Step into the world of precision cutting, where the clash of technology and innovation unfolds. Like two skilled swordsmen facing off, CO2 laser cutters and ultrasonic cutters battle for supremacy in the realm of precision. These cutting-edge machines, each with its unique set of advantages, vie for the title of the most precise tool in the industry. With the power to slice through materials with unparalleled accuracy, they are the epitome of precision engineering.

In this ultimate showdown, we will delve into the depths of CO2 laser cutters and ultrasonic cutters, exploring their inner workings and dissecting their capabilities. We will compare their precision prowess, examining the factors that contribute to their accuracy. From the speed of the cut to the intricacy of the design, no stone will be left unturned.

So, if you seek perfection in your cutting endeavors, join us as we unravel the mystery of CO2 laser cutters and ultrasonic cutters. Together, we will navigate the intricate world of precision cutting and determine which mighty tool reigns supreme in the battle for precision supremacy.

Key Takeaways

- CO2 laser cutters use high-powered lasers for precise cutting with clean edges, while ultrasonic cutters use high-frequency vibrations for non-contact cutting.

- CO2 laser cutters are versatile and can cut through a wide range of materials, except for reflective ones like copper and aluminum. Ultrasonic cutters are particularly suitable for delicate and brittle materials like glass and ceramics.

- CO2 laser cutters generally have a faster cutting speed, making them more efficient for large-scale production. Ultrasonic cutters have lower maintenance requirements and use less energy, resulting in reduced operational costs.

- When deciding between CO2 laser cutters and ultrasonic cutters, factors such as cutting speed, cutting quality, material compatibility, and cost need to be considered. Identifying specific needs helps in selecting the most suitable cutter.

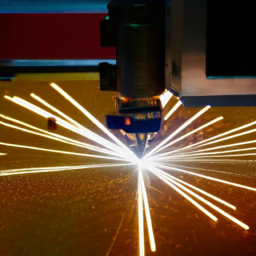

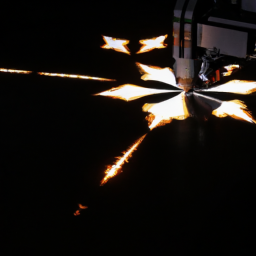

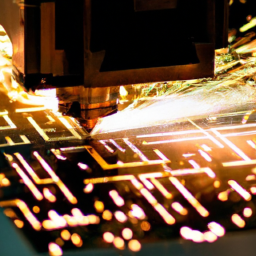

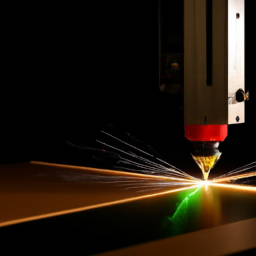

Understanding CO2 Laser Cutters

Now, let me take you through the fascinating world of CO2 laser cutters, where precision becomes an art form.

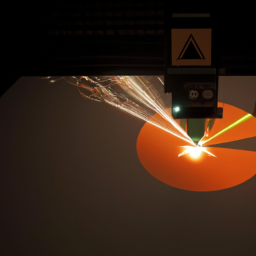

CO2 laser cutters are versatile machines that offer several advantages when it comes to precision cutting. With their high-powered lasers, they can effortlessly slice through a wide range of materials with incredible accuracy and clean edges. This makes them perfect for intricate designs and delicate materials that require precise cuts.

CO2 laser cutters find applications in various industries, including manufacturing, advertising, and crafts. They can be used to create intricate patterns on wood, acrylic, paper, and even fabrics. With their ability to cut complex shapes with precision, CO2 laser cutters have revolutionized the way we create and design.

Now, let’s delve into understanding ultrasonic cutters.

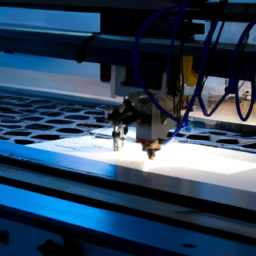

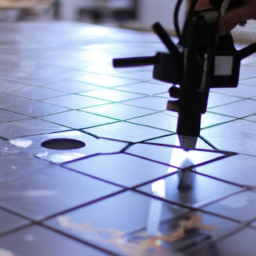

Understanding Ultrasonic Cutters

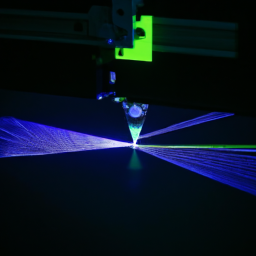

To better understand ultrasonic cutters, imagine a futuristic gadget that effortlessly slices through materials with precision. Ultrasonic cutter technology utilizes high-frequency vibrations to create clean and precise cuts.

Here are three advantages of ultrasonic cutters over traditional cutting methods:

-

Non-contact cutting: Unlike traditional cutting methods that involve blades or lasers coming into direct contact with the material, ultrasonic cutters work by vibrating at high frequencies, allowing for non-contact cutting. This eliminates the risk of material distortion or damage.

