Delve into the dynamic world of design software for laser cutting versus milling software to determine which offers superior precision. Pondering the perplexing question of precision, you seek to uncover the secrets behind these two powerful tools.

Both laser cutting software and milling software possess unique capabilities, yet the ultimate goal remains the same: to achieve utmost accuracy with intricate designs. By comparing precision levels, exploring industry applications, and analyzing case studies, you will embark on a journey towards making an informed decision for your project.

Prepare to plunge into the depths of technological prowess as you navigate the nuances of these software solutions. Discover the intricacies of laser cutting software, the complexities of milling software, and ultimately, which one reigns supreme in the realm of precision.

Let the battle of precision commence as you decipher which of these two giants shall prevail.

Key Takeaways

- Laser cutting software offers utmost accuracy and customization options for two-dimensional cutting, making it suitable for intricate and detailed designs.

- Laser cutting software benefits industries such as automotive, aerospace, and electronics by enabling precise cutting of complex shapes and designs.

- Milling software offers a wide range of functionality and features for creating intricate designs and complex geometries, and it is better suited for precise cuts on thicker materials and metals.

- Choosing the right software depends on the complexity of the project and the type of material being used, with laser cutting software being advantageous for intricate designs and milling software being better for thicker materials and metals.

Understanding Laser Cutting Software

Laser cutting software is like the artist’s paintbrush, allowing you to create precise and intricate designs with just a few clicks.

The advantages of laser cutting software are vast. Firstly, it offers high precision, enabling you to cut or engrave materials with extreme accuracy. This level of precision is especially beneficial when working with delicate or intricate designs. Additionally, laser cutting software provides a wide range of customization options, allowing you to adjust parameters such as speed, power, and focus to achieve desired results.

However, laser cutting software does have its limitations. It is primarily designed for two-dimensional cutting, which means it may struggle with complex three-dimensional designs. Furthermore, the software is limited by the capabilities of the laser cutter itself.

Now, let’s delve into exploring milling software, which offers its own unique advantages and limitations.

Exploring Milling Software

When exploring milling software, you’ll find that it offers a wide range of functionality and features to enhance your milling design process.

With this software, you can create intricate designs and complex geometries with precision and accuracy.

Additionally, milling software is compatible with various milling machines, allowing you to seamlessly transfer your designs and achieve consistent results across different platforms.

Functionality and features of milling software

Imagine yourself using milling software, where you effortlessly navigate through a sea of intricate design features and functionalities, like a skilled conductor leading a symphony of precision and creativity. With milling software, you have access to a wide range of capabilities that allow you to bring your designs to life with utmost accuracy.

The user interface is designed to be intuitive and user-friendly, with easily accessible tools and menus that help streamline your workflow. Here are some key features of milling software:

- Advanced 2D and 3D modeling capabilities

- Support for various file formats, including DXF and STL

- Simulation tools to visualize the milling process

- Toolpath optimization for efficient material removal

- Precision control over cutting parameters such as speed and depth

These features empower you to create intricate designs with intricate precision and accuracy. As you delve into the world of milling software, you’ll discover the immense potential it holds for bringing your ideas to life with unparalleled precision and finesse.

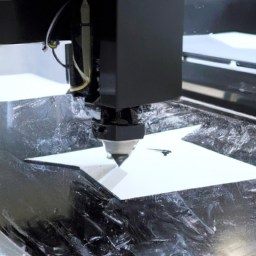

Precision and accuracy in milling design

With the precision and accuracy offered by modern milling software, your design ideas can become reality with unmatched finesse and attention to detail. Milling accuracy is determined by various factors, including the software’s ability to generate precise toolpaths and its compatibility with the milling machine. When comparing the precision of different milling software, it is important to consider the tolerance levels, which indicate the maximum allowable deviation from the intended design. Some software packages offer higher tolerance levels, allowing for more accurate milling. Additionally, the precision of the milling software can be enhanced by using advanced features such as adaptive toolpaths, which optimize the cutting process based on the material and tool conditions. In summary, milling software plays a crucial role in achieving high precision and accuracy in your designs. Transitioning to the next section, compatibility with different milling machines is another crucial aspect to consider.

