Imagine you’re an artist, standing before a blank canvas, ready to bring your masterpiece to life. You have two tools at your disposal: a precise and powerful laser beam, and a versatile and agile CNC machine. Each tool has its own unique qualities, allowing you to create intricate designs and flawless cuts. But which one is the right choice for your artistic vision?

In this article, we will explore the world of cutting-edge technology and delve into the differences between 3D laser cutting and CNC cutting. We will examine the mechanisms and processes behind each technique, as well as their applications in various industries. Moreover, we will compare the precision and accuracy that can be achieved with both methods.

By the end, you will have a clearer understanding of these cutting techniques, enabling you to choose the one that best suits your needs.

So, let us embark on this journey of exploration and discovery, as we compare and contrast the artistry of 3D laser cutting and CNC cutting.

Key Takeaways

- 3D laser cutting offers unparalleled accuracy and detail, making it suitable for precise parts in automobiles, complex components in aircraft, circuit boards in electronics, and medical devices.

- CNC cutting is versatile and can cut a wide range of materials, making it popular in automotive, aerospace, and woodworking industries.

- 3D laser cutting has a small heat-affected zone and minimal material distortion, while CNC cutting offers high accuracy, repeatability, and the ability to create complex shapes.

- The cost of equipment and maintenance for 3D laser cutting is high, which can be a barrier, whereas CNC cutting reduces the need for manual labor and saves time and costs.

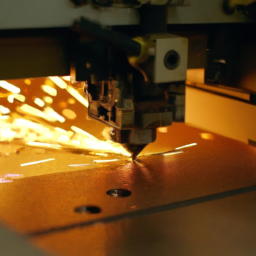

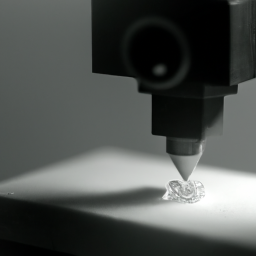

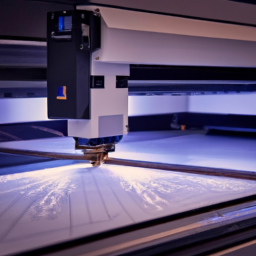

Mechanisms and Processes of 3D Laser Cutting

3D laser cutting uses a highly focused laser beam to precisely cut and shape materials, creating intricate designs with incredible speed and accuracy. This technology offers several advantages over other cutting methods.

Firstly, the laser beam can easily maneuver around complex shapes and contours, allowing for greater design flexibility. Additionally, the laser beam produces a small heat-affected zone, minimizing material distortion and reducing the need for post-processing.

However, 3D laser cutting does have its limitations. For instance, it is limited to certain materials that can be effectively cut by a laser, such as metals and plastics. Furthermore, the high cost of the laser cutting equipment and maintenance can be a barrier for some businesses.

Transitioning to the next section, the mechanisms and processes of CNC cutting provide an alternative to 3D laser cutting.

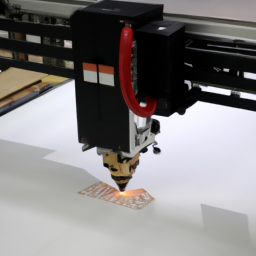

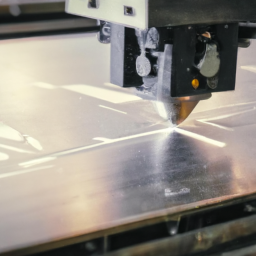

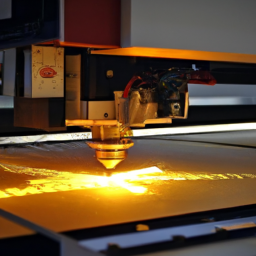

Mechanisms and Processes of CNC Cutting

When it comes to CNC cutting, you have a variety of mechanisms and processes at your disposal, like a toolbox full of options.

CNC cutting, or Computer Numerical Control cutting, is a versatile method that offers several advantages. One of the main advantages is its ability to produce highly precise and accurate cuts. CNC cutting machines can follow complex patterns and produce intricate designs with ease. Additionally, CNC cutting is capable of cutting a wide range of materials, such as metal, wood, plastic, and foam.

However, like any other technology, CNC cutting has its limitations. It can be slower compared to other cutting methods, and it may not be suitable for cutting very thick materials. Despite these limitations, CNC cutting remains a popular choice in various industries, including automotive, aerospace, and woodworking. It provides a cost-effective solution for precision cutting needs.

