Are you tired of the same old, outdated cutting methods? Do you crave precision and efficiency in your designs? Well, look no further! We have the ultimate solution for you.

Design software for laser cutting and plasma cutter software are here to revolutionize the way you create. These cutting-edge technologies will take your designs to a whole new level, offering unrivaled accuracy and speed.

Whether you’re a professional designer or a hobbyist, finding the right software is crucial. In this article, we will explore the world of laser cutting software and plasma cutter software, highlighting their unique features and benefits.

We will also discuss important considerations for both professional designers and hobbyists, so you can make an informed decision. So buckle up and get ready to embrace the future of cutting technology!

Key Takeaways

- Laser cutting software offers higher precision and efficiency with faster cutting speed and greater precision.

- Plasma cutter software is specifically designed for plasma cutting machines and can cut through thicker materials.

- Laser cutting software is ideal for those seeking precision and productivity, while plasma cutter software offers flexibility and customization.

- The choice between laser cutting and plasma cutter software depends on specific needs and preferences, as well as evaluating software capabilities and customization options.

Understanding Laser Cutting Software

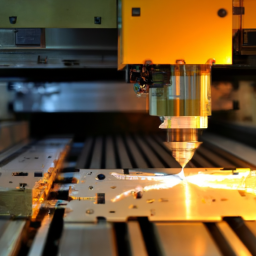

Laser cutting software is a game-changer for designers. It allows you to unleash your creativity and precision with just a few clicks. By integrating design software with laser cutting, you can optimize the entire process, from design creation to material cutting.

This software enables you to import your designs directly into the program, where you can modify and manipulate them as needed. You can also easily adjust cutting parameters such as speed, power, and focal length to achieve the desired results. Laser cutting software provides a comprehensive view of your design, allowing you to see exactly how it will be cut and ensuring accuracy.

Now, let’s explore plasma cutter software and see how it compares to laser cutting software.

Exploring Plasma Cutter Software

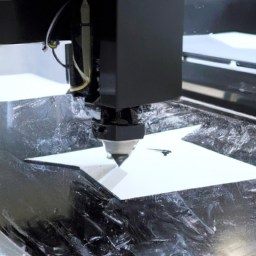

When exploring plasma cutter software, you’ll find that it differs from laser cutting software in several key ways. One major difference is that plasma cutter software is specifically designed for use with plasma cutting machines, whereas laser cutting software is designed for laser cutting machines.

This means that the two types of software have different capabilities and features. Some pros of using plasma cutter software include its ability to cut through thicker materials and its lower upfront cost compared to laser cutting machines. However, a potential con of using plasma cutter software is that it may produce rougher edges on the cut materials compared to laser cutting.

How it Differs from Laser Cutting Software

Imagine yourself navigating through a whimsical wonderland of software, specifically designed for the art of plasma cutting, offering a world of possibilities beyond the realms of laser cutting. As you explore this software, you’ll encounter a range of key features that make it unique.

Firstly, plasma cutter software allows for intricate and detailed designs. It has the ability to cut through a variety of materials, including metal, stone, and wood.

Secondly, it offers a greater degree of flexibility and customization. You can create complex shapes and patterns effortlessly.

Lastly, the software provides advanced control over the cutting process. You can adjust parameters such as speed and intensity.

While laser cutting software has its own advantages, such as precision and speed, the world of plasma cutter software offers a whole new level of creativity and versatility.

Now, let’s explore the pros and cons of using this software.

Pros and Cons

As you delve into the world of plasma cutting, you’ll discover a myriad of advantages and disadvantages to using this innovative technology.

When it comes to pros and cons, plasma cutting software offers several benefits. Firstly, it allows for faster cutting speeds compared to traditional methods, resulting in increased productivity. Additionally, plasma cutting software can handle a wider range of materials, including thick metals, making it more versatile. Another advantage is the ability to create intricate designs and shapes with precision.

However, there are also some drawbacks to consider. Plasma cutting may produce more heat and noise compared to laser cutting, and it can cause warping or distortion in certain materials. Furthermore, the initial cost of plasma cutting equipment and software can be higher.

Taking these factors into account, it’s important for professional designers to carefully evaluate which cutting method best suits their specific needs and requirements.

Considerations for Professional Designers

For professional designers, you’ll want to carefully consider the specific requirements and capabilities of both laser cutting and plasma cutter software.

Laser cutting software typically offers a wide range of advanced design features, allowing you to create intricate and precise designs. It provides the ability to work with vector files and offers advanced nesting capabilities for optimizing material usage. Laser cutting software also allows for easy manipulation and editing of designs, as well as the ability to create complex geometries.

On the other hand, plasma cutter software is more suited for thicker materials and can handle cutting through metal with ease. It offers features like kerf compensation and bevel cutting, which are essential for professional metal fabricators.

Considering these factors, professional designers can choose the software that best aligns with their specific design requirements.

Moving forward, let’s explore the factors to consider for hobbyists.

Factors to Consider for Hobbyists

When considering factors for hobbyists, two key points to consider are cost and accessibility, as well as ease of use.

The cost of the design software for laser cutting or plasma cutter software should be taken into account, as hobbyists may have a limited budget.

Additionally, accessibility is important for hobbyists, who may not have access to specialized software or equipment.

Ease of use is also crucial, as hobbyists may not have the same level of expertise as professional designers and need a user-friendly software.

Cost and Accessibility

To determine the best option for your needs, consider the cost and accessibility of laser cutting software compared to plasma cutter software. Did you know that laser cutting software tends to be more expensive initially, but can save you money in the long run due to its higher precision and efficiency?