Compatibility with different milling machines

Another essential factor to consider is how well the milling software is compatible with a variety of milling machines, ensuring a seamless and efficient milling process. The compatibility of the software with different milling machines depends on several factors. These factors include the software’s ability to communicate with the machine’s controller, the file formats it supports, and the specific software requirements of each machine. It is crucial to choose a milling software that can work with a wide range of machines to avoid limitations and compatibility issues.

By selecting a software with excellent milling machine compatibility, you can maximize the utilization of different machines and take advantage of their unique capabilities. Moving forward to comparing precision levels, it is important to evaluate the accuracy and repeatability of the milling software and its impact on the final product.

Comparing Precision Levels

In terms of precision levels, laser cutting software generally offers a higher degree of accuracy than milling software. Laser cutting operates by using a high-powered laser beam to precisely cut through materials, resulting in clean and precise edges. The laser beam can be controlled with great precision, allowing for intricate and detailed designs to be accurately reproduced.

On the other hand, milling software controls the movement of cutting tools, which may introduce some limitations in terms of precision. While milling machines can achieve high levels of accuracy, they may not match the precision offered by laser cutting technology. Therefore, if you require the utmost precision for your designs, laser cutting software would be the more suitable option.

Moving forward, it is important to consider additional factors when dealing with complex designs.

Considerations for Complex Designs

When it comes to intricate and elaborate designs, there are certain factors that need to be taken into consideration. Manufacturing limitations and material compatibility play a crucial role in determining the feasibility of complex designs in both laser cutting and milling software. Laser cutting software offers high precision and fine details, but it may have limitations when it comes to cutting certain materials or intricate shapes. On the other hand, milling software can handle a wider range of materials and complex designs, but it may not achieve the same level of precision as laser cutting. To illustrate this point, consider the following table:

| Software Type | Precision Level | Material Compatibility |

|---|---|---|

| Laser Cutting | High | Limited |

| Milling | Moderate | Wide range |

Understanding these considerations is crucial for designers and manufacturers to choose the most suitable software for their specific needs. Moving forward to the next section on industry applications and case studies.

Industry Applications and Case Studies

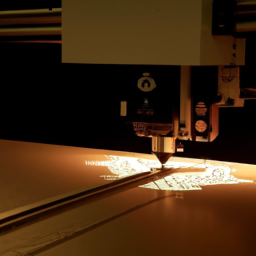

In the discussion of industry applications and case studies, you’ll explore the specific industries that benefit from laser cutting software and milling software.

Laser cutting software is particularly advantageous for industries such as automotive, aerospace, and electronics, where precision and intricate designs are crucial.

On the other hand, milling software finds its usefulness in industries like woodworking, metalworking, and prototyping, where the ability to sculpt and shape materials is essential.

Throughout this discussion, you’ll also encounter real-world examples that showcase the precision and effectiveness of these software tools in various industries.

Industries that benefit from laser cutting software

There’s a wide range of industries that can greatly benefit from laser cutting software. Laser cutting software offers numerous advantages that make it an essential tool in various sectors.

For example, in the automotive industry, laser cutting software enables precise cutting of complex shapes and designs for car components. This software also plays a crucial role in the aerospace industry, where it’s used to cut intricate parts with high accuracy and speed.

Additionally, the electronics industry benefits from laser cutting software by allowing manufacturers to create precise circuit boards and microchips. Other industries that benefit from laser cutting software include the fashion industry, where it’s used to create intricate patterns on fabrics, and the signage industry, where it enables the production of precise and detailed signage.

Transitioning to the subsequent section, industries that benefit from milling software also find immense value in precision cutting techniques.

Industries that benefit from milling software

Milling software unlocks a world of precision and craftsmanship, empowering industries to sculpt their visions with artistic finesse. With its advanced capabilities, milling software offers several advantages that have a significant impact on manufacturing processes. Here are three key benefits:

-

Enhanced Precision: Milling software provides precise control over cutting tools, allowing for intricate and complex designs to be realized with utmost accuracy. This level of precision ensures that every detail is faithfully reproduced, resulting in flawless end products.

-

Improved Efficiency: By optimizing tool paths and minimizing material waste, milling software streamlines the manufacturing process. It enables manufacturers to produce more components in less time, increasing productivity and reducing costs.

-

Versatility: Milling software supports a wide range of materials, including metals, plastics, and composites. This versatility enables industries such as automotive, aerospace, and jewelry to leverage milling technology for various applications.

