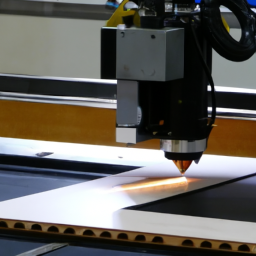

When it comes to creating intricate acrylic designs, precision and efficiency are paramount. This is where laser cutting and CNC cutting techniques come into play.

Laser cutting, known for its high accuracy and clean cuts, has become a popular choice among designers. On the other hand, CNC cutting offers its own set of advantages, combining speed and precision to deliver exceptional results.

In this article, we will compare and contrast laser cutting and CNC cutting for acrylic designs, exploring their strengths and limitations. We will delve into various factors such as precision, speed, versatility, cost, and maintenance requirements to help you make an informed decision.

By examining these key aspects, you will gain a comprehensive understanding of which technique is best suited for your acrylic design needs. So, whether you’re a professional designer or a DIY enthusiast, read on to discover the pros and cons of laser cutting and CNC cutting, and choose wisely for your next acrylic design project.

Key Takeaways

- Laser cutting offers high accuracy and clean cuts, making it ideal for intricate acrylic designs.

- CNC cutting combines speed and precision, making it suitable for complex shapes and contours.

- Laser cutting requires a higher initial investment but offers greater precision and versatility.

- CNC cutting has a lower upfront cost but may require more maintenance and tooling expenses.

Precision: Examining the Accuracy of Laser Cutting and CNC Cutting for Acrylic Designs

Get ready to dive into the world of precision as we compare the accuracy of laser cutting and CNC cutting for acrylic designs!

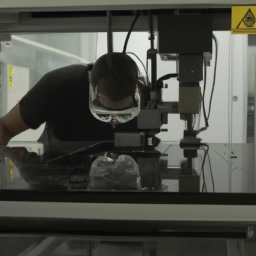

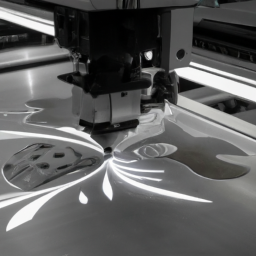

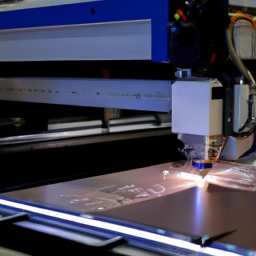

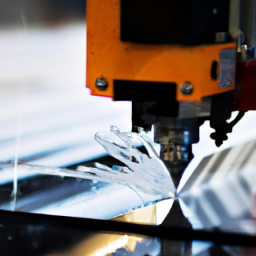

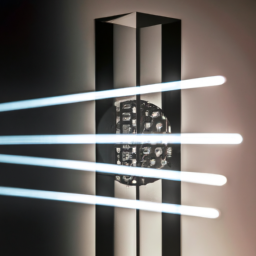

In this section, we will conduct an accuracy comparison and precision analysis between these two cutting methods. Laser cutting utilizes a high-powered laser beam to cut through the acrylic material with extreme accuracy. This method offers precise and clean cuts, allowing for intricate and complex designs.

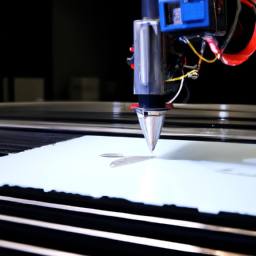

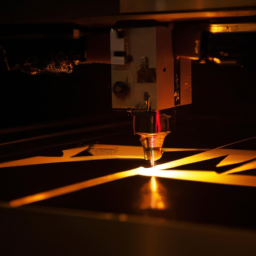

On the other hand, CNC cutting involves the use of computer-controlled machines to carve out acrylic designs. While CNC cutting also provides accurate results, it may not achieve the same level of precision as laser cutting due to the limitations of the cutting tools.

Now, let’s transition into the subsequent section about the speed of laser cutting and CNC cutting for acrylic designs.

Speed: Comparing the Efficiency of Laser Cutting and CNC Cutting for Acrylic Designs

You’ll be astonished at how swiftly and effortlessly acrylic designs come to life when using the precision of laser cutting or the finesse of CNC cutting. Both methods offer impressive efficiency and reduced production time compared to traditional cutting techniques.

