In the realm of design, precision is paramount. Just as a skilled artist wields a brush to create a masterpiece, a designer must carefully choose the tools that will bring their vision to life. When it comes to laser cutting technology, the software you use can make all the difference. It’s like having a laser-guided scalpel, capable of cutting through materials with surgical precision. But which software is best suited for this task? Should you stick with the traditional design software you’re familiar with, or opt for specialized design software tailored specifically for laser cutting?

In this article, we will explore the features and capabilities of both options, comparing their strengths and weaknesses. By the end, you’ll have a clear understanding of which design software is the optimal choice for your laser cutting needs. So, grab your metaphorical scalpel and let’s dive in!

Key Takeaways

- Laser cutting software offers specialized features and capabilities for designing objects to be cut with a laser.

- Laser cutting software allows for intricate designs with high precision and often includes nesting features.

- Laser cutting software provides optimization features to minimize material waste and allows for creating and editing 3D models.

- Traditional design software may have limitations and challenges for laser cutting.

Understanding Laser Cutting Technology

You’ll be amazed at how laser cutting technology precisely cuts through materials like a hot knife through butter. Over the years, there have been significant advancements in laser cutting technology, making it a valuable tool in various industries.

The benefits of laser cutting are numerous. Firstly, it offers unparalleled precision, allowing for intricate and complex designs that would be difficult to achieve with traditional cutting methods. Additionally, laser cutting is incredibly versatile, capable of working with a wide range of materials, including metals, plastics, and fabrics. This makes it an ideal choice for industries such as automotive, aerospace, and fashion.

Laser cutting also provides faster production times and eliminates the need for additional finishing processes. With laser cutting technology, you can achieve remarkable results with unparalleled precision and efficiency.

Transitioning to the subsequent section about traditional design software, it’s important to consider the limitations and drawbacks that come with using these tools.

Traditional Design Software

When it comes to traditional design software, there are several key points to consider.

First, an overview of the software reveals its basic functions and purpose.

Second, the features and capabilities of traditional design software encompass a wide range of tools and options for designing and creating various types of projects.

Lastly, it’s important to acknowledge the limitations and challenges that may arise when using traditional design software, such as compatibility issues or learning curves associated with complex features.

Overview of Traditional Design Software

Although traditional design software offers a wide range of features and tools, it may not be optimized for the precision and intricacy required in laser cutting.

While traditional software like Adobe Illustrator or AutoCAD provide advantages such as a familiar interface and a vast library of design elements, they have certain limitations when it comes to laser cutting. These software programs are primarily designed for general graphic design purposes, lacking specific features and capabilities required for laser cutting.

Designing intricate patterns or complex geometries for laser cutting can be challenging with traditional software, as they often lack the precision and accuracy needed for this process. Additionally, traditional software may not have the ability to generate the necessary vector files or optimize designs for efficient laser cutting.

Transitioning into the subsequent section, laser cutting software offers specialized features and capabilities tailored specifically for this task.

Features and Capabilities

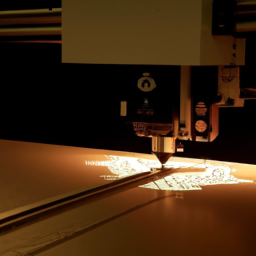

With specialized features and capabilities, laser cutting software allows you to effortlessly create intricate patterns and complex geometries, optimizing designs for precise and efficient laser cutting. One of the main advantages of laser cutting software is its ability to generate intricate designs with high precision, ensuring that every cut is accurate and clean.

Additionally, laser cutting software often includes features such as nesting, which helps to optimize material usage and minimize waste. However, there are also some disadvantages to consider. Laser cutting software can be more expensive than traditional design software, and it may require additional training to fully utilize its capabilities. Furthermore, some laser cutting software may have limitations in terms of file compatibility or the ability to handle certain design elements.