Moving on to the next section about applications of 3D laser cutting…

Applications of 3D Laser Cutting

In this discussion, we’ll explore the applications of 3D laser cutting. We’ll focus on the industries that extensively utilize this technology and the range of products that can be made with it.

Industries such as automotive, aerospace, and electronics heavily rely on 3D laser cutting for precise and intricate designs. Some examples of products made with 3D laser cutting include intricate metal parts for engines, precise components for aircraft, and intricate circuit boards for electronic devices.

Industries that Use 3D Laser Cutting

You’ll be amazed by the wide range of industries that rely on the precision and versatility of 3D laser cutting. This advanced technology offers several advantages over traditional cutting methods, making it the go-to choice for many businesses. Here are four industries that heavily utilize 3D laser cutting:

-

Automotive: 3D laser cutting is used to create intricate and precise parts for automobiles, including body panels, exhaust systems, and engine components.

-

Aerospace: The aerospace industry relies on 3D laser cutting to manufacture complex components for aircraft, such as turbine blades, fuselage parts, and landing gear.

-

Electronics: Precision is crucial in the electronics industry, and 3D laser cutting is used to create precise circuit boards, microchips, and other electronic components.

-

Medical: 3D laser cutting plays a vital role in the medical sector by manufacturing medical devices, implants, and surgical instruments with high accuracy.

These are just a few examples of the wide range of products made possible by 3D laser cutting. Now let’s delve into specific examples of products made with this cutting-edge technology.

Examples of Products Made with 3D Laser Cutting

It’s mind-blowing to see the intricate designs and precision of products made possible by the wonder of 3D laser cutting. This cutting-edge technology offers numerous advantages in the manufacturing industry.

Firstly, 3D laser cutting allows for unparalleled accuracy and detail, enabling the creation of complex shapes and patterns with ease. Additionally, it provides a high level of precision, ensuring minimal material waste and maximizing efficiency. However, there are limitations to consider.

One limitation is the thickness of materials that can be cut, as 3D laser cutting is most effective on thinner materials. Moreover, the cost of equipment and maintenance can be prohibitive for some businesses. Nevertheless, the advantages of 3D laser cutting make it a valuable tool in industries such as automotive, aerospace, and jewelry manufacturing.

Moving on to the next section about applications of CNC cutting, let’s explore another dimension of precision cutting.

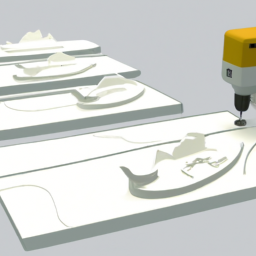

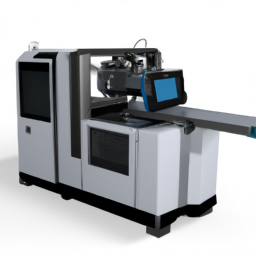

Applications of CNC Cutting

Discover the diverse range of applications for CNC cutting and how it can revolutionize your manufacturing process.

With CNC cutting, you can achieve precise and intricate cuts in a variety of materials, making it ideal for industries such as automotive, aerospace, and furniture manufacturing. Its advantages include high accuracy, repeatability, and the ability to create complex shapes with ease.

CNC cutting allows for efficient production and reduces the need for manual labor, saving both time and costs. However, it also has limitations, such as the need for skilled operators and the initial investment required for the machinery.

In the next section, we will compare the precision and accuracy of CNC cutting with 3D laser cutting.

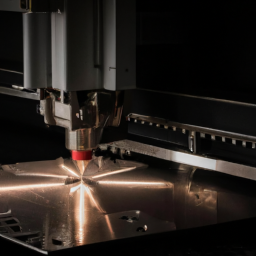

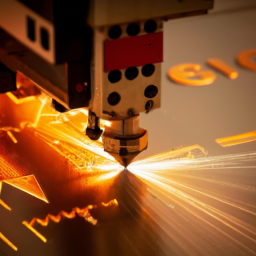

Comparing Precision and Accuracy

Get ready to witness the mind-blowing precision and accuracy of CNC cutting versus 3D laser cutting, where every cut is flawlessly executed with surgical precision. When comparing precision and accuracy between these two cutting methods, there are several factors that come into play. Factors such as feed rate, tool wear, and material properties can affect the precision and accuracy of the cuts. CNC cutting offers a higher level of precision due to its ability to control the feed rate and minimize tool wear. On the other hand, 3D laser cutting may have limitations in terms of precision due to beam divergence and material thickness. However, it offers advantages in terms of cutting complex shapes and thin materials. Overall, both methods have their advantages and limitations when it comes to precision cutting techniques. In the next section, we will delve into choosing the right cutting method for your specific needs.

