Are you searching for the perfect tool to streamline your cutting process? Look no further than the battle between CO2 laser cutters and rotary cutters. Like a duel between two skilled swordsmen, these cutting machines are poised to compete for the title of efficiency champion. But which one will reign supreme?

In this article, we will dissect the cutting mechanisms, speed, versatility, cost, maintenance, and safety considerations of CO2 laser cutters and rotary cutters. By delving into the nitty-gritty details, we aim to provide you with a comprehensive analysis to help you make an informed decision.

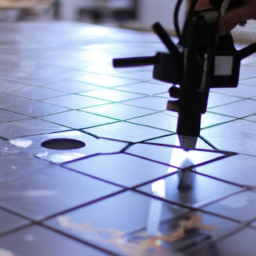

Imagine the precision of a surgeon’s scalpel combined with the speed of a cheetah. That’s what a CO2 laser cutter brings to the table. Its high-powered laser beam cuts through various materials with unparalleled accuracy, leaving behind clean, smooth edges.

On the other hand, the rotary cutter, like a tireless craftsman, excels in its ability to swiftly slice through a multitude of materials, offering a different level of efficiency.

Join us on this journey as we pit these cutting giants against each other to determine which one is truly the epitome of efficiency.

Key Takeaways

- CO2 laser cutters offer precision and intricate details, while rotary cutters excel in speed and efficiency.

- CO2 laser cutters have high-powered laser beams for quick and precise cuts, while rotary cutters may have slight variations in cutting depth, leading to less precise cuts.

- CO2 laser cutters can cut through a wide range of materials, including acrylic, wood, leather, fabric, and metal, while rotary cutters have fewer limitations but may not be suitable for materials with chlorine or PVC.

- CO2 laser cutters require regular maintenance, cleaning, and alignment, as well as proper ventilation to remove harmful fumes and particles, while rotary cutters have fewer maintenance requirements and easily replaceable cutting blades.

Cutting Mechanism and Precision

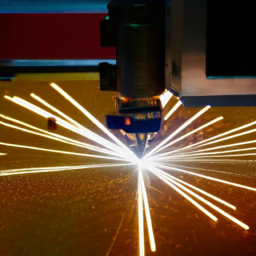

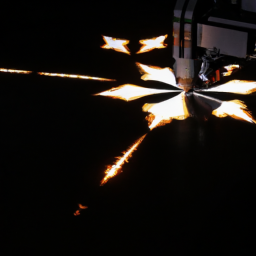

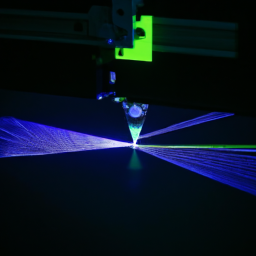

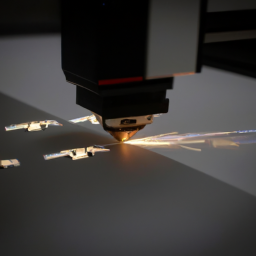

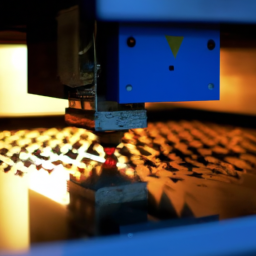

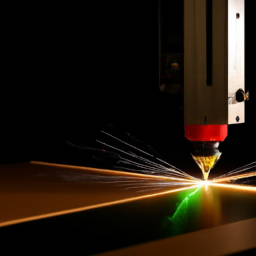

You’ll be amazed at the precision and intricate details you can achieve with a CO2 laser cutter, making it the superior choice over rotary cutters for your cutting needs. When it comes to cutting speed, CO2 laser cutters are incredibly efficient. The laser beam moves at high speeds, resulting in quick and precise cuts.

Additionally, CO2 laser cutters offer exceptional cutting accuracy. The laser can be controlled with great precision, allowing for intricate designs and complex shapes to be cut with ease. With a rotary cutter, on the other hand, achieving the same level of precision and accuracy can be challenging. The rotational motion of the cutter may lead to slight variations in cutting depth, resulting in less precise cuts.

Moving on to the next section on speed and efficiency, you’ll find that CO2 laser cutters excel in this area as well.

