Did you know that the global market for laser cutting machines is projected to reach $4.4 billion by 2025? With such a significant investment in laser cutting technology, it’s crucial to understand the role of design software in this process.

Design software plays a pivotal role in both laser cutting and die cutting, ensuring precision and efficiency in the cutting processes. However, when it comes to cost-effectiveness, choosing the right software can make all the difference.

In this article, we will compare the features and capabilities of design software for laser cutting and die cutter software, analyzing their cost factors to determine which option is more cost-effective. By understanding the benefits and limitations of each software, you will be able to make an informed decision that maximizes your productivity and minimizes your expenses.

So, let’s dive into the world of design software and discover which option is the most cost-effective for your cutting needs.

Key Takeaways

- Laser cutting software offers advanced features and is user-friendly

- Laser cutting software requires less maintenance and upgrades compared to die cutter software

- Laser cutting software improves productivity and efficiency with advanced technology

- Laser cutting software can result in lower long-term costs due to precise cutting and minimal material waste

Understanding Laser Cutting and Die Cutting Processes

Let’s dive into the world of laser cutting and die cutting to see how these processes work their magic!

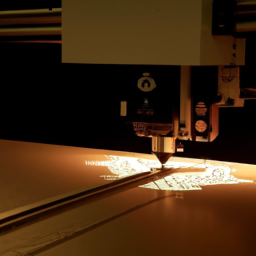

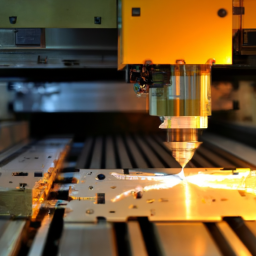

Laser cutting techniques involve using a high-powered laser beam to cut through various materials with precision and accuracy. This method is commonly used in industries such as automotive, aerospace, and manufacturing due to its ability to produce intricate designs and complex shapes.

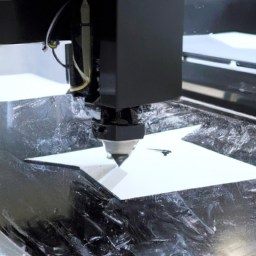

On the other hand, die cutting involves the use of a die, which is a specialized tool that cuts through materials using pressure. Die cutting materials include paper, cardboard, fabric, and even metal.

Both laser cutting and die cutting offer unique advantages depending on the project requirements.

Now, let’s explore the importance of design software in these cutting processes.

Importance of Design Software in Cutting Processes

The importance of efficient design tools in cutting processes can’t be overstated, as studies have shown that companies using specialized software experience a 25% increase in productivity. Design software specifically tailored for laser cutting or die cutting offers several advantages that have a significant impact on overall production costs:

-

Precision: Design software enables precise and accurate cutting, minimizing material waste and reducing the need for rework.

-

Optimization: These tools provide optimization features that allow for nesting, which maximizes material usage and reduces costs.

-

Time-saving: Design software automates the design process, eliminating the need for manual calculations and measurements.

By utilizing design software, companies can save time, reduce material waste, and increase productivity, ultimately leading to cost savings.

As we delve into the subsequent section about cost factors to consider, it’s important to assess the implications of design software on overall production costs.

Cost Factors to Consider

When considering the cost factors of design software for cutting processes, there are three key points to take into account.

First, the initial investment in design software is an important consideration, as it’ll determine the upfront cost of implementing the software.

Second, maintenance and upgrades should be considered, as they can add additional costs over time.

Lastly, efficiency and time savings should be evaluated, as these factors can impact the overall cost-effectiveness of the software in the long run.

Initial Investment in Design Software

Contrary to popular belief, initial investment in design software for laser cutting is more cost-effective than for die cutter software. When conducting a cost comparison, it’s important to consider the long-term benefits of the software.

Laser cutting software often offers more advanced features and capabilities, which can greatly enhance productivity and efficiency in the long run. Additionally, laser cutting software is typically more user-friendly and intuitive, reducing the time and resources required for training.

