Did you know that the global market for laser cutting machines is projected to reach $4.49 billion by 2025? With so many options available, it can be overwhelming to choose the right cutting tool for your business. CO2 laser cutters and vinyl cutters are two popular choices, each with their own unique advantages.

In this article, we will compare and contrast these two cutting technologies to help you make an informed decision. CO2 laser cutters are known for their precision and versatility, allowing you to cut a wide range of materials with intricate details. On the other hand, vinyl cutters are ideal for producing high-quality graphics and designs on vinyl sheets.

We will examine their cutting capabilities, cost considerations, and other factors to help you determine which cutter is best suited for your business needs. So, let’s dive in and find out which cutting tool will take your business to the next level.

Key Takeaways

- CO2 laser cutters offer greater precision and versatility compared to vinyl cutters.

- CO2 laser cutters have a smaller environmental impact, producing fewer waste materials and using less energy.

- Vinyl cutters are more affordable initially but may lack the precision and capabilities of CO2 laser cutters.

- The choice between CO2 laser cutters and vinyl cutters should consider factors such as environmental sustainability, integration into existing production processes, efficiency, cost comparison, and business needs.

Understanding CO2 Laser Cutters

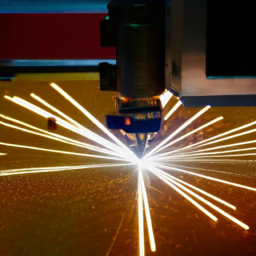

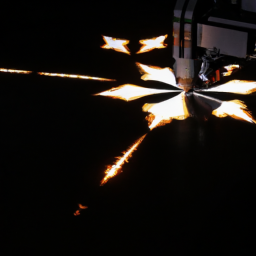

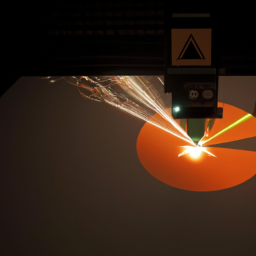

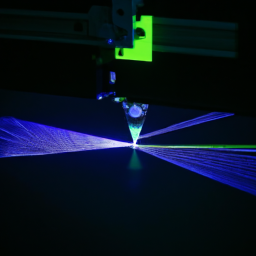

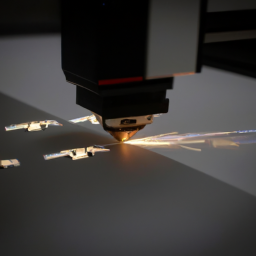

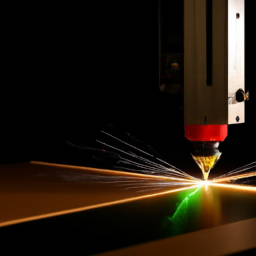

If you’re looking to understand CO2 laser cutters and how they can benefit your business, you’ve come to the right place! CO2 laser cutters are powerful machines that use a high-powered laser beam to cut through various materials with precision and accuracy.

One of the key advantages of CO2 laser cutters is their versatility. They can cut through a wide range of materials including wood, plastic, fabric, and even metal. Additionally, CO2 laser cutters offer high cutting speeds and can produce intricate designs with fine details.

However, there are also some disadvantages to consider. CO2 laser cutters can be expensive to purchase and maintain, and they require proper ventilation to remove harmful fumes.

Now, let’s transition into exploring vinyl cutters and their potential benefits for your business.

Exploring Vinyl Cutters

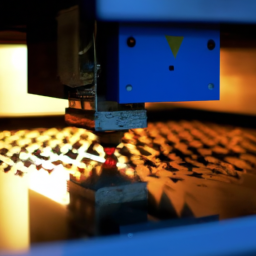

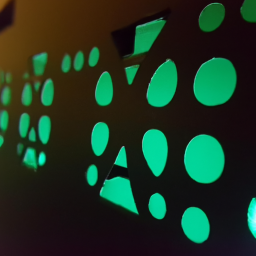

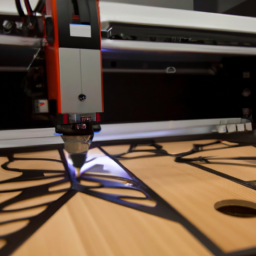

Exploring the world of vinyl cutters opens up a range of creative possibilities for your business. Vinyl cutters are versatile machines that can be used for various applications, such as creating decals, signs, stickers, and heat transfers. With precise cutting capabilities, they allow you to create intricate designs and achieve professional-looking results.

However, it’s important to keep in mind that vinyl cutters have their limitations. They are primarily designed for working with vinyl materials and may not be suitable for cutting thicker or harder materials. Additionally, the size of the cutting area can be a limiting factor for larger projects.

Despite these limitations, vinyl cutters can be a valuable tool for businesses that require precise and detailed cutting. Transitioning into comparing cutting capabilities, it’s important to consider the specific needs and requirements of your business before making a decision.

Comparing Cutting Capabilities

When comparing CO2 laser cutters and vinyl cutters, it’s important to consider their cutting capabilities.