Despite these challenges, laser cutting software offers a range of advanced features that can greatly enhance the precision and efficiency of your laser cutting projects.

Now, let’s explore the limitations and challenges associated with this software.

Limitations and Challenges

To fully utilize laser cutting software, you’ll need to invest in additional training, like learning a new language or mastering a new instrument, to unlock its full potential. While laser cutting software offers numerous advantages, it also comes with its limitations and challenges. One limitation is the complexity of the software itself, which requires a certain level of technical expertise to operate effectively. Additionally, laser cutting software may have limited compatibility with other design software, making it difficult to integrate designs from different platforms. Moreover, the precision and accuracy of laser cutting can be affected by factors such as material thickness, cutting speed, and beam quality. Despite these challenges, the advantages of laser cutting software, such as increased efficiency and precision, make it a valuable tool for designers. Transitioning to the subsequent section about ‘design software for laser cutting’, it is important to compare its limitations and advantages with traditional design software.

Design Software for Laser Cutting

When it comes to design software for laser cutting, there are several key points to consider.

First, an overview of laser cutting design software is necessary to understand its purpose and functionality.

Next, the features and capabilities of laser cutting design software play a crucial role in determining its effectiveness.

Lastly, compatibility with laser cutting machines is essential to ensure seamless integration and optimal results.

Overview of Laser Cutting Design Software

Laser cutting design software offers a range of advanced features that enhance precision and speed in the design process. With these software tools, you can create intricate designs with ease. Here are some key benefits of using laser cutting design software:

-

Laser cutting design software is designed to be intuitive and easy to use, allowing users to quickly learn and navigate the software. It has a user-friendly interface.

-

These software tools provide optimization features that automatically arrange and nest designs to minimize material waste and maximize efficiency. They offer design optimization.

-

Laser cutting design software allows you to create and edit 3D models, giving you a realistic preview of your design before cutting. It has 3D modeling capabilities.

-

You can easily customize your designs by adjusting parameters such as cut paths, power levels, and speed. It offers customization options.

-

Laser cutting design software supports a wide range of file formats, making it easy to import and export designs. It is compatible with various file formats.

These features and capabilities make laser cutting design software a powerful tool for creating precise and intricate designs.

Features and Capabilities

One of the standout features of laser cutting design software is its user-friendly interface. It is specifically designed to cater to the needs of laser cutting techniques, making it efficient and effective for designers. The software offers a range of advanced design tools that allow users to create intricate and precise designs. These tools include vector editing, parametric design, and nesting capabilities. Vector editing enables users to manipulate and modify shapes and lines with precision. Parametric design allows designers to create designs that can be easily modified by adjusting parameters, such as dimensions or angles. Nesting capabilities optimize material usage by automatically arranging designs to minimize waste. With these features and capabilities, laser cutting design software streamlines the design process and ensures optimal results. Transitioning to the next section, the software’s compatibility with laser cutting machines further enhances its functionality.

Compatibility with Laser Cutting Machines

To get the most out of your laser cutting experience, you’ll be amazed at how seamlessly this software integrates with your cutting machine, ensuring a smooth and efficient workflow.

Laser cutting machine compatibility is a crucial aspect to consider when choosing design software. The software should be able to communicate effectively with your machine, allowing you to easily transfer your designs and execute them accurately. This requires the software to have specific software requirements, such as compatibility with the machine’s firmware and file formats.

Additionally, the software should provide a user-friendly interface that allows you to control and optimize the settings of your laser cutting machine. By ensuring compatibility between the software and your machine, you can maximize your productivity and achieve precise and high-quality cuts.

Moving forward, let’s now dive into a comparison of features and capabilities.

Comparison of Features and Capabilities

When it comes to designing, you’ll find that laser cutting software offers a range of features and capabilities that traditional design software may lack.

Laser cutting software often provides a more specialized user interface, tailored specifically for designing objects to be cut with a laser. This interface allows for precise control over the cutting process, including the ability to adjust power, speed, and other settings to achieve the desired results.

