Designing software for laser cutting and waterjet cutting may seem similar at first glance, but their differences in efficiency become apparent once you delve deeper. When it comes to creating intricate designs, laser cutting software shines with its precision and speed. On the other hand, waterjet cutter software offers unique advantages in terms of versatility and compatibility with various materials.

In this article, we will explore the key features of laser cutting software that make it efficient, such as its ability to handle complex shapes with ease. Additionally, we will discuss the advantages of waterjet cutter software, including considerations for material thickness and type.

Moreover, we will delve into the workflow and integration capabilities of both software options, as well as their overall efficiency and cost-effectiveness. By the end, you will have a clear understanding of which software option is more efficient for your specific needs.

So, let’s dive into the fascinating world of design software for laser cutting and waterjet cutting and discover which one reigns supreme in terms of efficiency.

Key Takeaways

- Laser cutting software is known for its precision and speed in creating intricate designs, while waterjet cutter software offers versatility and compatibility with various materials.

- Laser cutting software seamlessly integrates with CAD software, allowing for accurate design transfer, while waterjet cutter software excels at cutting complex shapes and patterns.

- Laser cutting software generally has faster cutting speeds compared to waterjet cutting software and requires less energy and maintenance, making it more cost-effective.

- When choosing cutting software, factors to consider include material compatibility, compatibility with operating systems and hardware, seamless integration with other design and manufacturing tools, and easy import/export and integration with CAD programs.

Key Features of Laser Cutting Software

Laser cutting software is packed with features that make it a must-have tool for designers looking to bring their creations to life with precision and speed. One key feature is its ability to seamlessly integrate with CAD software, allowing designers to easily transfer their designs to the laser cutter. This integration ensures that the final product matches the original design with utmost accuracy.

Additionally, laser cutting software excels in optimizing cutting paths. It analyzes the design and determines the most efficient path for the laser to follow, minimizing material waste and reducing production time. By precisely cutting through the material, laser cutting software enables designers to achieve intricate and complex designs.

Transitioning to the advantages of waterjet cutter software, its unique capabilities offer a different set of benefits for designers.

Advantages of Waterjet Cutter Software

Forget about laser cutting software. You’ll be amazed at how waterjet cutter software effortlessly transforms your designs into masterpieces.

With waterjet cutter software, you can achieve precise cutting with the power of water. Here are three key benefits of using waterjet cutter software:

-

Versatility: Waterjet cutting allows you to work with a wide range of materials, including metals, plastics, ceramics, and even stone. This versatility gives you the freedom to explore different design possibilities.

-

Accuracy: Waterjet cutting offers exceptional precision, with tolerances as low as 0.1mm. This level of accuracy ensures that your designs are executed flawlessly, resulting in high-quality finished products.

-

Complex Shapes: Waterjet cutter software excels at cutting intricate shapes and patterns. The high-pressure water stream can effortlessly navigate tight corners and intricate details, allowing you to create complex designs with ease.

With these waterjet cutter benefits, you can take your designs to new heights of precision and complexity.

Now, let’s delve into the efficiency of designing complex shapes.

Efficiency in Designing Complex Shapes

When it comes to designing complex shapes, laser cutting software allows you to create intricate designs with precision and accuracy. With its high-powered laser beam, it can achieve detailed cuts on various materials, providing clean and precise edges.

On the other hand, waterjet cutter software offers the advantage of achieving detailed cuts with its high-pressure water stream, which can easily navigate through intricate designs. Both options offer time and cost savings in the design process by streamlining the production of complex shapes.

Creating Intricate Designs with Laser Cutting Software

Get ready to discover the endless possibilities of creating intricate designs with laser cutting software! Laser cutting software offers a range of features that allow you to achieve highly detailed and complex cuts with precision.

One of the key advantages of laser cutting software is the availability of customizable templates, which provide a starting point for your design. These templates can be easily modified using vector editing tools, allowing you to tailor the design to your specific needs.

With laser cutting software, you have full control over every aspect of your design, ensuring that every detail is perfect. However, while laser cutting software provides excellent precision and customization options, achieving detailed cuts with waterjet cutter software offers a different set of advantages.

Achieving Detailed Cuts with Waterjet Cutter Software

Achieving intricate and precise cuts becomes a breeze with waterjet cutter software, as it allows you to effortlessly navigate through the intricacies of your design. The software provides a range of features that enable you to achieve the highest level of precision in your cuts. One such feature is the ability to adjust the cutting speed and pressure, allowing you to achieve the perfect balance for achieving precision. Additionally, waterjet cutter software offers advanced material compatibility options, allowing you to select the appropriate settings for different materials, ensuring clean and accurate cuts every time. Whether you are working with metals, plastics, or composites, the software provides the necessary tools to achieve the desired level of precision. With waterjet cutter software, you can confidently create intricate designs with ease and achieve the precision you need for your projects.

