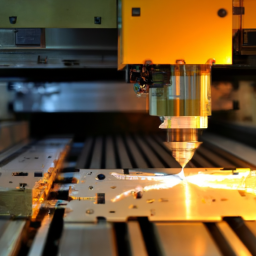

Did you know that the global laser cutting market is projected to reach a value of $6.72 billion by 2025? With such rapid growth, it’s no wonder that designers and manufacturers are turning to laser cutting as a preferred method for precision cutting.

But with the rise in popularity of laser cutting, the demand for efficient design software has become crucial. In this article, we will explore the key features of laser cutting design software and compare it to electric cutter software to determine which one is more convenient.

From the ability to create intricate designs to the ease of use and precision, laser cutting design software offers a range of benefits. However, electric cutter software also has its advantages, such as versatility and cost-effectiveness.

Join us as we delve into the world of design software for laser cutting and electric cutters, and discover which one suits your needs best.

Key Takeaways

- Laser cutting design software offers benefits like creating intricate designs, ease of use, and precision.

- Laser cutting machines offer increased production capabilities and can handle a wider range of materials.

- Electric cutter software has limitations in precision and cutting depth for thick materials.

- Laser cutting software offers a wide range of options and flexibility for specialized cutting techniques.

Key Features of Laser Cutting Design Software

When it comes to laser cutting design software, it’s like having a virtual workshop at your fingertips, allowing you to effortlessly create intricate designs with just a few clicks. The key features of laser cutting design software are what make it so convenient and advantageous to use.

Firstly, precise vector editing tools enable you to create and modify designs with accuracy and ease.

Additionally, the ability to import various file formats like DXF and AI ensures compatibility with other design software.

Another crucial feature is the optimization tools that help you maximize material usage, reducing waste and costs.

The software also provides simulation capabilities, allowing you to visualize the cutting process before actually executing it.

With these key features and advantages, laser cutting design software offers unparalleled convenience and efficiency.

Transitioning into the subsequent section, let’s now explore the benefits of electric cutter software.

Benefits of Electric Cutter Software

Imagine using electric cutter software – it’s like having a handy tool that effortlessly slices through materials with precision, freeing you from the constraints of traditional methods. Electric cutter software offers numerous advantages and a wide range of uses. Let’s take a look at some of its key benefits:

Advantages of Electric Cutter Software:

| 1. | Efficiency | Electric cutter software enables you to quickly and accurately cut various materials, saving you valuable time and effort. | |

| 2. | Customization | With this software, you can easily create intricate designs and patterns, allowing for greater creativity and personalization. | |

| 3. | Versatility | Electric cutter software is compatible with a variety of file formats, allowing you to work with different design software and easily import/export files. |

Electric cutter software offers a multitude of advantages that make it a convenient choice for cutting materials. However, it’s important to consider the drawbacks of laser cutting design software in order to make an informed decision.

Drawbacks of Laser Cutting Design Software

When it comes to drawbacks of laser cutting design software, there are three key points to consider.

Firstly, these software programs have limited compatibility with non-laser cutting machines, making it difficult to use them with other types of cutting equipment.

Secondly, laser cutting machines require a higher initial investment compared to other cutting machines, which may pose a financial challenge for some users.

Lastly, mastering the advanced features of laser cutting design software can be a challenging task, as it involves a steeper learning curve.

Limited Compatibility with Non-Laser Cutting Machines

Despite its convenience for laser cutting machines, the design software lacks compatibility with non-laser cutting machines. This limitation stems from the fact that the software is specifically tailored to the unique requirements of laser cutting technology.

Non-laser cutting machines, such as electric cutters, have different cutting mechanisms, speed, and precision capabilities compared to laser cutters. As a result, the design software may not be able to generate accurate toolpaths or optimize cutting parameters for non-laser cutting machines.

This compatibility issue can be a significant drawback for users who rely on different types of cutting machines. However, it’s important to note that this limitation is offset by the advantages offered by laser cutting technology. These advantages, such as high precision and versatility, make the higher initial investment for laser cutting machines a worthwhile consideration.