Additionally, laser cutting software typically includes tools for creating complex geometries, generating cutting paths, and optimizing material usage.

While traditional design software can also be used for laser cutting, it may have limitations and challenges when it comes to these specialized features.

Ultimately, the decision of which software to use depends on your specific needs and requirements for laser cutting.

Choosing the Best Option for Your Needs

If you want to find the perfect match for your laser cutting needs, it’s like searching for a needle in a haystack. Choosing the best option between design software for laser cutting and traditional design software can be a daunting task.

When it comes to customization options, design software specifically tailored for laser cutting takes the lead. It allows you to easily create intricate designs, adjust settings for different materials, and optimize cutting paths. On the other hand, traditional design software may offer limited customization options for laser cutting.

When considering cost, traditional design software may seem more appealing due to its broader range of functionalities. However, it’s important to factor in the additional costs of purchasing separate plugins or extensions for laser cutting capabilities.

Ultimately, the best option for your needs depends on the level of customization and cost comparison that you prioritize.

Frequently Asked Questions

What are the advantages of using design software specifically for laser cutting compared to traditional design software?

When comparing design software specifically for laser cutting to traditional design software, there are several advantages to consider.

Laser cutting software offers precise control over the laser’s movements, allowing for intricate and complex designs.

It also provides features like nesting, which optimizes material usage and reduces waste.

Furthermore, laser cutting software often includes libraries of pre-designed shapes and patterns, making it easier to create professional-looking designs.

Overall, laser cutting software offers specialized tools that enhance efficiency and accuracy in laser cutting projects.

Can traditional design software be used for laser cutting projects, or is it necessary to use software specifically designed for laser cutting?

Yes, traditional design software can be used for laser cutting projects. However, integrating laser cutting software into existing design workflows may present challenges. Transitioning from traditional design software to laser cutting software requires learning new tools and techniques specific to laser cutting. These challenges include understanding the intricacies of laser cutting parameters, material limitations, and optimizing designs for precise cutting.

It’s recommended to use software specifically designed for laser cutting to streamline the process and maximize efficiency.

Are there any limitations or restrictions when using traditional design software for laser cutting projects?

When using traditional design software for laser cutting projects, there are certain limitations and restrictions to consider. Traditional design software may not have the specific features required for laser cutting, such as the ability to generate intricate patterns or optimize cutting paths. Additionally, it may not have the necessary file formats for seamless integration with laser cutting machines. Therefore, it’s recommended to use software specifically designed for laser cutting to ensure precise and efficient results.

How user-friendly is design software for laser cutting compared to traditional design software?

Compared to traditional design software, design software for laser cutting offers a more user-friendly experience. The learning curve is generally smoother, thanks to intuitive interface designs that cater specifically to laser cutting projects. The software provides precise tools and features that allow users to easily create and edit designs for laser cutting.

With its technical focus and attention to detail, the software ensures a seamless and efficient workflow for laser cutting projects.

Are there any additional costs associated with using design software for laser cutting, or is it included with the laser cutting machine?

When using design software for laser cutting, there may be additional costs involved. Some software packages may be included with the laser cutting machine, while others may require separate licensing or subscription fees. Additionally, compatibility issues may arise between the design software and the laser cutting machine, which could require additional expenditures for software updates or hardware upgrades. It’s important to consider these potential costs when choosing design software for laser cutting.

Conclusion

In conclusion, when it comes to choosing between design software for laser cutting and traditional design software, the best option depends on your specific needs.

While traditional design software offers a wide range of features and capabilities, the design software specifically tailored for laser cutting provides precise and detailed tools for creating intricate designs.

With its ability to generate complex patterns and shapes, it can be likened to a virtual sculptor’s studio, where your ideas take form with unparalleled precision and finesse.

So, if you seek to bring your designs to life with utmost accuracy, the software designed for laser cutting is the way to go.