-

Versatility: Ultrasonic cutters can be used on various materials, including plastics, rubber, fabrics, and even delicate materials like paper or film. The flexibility of ultrasonic cutting technology makes it suitable for a wide range of industries and applications.

-

Clean cuts and edges: The high-frequency vibrations of ultrasonic cutters result in precise and clean cuts. The process reduces the chances of material fraying or melting, ensuring clean edges and minimal post-processing requirements.

With a clear understanding of ultrasonic cutter technology and its advantages over traditional cutting methods, we can now delve into the precision comparison between CO2 laser cutters and ultrasonic cutters.

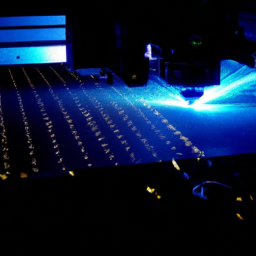

Precision Comparison

Achieving the utmost precision in your cutting needs can be effortlessly accomplished with the innovative technology of ultrasonic cutters. When it comes to precision comparison between CO2 laser cutters and ultrasonic cutters, an accuracy assessment reveals that ultrasonic cutters are superior.

The precision of ultrasonic cutters is unrivaled due to their high-frequency vibrations, which allow for precise and clean cuts. These cutters can achieve intricate details and sharp edges with minimal material loss. Additionally, ultrasonic cutters are able to cut through a wide range of materials, including hard and brittle substances, with exceptional precision. This level of accuracy is crucial in industries such as aerospace, electronics, and medical, where precision is paramount.

Transitioning into the next section about factors to consider in precision cutting, it is important to evaluate the specific requirements of your cutting projects.

Factors to Consider in Precision Cutting

When considering precision cutting, there are several key factors that you should take into account.

Firstly, material compatibility plays a crucial role in achieving accurate cuts. Different cutting methods may work better with certain materials, so it’s important to choose a cutting tool that’s compatible with the material you’re working with.

Secondly, cutting speed and efficiency are important considerations as they directly impact productivity. A tool that can cut quickly and efficiently will help you save time and increase output.

Lastly, maintenance and operational costs should also be considered. It’s important to choose a cutting tool that’s cost-effective to maintain and operate in order to maximize your return on investment.

Material compatibility

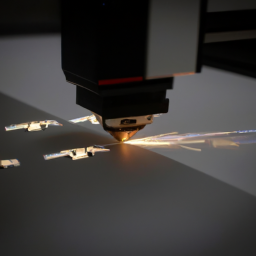

Material compatibility can make or break the precision of both CO2 laser cutters and ultrasonic cutters, leaving you frustrated and disappointed with the results. When it comes to laser cutting, CO2 lasers are highly versatile and can cut through a wide range of materials such as wood, plastics, and metals. However, they struggle with reflective materials like copper and aluminum.

On the other hand, ultrasonic cutters excel in cutting through delicate and brittle materials like glass and ceramics, but they may not be suitable for thicker or denser materials. It’s important to consider the specific material you’re working with and its compatibility with the cutting method you choose.

Now, let’s explore the next section, which focuses on cutting speed and efficiency.

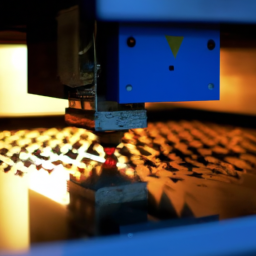

Cutting speed and efficiency

To maximize your productivity and ensure optimal results, consider the speed and efficiency of your chosen cutting method. When it comes to cutting accuracy, both CO2 laser cutters and ultrasonic cutters have made significant technological advancements.

CO2 laser cutters use a high-powered laser beam to precisely cut through materials, offering a high level of accuracy. On the other hand, ultrasonic cutters utilize ultrasonic vibrations to create clean and precise cuts. While both methods can achieve precise results, CO2 laser cutters generally have a faster cutting speed, allowing for increased efficiency. This makes them a preferred choice for large-scale production or time-sensitive projects.

However, it’s important to note that the cutting speed and efficiency can vary depending on the specific model and the material being cut. Transitioning into the subsequent section about maintenance and operational costs, it is essential to consider these factors alongside the cutting speed and efficiency for a comprehensive evaluation.

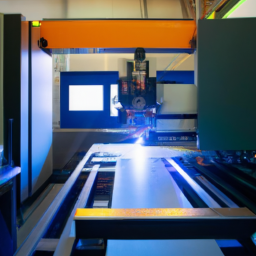

Maintenance and operational costs

Consider the costs of upkeep and operation as you navigate the world of cutting technology, so you can ensure your wallet doesn’t take a hit like a punch to the gut.

When comparing CO2 laser cutters and ultrasonic cutters, it’s essential to evaluate the cost comparison and long-term benefits. CO2 laser cutters typically have higher maintenance and operational costs due to the need for regular replacement of laser tubes and optics.