Here are some reasons why:

-

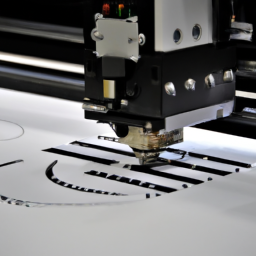

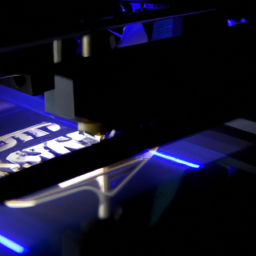

Laser cutting: This method uses a high-powered laser beam to vaporize or melt the acrylic material, resulting in clean and precise cuts. Its automation capabilities allow for faster production speeds and minimal operator intervention.

-

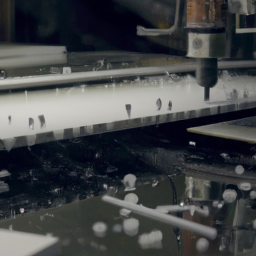

CNC cutting: With computer numerical control, this method employs a computer program to guide the cutting tool. The automated process ensures consistent and accurate results, reducing the time required for manual adjustments.

-

Efficiency: Both laser cutting and CNC cutting enable a streamlined production process, maximizing efficiency and minimizing waste material.

-

Production time: The combination of speed and automation in laser cutting and CNC cutting significantly reduces production time, allowing for quicker turnaround and increased productivity.

As we transition into the subsequent section about versatility, it’s important to note the wide range of applications for both laser cutting and CNC cutting in acrylic designs without missing a beat.

Versatility: Exploring the Range of Applications for Laser Cutting and CNC Cutting in Acrylic Designs

Discover the endless possibilities of using laser cutting and CNC cutting to bring your acrylic designs to life with unparalleled versatility.

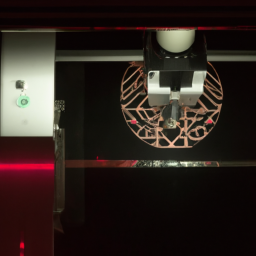

When it comes to exploring design possibilities, both laser cutting and CNC cutting offer a wide range of options. Laser cutting allows for intricate and detailed designs, creating precise cuts and intricate patterns with ease.

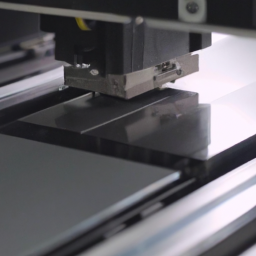

On the other hand, CNC cutting provides the flexibility to cut complex shapes and contours, making it ideal for designs that require intricate 3D elements.

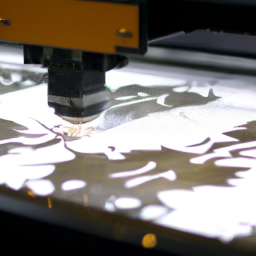

Additionally, both methods offer excellent material compatibility, allowing for seamless cutting of acrylic without compromising its structural integrity.

As we delve into the next section about cost, it’s important to note that these versatile cutting techniques come with their own financial considerations.

Cost: Analyzing the Financial Considerations of Laser Cutting and CNC Cutting for Acrylic Designs

Imagine the satisfaction of seeing your acrylic designs come to life while carefully considering the financial implications of laser cutting and CNC cutting. When it comes to cost, both methods have their own considerations.

Laser cutting typically requires a higher initial investment due to the cost of the laser machine itself. However, it offers greater precision and versatility, allowing for intricate designs and reducing material waste.

On the other hand, CNC cutting machines tend to have a lower upfront cost but may require more maintenance and tooling expenses over time. Additionally, CNC cutting may produce rougher edges that require additional finishing.

Overall, a thorough cost analysis is necessary to determine the most suitable option for your acrylic designs. Transitioning into the subsequent section about maintenance, understanding the maintenance requirements for laser cutting and CNC cutting machines is crucial for optimal performance and longevity.

Maintenance: Understanding the Maintenance Requirements for Laser Cutting and CNC Cutting Machines in Acrylic Designs

Maintaining your laser cutting and CNC cutting machines is essential for optimal performance and longevity in creating your acrylic designs. To ensure your machines continue to operate smoothly, it’s important to understand the maintenance requirements for both laser cutting and CNC cutting machines in acrylic designs. Here are three key aspects to consider:

-

Regular cleaning: Both laser cutting and CNC cutting machines require regular cleaning to remove debris and prevent build-up that can affect the quality of your cuts. This involves cleaning the cutting bed, lenses, and other components.