While the initial investment for laser cutting software may be higher, the increased productivity and efficiency can result in significant cost savings over time. Furthermore, laser cutting software often requires less maintenance and upgrades compared to die cutter software, further reducing long-term costs.

Transitioning into the subsequent section about maintenance and upgrades, it’s important to evaluate these factors to determine the true cost-effectiveness of the software.

Maintenance and Upgrades

Discover how easy it is to maintain and upgrade your chosen option. When it comes to maintenance costs, design software for laser cutting and die cutter software have their own considerations.

Laser cutting software typically requires regular updates to ensure compatibility with new laser technologies and materials. These updates can be costly, especially if you have multiple licenses or need to upgrade multiple machines.

On the other hand, die cutter software may have lower maintenance costs since it doesn’t rely on specific hardware updates. However, it’s important to note that die cutter software may still require occasional updates to improve software compatibility and address any bugs or issues.

These maintenance costs should be taken into account when considering the overall cost-effectiveness of each option.

Moving forward into the subsequent section about efficiency and time savings, you’ll discover how these factors can further impact your decision-making process.

Efficiency and Time Savings

In the previous subtopic, we discussed the importance of maintenance and upgrades in both laser cutting and die cutter software. Now, let’s shift our focus to the current subtopic: efficiency and time savings.

When it comes to design software for laser cutting, the advancements in technology have led to improved productivity and a streamlined workflow. With laser cutting software, you can easily import and manipulate designs, optimizing them for the cutting process. The software also offers features like nesting, which allows you to arrange multiple designs on a single sheet of material, minimizing waste and maximizing efficiency.

Additionally, laser cutting software often includes automated features such as path optimization and toolpath generation, saving you valuable time and effort. With these time-saving capabilities, laser cutting software proves to be a cost-effective choice for businesses.

Transitioning into the subsequent section, let’s now explore the features and capabilities of laser cutting software.

Features and Capabilities of Laser Cutting Software

Laser cutting software, with its extensive range of features and capabilities, can be as precise and versatile as a Swiss army knife. It offers several advantages over traditional methods, making it a cost-effective choice for designers. Here are five key features and capabilities of laser cutting software:

-

Vector-based design: Laser cutting software uses vector graphics to create precise and scalable designs, ensuring accuracy and consistency in the final product.

-

Material optimization: The software analyzes the design and suggests the most efficient arrangement of shapes on the material, minimizing waste and reducing costs.

-

Parametric design: With laser cutting software, designers can easily modify parameters such as dimensions or angles, allowing for quick iterations and customization.

-

Automation: Laser cutting software automates the cutting process, eliminating the need for manual intervention and reducing the chance of errors.

-

Compatibility with various file formats: Laser cutting software supports a wide range of file formats, making it compatible with different design software and facilitating seamless workflows.

Transitioning to the subsequent section about the features and capabilities of die cutter software, it’s important to note that while laser cutting software offers numerous advantages, die cutter software also has its own unique set of features and capabilities.

Features and Capabilities of Die Cutter Software

Explore the incredible features and capabilities of die cutter software that will revolutionize your design process and boost efficiency. Die cutter software is designed specifically for compatibility with die cutting machines, ensuring seamless integration and optimal performance.

This software offers advanced automation features, allowing you to automate key tasks such as file preparation, nesting, and cutting. With die cutter software, you can easily import and manipulate vector graphics, making it easy to create intricate designs and patterns.

The software also provides precise control over cutting parameters, ensuring accurate and consistent results. By streamlining the design and cutting process, die cutter software helps reduce waste and increase production speed.

Transitioning to the next section, let’s now compare the cost-effectiveness of laser cutting software and die cutter software.

Cost-Effectiveness Comparison

Now that you understand the features and capabilities of die cutter software, let’s delve into the cost-effectiveness comparison between design software for laser cutting and die cutter software. This will help you make an informed decision about which option is more suitable for your needs.