Speed and Efficiency

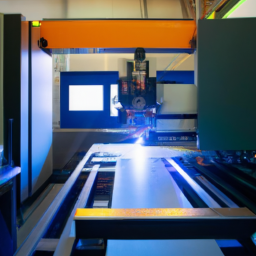

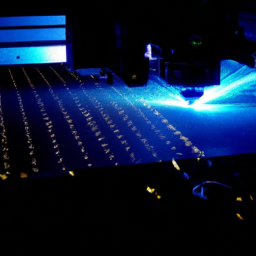

When it comes to speed and efficiency, it’s like racing a Ferrari against a tricycle. CO2 laser cutters outshine rotary cutters in terms of cutting speed and productivity. The laser beam used in CO2 laser cutters moves at an incredibly high speed, making precise cuts in a matter of seconds. This allows for faster production rates and increased efficiency in manufacturing processes.

In comparison, rotary cutters rely on a spinning blade that may not be as swift, resulting in slower cutting speeds and reduced productivity. However, it’s important to note that while CO2 laser cutters excel in speed and efficiency, they may not be as versatile as rotary cutters in terms of material compatibility.

Despite this limitation, the advantages of CO2 laser cutters in terms of speed and productivity cannot be ignored.

Versatility and Material Compatibility

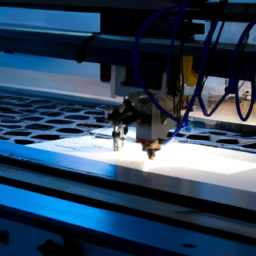

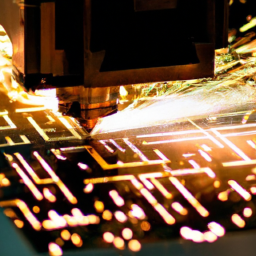

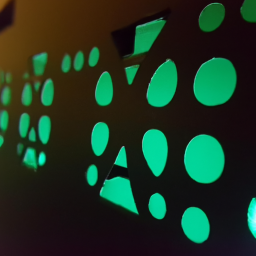

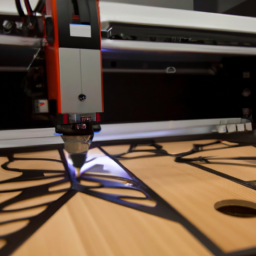

The incredible versatility and wide range of materials that can be used with CO2 laser cutters will leave you amazed and inspired. CO2 laser cutters are known for their ability to cut through a variety of materials such as acrylic, wood, leather, fabric, and even metal. However, it is important to note that there are some material limitations when using CO2 laser cutters.

For instance, materials that contain chlorine or PVC can release toxic gases when cut with a CO2 laser. Additionally, some materials may require additional precautions or adjustments to achieve optimal results. Despite these limitations, CO2 laser cutters still offer a high level of design flexibility. They can cut intricate patterns, engrave detailed designs, and even etch images onto various materials. This versatility allows for endless creative possibilities in design and fabrication.

Moving forward to the next section about ‘cost and maintenance,’ it’s important to consider these factors when deciding between CO2 laser cutters and rotary cutters.

Cost and Maintenance

Maintaining and operating CO2 laser cutters can be costly and time-consuming, while rotary cutters offer a more efficient and cost-effective alternative. When it comes to cost effectiveness, rotary cutters have a clear advantage. CO2 laser cutters require regular maintenance, such as cleaning and alignment, which can be time-consuming and expensive. Additionally, the laser tubes used in CO2 laser cutters have a limited lifespan and need to be replaced periodically, adding to the overall maintenance costs. On the other hand, rotary cutters have fewer maintenance requirements and their cutting blades can be easily replaced at a lower cost. Moreover, the initial investment for a rotary cutter is generally lower than that of a CO2 laser cutter. Transitioning to the next section about safety considerations, it is important to consider the potential hazards associated with both types of cutters.

Safety Considerations

When it comes to safety considerations, there are important measures that need to be taken for both CO2 laser cutters and rotary cutters.

For CO2 laser cutters, it’s crucial to implement safety measures such as wearing protective eyewear and ensuring proper ventilation to prevent exposure to harmful fumes.

As for rotary cutters, precautions should be taken to avoid accidental injuries, such as using a safety guard and ensuring the cutter is properly maintained.

It’s essential to be aware of the potential hazards associated with both types of cutters and take the necessary precautions to ensure a safe working environment.

Safety measures for CO2 laser cutters

To ensure your safety while using CO2 laser cutters, it’s crucial to familiarize yourself with the necessary safety measures.

First and foremost, laser cutter ventilation is essential. Proper ventilation helps to remove harmful fumes and particles created during the cutting process. This can be achieved through the use of exhaust systems or air purifiers specifically designed for laser cutters.

Additionally, laser cutter training is imperative. Understanding how to operate the machine safely and efficiently reduces the risk of accidents. Training typically covers topics such as machine setup, laser power settings, and proper material handling.

By following these safety measures, you can minimize the potential hazards associated with CO2 laser cutters.

