Are you tired of cutting through materials manually, wasting time and effort? Well, fret no more because in the world of automated cutting machines, two powerhouses stand out: CO2 laser cutters and plasma cutters. These cutting-edge tools offer precision and efficiency, revolutionizing the way industries fabricate and create.

But which one is better suited for your specific needs? Let’s dive into the world of CO2 laser cutters and plasma cutters, comparing their features, capabilities, and real-world applications. By examining case studies and real-world examples, this article will provide you with the knowledge and insights necessary to make an informed decision.

So, whether you’re in the manufacturing, automotive, or construction industry, join us as we explore the pros and cons, the technical specifications, and everything you need to know about CO2 laser cutters and plasma cutters.

It’s time to cut through the confusion and find the perfect cutting machine for your needs.

Key Takeaways

- CO2 laser cutters are highly accurate and versatile, but require regular maintenance and expensive repairs.

- Plasma cutters are fast and precise, with lower maintenance costs and generally more affordable.

- CO2 laser cutters are ideal for intricate designs and can handle a variety of materials, but have limitations in thickness and may require additional safety measures.

- Plasma cutters are better for cutting thicker materials and metals, but produce heat and noise during operation.

Understanding CO2 Laser Cutters

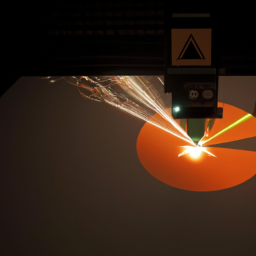

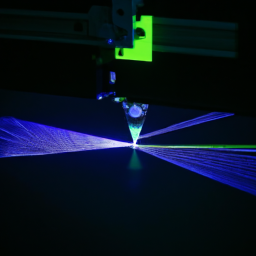

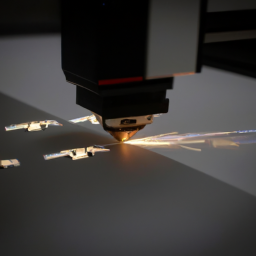

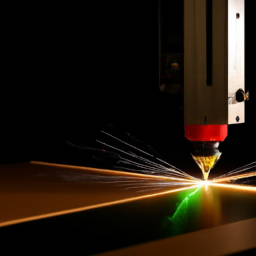

If you want precision and speed, look no further than CO2 laser cutters. These machines are renowned for their ability to make precise cuts with incredible speed. The laser beam emitted by the CO2 laser cutter is highly focused and can cut through a variety of materials, including wood, acrylic, and metal.

One of the main advantages of using a CO2 laser cutter is its accuracy. It can produce intricate designs and complex shapes with ease. However, there are some drawbacks to consider. CO2 laser cutters require regular maintenance and can be expensive to repair. It’s important to weigh the pros and cons before making a decision.

Now, let’s explore plasma cutters and see how they compare.

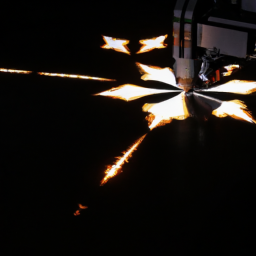

Exploring Plasma Cutters

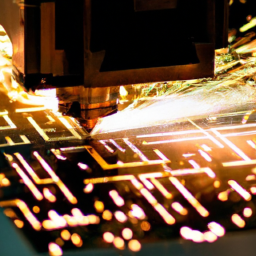

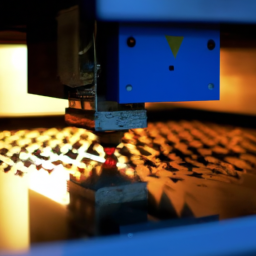

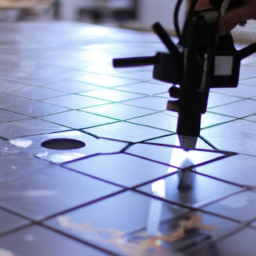

When exploring plasma cutters, it’s important to understand how they work. Plasma cutters use a high-velocity jet of ionized gas to cut through various materials. They work by creating an electrical circuit through the gas, which causes the gas to become plasma and produce a focused and powerful cutting beam.