-

Lubrication: Proper lubrication of the moving parts is crucial for smooth and efficient operation. This includes lubricating the rails, bearings, and other mechanical components as recommended by the manufacturer.

-

Calibration: Laser cutting machines require periodic calibration to ensure precise cuts. CNC cutting machines also need calibration to maintain accuracy and consistency in cutting dimensions.

When comparing maintenance costs for laser cutting and CNC cutting machines in acrylic designs, it’s important to consider factors such as the frequency of maintenance tasks and the cost of replacement parts. Transitioning into the next section on decision-making, it’s important to carefully consider these maintenance requirements when choosing between laser cutting and CNC cutting for your acrylic designs.

Decision-Making: Factors to Consider When Choosing Between Laser Cutting and CNC Cutting for Acrylic Designs

Consider the factors that will guide your decision when choosing between laser cutting and CNC cutting for your acrylic designs.

One important factor to consider is the design complexity. Laser cutting is more suitable for intricate and detailed designs due to its high precision and ability to cut intricate patterns. On the other hand, CNC cutting is better suited for simpler designs that require straight lines and basic shapes.

Another factor to consider is the material thickness. Laser cutting is more versatile when it comes to cutting thicker acrylic materials, as it can handle thicker materials with ease. CNC cutting, on the other hand, may have limitations when it comes to cutting thicker materials.

Therefore, if your acrylic designs have complex patterns and require cutting through thicker materials, laser cutting would be the preferred choice.

Frequently Asked Questions

Can laser cutting or CNC cutting be used for materials other than acrylic?

Laser cutting and CNC cutting are versatile techniques that can be used for materials other than acrylic. Laser cutting is highly effective for wood designs, offering precise and intricate cuts. It excels in creating intricate patterns and detailed designs with minimal material wastage.

On the other hand, laser cutting has advantages over CNC cutting for metal designs. It’s highly precise and can work with various metal types, making it ideal for creating complex and intricate metal designs.

How often do laser cutting machines need to be calibrated for optimal accuracy?

Laser cutting machines require regular calibration to maintain optimal accuracy. The calibration frequency depends on various factors, such as the machine’s usage, environmental conditions, and the manufacturer’s recommendations. Typically, it’s recommended to calibrate laser cutting machines every 6 to 12 months.

This ensures that the machine’s components, such as mirrors, lenses, and motors, are aligned correctly, resulting in precise cutting and consistent quality. Regular calibration is crucial to achieve accurate and reliable results in laser cutting operations.

Are there any safety considerations when using laser cutting machines?

To ensure safety when using laser cutting machines, there are several essential precautions to follow.

First, operators must receive necessary training on machine operation, maintenance, and emergency protocols.

Additionally, proper ventilation and exhaust systems should be in place to minimize exposure to fumes and particles generated during cutting.

Personal protective equipment, such as safety goggles and gloves, should be worn at all times.

Regular inspection and maintenance of the machine and its components are also crucial for safe operation.

Can CNC cutting machines create more intricate designs than laser cutting machines?

CNC cutting machines have the potential to create more intricate designs compared to laser cutting machines. The precision of CNC cutting allows for intricate details and complex shapes to be achieved with accuracy.

For example, imagine a company that specializes in creating custom acrylic jewelry. With CNC cutting, they can produce intricate designs with precise details, such as delicate filigree patterns or intricate geometric shapes.

Laser cutting, on the other hand, offers more versatility and can easily cut through a variety of materials, including acrylic.

What is the typical lifespan of a laser cutting machine compared to a CNC cutting machine?

The typical lifespan of a laser cutting machine is shorter compared to a CNC cutting machine. Laser cutting machines tend to have a lifespan of around 8 to 10 years, while CNC cutting machines can last for 15 to 20 years with proper maintenance.

This is due to the fact that laser cutting machines have more complex components, such as the laser source, mirrors, and lenses, which are prone to wear and require regular replacement. On the other hand, CNC cutting machines have simpler mechanical components that are more durable and have a longer lifespan.

Conclusion

In conclusion, when choosing between laser cutting and CNC cutting for acrylic designs, you must carefully consider multiple factors.

The precision of laser cutting surpasses that of CNC cutting, ensuring accurate and intricate designs. While laser cutting may be slower than CNC cutting, it offers greater versatility in terms of applications.

However, CNC cutting machines are generally more cost-effective than laser cutting machines. Additionally, both techniques require regular maintenance to ensure optimal performance.

Ultimately, the decision lies in your specific requirements and priorities.