When it comes to material compatibility, it is essential to consider the types of materials that can be processed by each software. Design software for laser cutting typically supports a wider range of materials, including wood, acrylic, metal, and fabric. On the other hand, die cutter software is more limited in terms of material compatibility, often being designed specifically for paper and thin materials.

To determine long-term cost analysis, you must consider factors such as initial investment, maintenance costs, and material waste. Design software for laser cutting often requires a higher initial investment due to the expensive laser cutting machines. However, it can result in lower long-term costs due to its precise cutting capabilities and minimal material waste. In contrast, die cutter software may have a lower initial investment, but the ongoing costs of replacing cutting dies and higher material waste can add up over time.

The cost-effectiveness of design software for laser cutting versus die cutter software depends on factors such as material compatibility and long-term cost analysis. Consider your specific needs and goals before making a decision.

Frequently Asked Questions

What are the main differences between laser cutting and die cutting processes?

Laser cutting and die cutting differ in several key aspects. Laser cutting employs a high-powered laser beam to precisely cut through materials, offering advantages such as intricate designs and smooth edges.

In contrast, die cutting uses a sharp blade to stamp out shapes from materials. When comparing cutting speed, laser cutting is often faster due to its ability to move swiftly and cut multiple shapes simultaneously.

Overall, laser cutting offers superior design capabilities and higher cutting speeds compared to die cutting.

How does the choice of design software impact the efficiency and accuracy of cutting processes?

The choice of design software significantly affects the efficiency and accuracy of cutting processes.

First, the software’s impact on material waste reduction is crucial. Laser cutting software allows for intricate designs, minimizing material waste. In comparison, die cutting software may result in more waste due to the limitations of the dies.

Second, laser cutting generally offers higher cutting speeds and precision compared to die cutting, providing more accurate and faster results.

Apart from the cost of the software itself, what other factors should be considered when evaluating the cost-effectiveness of laser cutting and die cutter software?

When evaluating the cost effectiveness of laser cutting and die cutter software, several factors should be considered.

Maintenance costs play a crucial role, as ongoing expenses can significantly impact the overall budget.

Additionally, training and support for the software are essential to ensure efficient operation.

Compatibility with existing equipment is another crucial factor to consider, as it affects the integration and functionality of the software within the current setup.

Evaluating these factors will help determine the true cost effectiveness of laser cutting and die cutter software.

What advanced features and capabilities does laser cutting software offer in comparison to die cutter software?

Laser cutting software offers unique design possibilities that allow you to create intricate and complex designs with ease. With enhanced precision and detail capabilities, you can achieve highly accurate cuts and intricate patterns that aren’t possible with die cutter software.

Laser cutting software enables you to work with a wide range of materials and thicknesses, providing you with greater flexibility and versatility in your designs. Its advanced features and capabilities make it a valuable tool for achieving precise and intricate cuts.

Can you provide specific examples of industries or applications where laser cutting software is more cost-effective than die cutter software, and vice versa?

In the automotive industry, laser cutting software proves to be more cost-effective than die cutter software due to its superior speed and precision. Laser cutting processes are known for their high cutting speeds and ability to create intricate designs with minimal material waste. This allows automotive manufacturers to reduce production time and costs, as well as optimize material usage.

On the other hand, die cutter software may be more cost-effective in industries where precision is not critical and lower cutting speeds are acceptable.

Conclusion

In conclusion, when comparing design software for laser cutting and die cutter software, it’s clear that laser cutting software is more cost-effective.

With its advanced features and capabilities, laser cutting software allows for more precise and efficient cutting, resulting in less material wastage and reduced production time. This is like having a sharp, high-speed scalpel in the hands of a skilled surgeon, ensuring accurate and efficient cuts.

Therefore, investing in laser cutting software is a wise choice for businesses looking to maximize cost-effectiveness in their cutting processes.