Now, let’s move on to discussing the safety measures for rotary cutters.

Safety measures for rotary cutters

Ensure your safety while using rotary cutters by practicing proper precautions and procedures. Safety precautions are crucial when using these tools, especially because of the sharp blades involved.

Before starting, always inspect the cutter for any damage or loose parts. Make sure to wear protective gloves and safety glasses to prevent any injuries. Keep the work area clean and organized to avoid accidents.

When using the rotary cutter, hold it firmly and use a cutting mat to protect the surface underneath. Regular blade maintenance is essential to ensure smooth and efficient cutting. Replace dull blades promptly to prevent accidents and ensure clean cuts. Properly dispose of used blades in a designated container.

By following these safety measures, you can minimize the risk of accidents and injuries. Moving on to potential hazards and precautions, it’s important to be aware of the risks involved in using rotary cutters.

Potential hazards and precautions

Watch out for potential hazards and take necessary precautions while using rotary cutters to keep yourself safe. Rotary cutters can pose several potential risks if they’re not used properly.

One major hazard is the sharp blade, which can cause severe cuts if it’s mishandled. Always make sure that the blade is securely locked in place and use a cutting mat to protect your work surface.

Another risk is the possibility of accidentally cutting yourself while changing the blade. To avoid this, make sure to follow the manufacturer’s instructions carefully when replacing the blade and use a blade changing tool if it’s provided.

It’s also important to wear appropriate protective gear, such as cut-resistant gloves and safety glasses, to minimize the risk of injury.

Lastly, always store rotary cutters in a safe and secure manner, out of reach of children and pets. Following these safety guidelines will help ensure a safe and efficient rotary cutting experience.

Frequently Asked Questions

Can a CO2 laser cutter be used on reflective materials like metals?

Absolutely! A CO2 laser cutter can be used on reflective materials like metals, but with certain limitations. The key factor is laser cutter power, as higher power lasers are better suited for cutting through reflective materials.

However, even with high power, some metals can still reflect a significant amount of laser energy, resulting in incomplete cuts or damage to the machine. To overcome this, additional techniques like using a protective coating or reducing the laser power may be necessary to achieve successful cutting on reflective materials.

How often does a rotary cutter blade need to be replaced?

To maintain a rotary cutter, it’s important to regularly check and replace the blades. The longevity of the blades depends on several factors, such as the frequency of use, the type of materials being cut, and the quality of the blades themselves. On average, rotary cutter blades need to be replaced every few months or after approximately 150-200 hours of cutting. Proper rotary cutter maintenance ensures optimal performance and extends the lifespan of the blades.

Are there any safety precautions or certifications required when using a CO2 laser cutter?

When using a CO2 laser cutter, there are important safety requirements and a certification process that must be followed. Are you aware of these necessary precautions?

Safety measures include wearing proper protective gear, such as goggles and gloves, and ensuring that the work area is well-ventilated. Additionally, operators must be certified to operate the laser cutter, as it requires technical knowledge and expertise.

Following these safety guidelines is crucial to prevent accidents and ensure a safe working environment.

Can a rotary cutter achieve the same level of precision as a CO2 laser cutter?

A rotary cutter can achieve a similar level of precision as a CO2 laser cutter. However, it has certain advantages over laser cutters.

Rotary cutters are capable of handling thicker materials and can cut through materials that are not suitable for laser cutting, such as certain types of fabric. Additionally, rotary cutters are more cost-effective and require less maintenance compared to laser cutters.

However, laser cutters have superior precision capabilities and can produce more intricate and detailed cuts.

What is the typical lifespan of a CO2 laser cutter before it needs to be replaced?

The typical lifespan of a CO2 laser cutter before replacement depends on various factors, including usage, maintenance, and quality. With regular maintenance, a well-maintained CO2 laser cutter can last between 5 to 10 years. However, this may vary based on the manufacturer and specific model.

It is important to factor in the cost of routine maintenance, such as replacing consumables and servicing, when comparing the overall cost of operating a CO2 laser cutter versus a rotary cutter.

Conclusion

In conclusion, after analyzing the various factors, it is clear that CO2 laser cutters are undeniably the epitome of efficiency in the world of cutting technology. The precision they offer is unmatched, ensuring flawless and intricate cuts with utmost accuracy.

Additionally, their lightning-fast speed guarantees unparalleled efficiency in completing projects. The versatility and material compatibility of CO2 laser cutters further solidify their superiority.

Moreover, when considering the cost and maintenance aspects, it is evident that the initial investment is justified by the long-term benefits. Safety considerations also favor the CO2 laser cutters, making them the ultimate choice for those who prioritize efficiency and excellence.