As we delve into real-world examples of precision in action, let’s explore the fascinating possibilities that arise from the marriage of design and technology.

Real-world examples of precision in action

Imagine the thrill of watching a 3D printer effortlessly bring to life intricate jewelry designs with a level of precision that surpasses human capabilities. Real-world case studies demonstrate the power of precision in manufacturing. For example, in the aerospace industry, precision milling software is used to create complex turbine blades that meet strict performance requirements. The medical field benefits from precision in the form of custom surgical instruments that are tailored to fit each patient’s unique anatomy. Additionally, precision milling software is utilized in the automotive industry to produce high-quality engine components that ensure optimal performance. These examples highlight the importance of precision in various industries and showcase the capabilities of milling software. Transitioning into the subsequent section about making the best choice for your project, it is crucial to consider the level of precision required to achieve your desired outcome.

Making the Best Choice for Your Project

When deciding between laser cutting and milling software, it’s important to choose the option that best suits the precision needs of your project.

Choosing between laser cutting and milling software involves considering several factors for selecting the right software. First and foremost, you need to evaluate the complexity of your project. Laser cutting software is generally more suitable for intricate designs that require fine details and delicate cuts.

On the other hand, milling software is better suited for projects that require precise and accurate cuts on thicker materials. Additionally, consider the type of material you will be working with. Laser cutting software is more compatible with materials like wood, acrylic, and fabric, while milling software is better suited for metals and harder materials.

By carefully assessing these factors, you can make an informed decision and ensure that your project achieves the desired level of precision.

Frequently Asked Questions

What are the typical costs associated with laser cutting and milling software?

Typical pricing models for laser cutting and milling software can vary depending on whether you choose open source or commercial options. Open source software is often free to use, but may lack comprehensive features and support.

Commercial software, on the other hand, can range from a few hundred to several thousand dollars, depending on the complexity and capabilities.

It’s important to carefully evaluate your needs and budget before deciding which option is the most suitable for you.

Can laser cutting software also be used for 3D printing?

Laser cutting software is primarily designed for controlling laser cutters, which are different from 3D printers. Laser cutters use a focused laser beam to cut or engrave materials, while 3D printers build objects layer by layer.

While laser cutting software can generate 2D designs for 3D printing, it lacks the necessary features for controlling the complex movements and extrusion processes of 3D printers. Therefore, laser cutting software is not compatible with 3D printers.

Are there any limitations or challenges when using milling software for intricate designs?

When using milling software for intricate designs, there are some limitations and challenges to consider.

One limitation is the need for specialized tools and machinery to accurately execute the milling process. Additionally, milling software may struggle to accurately represent intricate details, resulting in a loss of precision.

Challenges may arise when selecting appropriate cutting paths and optimizing tool paths for complex designs. However, with careful planning and expertise, these limitations and challenges can be overcome to achieve precise results.

How do laser cutting and milling software differ in terms of user-friendliness?

You might be concerned that laser cutting and milling software can be difficult to navigate, but rest assured, the user interface of both types of software is designed with user-friendliness in mind.

The learning curve for laser cutting software is relatively low, with intuitive menus and clear instructions.

On the other hand, milling software may require a bit more time to master due to its complex toolpaths and parameters.

However, with practice and familiarity, both software options can be easily navigated and utilized for precise designs.

Are there any software options that combine both laser cutting and milling capabilities?

When it comes to the integration of laser cutting and milling functions in design software, there are options available that combine both capabilities. These software solutions allow users to seamlessly switch between laser cutting and milling processes within the same platform.

In terms of precision and accuracy, laser cutting is known for its high level of precision due to its focused laser beam. On the other hand, milling processes offer a different level of precision, relying on cutting tools to remove material.

Ultimately, the choice between laser cutting and milling depends on the specific requirements of the project.

Conclusion

In conclusion, when it comes to precision, laser cutting software takes the lead. Its ability to create intricate and delicate designs with utmost accuracy is unmatched.

Milling software, on the other hand, may not provide the same level of precision, especially for complex designs.

Therefore, if you’re aiming for meticulous and flawless results, laser cutting software is the way to go. Remember, in the world of design, "precision is the name of the game," and laser cutting software ensures just that.