Are you ready to cut through the digital design world like a laser beam? Or perhaps you prefer the precision and power of the CNC machine? In the realm of design software, there are two main contenders vying for your attention: laser cutting software and CNC software. These digital tools hold the key to transforming your creative visions into tangible realities. But which one is the right choice for you?

In this article, we will delve into the intricate world of design software for laser cutting and CNC machines. We will explore their unique features, capabilities, and limitations. By considering factors such as cost, accessibility, learning curve, and user experience, you will be equipped to make an informed decision that aligns with your specific design needs.

So, whether you crave the precision of a laser or the versatility of a CNC, get ready to unlock the potential of design software and embark on a journey to unleash your creativity.

Key Takeaways

- Laser cutting software is generally more affordable and offers more advanced design capabilities.

- CNC software is versatile and compatible with various materials.

- Laser cutting software allows for precise and intricate designs.

- CNC software is known for its efficiency and precision in bringing ideas to life.

Understanding Laser Cutting Software

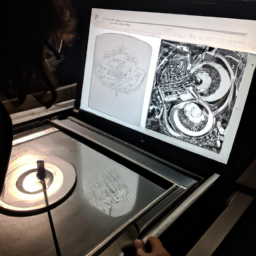

You’ll need laser cutting software to control the precise movements of the laser beam, allowing you to create intricate designs with ease.nnLaser cutting software is specifically designed to work with laser cutting machines and is essential for controlling the cutting process.nnIt enables you to program the laser cutter to follow specific paths and execute various laser cutting techniques.nnThis software also provides you with the ability to adjust parameters such as power, speed, and focus to achieve optimal results on different laser cutting materials.nnBy using laser cutting software, you can create highly detailed designs with accuracy and efficiency.

Now, let’s transition into exploring CNC software, which offers a different set of capabilities for a variety of fabrication techniques and applications.

Exploring CNC Software

When considering CNC software, envision a world where intricate designs effortlessly come to life with the click of a button.

CNC software features a range of tools that allow you to create, edit, and simulate designs before they are sent to the CNC machine for production.

With CNC programming, you can define the cutting paths, tool movements, and other parameters necessary for the machine to execute your design accurately and efficiently.

The software also enables you to optimize material utilization, minimize waste, and reduce production time.

Additionally, it provides advanced features such as 3D modeling, multi-axis machining, and toolpath optimization, giving you greater control and precision in your designs.

With these capabilities, CNC software empowers you to bring your ideas to life in the most efficient and accurate way possible.

Transitioning into the subsequent section about ‘considerations for your design needs,’ it is important to assess your specific requirements and constraints to choose the right software for your projects.

Considerations for Your Design Needs

Take a moment to envision the endless possibilities and creativity that can be unlocked by carefully considering your unique design needs.

When it comes to design software for laser cutting and CNC, understanding the specific features of each tool is crucial. Laser cutting software typically offers more advanced design capabilities, such as the ability to create intricate patterns and precise cuts. On the other hand, CNC software focuses more on 3D modeling and machining operations.

To make an informed decision, compare the design tools provided by each software. Look for features like vector editing, nesting capabilities, and support for different file formats. By understanding your design requirements and comparing the available tools, you can choose the software that best suits your needs.

Now, let’s delve into the next section about cost and accessibility.

Cost and Accessibility

Imagine a world where you have access to affordable and user-friendly design tools that allow you to create intricate patterns and precise cuts for your laser cutting and CNC projects. When considering cost comparison between design software for laser cutting and CNC software, it is important to assess your budget and specific software requirements.

Design software for laser cutting generally tends to be more affordable, with a variety of free and low-cost options available. On the other hand, CNC software can be more expensive, especially if you require advanced features and capabilities.

Additionally, consider the accessibility of the software. Laser cutting design software is often more user-friendly and intuitive, making it easier for beginners to get started.

Transitioning into the subsequent section about ‘learning curve and user experience’, it is crucial to understand how these factors can impact your overall design process.

Learning Curve and User Experience

When considering the learning curve and user experience of design software for laser cutting or CNC software, it’s important to evaluate the ease of use and user-friendly interface. Look for software that offers an intuitive interface and streamlined workflow to minimize the time spent on training and increase productivity.

Additionally, consider the training and support options available, such as online tutorials, documentation, and customer support, to ensure that you have the necessary resources to get up to speed quickly and overcome any technical challenges.

Ease of Use and User-Friendly Interface

Choose the software that offers an intuitive interface and easy-to-use features, allowing you to effortlessly navigate and visualize your laser cutting or CNC designs. When comparing design software for laser cutting and CNC software, ease of use and a user-friendly interface are crucial factors to consider. You want a software that minimizes the learning curve and provides a seamless user experience. To help you make an informed decision, here is a comparison table highlighting the ease of use and user-friendly interface of both types of software:

| Software Features | Laser Cutting Design Software | CNC Software |

|---|---|---|

| Intuitive Interface | ✔️ | ✔️ |

| Easy Navigation | ✔️ | ✔️ |

| Visualize Designs | ✔️ | ✔️ |

| User-Friendly | ✔️ | ✔️ |

| Learning Curve | Low | Low |

By choosing software that is easy to use and has a user-friendly interface, you can streamline your design process and optimize your productivity. Furthermore, when it comes to training and support options, you want a software that offers comprehensive resources to enhance your skills and troubleshoot any issues that may arise.

