In the realm of precision cutting, the importance of design software cannot be overstated. When it comes to achieving accuracy, laser cutting and router cutting are two popular methods that rely heavily on their respective software. Each technique has its own unique advantages, but the question remains: which is more accurate?

Let’s delve into the world of design software for laser cutting and router cutting, and explore the levels of precision they offer.

Laser cutting software, known for its refined and sophisticated capabilities, allows for intricate designs to be executed with utmost precision. On the other hand, router cutting software offers a different approach, providing accuracy through a different set of algorithms and techniques.

Understanding the differences between these two software options is crucial in determining which one is best suited for your project. In this article, we will compare the precision levels of laser cutting software and router cutting software, analyzing their strengths and weaknesses.

By the end, you will be equipped with the knowledge needed to make an informed decision when selecting the most accurate software for your cutting needs. So, let’s dive in and explore the fascinating world of design software for laser cutting and router cutting.

Key Takeaways

- Laser cutting software is specifically designed for laser cutting machines and offers higher accuracy compared to other options.

- Laser cutting software allows for intricate designs with utmost precision, defines cutting paths, adjusts settings, and simulates the cutting process.

- Router cutting software offers accuracy through different algorithms and techniques, allowing for precise designs with routers.

- Factors to consider when selecting software for laser cutting or router projects include compatibility with the cutting machine, the level of precision required, and the ease of use.

Understanding Laser Cutting Software

You’ll be amazed at how laser cutting software allows you to precisely control the beam’s movement and create intricate designs with ease.

Laser Cutting Software vs. Router Cutting Software is a topic that revolves around Accuracy in Design Software.

Laser cutting software is specifically designed to work with laser cutting machines, offering a range of features and tools that enable you to achieve a high level of accuracy in your designs.

With laser cutting software, you can define the cutting path, adjust the power and speed settings, and even simulate the cutting process before actually starting it. This level of precision ensures that your final product matches your design perfectly.

Now, let’s explore router cutting software and see how it compares to laser cutting software.

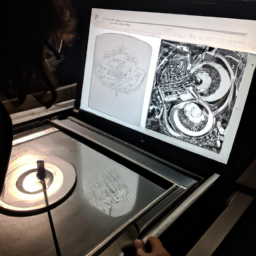

Exploring Router Cutting Software

When using Router Cutting Software, you have the ability to create precise designs for cutting materials with a router. This software offers a range of features and tools that allow for accurate design. It includes the ability to generate toolpaths, define cutting depths, and adjust cutting speeds.

However, it is important to note that while Router Cutting Software offers many benefits, such as increased efficiency and accuracy, it also has limitations. These limitations include the requirement for a compatible router and the need for proper training to fully utilize its capabilities.

How Router Cutting Software Works

Router cutting software works by converting digital designs into instructions that guide a router to accurately cut and shape the material.

This software utilizes various router cutting techniques to achieve precise results. Firstly, it optimizes router cutting speed by analyzing the design and determining the most efficient toolpath. It then calculates the appropriate depth and direction for each cut, ensuring accuracy and minimizing material wastage.

Additionally, the software allows for the customization of cutting parameters such as feed rate and spindle speed, which further enhances precision. Moreover, it provides advanced nesting capabilities, arranging multiple parts on the material to maximize material utilization and minimize production time.

By incorporating these features and tools, router cutting software ensures that the final product matches the digital design with utmost accuracy.

Features and Tools for Accurate Design

Explore the impressive array of features and tools that ensure your designs are executed with unparalleled precision. Router cutting software incorporates advanced techniques such as 3D modeling to achieve the highest level of accuracy.

With this software, you have the ability to create intricate designs and complex geometries with ease. The software allows you to precisely control the cutting path, speed, and depth, ensuring every detail is accurately reproduced. Additionally, you can preview the design before cutting, allowing you to make any necessary adjustments to achieve the desired outcome.

These features, combined with the ability to import and export various file formats, make router cutting software an invaluable tool for precise design execution.

As we move into discussing the benefits and limitations of router cutting software, it’s important to note the role these advanced features play in achieving accurate results.

Benefits and Limitations of Router Cutting Software

One of the great advantages of using router cutting software is that it allows you to easily create intricate designs and complex geometries. This software provides a wide range of features and tools that enable you to achieve precision and accuracy in your designs. However, it also has some drawbacks that are important to consider. One limitation of router cutting software is that it may not be as accurate as laser cutting software. This is because routers rely on physical contact with the material, which can result in slight variations and imperfections in the final product. Additionally, router cutting software may require more setup and calibration to achieve the desired accuracy. Despite these drawbacks, router cutting software can still produce high-quality designs with a level of accuracy that is suitable for many applications.

Transitioning into the subsequent section about comparing accuracy levels, it is important to understand how laser cutting software compares in terms of precision and accuracy.

Comparing Accuracy Levels

Achieve greater precision by using laser cutting software, which offers a higher level of accuracy compared to other options and ensures impeccable results for your projects. When evaluating precision in CNC machining, laser cutting stands out as the most accurate method. Unlike 3D printing, which may result in slight variations due to layering, laser cutting provides consistent and precise cuts every time. The laser beam’s focused heat allows for intricate designs and sharp edges, ensuring that your projects are executed with meticulous accuracy.

