Are you tired of the traditional methods of woodworking, where measuring and cutting require hours of painstaking precision? Well, fear not! In the world of modern woodworking, there are two cutting techniques that will revolutionize your craft: laser cutting and CNC cutting.

It’s ironic, isn’t it? In an industry known for its timeless traditions, these cutting-edge technologies offer unparalleled precision and efficiency. Laser cutting, with its focused beam of intense light, can effortlessly slice through wood with the utmost accuracy. On the other hand, CNC cutting, controlled by a computer, can create intricate patterns and shapes with astonishing detail.

Both techniques have their own unique advantages and limitations, making them suitable for different applications in woodworking. So, if you’re ready to take your woodworking to the next level, join us as we delve into the world of laser cutting and CNC cutting, and discover which technique is the perfect fit for your projects.

Key Takeaways

- Laser cutting offers intricate designs and patterns with extreme accuracy.

- CNC cutting allows for rapid and accurate cutting of intricate patterns and shapes.

- Laser cutting is faster, more efficient, and reduces material waste compared to traditional methods.

- CNC cutting is cost-effective and increases production speed compared to traditional methods.

Overview of Laser Cutting

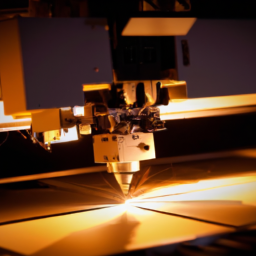

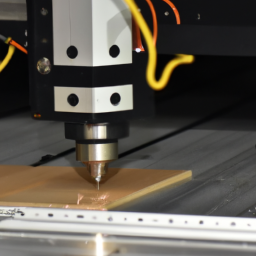

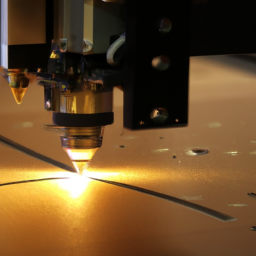

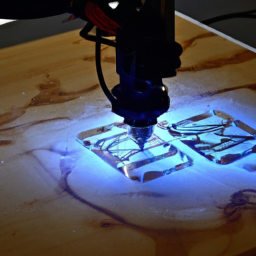

Laser cutting is like having a woodworking wizard wielding a magical beam of light that effortlessly slices through wood with precision and finesse. It’s a modern technology that has revolutionized woodworking by offering numerous advantages over traditional techniques.

One of the key advantages of laser cutting is its ability to cut intricate designs and patterns with extreme accuracy, which is nearly impossible to achieve manually. The laser beam produces a high-quality finish, eliminating the need for additional sanding or finishing. Moreover, laser cutting allows for greater precision and repeatability, ensuring consistent results every time.

Compared to traditional woodworking methods, laser cutting is faster, more efficient, and reduces material waste. It’s a game-changer in the woodworking industry.

Moving on to the overview of CNC cutting…

Overview of CNC Cutting

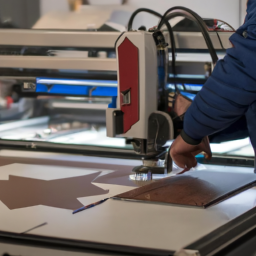

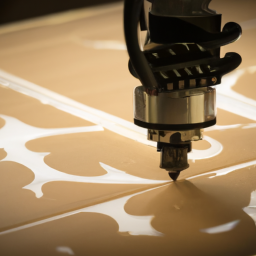

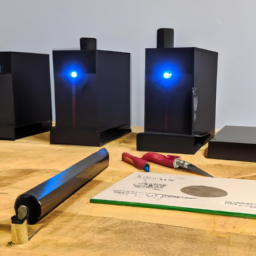

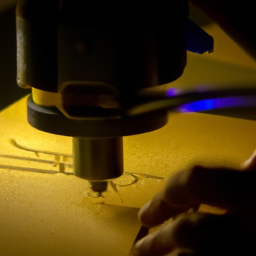

CNC cutting is a highly efficient and precise method used in woodworking. It involves the use of computer-controlled machines to accurately cut and shape wood materials.

By following a pre-determined design, the CNC machine can rapidly and accurately cut intricate patterns, curves, and shapes, saving time and effort. This technology offers several advantages in woodworking, including increased productivity, improved accuracy, and the ability to create complex designs that would be difficult to achieve by hand.