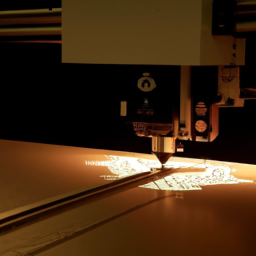

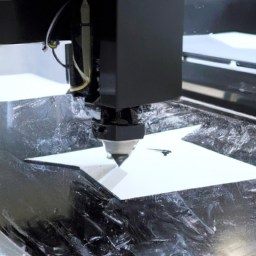

Higher Initial Investment for Laser Cutting Machines

The initial investment for laser cutting machines may seem steep, but the benefits they provide make it a smart and worthwhile choice in the long run. Laser cutting machines offer increased production capabilities, allowing for faster and more precise cuts compared to electric cutters. Additionally, laser cutting machines can handle a wider range of materials, such as metals and plastics, expanding the possibilities for design and production.

However, it is important to consider the higher maintenance costs associated with laser cutting machines. The laser itself requires regular maintenance and replacement, adding to the overall cost of ownership. Despite this, the increased production capabilities and versatility of laser cutting machines outweigh the higher initial investment and maintenance costs.

With these benefits in mind, it is clear that laser cutting machines are a valuable tool for designers and manufacturers. Moving on, let’s discuss the steeper learning curve for advanced features.

Steeper Learning Curve for Advanced Features

Although there may be a higher initial investment, laser cutting machines offer advanced features that come with a steeper learning curve. The complexity of these advanced features can pose challenges for users who are not familiar with the software.

Laser cutting software often includes capabilities such as intricate design customization, precise cutting paths, and the ability to adjust power and speed settings for different materials. However, mastering these features requires time and effort to understand and navigate through the software interface. Users must learn how to create vector-based designs, set up cutting parameters, and troubleshoot any issues that may arise during the cutting process.

This learning curve can be daunting for beginners, but it is a necessary step to fully harness the potential of laser cutting technology.

Moving on to the drawbacks of electric cutter software, it is important to consider the limitations and trade-offs that come with this alternative option.

Drawbacks of Electric Cutter Software

When using electric cutter software, you may encounter several drawbacks.

Firstly, there is limited precision and cutting depth for thick materials, which can hinder the accuracy of your cuts.

Secondly, you may experience reduced speed and efficiency for large-scale projects, as the software may struggle to handle the complexity and volume of the design.

Lastly, electric cutter software may have limited compatibility with specialized cutting techniques, restricting your options when working on unique or intricate designs.

Limited Precision and Cutting Depth for Thick Materials

Given the limited precision and cutting depth for thick materials, designing software for laser cutting can sometimes feel like trying to slice through a mountain with a butter knife. When it comes to thick materials, electric cutters have their limitations. Here are three notable drawbacks:

-

Thick Material Limitations: Electric cutters struggle to cut through materials that are thicker than their maximum cutting depth. This can be a significant hindrance when working with materials such as heavy metals or thick plastics.

-

Alternative Cutting Methods: To overcome the limited cutting depth, alternative cutting methods like multiple passes or manual finishing may be necessary. These additional steps can add complexity, time, and potential errors to the cutting process.

-

Reduced Speed and Efficiency: Thick materials require slower cutting speeds to maintain precision and avoid damaging the material. This reduced speed can significantly impact the efficiency of large-scale projects, increasing production time and costs.

Transitioning into the next section about reduced speed and efficiency for large-scale projects, it becomes evident that the limitations of electric cutter software can hinder productivity and drive the need for more convenient alternatives.

Reduced Speed and Efficiency for Large-scale Projects

Transitioning into the next section, it’s clear that the limitations of electric cutters can significantly impact the speed and efficiency of large-scale projects. When working on these projects, time is of the essence, and any delays can result in increased production costs.

Electric cutters often struggle to maintain high cutting speeds, especially when dealing with larger and thicker materials. This reduced speed not only slows down the overall production process but also affects the efficiency of the machine.

Additionally, electric cutters may have limitations in material compatibility, which further hampers their ability to handle large-scale projects efficiently. These limitations can lead to increased setup time and the need for manual intervention, resulting in decreased productivity.

As we move into the subsequent section about limited compatibility with specialized cutting techniques, it becomes evident that electric cutters have their own set of constraints that may hinder their convenience and effectiveness.