On the other hand, ultrasonic cutters have lower maintenance requirements and don’t rely on costly consumables. Additionally, ultrasonic cutters use less energy, resulting in reduced operational costs over time.

By carefully analyzing the maintenance and operational costs, you can make an informed decision when choosing the right cutter for your needs, ensuring maximum precision without breaking the bank.

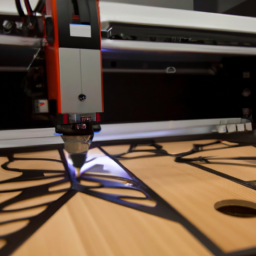

Choosing the Right Cutter for Your Needs

When deciding which cutter is more precise, it’s essential to take into account factors such as the intricacy of the design and the desired level of accuracy. Both CO2 laser cutters and ultrasonic cutters have their strengths and weaknesses, so choosing the right one for your needs requires careful consideration. Here are four key factors to consider:

-

Cutting Speed: CO2 laser cutters are generally faster than ultrasonic cutters, making them ideal for projects that require high production rates.

-

Cutting Quality: Laser cutters offer excellent precision and produce clean, smooth cuts. Ultrasonic cutters excel at cutting soft materials without causing damage or distortion.

-

Material Compatibility: Laser cutters are versatile and can cut a wide range of materials, including wood, acrylic, and metal. Ultrasonic cutters are better suited for delicate materials like textiles and thin plastics.

-

Cost: CO2 laser cutters tend to have higher initial costs and maintenance expenses compared to ultrasonic cutters, so budget considerations may influence your decision.

Consider these factors carefully to determine which cutter will best meet your specific needs for laser vs. ultrasonic cutting quality comparison.

Frequently Asked Questions

Are CO2 laser cutters or ultrasonic cutters more expensive?

Co2 laser cutters are generally more expensive than ultrasonic cutters. In a cost comparison analysis, it was found that the average price of a Co2 laser cutter is around $10,000, whereas an ultrasonic cutter costs approximately $5,000.

However, it’s important to note that precision analysis is crucial when considering the overall value. While ultrasonic cutters are more affordable, Co2 laser cutters offer higher precision and accuracy in cutting materials, making them a preferred choice for many industries.

Can both CO2 laser cutters and ultrasonic cutters be used on all types of materials?

Both CO2 laser cutters and ultrasonic cutters can be used on a wide range of materials, but each has its pros and cons. CO2 laser cutters are highly precise and efficient for materials like wood, acrylic, and fabrics. They provide clean and smooth cuts, but can be limited when it comes to certain metals.

On the other hand, ultrasonic cutters excel in cutting materials like rubber, plastic, and foam. They are less precise than CO2 laser cutters, but offer faster cutting speeds and are ideal for intricate designs.

What safety precautions should be taken when using CO2 laser cutters or ultrasonic cutters?

When operating CO2 laser cutters or ultrasonic cutters, it’s essential to adhere to strict safety precautions. For CO2 laser cutters, ensure that the machine is properly ventilated to prevent the buildup of harmful fumes. Additionally, wear appropriate protective gear, such as safety glasses and gloves, to avoid injury.

When using ultrasonic cutters, be cautious of the sharp cutting edges. Make sure the material is securely held in place to prevent accidents.

Both technologies have their advantages and disadvantages, so it’s crucial to understand their specific safety requirements.

How long does it take to learn how to operate a CO2 laser cutter or an ultrasonic cutter?

Learning how to operate a CO2 laser cutter or an ultrasonic cutter can take a significant amount of time. On average, it takes around 40 hours of training to become proficient in operating these machines. The learning curve can be steep due to the technical nature of these devices.

Additionally, both types of cutters require regular maintenance to ensure optimal performance. It’s crucial to follow manufacturer guidelines and perform routine checks to prevent any potential issues.

Can CO2 laser cutters or ultrasonic cutters be used for both small-scale and large-scale cutting projects?

Yes, both CO2 laser cutters and ultrasonic cutters can be used for both small-scale and large-scale cutting projects. CO2 laser cutters are ideal for intricate designs due to their high precision and ability to cut through various materials. Ultrasonic cutters, on the other hand, are better suited for delicate materials as they use high-frequency vibrations to achieve clean and precise cuts. Both types of cutters offer versatility and can be used effectively for different cutting projects.

Conclusion

In conclusion, when it comes to precision cutting, CO2 laser cutters outperform ultrasonic cutters. CO2 laser cutters offer unparalleled accuracy in cutting various materials, with a precision level of up to 0.001 inches. This statistic is particularly fascinating as it showcases the remarkable precision that can be achieved with CO2 laser technology.

When selecting a cutter for your needs, it’s crucial to consider factors such as material type, thickness, and desired level of precision. Make an informed decision and choose the right cutter that meets your specific requirements.