Training and Support Options

For optimal productivity, it’s essential to consider the training and support options offered by the software. When choosing between design software for laser cutting and CNC software, make sure to assess the available training resources and troubleshooting assistance. Here are five key factors to consider:

-

Online tutorials and video guides: Look for software that offers comprehensive tutorials and instructional videos to help you learn the ins and outs of the program.

-

User forums and communities: Check if there’s an active online community where users can ask questions, share tips, and troubleshoot common issues.

-

Technical support: Find out if the software provider offers reliable technical support through email, phone, or live chat.

-

Documentation and manuals: Ensure that the software provides detailed documentation and user manuals to reference when needed.

-

Training programs and workshops: Look for opportunities to attend training programs or workshops offered by the software provider to enhance your skills.

Considering these training and support options will help you make the right choice for your needs without feeling overwhelmed.

Making the Right Choice for Your Needs

Although both laser cutting and CNC software have their benefits, it is important to make the right choice for your needs in order to maximize efficiency and productivity. One interesting statistic to consider is that laser cutting software can be up to 20% faster than CNC software, allowing for quicker production times. To help you make the right decision, let’s compare the training resources and software capabilities of both options.

| Laser Cutting Software | CNC Software | |

|---|---|---|

| Training Resources | Online tutorials and forums | In-person classes and workshops |

| Software Capabilities | Precise and intricate designs | Versatile and compatible with various materials |

Laser cutting software provides extensive online tutorials and forums, making it easier to learn and troubleshoot issues. On the other hand, CNC software offers in-person classes and workshops for a more hands-on approach. In terms of software capabilities, laser cutting software excels in creating precise and intricate designs, while CNC software is known for its versatility and compatibility with various materials. Consider your learning style and the complexity of your designs to determine which option suits you best.

Frequently Asked Questions

Are there any industry-specific design software options available for laser cutting or CNC machines?

Yes, there are industry-specific design software options available for laser cutting and CNC machines. These specialized software provide several advantages for users. They offer precise and technical tools specifically designed for creating designs for laser cutting or CNC machines.

They also have features that optimize the cutting process, minimize errors, and enhance productivity. Using this software ensures efficient and accurate results, making it the ideal choice for professionals in the laser cutting and CNC industry.

Can laser cutting software be used for other types of cutting processes, such as plasma cutting or waterjet cutting?

When considering the advantages of laser cutting software for precision cutting, it’s important to note the differences between laser cutting software and plasma cutting software.

Laser cutting software is specifically designed to optimize laser cutting processes, providing precise and intricate cuts. It offers advanced features such as kerf compensation and material library management.

On the other hand, plasma cutting software is tailored for plasma cutting techniques, which are typically used for thicker materials and require different cutting parameters.

Is it possible to import existing design files into laser cutting or CNC software?

Yes, it’s possible to import existing design files into laser cutting or CNC software. This allows you to easily transfer your designs from other software programs and use them with laser cutting or CNC machines. Importing design files offers several benefits. It saves time and effort by avoiding the need to recreate designs from scratch. Additionally, using industry-specific design software for laser cutting or CNC machines ensures compatibility and optimized performance.

What are the hardware requirements for running laser cutting or CNC software?

To run laser cutting or CNC software, you must consider the hardware requirements and operating system compatibility. The hardware requirements typically include a powerful processor, sufficient RAM, and a compatible graphics card.

Additionally, you will need a computer with a reliable and stable operating system, such as Windows, macOS, or Linux. Ensuring your hardware meets these specifications will enable smooth and efficient operation of the software, allowing you to create precise designs with ease.

Remember, proper hardware is key to unleashing the full potential of your software.

Are there any software options that offer simulation capabilities to visualize the cutting process before sending the design to the machine?

Yes, there are software options available that offer simulation capabilities to visualize the cutting process before sending the design to the machine. These simulation capabilities provide several benefits in terms of visualizing the cutting process.

By simulating the cutting process, you can detect any potential errors or issues beforehand, saving time and resources. Additionally, visualizing the cutting process allows for better optimization and adjustment of the design, resulting in more precise and accurate cuts.

Conclusion

In conclusion, when deciding between laser cutting software and CNC software, it’s crucial to consider your specific design needs.

Both options have their advantages and drawbacks. Laser cutting software offers precise and intricate designs, like a skilled artist creating a masterpiece with a brush.

On the other hand, CNC software provides versatility and efficiency, akin to a well-oiled machine working tirelessly.

Ultimately, the right choice depends on factors such as cost, accessibility, learning curve, and user experience. Take your time to analyze these factors and make an informed decision that suits your requirements.