How CNC Cutting Works

To truly appreciate the artistry of woodworking, picture yourself standing in awe as the precision of CNC cutting effortlessly transforms raw timber into intricate masterpieces. CNC cutting works by using computer-controlled machines to precisely cut and shape wood. Here’s how it works:

-

Computer-Aided Design (CAD): The design is created using specialized software, allowing for precise measurements and intricate detailing.

-

Material Selection: The type of wood and its thickness are chosen, ensuring compatibility with the CNC machine.

-

Programming: The CAD design is translated into machine-readable code, which guides the CNC machine’s movements.

-

Cutting Process: The CNC machine uses various cutting techniques, such as routing, drilling, and sawing, to shape the wood according to the design.

With its ability to execute complex designs accurately and efficiently, CNC cutting offers numerous advantages in woodworking. Now, let’s explore the advantages of CNC cutting in woodworking without missing a beat.

Advantages of CNC Cutting in Woodworking

One of the biggest advantages of using CNC cutting in woodworking is that it allows for highly precise and intricate designs to be created effortlessly. This precision is achieved through the use of computer-controlled machinery, which ensures that each cut is made with accuracy and consistency. Additionally, CNC cutting offers cost effectiveness and increased production speed compared to traditional methods. With the ability to automate the cutting process, CNC machines can produce large quantities of identical pieces in a fraction of the time it would take a skilled craftsman. This not only saves time and money but also allows for increased productivity and faster completion of woodworking projects. Moreover, CNC cutting provides a level of precision and accuracy that is unmatched by other methods, ensuring that each piece is cut to the exact specifications required. Transitioning into the subsequent section about ‘precision and accuracy,’ these factors play a crucial role in the overall quality of the finished product.

Precision and Accuracy

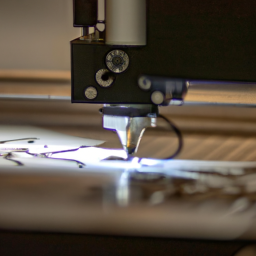

When using laser cutting or CNC cutting in woodworking, have you ever wondered how precise and accurate your cuts will be? Precision and accuracy are crucial factors when it comes to woodworking, and both laser cutting and CNC cutting excel in this aspect.

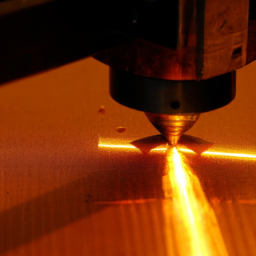

Laser cutting offers numerous benefits in terms of precision, as it uses a highly focused laser beam to make intricate cuts with minimal kerf width. This allows for intricate designs and precise detailing. On the other hand, CNC cutting also delivers exceptional precision by utilizing computer-controlled movements to make accurate cuts. However, it’s important to note that laser cutting tends to have a slight advantage in terms of precision, as it can achieve finer details and tighter tolerances compared to CNC cutting.

Moving forward, let’s explore the versatility and flexibility of these cutting techniques.

Versatility and Flexibility

Now that we’ve explored the precision and accuracy of laser cutting and CNC cutting in woodworking, let’s dive into their versatility and flexibility.

When it comes to versatility, both laser cutting and CNC cutting offer immense possibilities. With laser cutting, you can effortlessly cut intricate designs and complex shapes with ease. On the other hand, CNC cutting provides the flexibility to work on a wide range of materials, from wood to metal, allowing you to create diverse projects.

In terms of cost-effectiveness, CNC cutting is often more affordable due to lower initial investment costs. Furthermore, when it comes to speed and efficiency, laser cutting takes the lead, as it can complete cuts much faster than CNC cutting.

As we move forward, it’s important to consider the limitations and considerations of both methods.

Limitations and Considerations

Although both methods offer immense possibilities, it is important to consider the limitations and considerations of laser cutting and CNC cutting in woodworking. When it comes to drawbacks, laser cutting can be limited by the type of materials it can work with. For example, certain materials like PVC or polycarbonate can release toxic fumes when cut with a laser, making it unsuitable for those applications. On the other hand, CNC cutting is limited by the size of the machine itself, as larger pieces of wood may not fit within the cutting area. Additionally, material compatibility is another important consideration. Laser cutting is great for intricate designs and delicate cuts, while CNC cutting excels at creating precise, repetitive cuts. Moving forward, it is crucial to understand how these limitations and considerations affect the applications in woodworking.

