser titans? In one corner, we have the mighty CO2 laser cutter, a powerhouse of precision and versatility. And in the other corner, we have the agile fiber laser cutter, armed with lightning-fast speed and unmatched efficiency. These two contenders are ready to battle it out for the title of the ultimate cutting machine.

But which one should you choose? Fear not, for we are here to guide you through this epic showdown. In this article, we will delve into the inner workings of CO2 laser cutters and explore the capabilities of fiber laser cutters. We will compare their speed, precision, material compatibility, costs, and maintenance requirements.

By the end, you will have all the knowledge you need to make an informed decision and select the laser cutter that best suits your needs. Get ready, because the laser revolution awaits!

Key Takeaways

- CO2 laser cutters are versatile and popular among hobbyists, but they are better suited for non-metallic materials and require regular maintenance.

- Fiber laser cutters are widely used in industries like automotive and aerospace due to their low maintenance requirements, high energy efficiency, and ability to cut reflective materials without additional processes.

- Fiber laser cutters offer higher cutting speeds, greater accuracy, and lower operating costs compared to CO2 laser cutters.

- Factors to consider when choosing between CO2 and fiber laser cutters include precision, speed, materials, and budget, as well as real-life examples, cost analysis, customer reviews, and practical application case studies.

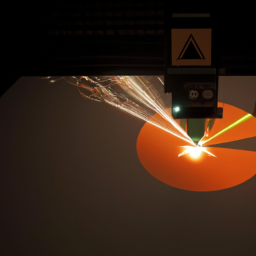

Understanding CO2 Laser Cutters

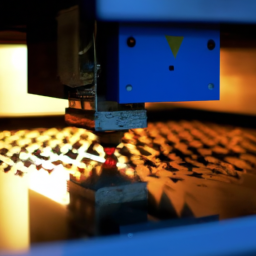

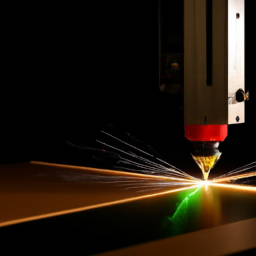

If you’re thinking about getting a laser cutter, you should totally check out CO2 laser cutters because they’re super versatile and can cut through a wide range of materials!

CO2 laser cutters are particularly popular among hobbyists due to their affordability and ease of use. One of the biggest advantages of CO2 laser cutters is their ability to cut through materials like wood, acrylic, fabric, and even some metals. They offer high precision and can create intricate designs with ease.

Additionally, CO2 laser cutters have a longer lifespan compared to other types of laser cutters, making them a cost-effective choice in the long run.

Now, let’s delve into exploring fiber laser cutters and see how they compare to CO2 laser cutters.

Exploring Fiber Laser Cutters

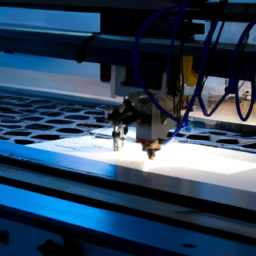

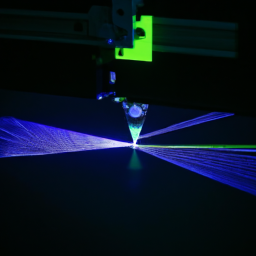

When it comes to understanding fiber laser cutters, it’s important to know how they work, their applications, and the benefits they offer.

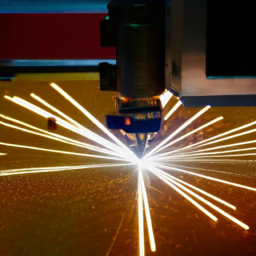

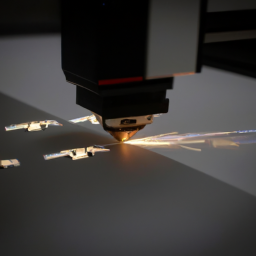

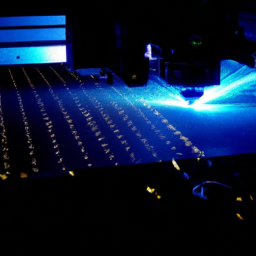

Fiber laser cutters use a high-powered laser beam that is transmitted through a flexible optic fiber, providing precise and efficient cutting capabilities.

These machines are commonly used in industries such as automotive, aerospace, and electronics, due to their ability to cut a wide range of materials with high precision and speed.

Additionally, fiber laser cutters offer advantages like low maintenance requirements, high energy efficiency, and the ability to cut reflective materials without the need for additional coatings or processes.

How Fiber Laser Cutters Work

Imagine stepping into the world of fiber laser cutters, where beams of light dance delicately across materials, effortlessly slicing through with precision and finesse, like a graceful ballet performance on a sheet of metal.