Choosing the Right Cutting Method

When selecting the ideal cutting method, envision the perfect balance between precision and efficiency. Here are four key factors to consider when choosing between 3D laser cutting and CNC cutting:

-

Benefits of 3D Laser Cutting:

- High precision: 3D laser cutting offers exceptional accuracy, making it ideal for intricate designs and complex geometries.

- Versatility: It can cut a wide range of materials, including metals, plastics, wood, and more.

- Minimal heat distortion: The laser beam generates minimal heat, reducing the risk of material warping or damage.

- Smooth edges: 3D laser cutting leaves clean, burr-free edges, eliminating the need for additional finishing processes.

-

Advantages of CNC Cutting:

- Cost-effective: CNC cutting is generally more affordable, making it suitable for larger production runs.

- Flexibility: It can handle a variety of cutting tasks, including straight cuts, curves, bevels, and more.

- Faster cutting speed: CNC cutting machines can operate at high speeds, reducing production time.

- Automation: CNC cutting eliminates the need for manual intervention, improving productivity and reducing errors.

Considering these factors will help you make an informed decision based on your specific needs and requirements.

Frequently Asked Questions

How does the speed of 3D laser cutting compare to CNC cutting?

The speed of 3D laser cutting surpasses that of CNC cutting. With laser precision, it swiftly carves through materials, achieving intricate designs in a fraction of the time.

CNC cutting, on the other hand, relies on mechanical tools that require more time to maneuver and shape the material.

The efficiency of 3D laser cutting is unmatched, making it the preferred choice for industries that prioritize speed and accuracy.

Can both 3D laser cutting and CNC cutting handle thick materials?

Both 3D laser cutting and CNC cutting are capable of handling thick materials, but 3D laser cutting has certain advantages in this regard. The precision and speed of 3D laser cutting allow for efficient cutting of thick materials, while maintaining accuracy. In comparison, while CNC cutting can also handle thick materials, it may not be as efficient in terms of speed.

Therefore, when it comes to cutting thick materials, 3D laser cutting offers a superior solution.

Are there any limitations to the size of objects that can be cut using 3D laser cutting or CNC cutting?

When it comes to the size of objects that can be cut, both 3D laser cutting and CNC cutting have their limitations.

3D laser cutting has limitations in terms of the thickness of the material that can be cut, as laser beams may struggle to penetrate thick objects efficiently.

On the other hand, CNC cutting has limitations in terms of the physical size of the object that can be accommodated by the machine.

Therefore, both methods have their own constraints when it comes to the size of objects that can be cut.

What types of materials are commonly used in 3D laser cutting and CNC cutting?

In 3D laser cutting, commonly used materials include metals like steel, aluminum, and titanium, as well as plastics and wood.

CNC cutting, on the other hand, can work with a wider range of materials such as metals, plastics, wood, foam, and composites. However, 3D laser cutting offers advantages over CNC cutting in terms of material precision.

The laser beam used in 3D laser cutting allows for more intricate and precise cuts, resulting in higher accuracy and finer details in the finished product.

How does the cost of 3D laser cutting compare to CNC cutting?

When comparing the cost of 3D laser cutting and CNC cutting, it’s important to consider the precision comparison as well.

3D laser cutting generally has a higher initial cost due to the expensive laser equipment required. However, it offers greater precision and accuracy compared to CNC cutting.

CNC cutting, on the other hand, has a lower initial cost but may require more maintenance and calibration over time.

Overall, the cost comparison between the two techniques depends on factors such as material type, complexity of the design, and volume of production.

Conclusion

Now that you’ve explored the mechanisms and processes of 3D laser cutting and CNC cutting, as well as their respective applications, it’s time to make a decision.

Choosing the right cutting method can be both exciting and daunting. The precision and accuracy of these techniques can greatly impact the outcome of your project.

So, take a moment to consider your requirements and goals. The right choice could mean the difference between success and disappointment.