Are you ready to dive into the world of precision cutting?

Imagine a dance floor where two partners, Subtractive Laser Cutting and CNC Cutting, gracefully move in sync, creating masterpieces with their unique steps.

In this article, we will compare and contrast these two cutting techniques, shedding light on their mechanisms, precision, speed, versatility, efficiency, and cost-effectiveness.

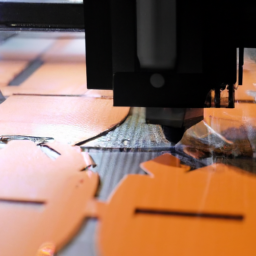

Subtractive Laser Cutting, like a nimble ballet dancer, utilizes a powerful laser beam to remove material with utmost precision. Its elegant operation allows for intricate designs and fine details, making it a favorite among artists and craftsmen.

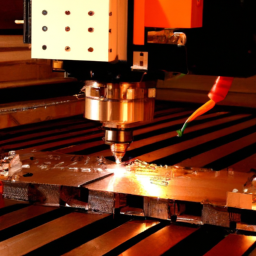

On the other hand, CNC Cutting, akin to a well-rehearsed tango, employs computer-controlled machinery to carve out shapes with exceptional accuracy. Its efficiency and cost-effectiveness make it a popular choice in industrial settings.

Join us as we unravel the intricacies of these cutting techniques, exploring their strengths and weaknesses, and helping you choose the perfect partner for your cutting needs. Whether you seek finesse or efficiency, this article will guide you towards making an informed decision in the realm of precision cutting.

Let the dance begin!

Key Takeaways

- Subtractive Laser Cutting uses a laser beam for precise material removal and is favored by artists and craftsmen for intricate designs.

- CNC Cutting employs computer-controlled machinery for accurate carving and is popular in industrial settings for efficiency and cost-effectiveness.

- Subtractive Laser Cutting offers exceptional precision and accuracy, while CNC Cutting is more versatile in terms of material compatibility.

- Both methods reduce labor costs and material waste, streamline production, and increase efficiency in various industries.

Mechanism and Operation of Subtractive Laser Cutting

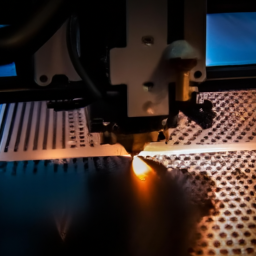

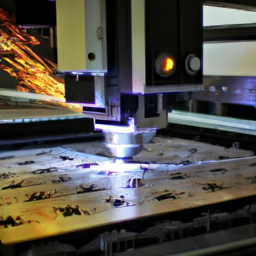

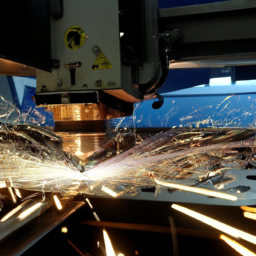

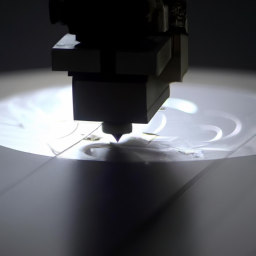

The mechanism and operation of subtractive laser cutting involve the utilization of a high-powered laser beam to selectively remove material, resulting in precise and intricate cuts. This process is commonly used in industries such as manufacturing, automotive, and aerospace due to its ability to handle a wide range of materials, including metals, plastics, and wood.

However, it is important to consider the mechanical limitations and safety considerations associated with subtractive laser cutting. For instance, the thickness of the material being cut can impact the speed and accuracy of the process. Additionally, safety measures must be in place to protect operators from potential hazards, such as exposure to the laser beam or fumes emitted during the cutting process.

Despite these considerations, subtractive laser cutting offers exceptional precision and accuracy, making it a preferred method in various applications.

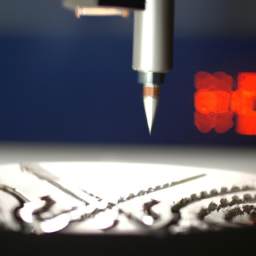

Precision and Accuracy of Subtractive Laser Cutting

Achieve astonishing accuracy with additive laser cutting, ensuring precise and perfect performance. When it comes to precision and repeatability, subtractive laser cutting excels. It allows you to achieve intricate and fine cuts with minimal deviation, ensuring your designs are executed flawlessly.