Fiber laser cutters have gained popularity due to their numerous advantages. Unlike CO2 laser cutters, fiber laser cutters offer higher cutting speeds, greater cutting accuracy, and lower operating costs. This is achieved through a unique fiber laser cutting process, where the laser beam is generated within optical fibers and then transmitted to the cutting head.

This process allows for better control of the laser beam, resulting in cleaner and more precise cuts. Fiber laser cutters find applications in various industries, including automotive, aerospace, and electronics, due to their ability to cut through a wide range of materials.

In the subsequent section, we will explore the applications and benefits of fiber laser cutters, showcasing their versatility and efficiency.

Applications and Benefits of Fiber Laser Cutters

Step into the world of fiber laser cutters and discover their wide range of applications and the numerous benefits they offer.

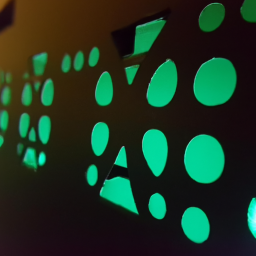

Fiber laser cutters are highly versatile tools that can be used in various industries, including automotive, aerospace, and electronics. They excel at cutting different materials such as metals, plastics, and even fabrics with incredible precision. With their high power and focused beam, fiber laser cutters can achieve intricate designs and produce clean, smooth edges.

Additionally, fiber laser cutting is a non-contact process, meaning there is no physical contact between the laser and the material being cut, reducing the risk of damage or contamination. Furthermore, fiber laser cutters are known for their high cutting speeds, allowing for increased productivity and efficiency.

Transitioning into the subsequent section, let’s now compare the speed and precision of fiber laser cutters with CO2 laser cutters.

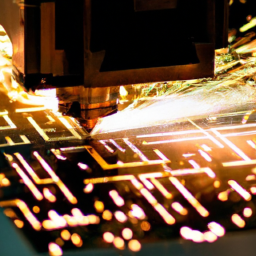

Comparing Speed and Precision

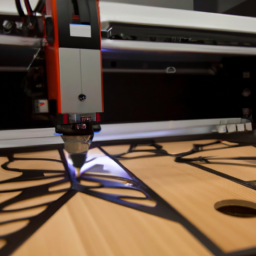

Not only are fiber laser cutters faster, but they also offer superior precision compared to CO2 laser cutters.

When it comes to speed vs. cost, fiber laser cutters outperform their CO2 counterparts. The high-powered fiber lasers can cut through materials at incredibly high speeds, reducing production time and increasing efficiency. On the other hand, CO2 laser cutters may be slower, which can impact productivity and overall cost-effectiveness.

In terms of precision vs. versatility, fiber lasers excel in delivering precise cuts with minimal heat-affected zones. This makes them ideal for cutting intricate designs and delicate materials. CO2 lasers, although versatile, may not offer the same level of precision as fiber lasers.

Considering material compatibility, it is important to evaluate which laser cutter is best suited for your specific material requirements.

Considering Material Compatibility

Considering the materials you work with, it’s fascinating to note that fiber laser cutters have been found to be compatible with a wide range of materials, including metals, plastics, and even reflective surfaces. This advantage stems from the wavelength of the fiber laser, which allows for efficient absorption by different materials. In contrast, CO2 laser cutters are better suited for non-metallic materials, such as wood, acrylic, and rubber. While CO2 lasers can also cut metals, the process is slower and less precise. However, it’s important to acknowledge the limitations of fiber laser cutters. They may struggle with thicker materials and are not as effective for intricate designs. So, when considering material compatibility, it’s crucial to evaluate the advantages and limitations of each type of laser cutter. Transitioning into the subsequent section about evaluating costs and maintenance, it is necessary to analyze these factors alongside material compatibility for an informed decision-making process.

Evaluating Costs and Maintenance

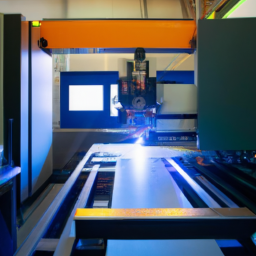

When it comes to evaluating costs and maintenance, you’ll want to carefully consider the long-term investment and upkeep required for your chosen laser cutter. Conducting a cost analysis is crucial to determine the financial feasibility of each option.

CO2 laser cutters generally have a higher upfront cost compared to fiber laser cutters. However, they can be more cost-effective for cutting thicker materials and are suitable for a wider range of applications.

On the other hand, fiber laser cutters have lower maintenance costs due to their simpler design and fewer moving parts. They also offer higher cutting speeds and are more energy-efficient.

Maintenance comparison is another important factor to consider. CO2 laser cutters require regular maintenance to ensure optimal performance, including gas replacement, alignment checks, and tube replacements.

Fiber laser cutters, on the other hand, have minimal maintenance requirements, mainly focusing on cleaning lenses and checking the optical system.

By conducting a thorough cost analysis and maintenance comparison, you can make an informed decision on which laser cutter is the right choice for your specific needs.

Making the Right Choice

When making the decision between CO2 and fiber laser cutters, there are several factors that you need to consider.

