Did you know that design software for laser cutting is used in a wide range of industries, including automotive, aerospace, and fashion, while vinyl cutter software is primarily used in the sign-making and crafting industries?

These two types of software offer different features and capabilities, making them suitable for different applications.

Laser cutting software allows for intricate and precise designs, while vinyl cutter software is more limited in terms of complexity.

In this article, we will explore the features and limitations of both types of software, as well as their applications in various industries.

Additionally, we will discuss the cost and investment considerations when choosing the right software for your needs.

So, whether you’re a professional designer or a hobbyist, read on to discover which software is more versatile for your specific requirements.

Key Takeaways

- Laser cutting software offers intricate and precise designs for industries such as automotive, aerospace, and fashion.

- Laser cutting software allows for importing and manipulating various file formats, optimizing designs, and working with materials like paper, wood, and fabric.

- Laser cutting software requires a more robust hardware setup compared to vinyl cutter software.

- Vinyl cutter software is primarily used in sign-making and crafting industries, offering simplicity, ease of use, and compatibility with materials like vinyl and adhesive-backed film.

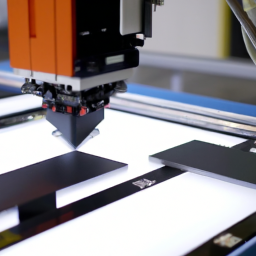

Features and Capabilities of Design Software for Laser Cutting

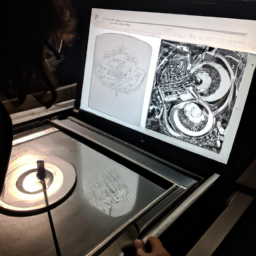

You’ll be amazed at the wide range of features and capabilities that design software for laser cutting offers! With this software, you can easily create intricate 3D models that can be cut with precision using a laser cutter.

The software allows you to import and work with various file formats, ensuring compatibility with your existing design files. It also provides advanced tools for manipulating and editing designs, such as scaling, rotating, and mirroring.

Additionally, the software allows you to optimize your designs for laser cutting by specifying cutting paths and adjusting power settings. All these features make design software for laser cutting incredibly versatile and powerful.

Now, let’s explore the benefits and limitations of vinyl cutter software.

Benefits and Limitations of Vinyl Cutter Software

Vinyl cutter software offers a range of advantages, but it also has its limitations. One of the main advantages of vinyl cutter software is its simplicity and ease of use. It allows users to easily create and edit designs for vinyl cutting, making it accessible even for beginners.

Additionally, vinyl cutter software is versatile and can work with a wide variety of materials, including vinyl, heat transfer vinyl, and adhesive-backed film. This makes it suitable for various applications such as creating signs, decals, and custom apparel.

However, vinyl cutter software has its limitations. It is primarily designed for 2D cutting and lacks the complex features and capabilities of design software for laser cutting. It may not be ideal for intricate designs or cutting thick materials.

Transitioning into the subsequent section, let’s explore the applications and industries that benefit from the advanced features of laser cutting software.

Applications and Industries for Laser Cutting Software

Industries across the globe are buzzing with excitement over the mind-blowing capabilities of laser cutting software, revolutionizing the way intricate designs are brought to life. Laser cutting software is not only used in industrial settings but also finds applications in art and crafts as well as architectural models. With laser cutting software for art and crafts, artists can create intricate designs on various materials like paper, wood, and fabric. This software allows for precise cutting and engraving, bringing artistic visions to reality. Similarly, laser cutting software for architectural models enables architects to create detailed and accurate miniature models of buildings and structures. The software ensures precise cutting and allows for intricate details to be incorporated. The versatility of laser cutting software makes it an essential tool for industries and applications that require intricate designs and precision. Moving on to industries and applications for vinyl cutter software…

Industries and Applications for Vinyl Cutter Software

The diverse range of industries and applications that benefit from vinyl cutter software is truly remarkable. Vinyl cutter software is widely used in the sign making industry, allowing businesses to create custom signs and graphics with precision and ease. From small businesses to large corporations, vinyl cutter software is an essential tool for creating eye-catching signage that captures attention and promotes brands.

Additionally, vinyl cutter software is also utilized in the apparel design industry, enabling designers to create intricate and detailed designs for t-shirts, hats, and other garments. The versatility of vinyl cutter software makes it a valuable asset in industries where precision and customization are key.

Transitioning into the subsequent section about cost and investment considerations, it’s important to understand how the benefits of vinyl cutter software can outweigh the initial investment.

Cost and Investment Considerations

When considering cost and investment considerations for vinyl cutter software, there are several key points to keep in mind.

First, you need to consider the software pricing and licensing options available, as this will affect both the initial investment and any ongoing costs.

Secondly, it’s important to assess the equipment and hardware requirements, as these will impact the overall cost and performance of the software.

Lastly, you should evaluate the return on investment and scalability potential of the software, to ensure that it aligns with your business goals and can grow with your needs.

Software Pricing and Licensing

Software pricing and licensing can be like a double-edged sword, acting as both the gatekeeper and the golden key to unlocking the full potential of laser cutting and vinyl cutting. When considering software for laser cutting or vinyl cutting, it’s crucial to take into account the cost and licensing fees associated with the software. Here are some key points to consider:

-

Software support and training: Look for software packages that offer comprehensive support options and training materials to ensure you can fully utilize the software’s capabilities.

-

Software updates and maintenance: Check if the software provider offers regular updates and maintenance services to keep your software up-to-date and functioning optimally.