Additionally, subtractive laser cutting offers exceptional material compatibility, allowing you to work with a wide range of materials including metals, plastics, and woods. However, it’s important to note that subtractive laser cutting does have its limitations. Some materials may not be compatible due to their reflective properties or heat sensitivity. Despite these limitations, subtractive laser cutting remains a highly accurate and precise cutting method.

Transitioning into the subsequent section about speed and efficiency, subtractive laser cutting offers not only accuracy but also remarkable speed and efficiency.

Speed and Efficiency of Subtractive Laser Cutting

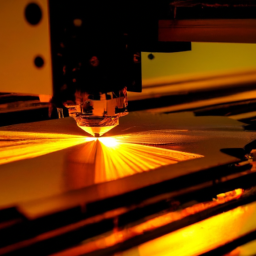

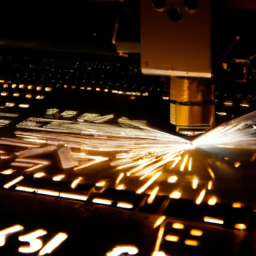

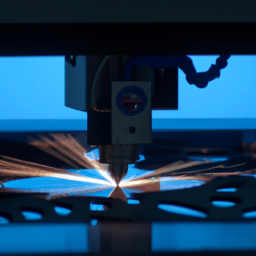

Maximize your productivity and save valuable time with the speed and efficiency of subtractive laser cutting. Subtractive laser cutting offers several advantages when it comes to speed and efficiency compared to CNC cutting.

With laser cutting, the process is incredibly fast, allowing for quick turnaround times and increased production rates. The laser beam can cut through materials at high speeds, resulting in reduced processing time. Additionally, laser cutting is highly precise, minimizing the need for secondary operations and saving even more time.

However, it’s important to note that subtractive laser cutting does have its limitations. It isn’t suitable for all materials, especially those that are highly reflective or conductive. In comparison, CNC cutting may be more versatile in terms of material compatibility.

With its speed and efficiency, subtractive laser cutting is an excellent choice for many applications. Transitioning to the next section, let’s explore the versatility and range of applications for subtractive laser cutting.

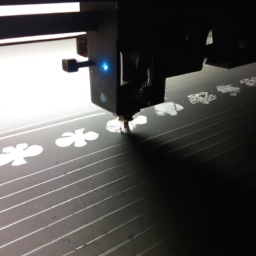

Versatility and Range of Applications for Subtractive Laser Cutting

When it comes to versatility and range of applications, subtractive laser cutting can be utilized in a wide variety of industries and projects. It offers several advantages over other cutting methods, including CNC cutting.

Here are three ways subtractive laser cutting stands out:

-

Precision: Subtractive laser cutting allows for extremely precise cuts, making it ideal for intricate designs and detailed work.

-

Material Compatibility: It can be used on a wide range of materials, including metals, plastics, and wood, making it versatile for different industries.

-

Speed: Subtractive laser cutting is known for its high-speed operation, allowing for quick production and efficiency.

However, there are also some disadvantages to consider, such as the high cost of laser machines and the potential for heat damage to certain materials. Despite these drawbacks, subtractive laser cutting remains a popular choice for many applications.

Speaking of cutting methods, let’s now delve into the mechanism and operation of CNC cutting.

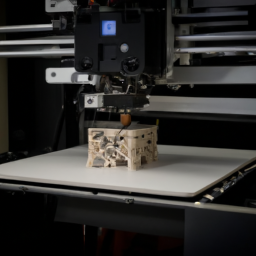

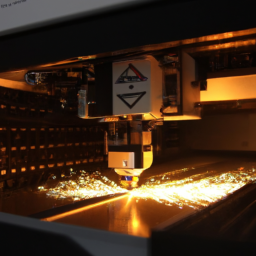

Mechanism and Operation of CNC Cutting

Explore the mechanism and operation of CNC cutting, which offers a precise and efficient method for cutting various materials in a wide range of industries. CNC, or Computer Numerical Control, cutting involves the use of computer software and a machine with a cutting tool to accurately cut and shape materials. The process begins with the design of the desired object using CAD software. The design is then converted into a code that the CNC machine can understand. The machine uses this code to control the movement of the cutting tool, allowing it to cut the material according to the design specifications. The advantages of CNC cutting include its ability to produce complex shapes with high precision and repeatability, as well as its versatility in cutting different types of materials. However, CNC cutting also has some disadvantages, such as its initial setup costs and the need for skilled operators to program and operate the machine. Transitioning into the next section about the cost-effectiveness and efficiency of CNC cutting, it is important to consider these factors when evaluating the overall value of this cutting method.