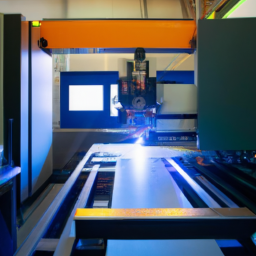

Plasma cutters have a wide range of applications and uses. They’re commonly used in industries such as metal fabrication, automotive repair, and construction. Plasma cutters can easily cut through materials like steel, aluminum, and stainless steel, making them versatile and efficient tools for cutting and shaping metal.

One of the main advantages of plasma cutters is their speed and precision. They can cut through thick materials quickly and accurately, allowing for faster production and reduced labor costs. Additionally, plasma cutters produce clean and precise cuts, minimizing the need for secondary finishing operations.

Overall, plasma cutters are a valuable tool for any industry that requires efficient and precise metal cutting.

How Plasma Cutters Work

Plasma cutters use high-temperature ionized gas to effortlessly slice through different types of materials. These tools are highly efficient and provide a precise cutting mechanism. However, it is important to consider plasma cutter safety and maintenance to ensure optimal performance and longevity.

To better understand the importance of safety and maintenance, let’s take a look at the following table:

| Plasma Cutter Safety | Plasma Cutter Maintenance |

|---|---|

| Wear protective gear | Regularly clean the cutter |

| Ensure proper ventilation | Inspect and replace consumables |

| Avoid contact with the plasma arc | Check for loose connections |

| Keep the work area clear | Calibrate the machine regularly |

By following these guidelines, you can mitigate any potential risks and maintain the functionality of your plasma cutter.

Now, let’s move on to the next section, where we will explore the various applications and uses of plasma cutters.

Applications and Uses of Plasma Cutters

To fully explore the versatility and power of plasma cutters, you need to know how they can revolutionize your cutting tasks and make your projects a breeze.

Plasma cutters are extensively used in the automotive industry for various applications. They are commonly used to cut through metal sheets, creating precise and intricate designs for car parts and bodywork. Additionally, plasma cutters play a crucial role in metal fabrication and construction. They enable workers to effortlessly cut through thick metal plates, beams, and pipes, making construction projects more efficient and precise.

Whether you need to create customized car parts or tackle large-scale construction projects, plasma cutters offer the precision and speed required for the job. With their ability to cut through various metals and their applications in the automotive industry and metal fabrication, plasma cutters are a valuable tool for any cutting task.

Moving on to the next section, let’s explore the advantages of plasma cutters.

Advantages of Plasma Cutters

By using a plasma cutter, you can effortlessly achieve precise and intricate designs, making your cutting tasks a breeze. The advantages of plasma cutters are numerous.

Firstly, they have the ability to cut through a wide range of materials, including metal, stainless steel, and aluminum, with ease. Additionally, plasma cutters have a high cutting speed, allowing for quick and efficient completion of projects. They also produce clean and smooth cuts, minimizing the need for additional finishing work.

However, it is important to note that plasma cutters have their limitations. They’re not suitable for cutting materials that are thicker than their maximum cutting capacity. Furthermore, plasma cutters produce a significant amount of heat and noise during operation.

Transitioning into the subsequent section about comparing CO2 laser cutters and plasma cutters, it is essential to consider the various factors that differentiate these two cutting tools.

Comparing CO2 Laser Cutters and Plasma Cutters

When it comes to comparing CO2 laser cutters and plasma cutters, the choice boils down to a fiery precision or a laser-sharp accuracy. To help you make an informed decision, let’s examine the key differences between these two cutting machines:

-

Laser Cutter Precision: CO2 laser cutters offer exceptional precision with intricate designs and fine details. The focused laser beam ensures clean and precise cuts, making it ideal for delicate materials like acrylic and wood.

-

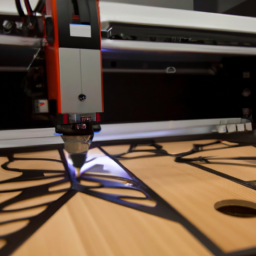

Plasma Cutter Speed: On the other hand, plasma cutters excel in speed and efficiency. The intense heat generated by the plasma arc swiftly cuts through thicker materials like steel and aluminum, making it a preferred choice for industrial applications.

-

Material Compatibility: CO2 laser cutters are versatile and can handle a wide range of materials, including fabrics, plastics, and even glass. Plasma cutters, however, are primarily used for metal cutting applications.