-

Cost of licensing: Evaluate the pricing models available, such as one-time purchase, subscription, or per-machine licensing, to determine the most cost-effective option for your needs.

-

Flexibility of licensing: Consider if the software allows for easy transfer of licenses between machines or if additional licenses need to be purchased for each machine.

Understanding these factors will help you make an informed decision about software pricing and licensing, enabling you to maximize the potential of your laser cutting or vinyl cutting setup.

Moving on to equipment and hardware requirements…

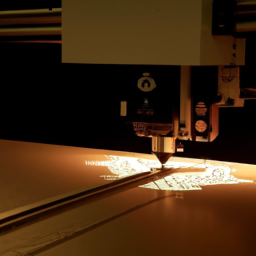

Equipment and Hardware Requirements

Now that we’ve examined the pricing and licensing aspects of design software for laser cutting and vinyl cutting, let’s turn our attention to the equipment and hardware requirements.

When considering these software options, it’s crucial to assess their compatibility and system requirements. Laser cutting software usually requires a more robust hardware setup due to the complexity of the cutting process, including a powerful computer and a compatible laser cutter.

On the other hand, vinyl cutter software can be more flexible in terms of hardware requirements, often working with standard desktop printers and cutters.

Additionally, training and support options play a vital role in ensuring a smooth transition to using the software effectively. Many laser cutting software providers offer comprehensive training programs and ongoing technical support. Similarly, vinyl cutter software providers also offer training resources, although they may not be as extensive.

As we move forward, let’s explore the return on investment and scalability of these software options.

Return on Investment and Scalability

To assess the return on investment and scalability of design software for laser cutting and vinyl cutter software, it’s important to consider their long-term value and potential for growth.

Scalability and long-term growth are crucial factors to consider when making a decision. Design software for laser cutting offers a wide range of capabilities and can be used for various applications, making it highly scalable and adaptable to different business needs.

On the other hand, vinyl cutter software may have limitations in terms of versatility and scalability, as it’s primarily focused on cutting vinyl materials.

When calculating return on investment, it’s essential to consider factors such as initial cost, maintenance expenses, and the potential for increased productivity and efficiency. By carefully evaluating these aspects, you can make an informed decision about choosing the right software for your needs, ensuring long-term success and growth.

Choosing the Right Software for Your Needs

When it comes to selecting the perfect software for your needs, it’s essential to consider which one provides the most versatility between laser cutting and vinyl cutting. Both options have their advantages, but the choice ultimately depends on your specific requirements.

Laser cutting software offers a wide range of customization options, allowing you to create intricate designs with precision. It also provides a user-friendly interface, making it easier for beginners to navigate and operate.

On the other hand, vinyl cutter software is also versatile, allowing you to work with various materials such as vinyl, fabric, and paper. It offers a user-friendly interface as well, making it accessible to users of all skill levels.

Ultimately, the right software for you will depend on your specific needs and preferences.

Frequently Asked Questions

Can design software for laser cutting be used with any type of laser cutter?

Yes, design software for laser cutting can be used with different laser cutter models. The compatibility of design software with various laser cutter models allows for greater flexibility and options in terms of cutting capabilities. Unlike vinyl cutter software, design software for laser cutting offers more advanced features and precision, making it an ideal choice for intricate designs and complex cutting tasks. This gives users an advantage in achieving highly detailed and professional results.

Is vinyl cutter software limited to cutting only vinyl materials?

Vinyl cutter software isn’t limited to cutting only vinyl materials. In fact, it has potential applications beyond just vinyl cutting. According to recent data, vinyl cutter software can also be used for cutting materials such as paper, cardstock, fabric, and even thin wood. However, it does have its limitations in terms of material compatibility. It may not be suitable for cutting thicker or harder materials like metal or acrylic.

What are some industries that commonly use laser cutting software?

Industries that commonly use laser cutting software include automotive, aerospace, electronics, and signage.

Laser cutting software offers numerous benefits in the automotive industry, such as precision cutting of complex shapes, reducing material waste, and increasing production speed. With laser cutting software, automotive manufacturers can achieve higher accuracy and efficiency in fabricating components, resulting in improved product quality and cost-effectiveness.

The versatility and precision of laser cutting software make it an essential tool in various industries.

Can vinyl cutter software be used for intricate and detailed designs?

Vinyl cutter software has limitations when it comes to intricate and detailed designs. It can handle basic shapes and simple designs, but it may struggle with complex patterns and fine details.

On the other hand, design software for laser cutting offers numerous advantages in the fashion industry. It allows for precise and intricate designs to be created, which is essential for creating intricate patterns and delicate cuts on fabrics and materials.

Are there any additional costs associated with using design software for laser cutting or vinyl cutter software?

When comparing the cost of design software for laser cutting versus vinyl cutter software, there may be additional expenses to consider.

While the initial purchase of the software is a factor, there could be ongoing fees for updates and technical support.

Additionally, training resources are essential for learning and troubleshooting both types of software. Online tutorials, user forums, and manufacturer-provided documentation are common resources available for users to enhance their skills and resolve any issues that may arise.

Conclusion

In conclusion, after thoroughly examining the features, benefits, and limitations of design software for laser cutting and vinyl cutter software, it is evident that laser cutting software offers more versatility.

Its advanced capabilities, such as intricate design options and compatibility with a wide range of materials, make it a preferred choice for various industries.

While vinyl cutter software has its own applications, its limitations in terms of material compatibility and design complexity restrict its versatility.

Therefore, when considering the investment and long-term benefits, choosing laser cutting software is the more logical and effective choice.