Applications in Woodworking

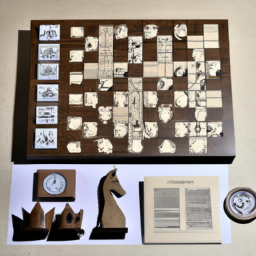

Explore the various ways you can incorporate laser cutting and CNC cutting into your woodworking projects to enhance precision and create intricate designs. Both laser cutting and CNC cutting offer unique advantages and can be used in different types of woodworking applications.

-

Intricate Designs: Laser cutting allows for precise and detailed cuts, making it ideal for creating intricate designs in wood. CNC cutting, on the other hand, offers versatility and can be used to create both simple and complex shapes.

-

Speed and Efficiency: Laser cutting is faster compared to CNC cutting, making it a better choice for large-scale production. However, CNC cutting offers more flexibility and can handle a wider range of materials.

-

Cost Comparison: Laser cutting machines are generally more expensive than CNC machines. However, laser cutting can save costs in the long run due to its high precision, which reduces material waste.

-

Material Compatibility: Laser cutting can work with a variety of materials, including wood, acrylic, and metal. CNC cutting is mainly used for wood and can work with various thicknesses.

By understanding the different types and cost comparison of laser cutting and CNC cutting, you can choose the method that best suits your woodworking projects.

Frequently Asked Questions

How do laser cutting and CNC cutting compare in terms of cost-effectiveness?

When considering cost-effectiveness, both laser cutting and CNC cutting offer efficient solutions in woodworking.

Laser cutting utilizes the precision of a focused laser beam to effortlessly slice through materials, minimizing waste and maximizing efficiency.

Meanwhile, CNC cutting employs computer-controlled machines to achieve accurate cuts, reducing human error and saving time.

Both methods optimize productivity and minimize costs by streamlining the cutting process, making them valuable tools in the woodworking industry.

Can laser cutting or CNC cutting be used for curved or intricate designs in woodworking?

Laser cutting and CNC cutting are both suitable for curved and intricate designs in woodworking. Laser cutting offers high precision and the ability to create intricate details, making it ideal for delicate designs. On the other hand, CNC cutting provides versatility and can handle larger and thicker materials.

While laser cutting has limitations in terms of material thickness and may produce burn marks, CNC cutting can handle a wider range of materials. Both methods have their advantages and best applications in woodworking.

What are the main safety considerations when using laser cutting or CNC cutting in woodworking?

When using laser cutting or CNC cutting in woodworking, there are several safety considerations to keep in mind.

First and foremost, always wear appropriate personal protective equipment, such as safety glasses and gloves, to protect yourself from potential hazards.

Additionally, ensure that the equipment is properly maintained and regularly inspected to prevent any malfunctions or accidents.

It’s also crucial to have a clear understanding of the machine’s operating instructions and to follow proper safety protocols at all times.

Are there any specific maintenance requirements for laser cutting machines or CNC cutting machines in woodworking?

To keep your laser cutting machine in top shape, regular maintenance is crucial. Clearing debris, checking and cleaning the optics, and calibrating the laser power are essential maintenance requirements for laser cutting machines.

Additionally, ensuring proper ventilation and replacing worn-out parts are vital steps.

Similarly, for CNC cutting machines, routine maintenance like lubricating the axis, checking and replacing worn-out bits, and inspecting the electrical connections are necessary to ensure optimal performance.

What is the environmental impact of laser cutting compared to CNC cutting in woodworking?

When comparing the environmental impact of laser cutting and CNC cutting in woodworking, energy consumption and waste generation are important factors to consider.

Laser cutting generally consumes less energy than CNC cutting due to its precise and focused cutting process. Additionally, laser cutting produces less waste because it creates narrow kerf widths, resulting in higher material efficiency.

CNC cutting, on the other hand, may require more energy and generate more waste due to its cutting method and wider kerf widths.

Conclusion

So there you have it, the comparison between laser cutting and CNC cutting in woodworking.

While both methods offer precision and accuracy, it is clear that laser cutting takes the crown in terms of versatility and flexibility.

However, it’s important to consider the limitations of laser cutting, such as the inability to cut thick materials.

In the end, the choice between the two depends on the specific woodworking application. Whether you’re aiming for intricate designs or need to cut through thick materials, both laser cutting and CNC cutting have their place in the workshop.