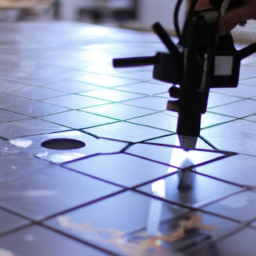

CO2 laser cutters are known for their precision and versatility, allowing for intricate and detailed cuts on a wide range of materials.

On the other hand, vinyl cutters excel in cutting speed and efficiency, making them a great choice for high-volume production.

Ultimately, the choice between the two machines will depend on the specific materials and thicknesses you plan to work with, as each has its own strengths in this regard.

Precision and Versatility of CO2 Laser Cutters

You’ll be amazed at the precision and versatility of CO2 laser cutters, allowing you to unlock a world of creative possibilities and elevate your business to new heights. Here are some key features that make CO2 laser cutters stand out:

-

CO2 laser cutter applications: With a CO2 laser cutter, you can effortlessly cut through a wide range of materials, including wood, acrylic, fabric, and even metal. This opens up endless opportunities for creating intricate designs and customized products.

-

Precision: CO2 laser cutters offer exceptional precision, enabling you to achieve intricate cuts with sharp edges and clean lines. This level of accuracy is crucial for industries like signage, jewelry making, and architectural modeling.

-

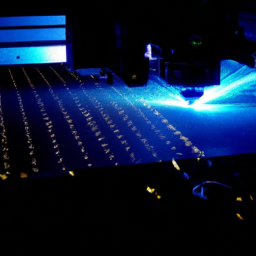

Versatility: CO2 laser cutters are incredibly versatile, allowing you to not only cut but also engrave and etch various materials. This versatility expands the range of products you can offer to your customers.

-

CO2 laser cutter maintenance: While CO2 laser cutters require regular maintenance, they’re generally easy to maintain. Routine tasks like cleaning the lens, checking the alignment, and replacing consumables ensure optimal performance.

-

Integration with design software: CO2 laser cutters seamlessly integrate with design software, allowing you to easily transfer designs and patterns for precise cutting.

Now, let’s explore the cutting speed and efficiency of vinyl cutters.

Cutting Speed and Efficiency of Vinyl Cutters

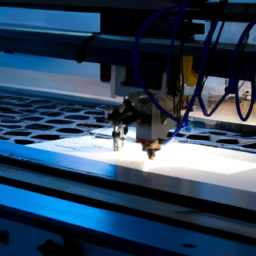

Improve your production process with vinyl cutters by experiencing their impressive cutting speed and efficient performance. Vinyl cutters are known for their ability to quickly and accurately cut through various materials, making them a valuable asset for businesses that require high-speed production. Additionally, vinyl cutter software allows for precise control over the cutting process, ensuring clean and precise cuts every time. To further enhance the understanding of vinyl cutters, consider the following table:

| Aspect | Vinyl Cutters |

|---|---|

| Cutting Speed | High |

| Material Compatibility | Versatile |

| Maintenance | Regular cleaning and blade replacement |

| Software | User-friendly with various design options |

| Cost | Affordable |

As you explore the advantages of vinyl cutters, it is essential to understand which machine is better for different materials and thicknesses.

Which Machine is Better for Different Materials and Thicknesses

Now that we’ve discussed the cutting speed and efficiency of vinyl cutters, let’s move on to another important aspect: which machine is better for different materials and thicknesses.

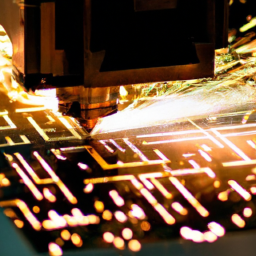

This is a crucial consideration for businesses that work with a variety of materials. When it comes to different materials, CO2 laser cutters offer more versatility. They can effectively cut through materials like wood, acrylic, leather, and even certain metals. On the other hand, vinyl cutters are primarily designed for cutting vinyl and other thin materials.

In terms of thicknesses, CO2 laser cutters have an advantage again. They can handle thicker materials, with some machines capable of cutting through materials up to 1 inch thick. Vinyl cutters, on the other hand, are better suited for thinner materials, typically up to a few millimeters thick.

Considering the different materials and thicknesses your business works with, it’s important to choose a machine that can meet your specific needs.

Now, let’s delve into the cost considerations when it comes to CO2 laser cutters and vinyl cutters.

Cost Considerations

When comparing CO2 laser cutters and vinyl cutters, it’s important to factor in the cost considerations. The cost vs. quality analysis is crucial in making the right decision for your business. While CO2 laser cutters tend to have a higher upfront cost, they offer greater precision and versatility, making them a long-term investment. On the other hand, vinyl cutters are more affordable initially, but they may lack the precision and capabilities of CO2 laser cutters. To help you compare the costs of these machines, here is a table that outlines the main cost considerations for each:

| Cost Consideration | CO2 Laser Cutters | Vinyl Cutters |

|---|---|---|

| Initial Investment | Higher | Lower |

| Maintenance Costs | Moderate | Low |

| Material Costs | Higher | Lower |

| Operational Efficiency | Higher | Lower |

| Long-Term Value | Greater | Lesser |

Considering these cost factors, you can determine which machine is best suited for your business needs. Moving forward, it’s important to consider other factors that will further enhance your decision-making process.