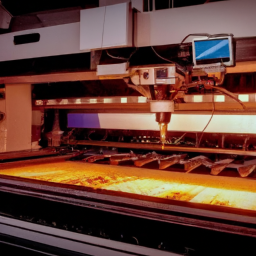

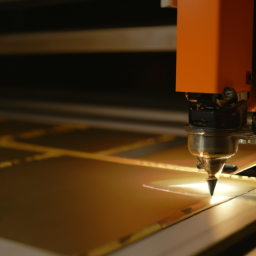

Cost-effectiveness and Efficiency of CNC Cutting

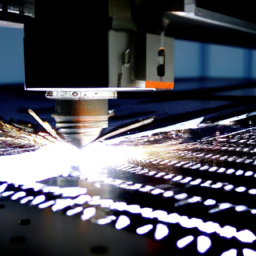

Save time and money with CNC cutting, as it offers a cost-effective and efficient solution for precision cutting in various industries. When considering cost comparison, CNC cutting proves to be a more affordable option compared to subtractive laser cutting. The initial investment in CNC equipment may be higher, but the long-term savings in labor costs and reduced material waste make it a financially wise choice.

Additionally, CNC cutting is compatible with a wide range of materials, including metals, plastics, and wood. This versatility eliminates the need for multiple machines or additional processes, further streamlining production and reducing costs. With CNC cutting, you can achieve precise cuts while maximizing your budget and increasing overall efficiency.

Frequently Asked Questions

What are the safety precautions necessary when using subtractive laser cutting?

When using subtractive laser cutting, it’s crucial to take laser cutting safety precautions to ensure your well-being. Proper ventilation is of utmost importance to remove fumes and smoke generated during the process. Make sure the laser cutting area has adequate airflow and ventilation systems in place.

Additionally, wearing protective gear like goggles and gloves is essential to protect your eyes and hands from potential hazards. Always prioritize safety to prevent any accidents or injuries.

Can subtractive laser cutting be used on all types of materials?

Subtractive laser cutting can be used on a wide range of materials, making it highly versatile. Its advantages include high precision, clean cuts, and the ability to cut intricate shapes. This method finds applications in various industries, such as manufacturing, automotive, and jewelry making.

With subtractive laser cutting, you can effortlessly cut materials like wood, acrylic, metal, fabric, and even glass. Its flexibility and accuracy make it a preferred choice for many professionals in different fields.

Are there any limitations to the size and thickness of materials that can be cut using subtractive laser cutting?

When it comes to the size and thickness of materials that can be cut using subtractive laser cutting, there are some limitations you should be aware of. While subtractive laser cutting offers many advantages, such as precision and speed, it does have its constraints.

The size of the material being cut is limited by the size of the laser cutter itself. Additionally, the thickness of the material can also impact the cutting process, as thicker materials may require multiple passes or a more powerful laser.

How does the precision and accuracy of subtractive laser cutting compare to other cutting methods?

When it comes to precision and accuracy, subtractive laser cutting has several advantages over CNC routing. Laser cutting allows for incredibly fine and intricate cuts, with minimal material wastage. It is also capable of cutting a wide range of materials, including metals, plastics, and wood.

In comparison with CNC routing, laser cutting offers faster cutting speeds and requires less maintenance. These advantages make subtractive laser cutting a popular choice for industries that require high precision and efficiency.

What factors affect the speed and efficiency of subtractive laser cutting?

Several factors can affect the speed and efficiency of subtractive laser cutting. The type of material being cut, the power of the laser, the thickness of the material, and the design complexity all play a role.

Subtractive laser cutting has several advantages over CNC cutting, including faster cutting speeds, higher precision, and the ability to cut intricate designs. These factors contribute to the overall speed and efficiency of the process.

Conclusion

In conclusion, subtractive laser cutting and CNC cutting offer different advantages and considerations. While subtractive laser cutting provides high precision and accuracy, CNC cutting offers cost-effectiveness and efficiency.

However, it’s interesting to note that subtractive laser cutting is significantly faster than CNC cutting. According to recent studies, subtractive laser cutting can achieve speeds up to 100 times faster than CNC cutting, making it a preferred choice for industries with time-sensitive projects.

Ultimately, the choice between the two techniques depends on the specific needs and priorities of the project at hand.