When comparing the cost of laser cutting software and plasma cutter software, it’s important to take into account both the initial investment and the long-term savings. While laser cutting software may have a higher upfront cost, it offers greater precision and efficiency, resulting in less material waste and lower operating costs over time. Additionally, laser cutting software often provides more advanced features and capabilities, giving you more design options and flexibility.

Now, let’s dive into the next section and explore the ease of use for both options.

Ease of Use

Are you looking for a user-friendly option that’ll make your cutting process a breeze? When it comes to ease of use, laser cutting software takes the lead. Laser cutting software usually offers a more intuitive user interface, making it easier for beginners to navigate and operate. It also comes with a wide range of integration options, allowing you to seamlessly import files from various design software. With laser cutting software, you can easily adjust settings like power, speed, and beam focus, giving you precise control over your cuts. This level of control ensures accuracy and reduces the chances of errors. So, if you want software that’s easy to use and offers seamless integration options, laser cutting software is your best bet. Now let’s dive into comparing cutting speed and efficiency.

Comparing Cutting Speed and Efficiency

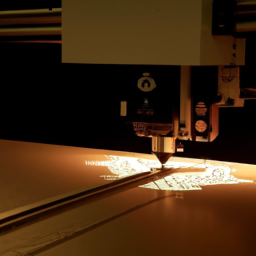

The speed and efficiency of laser cutting software surpasses that of plasma cutter software by leaps and bounds, making it the ultimate choice for precision and productivity. Here are three reasons why laser cutting software reigns supreme:

-

Faster Cutting Speed: Laser cutting technology offers high cutting speeds, allowing you to complete projects in a fraction of the time compared to plasma cutting. This increased speed translates to quicker turnaround times and increased productivity.

-

Greater Precision: Laser cutting software provides unparalleled precision, enabling you to achieve intricate designs with utmost accuracy. The laser beam’s narrow width ensures clean and smooth cuts, eliminating the need for additional finishing processes.

-

Enhanced Efficiency: Laser cutting software optimizes material usage, minimizing waste and maximizing your resources. Additionally, it allows for nesting capabilities, enabling you to arrange multiple parts efficiently, reducing production time and costs.

When it comes to laser cutting vs. plasma cutting, the speed and efficiency advantages of laser cutting software make it the ideal choice for those seeking precision and productivity. Now, let’s delve into making the right choice for your needs.

Making the Right Choice for Your Needs

Imagine standing in front of two different machines, each with its own unique capabilities and advantages. When it comes to choosing between design software for laser cutting and plasma cutter software, evaluating the software capabilities should be a priority.

Laser cutting software typically offers more advanced features and options, allowing for greater precision and complexity in designs. On the other hand, plasma cutter software may be more user-friendly and easier to learn, making it a good choice for beginners or those with simpler cutting needs.

Additionally, customization options available in the software should also be considered. Laser cutting software often provides more flexibility in terms of design customization and material compatibility.

Ultimately, the right choice depends on your specific needs and preferences.

Frequently Asked Questions

What are the main differences between laser cutting software and plasma cutter software?

The main differences between laser cutting software and plasma cutter software lie in their capabilities and precision.

Laser cutting software offers higher precision and accuracy due to its focused laser beam. It also provides a wider range of design options, including intricate patterns and fine details.

Additionally, laser cutting software allows for faster cutting speeds and cleaner cuts. These advantages make laser cutting software a preferred choice for projects that require high precision and intricate designs.

Can laser cutting software be used with a plasma cutter, and vice versa?

You might think that laser cutting software and plasma cutter software can be used interchangeably, but you couldn’t be more wrong. Laser cutting software is like a knight in shining armor for laser cutters, ensuring precision and efficiency.

On the other hand, plasma cutters have their own specialized software that caters to their unique needs. Trying to use laser cutting software with a plasma cutter, or vice versa, would be like trying to fit a square peg into a round hole. It simply won’t work.

Stick to using the compatible software for each type of cutter to reap the benefits of specialized software.

Are there any specific design software options that are recommended for laser cutting or plasma cutting?

When it comes to design software options for laser cutting or plasma cutting, there are several recommended choices available.

For laser cutting, popular software includes AutoCAD, CorelDRAW, and Adobe Illustrator. These programs offer precise design capabilities and compatibility with laser cutting machines.

On the other hand, for plasma cutting, software like PlasmaCAM and Hypertherm ProNest prove to be efficient and user-friendly. Both options have their pros and cons, so it’s essential to consider factors like budget, complexity, and specific requirements before making a decision.

How do laser cutting and plasma cutting software affect the overall cost of a project?

The choice of laser cutting or plasma cutting software can significantly impact the overall cost of a project. Laser cutting software offers precise control and speed, resulting in reduced production time and increased efficiency. However, it may require higher upfront costs and is more suitable for thinner materials.

On the other hand, plasma cutting software is cost-effective and versatile for thicker materials but may have a longer project timeline due to slower cutting speeds. Considerations for material thickness and project timeline are crucial when determining the software’s impact on the overall cost.

Are there any limitations or constraints when using design software for laser cutting or plasma cutting?

When using design software for laser cutting, it’s important to be aware of the limitations it may have. These can include restrictions on the complexity of designs, as well as the types of materials that can be used.

On the other hand, design software for plasma cutting may have constraints when it comes to precision and fine details. It’s crucial to understand these limitations and constraints to ensure that your project can be executed successfully.

Conclusion

In conclusion, whether you’re a professional designer or a hobbyist, choosing the right software for your laser cutting or plasma cutting needs is crucial.

Laser cutting software offers precision and accuracy, like a surgeon’s steady hand, while plasma cutter software brings the power and intensity, like a roaring dragon.

Consider your specific requirements, such as design complexity and cutting speed, to make an informed decision.

So, dive into the world of cutting-edge technology and unleash your creative potential with the perfect software companion for your cutting needs.