-

Maintenance and Operating Costs: CO2 laser cutters require regular maintenance, such as replacing the laser tube, which can be costly. Plasma cutters, on the other hand, have lower maintenance costs and are generally more affordable.

Considering these factors, it’s crucial to weigh the precision of a laser cutter against the speed of a plasma cutter when choosing a cutting machine.

Factors to Consider When Choosing a Cutting Machine

When choosing a cutting machine, there are several factors you need to consider.

Firstly, you should evaluate your project requirements and specifications to ensure that the machine you choose can meet your needs.

Secondly, you must take budget and cost considerations into account, as different machines have varying price ranges and operational costs.

Lastly, available space and power requirements are crucial factors to consider, as you need to ensure that the machine can be accommodated in your workspace and has the necessary power supply.

Project Requirements and Specifications

To determine which laser cutter is better for your needs, you should consider your project requirements and specifications. Two important factors to consider are your project budget and material compatibility. Firstly, evaluate your project budget to determine how much you are willing to spend on a cutting machine. CO2 laser cutters generally have a higher upfront cost compared to plasma cutters, but they offer more precision and versatility. On the other hand, plasma cutters are typically more affordable and are better suited for cutting thicker materials. Secondly, consider the materials you will be working with. CO2 laser cutters are ideal for materials like wood, acrylic, and fabric, while plasma cutters are better for metals. By analyzing your project requirements and material compatibility, you can make an informed decision on which cutting machine is best for your needs. Moving forward, it is important to also consider budget and cost considerations.

Budget and Cost Considerations

Consider your budget and the overall cost of the cutting machine to help you make an informed decision on which option is the most financially viable for your specific needs. When comparing the cost of CO2 laser cutters and plasma cutters, several factors come into play.

-

Cost comparison: CO2 laser cutters are generally more expensive upfront compared to plasma cutters. The initial investment for a CO2 laser cutter can be significantly higher due to the complexity of the technology involved.

-

Long term savings: While CO2 laser cutters may have a higher initial cost, they often provide long-term savings through reduced maintenance and lower operating costs. Plasma cutters, on the other hand, may require more frequent consumable replacements and have higher energy consumption.

Considering the cost comparison and potential long-term savings, you can now delve into the next section about available space and power requirements.

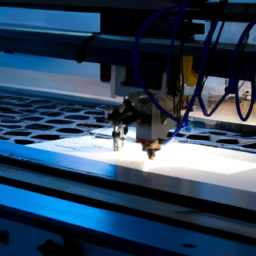

Available Space and Power Requirements

Take a moment to envision the available space in your workshop and the power requirements needed for the cutting machine, as this will directly impact your ability to efficiently operate and maximize productivity. When comparing CO2 laser cutters to plasma cutters, it is important to consider their power consumption and size limitations.

CO2 laser cutters typically require more power than plasma cutters, as they use high-intensity laser beams to cut through materials. This means that you will need to ensure that your workshop has the necessary electrical capacity to support the CO2 laser cutter. Additionally, CO2 laser cutters tend to be larger in size compared to plasma cutters, which may pose space constraints in smaller workshops.

To better understand the differences in power consumption and size limitations, refer to the table below:

| CO2 Laser Cutter | Plasma Cutter | |

|---|---|---|

| Power | High | Low |

| Size | Large | Small |

Considering these factors will help you determine which cutting machine is better suited for your workshop. Now, let’s explore some case studies and real-world examples to further illustrate the practical applications of CO2 laser cutters and plasma cutters.

Case Studies and Real-World Examples

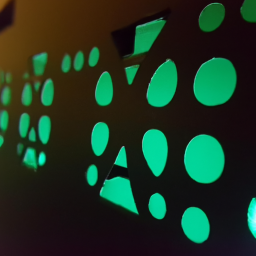

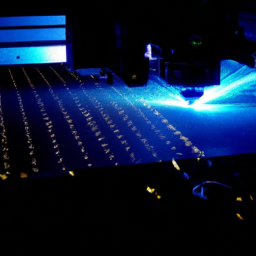

One of the best examples of the efficiency of CO2 laser cutters is their use in the automotive industry, where they’re able to precisely cut intricate designs on car panels. This technology has been employed in various case studies and real-world examples, showcasing its versatility and accuracy.

In one case study, a car manufacturer utilized a CO2 laser cutter to create custom logos on car doors, resulting in a more visually appealing and personalized product.