This level of precision is crucial for industries such as aerospace, automotive, and electronics, where even the smallest error can have significant consequences. Transitioning into the next section on precision in laser cutting, you can confidently rely on laser cutting software to deliver unparalleled accuracy for your cutting needs.

Precision in Laser Cutting

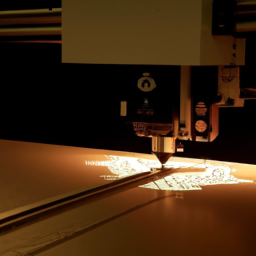

Immerse yourself in the world of laser cutting precision and experience the flawless execution of intricate designs with sharp edges that can make all the difference in industries like aerospace, automotive, and electronics.

Laser cutting software offers exceptional accuracy due to its ability to control laser beams with high precision. The speed of laser cutting is unmatched, allowing for quick and efficient production. Additionally, laser cutting can be performed on a wide range of materials, including metals, plastics, and woods. This versatility makes laser cutting software a top choice for many industries.

However, while laser cutting excels in precision, it’s important to note that router cutting also has its own advantages.

Transitioning into the subsequent section, let’s explore the precision in router cutting and how it compares to laser cutting.

Precision in Router Cutting

Discover the astonishing precision of router cutting and witness the meticulous craftsmanship that can bring your wildest creations to life. Router cutting techniques have evolved to achieve unparalleled precision, allowing for intricate designs and flawless edges.

Here are five key aspects that contribute to the precision of router cutting:

-

Advanced spindle technology: High-speed spindles with precise rotation control ensure accurate cutting depths and clean, crisp lines.

-

State-of-the-art CNC controllers: These sophisticated systems enable precise movements, ensuring that every cut is executed with utmost accuracy.

-

Precision tooling: Specialized router bits with sharp cutting edges and fine-tuned geometries are essential for achieving intricate details and smooth finishes.

-

Rigidity and stability: Sturdy machine structures and secure workholding fixtures minimize vibrations, resulting in precise cuts without any deviations.

-

Advanced software algorithms: Cutting-edge software algorithms calculate tool paths with utmost precision, optimizing cutting speeds and minimizing errors.

Understanding the precision achieved through router cutting techniques is crucial when choosing the right software for your project.

Choosing the Right Software for Your Project

When it comes to your project, finding the right software can make all the difference in bringing your creative vision to life. When selecting software for your laser cutting or router project, there are several factors to consider. Firstly, it is crucial to ensure that the software is compatible with your cutting machine. Compatibility issues can lead to inaccuracies and errors in the final product. Additionally, you should consider the level of precision required for your project and choose software that can deliver the necessary accuracy. To help you make an informed decision, here is a table highlighting key factors to consider when selecting software:

| Factors to Consider | Importance |

|---|---|

| Compatibility | High |

| Precision | High |

| Ease of use | Medium |

By carefully evaluating these factors, you can choose the right software that will guarantee accurate and precise results for your project.

Frequently Asked Questions

What are the advantages of using laser cutting software over router cutting software?

Laser cutting software offers several advantages over router cutting software. Firstly, laser cutting software provides greater precision and accuracy due to its ability to create intricate designs with finer details.

Secondly, laser cutting software offers a wider range of material compatibility, allowing you to work with various materials such as wood, acrylic, and metal.

These advantages make laser cutting software the preferred choice for those seeking precise and versatile cutting capabilities.

Can laser cutting software be used with different types of materials?

Yes, laser cutting software can be used with different types of materials. The compatibility of laser cutting software allows it to work with a wide range of materials, including wood, acrylic, metal, fabric, and more.

This makes it a versatile tool for various industries, such as manufacturing, signage, and fashion. Laser cutting software provides precise control over cutting parameters, ensuring accurate and clean cuts on different materials, making it an ideal choice for many applications.

Is there a significant difference in accuracy levels between laser cutting and router cutting software?

When comparing the accuracy of laser cutting and router cutting software, it’s interesting to note that laser cutting software generally provides a higher level of precision. This can be attributed to the ability of laser cutting machines to achieve finer cuts and intricate designs with minimal material waste.

However, it’s crucial to acknowledge that router cutting software can still deliver satisfactory accuracy for certain applications. The impact of software on cutting precision is significant, as it determines the intricacy and quality of the final product.

Are there any specific design considerations to keep in mind when using laser cutting software?

When using laser cutting software, there are several design considerations to keep in mind. Firstly, you need to ensure that your design is compatible with the materials you’re working with. Different materials require different cutting parameters, such as power and speed.

Additionally, you should consider factors like kerf width and heat-affected zone. These design considerations are crucial in achieving accurate and precise laser cuts.

How do I determine the right software for my specific project requirements?

To determine the right software for your specific project requirements, you need to evaluate your project needs and determine software compatibility. Consider factors such as the type of machine you’re using and the complexity of your design. Also, assess the features offered by each software.

Evaluate if the software supports the file formats you need and if it allows for precise control over cutting or routing paths.

Careful evaluation will ensure that you choose the most suitable software for your project.

Conclusion

In conclusion, when it comes to accuracy in design software for laser cutting versus router software, the former takes the lead. Laser cutting software offers a higher level of precision, allowing for intricate and detailed cuts. Its ability to work with a variety of materials and thicknesses further enhances its accuracy.

While router cutting software is capable, it falls slightly short in terms of precision compared to laser cutting. Therefore, for projects that require utmost accuracy and precision, laser cutting software is the optimal choice.