Factors to Consider for Your Business

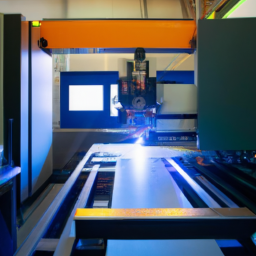

Consideration of various factors will help you make an informed decision for your business. For example, CO2 laser cutters offer greater precision and versatility compared to vinyl cutters. CO2 laser cutters utilize a high-powered laser beam to accurately cut through a wide range of materials, including wood, acrylic, and metal, with minimal heat-affected zones. This precision allows for intricate designs and complex shapes, making them ideal for businesses that require intricate detailing.

Additionally, CO2 laser cutters can be seamlessly integrated into existing production processes, providing a smooth transition and increasing efficiency. On the other hand, vinyl cutters are limited to cutting vinyl sheets and may not offer the same level of precision as CO2 laser cutters. Moreover, CO2 laser cutters have a smaller impact on environmental sustainability compared to vinyl cutters. They produce fewer waste materials and use less energy.

Considering these factors will help you make the right choice for your business without compromising on quality or sustainability.

Making the Right Choice

With their precision and versatility, CO2 laser cutters offer businesses the ability to create intricate designs and complex shapes, seamlessly integrating into existing production processes and increasing efficiency. However, before making a decision, it’s important to consider the cost comparison and maintenance requirements of both CO2 laser cutters and vinyl cutters.

To help you make the right choice for your business, here is a comparison table:

| Factors | CO2 Laser Cutters | Vinyl Cutters |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance | Moderate | Low |

| Versatility | High | Limited |

| Precision | High | Medium |

| Material | Wide range | Limited |

CO2 laser cutters typically have a higher initial cost compared to vinyl cutters. However, they offer greater versatility and precision, allowing you to work with a wider range of materials. On the other hand, vinyl cutters have a lower initial cost and require less maintenance. Consider your business needs, budget, and long-term goals when making a decision.

Frequently Asked Questions

Are CO2 laser cutters more expensive than vinyl cutters?

Yes, CO2 laser cutters are generally more expensive than vinyl cutters. The cost difference lies in the complexity of the technology involved. However, when considering the benefits of vinyl cutters, the investment may be worth it.

Vinyl cutters offer precise and detailed cuts, making them ideal for intricate designs. They’re also versatile and can work with a wide range of materials.

Ultimately, the decision should be based on your specific business needs and budget.

Can vinyl cutters create intricate designs like CO2 laser cutters?

Vinyl cutters have limitations when it comes to creating intricate designs compared to CO2 laser cutters. While vinyl cutters can produce detailed designs, they may struggle with intricate patterns due to their cutting method.

On the other hand, CO2 laser cutters offer exceptional precision and can effortlessly create intricate designs. The laser cutting technology allows for extremely fine details and intricate shapes, making it the preferred choice for businesses that require high precision cutting.

How long does it take to learn how to operate a CO2 laser cutter?

To operate a CO2 laser cutter, the learning curve can vary depending on your previous experience with similar machines. However, with proper training, you can become proficient in a relatively short amount of time.

On average, it takes around 1-2 weeks of training to learn the basics of operating a CO2 laser cutter. This includes understanding the software, calibrating the machine, and executing precise cuts. Continued practice and experience will further enhance your skills and efficiency.

Do vinyl cutters require any special maintenance or upkeep?

Maintaining and keeping up with a vinyl cutter is like tending to a delicate garden. Just as a garden requires regular watering, pruning, and pest control, a vinyl cutter also needs special maintenance and upkeep to ensure its optimal performance.

This includes cleaning the cutting blades, regularly checking and replacing worn-out parts, and keeping the machine free from dust and debris. By providing proper care, your vinyl cutter will continue to produce precise and quality designs for your business.

Are there any safety precautions to consider when using a CO2 laser cutter?

When using a CO2 laser cutter, there are several safety precautions to consider. First, ensure that the machine is properly ventilated to remove any harmful fumes or smoke generated during the cutting process. Adequate ventilation helps protect you from inhaling potentially dangerous particles.

Additionally, always wear appropriate personal protective equipment, such as safety glasses and gloves, to prevent any injuries. It’s also important to follow the manufacturer’s guidelines and instructions for safe operation of the CO2 laser cutter.

Conclusion

In conclusion, when deciding between CO2 laser cutters and vinyl cutters for your business, it’s crucial to carefully assess your specific needs and requirements.

While CO2 laser cutters offer precision and versatility in cutting various materials, vinyl cutters are cost-effective and suitable for simpler designs.

Consider factors such as cutting capabilities, cost considerations, and the nature of your business before making a decision.

Ultimately, the choice boils down to finding the perfect balance between functionality and affordability, ensuring long-term success.