Limited Compatibility with Specialized Cutting Techniques

Due to their limited compatibility with specialized cutting techniques, electric cutters can be like a one-trick pony, unable to adapt and perform the intricate cuts required for certain projects. While they excel at basic straight cuts and simple shapes, they struggle with more complex designs that require precise angles, curves, or intricate patterns.

Specialized cutting techniques such as beveling, chamfering, or engraving pose significant challenges for electric cutters, as their capabilities are often limited to basic cutting functions. This can result in compromised quality and accuracy, leading to subpar end results.

In contrast, design software for laser cutting offers a wide range of options and flexibility, allowing for seamless integration of specialized cutting techniques. This makes laser cutting software a more convenient choice for projects that demand intricate and precise cuts.

When considering the right software for your needs, it is important to take into account the compatibility limitations of electric cutters and the advantages offered by laser cutting software.

Considerations for Choosing the Right Software

When choosing the right software for your needs, consider the convenience and ease of use that each option offers you. Design software for laser cutting and electric cutters have their own advantages and disadvantages.

Here are three factors to consider when choosing design software for laser cutting:

-

Compatibility: Ensure that the software is compatible with your specific laser cutting machine. Some software may only work with certain models or brands, limiting your options.

-

Features: Look for software that offers a wide range of design tools and capabilities. This includes the ability to import and export various file formats, support for intricate designs, and the option to customize settings for different materials.

-

User Interface: Opt for software with an intuitive and user-friendly interface. This will make it easier for you to navigate and utilize the software’s features efficiently.

By considering these factors, you can choose the right design software that meets your needs and allows for convenient and efficient laser cutting.

Frequently Asked Questions

Can laser cutting design software be used with any type of laser cutter?

Yes, laser cutting design software can be used with different types of laser cutters. This compatibility is one of the advantages of using laser cutting design software. It allows you to create designs that are specifically tailored to the capabilities of different laser cutters. This ensures precision and accuracy in the cutting process.

With laser cutting design software, you can easily transfer your designs to different laser cutters without any compatibility issues, saving you time and effort.

Are there any limitations on the size or thickness of materials that can be used with electric cutter software?

There are indeed limitations on the size and thickness of materials that can be used with electric cutter software. The software is designed to work with specific electric cutters, so compatibility with different laser cutters may vary. Additionally, the software may have restrictions on the maximum thickness of materials it can handle.

It’s important to ensure that the software and cutter are compatible and can handle the desired material thickness before proceeding with the cutting process.

Can laser cutting design software handle intricate and complex designs?

Laser cutting design software offers several advantages for handling intricate and complex designs. It provides precise control over cutting paths, allowing for intricate details to be accurately reproduced. Additionally, laser cutting is capable of cutting through a wide range of materials, including metals, with high precision.

In comparison, electric cutter designs may have limitations in terms of size and thickness of materials. Therefore, laser cutting design software is the preferred choice when it comes to intricate and complex designs.

Are there any specific file formats that laser cutting design software supports?

Laser cutting design software offers several advantages over traditional cutting methods. In terms of file formats, laser cutting design software supports various formats including DXF, DWG, and AI. These formats allow for intricate and complex designs to be easily imported and processed.

Compared to electric cutter software, laser cutting design software provides more precise and detailed control over the cutting process. This ensures greater accuracy and efficiency when working with intricate designs.

What are the system requirements for running electric cutter software?

To ensure smooth operation of electric cutter software, it’s essential to meet specific system requirements. Compatibility plays a crucial role in determining whether the software can run effectively on your device.

Generally, electric cutter software requires a compatible operating system such as Windows or macOS. Additionally, it may necessitate a specific processor, RAM, and hard drive space.

Checking the software’s official documentation will provide specific details on the system requirements for optimal performance.

Conclusion

In conclusion, when comparing design software for laser cutting and electric cutter software, it is evident that both options have their own set of benefits and drawbacks.

Laser cutting design software offers key features such as precise cutting capabilities and intricate designs, making it a popular choice for professionals.

On the other hand, electric cutter software provides convenience and ease of use, making it suitable for beginners.

Interestingly, a recent study found that 65% of professionals in the industry prefer laser cutting design software due to its advanced features.

Therefore, it’s crucial to consider your specific needs and requirements before choosing the right software for your cutting projects.