Another example involves the use of CO2 laser cutters to fabricate complex patterns on car seats, enhancing the overall aesthetic appeal of the interior.

Additionally, CO2 laser cutters have been employed to create intricate designs on car dashboards, providing a sleek and modern look.

These case studies and real-world examples demonstrate the effectiveness of CO2 laser cutters in the automotive industry. Considering their precision and versatility, they’re a viable option for various applications.

Now, let’s discuss how to make the final decision regarding which cutting technology to choose.

Making the Final Decision

When it comes to making the final decision on which cutting technology to choose, picture yourself standing in front of a sleek car with intricately designed logos, patterns on the seats, and a modern dashboard, all made possible by the efficiency and precision of CO2 laser cutters.

As you weigh your options, it’s essential to consider the pros and cons of both CO2 laser cutters and plasma cutters. CO2 laser cutters offer high precision and clean cuts, making them ideal for intricate designs and delicate materials. However, they’re limited in terms of thickness and may require additional safety measures.

On the other hand, plasma cutters excel at cutting thicker materials and are more cost-effective. However, they produce rougher cuts and may require post-processing.

By carefully considering these factors, you can make an informed decision that best suits your specific needs.

Frequently Asked Questions

Can CO2 laser cutters and plasma cutters be used on the same types of materials?

Yes, CO2 laser cutters and plasma cutters can both be used on the same types of materials.

For example, in the automotive industry, both CO2 laser cutters and plasma cutters are used to cut metal sheets for various applications.

However, when it comes to cutting speed, CO2 laser cutters are generally faster than plasma cutters.

Industries like aerospace, automotive, and electronics benefit the most from the precise cutting capabilities of CO2 laser cutters, while plasma cutters are commonly used in heavy fabrication and construction industries.

Are CO2 laser cutters more expensive to purchase and maintain compared to plasma cutters?

When comparing the cost of purchasing and maintaining CO2 laser cutters and plasma cutters, it’s important to consider several factors. CO2 laser cutters tend to be more expensive upfront due to their complex technology and high precision capabilities.

Additionally, the maintenance costs for CO2 laser cutters can be higher as they require regular calibration and replacement of laser tubes. On the other hand, plasma cutters are generally more affordable and have lower maintenance costs.

However, it’s crucial to also consider the material compatibility of both types of cutters before making a decision.

How long does it typically take to cut a piece of material using a CO2 laser cutter versus a plasma cutter?

When comparing the cutting speed of CO2 laser cutters and plasma cutters, it’s important to consider the material being cut.

CO2 laser cutters generally have a faster cutting speed compared to plasma cutters. The precision and accuracy of the cut also depend on the type of cutter used.

CO2 laser cutters offer a higher level of precision and accuracy in comparison to plasma cutters. Ultimately, the cutting speed, precision, and accuracy of the cutter will determine which one is better suited for your needs.

Can CO2 laser cutters and plasma cutters be used for intricate and detailed designs?

Co2 laser cutters excel at creating intricate designs with their precise and focused beam of light. The concentrated heat allows for clean and intricate cuts, making them ideal for delicate materials and intricate designs.

On the other hand, plasma cutters are better suited for detailed designs due to their ability to produce a wider and more intense arc. The high temperature and velocity of plasma enable them to cut through thicker materials with intricate details.

Are there any safety concerns or precautions to consider when using CO2 laser cutters or plasma cutters?

When using CO2 laser cutters or plasma cutters, it’s important to take safety measures and precautions. Both machines pose unique safety concerns.

With CO2 laser cutters, it’s crucial to wear appropriate eye protection due to the intense laser beam. Additionally, proper ventilation is necessary to prevent the release of toxic fumes.

On the other hand, plasma cutters can emit sparks and hot metal, requiring the use of protective clothing and a fire extinguisher nearby.

Conclusion

In conclusion, when it comes to choosing between CO2 laser cutters and plasma cutters, it ultimately depends on your specific needs and requirements.

While CO2 laser cutters offer precise and intricate cuts, plasma cutters excel in cutting thicker materials at a faster speed.

Consider factors such as the type of materials you work with, the desired cutting speed, and your budget.

Remember, "choosing the right cutting machine is like finding the perfect tool for a delicate masterpiece."

So, analyze your needs carefully and make an informed decision to achieve the best results.