These factors include the specific needs of your business, the materials you will be working with, and your budget.

Real-life examples and testimonials can provide valuable insights into the experiences of others who’ve already made this choice, helping you make an informed decision for your own business.

Factors to Consider When Choosing Between CO2 and Fiber Laser Cutters

One important factor to consider when choosing between CO2 and fiber laser cutters is the level of precision and speed that each machine offers. CO2 laser cutters are known for their versatility and ability to cut through a wide range of materials, including metals, plastics, and woods. However, they may not offer the same level of precision as fiber laser cutters, which are renowned for their accuracy and speed.

Fiber laser cutters use advanced laser cutting techniques to achieve high-quality, intricate cuts with minimal heat affected zones. Additionally, fiber laser cutters are becoming increasingly popular in the market due to their efficiency and cost-effectiveness. Real-life examples and testimonials demonstrate the impressive capabilities of fiber laser cutters in various industries, making them a compelling choice for many.

Real-Life Examples and Testimonials

Now that we’ve discussed the factors to consider when choosing between CO2 and fiber laser cutters, let’s delve into real-life examples and testimonials from satisfied customers.

These case studies provide valuable insights into the practical applications and benefits of both types of laser cutters. By examining these real-life scenarios, you can gain a better understanding of how each machine performs in different industries and environments.

Furthermore, customer reviews offer firsthand accounts of the advantages and limitations of CO2 and fiber laser cutters, helping you make a well-informed decision. Whether it’s a small business owner praising the precision of a fiber laser cutter or a large manufacturing company highlighting the cost-effectiveness of a CO2 laser cutter, these real-life experiences will provide you with valuable information to guide your choice.

Frequently Asked Questions

Are CO2 laser cutters more expensive to purchase and maintain compared to fiber laser cutters?

CO2 laser cutters tend to be more expensive to purchase and maintain compared to fiber laser cutters. In terms of cost, CO2 laser cutters usually have higher upfront prices due to their more complex technology.

Additionally, CO2 lasers require regular maintenance, including gas refills and lens replacements, which can add to the overall maintenance costs. On the other hand, fiber laser cutters have a simpler design and require less maintenance, making them a more cost-effective option.

Can fiber laser cutters achieve the same level of precision as CO2 laser cutters?

While some may argue that fiber laser cutters cannot achieve the same level of precision as CO2 laser cutters, a precision comparison reveals a different story. In fact, fiber laser cutters have proven to be just as accurate, if not more so, than their CO2 counterparts.

Additionally, when considering a cost analysis, fiber laser cutters often offer a more cost-effective solution due to their lower maintenance requirements and higher energy efficiency. Therefore, choosing a fiber laser cutter can provide both precision and financial benefits.

Are there any limitations or specific materials that cannot be cut using CO2 laser cutters?

CO2 laser cutters have certain limitations and cannot cut certain materials. The main limitation is that CO2 lasers aren’t suitable for cutting metals or reflective materials, as they aren’t able to effectively absorb the laser energy.

Additionally, CO2 lasers aren’t ideal for cutting thick materials, as they have a limited depth of cut.

Some materials that cannot be cut using CO2 laser cutters include aluminum, copper, brass, and other highly reflective or conductive materials.

What are the main advantages of using fiber laser cutters over CO2 laser cutters?

Fiber laser cutters slice through materials like a hot knife through butter, leaving clean, precise cuts in their wake. When it comes to advantages, fiber laser cutters reign supreme.

They boast lightning-fast cutting speeds, outpacing CO2 laser cutters by up to three times. This means increased productivity and reduced production time for your projects.

With their advanced technology and unmatched efficiency, fiber laser cutters are the clear choice for those seeking optimal performance and results.

Are there any specific safety precautions or regulations to consider when operating CO2 or fiber laser cutters?

When operating CO2 or fiber laser cutters, there are specific safety precautions and regulations to consider. These include wearing appropriate personal protective equipment, ensuring proper ventilation, and implementing lockout/tagout procedures.

Additionally, regular maintenance is crucial to prevent accidents and ensure optimal performance.

In terms of precision comparison, fiber laser cutters offer higher accuracy due to their smaller wavelength. However, they also have material limitations, such as difficulty cutting reflective or thick materials.

Despite this, the advantages of fiber laser cutters, such as higher cutting speeds and lower maintenance costs, make them a popular choice in many industries.

Conclusion

In conclusion, when it comes to choosing between CO2 laser cutters and fiber laser cutters, you need to carefully consider your specific needs and requirements.

While CO2 laser cutters offer versatility and are well-suited for cutting thicker materials, fiber laser cutters provide exceptional speed and precision for thin materials.

Moreover, fiber laser cutters have lower maintenance costs and offer better energy efficiency.

As the saying goes, "Choose the tool that matches your task," and in this case, make an informed decision based on speed, precision, material compatibility, and overall cost-effectiveness.