Transition: Moving on to the next section about ‘time and cost savings in the design process’, let’s explore how waterjet cutter software can streamline your workflow and optimize your resources.

Time and Cost Savings in Design Process

By streamlining the design process and optimizing resources, waterjet cutter software can save both time and money for manufacturers.

For example, a company that specializes in custom metal fabrication was able to reduce the time it took to produce intricate parts by 50% using waterjet cutter software, resulting in significant cost savings and improved efficiency.

The software’s advanced algorithms and intuitive user interface allow designers to quickly convert their designs into machine-readable formats, eliminating the need for manual programming. This not only saves time but also reduces the likelihood of errors and rework.

Additionally, waterjet cutter software enables efficient nesting of parts, maximizing material utilization and minimizing waste. By accurately calculating cutting paths and adjusting for material thickness, the software ensures precise and optimized cuts.

These time and cost-saving features make waterjet cutter software a highly cost-effective and time-efficient solution for manufacturers.

Moving on to considerations for material thickness and type…

Considerations for Material Thickness and Type

Choose the most suitable software for your laser cutting or waterjet cutting needs based on the thickness and type of materials you work with. Material compatibility is a crucial factor to consider when selecting software for your cutting process.

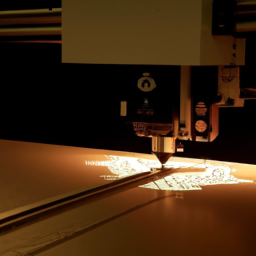

Laser cutting software is generally more compatible with a wide range of materials, including metals, plastics, and woods. It offers precise control over the cutting process, ensuring clean and accurate cuts. On the other hand, waterjet cutting software is better suited for cutting thicker materials such as stone, glass, and composites. It utilizes a high-pressure stream of water mixed with an abrasive material to cut through these tougher materials.

Additionally, cutting speed is another aspect to consider. Laser cutting software typically offers faster cutting speeds compared to waterjet cutting software.

Transitioning into the next section about workflow and integration with other software, it is important to evaluate how the chosen software integrates seamlessly with your existing design and manufacturing software tools.

Workflow and Integration with Other Software

Seamlessly integrating your cutting software with other design and manufacturing tools streamlines your workflow, making the process smoother and more efficient. To ensure a seamless integration, you need to consider the following:

-

Integration challenges: Different software programs may have compatibility issues, making it difficult to transfer files and data seamlessly between them. It’s crucial to choose software that supports common file formats and offers robust integration capabilities.

-

Compatibility issues: The software you choose should be compatible with the operating system and hardware you’re using. It’s essential to check the system requirements and ensure that your software is compatible with your existing setup.

-

Workflow optimization: Look for software that allows for easy import and export of design files, as well as integration with other software tools such as CAD programs. This’ll enable a smooth transition between different stages of the design and manufacturing process.

By addressing these integration challenges and compatibility issues, you can optimize your workflow and enhance overall efficiency and cost-effectiveness in your laser cutting or waterjet cutting operations.

Overall Efficiency and Cost-effectiveness

One common concern when integrating different tools and software is the potential increase in costs, but there are strategies to ensure overall efficiency and cost-effectiveness in your workflow.

When comparing design software for laser cutting and waterjet cutter software, it is important to consider their cost effectiveness and overall performance. Laser cutting software generally offers higher efficiency due to its ability to create intricate designs with precision and speed. It also tends to be more cost-effective as it requires less energy and maintenance compared to waterjet cutting.

Additionally, laser cutting software often provides features such as nesting optimization, which minimizes material waste and reduces production costs. However, the choice between laser cutting and waterjet cutting ultimately depends on the specific requirements of your project and the materials being used.

Frequently Asked Questions

Can laser cutting software be used with a waterjet cutter machine?

Yes, laser cutting software can be used with a waterjet cutter machine, providing several advantages. The compatibility of laser cutting software with waterjet cutter software allows for increased precision, efficiency, and flexibility in the cutting process. Laser cutting software offers advanced programming capabilities, such as nesting and path optimization, which can optimize material usage and reduce cutting time.

Additionally, the software enables easy design transfer and compatibility with various file formats, making it a valuable tool for waterjet cutting operations.

Are there any limitations in terms of material thickness for waterjet cutter software?

When it comes to waterjet cutter software, there are indeed limitations in terms of material thickness. These limitations primarily depend on the power and capabilities of the waterjet cutter machine being used. Thicker materials may require multiple passes or specialized techniques to achieve desired results.

On the other hand, laser cutting software offers advantages such as precise and efficient cutting, especially for thinner materials. Its high-powered laser beam allows for intricate designs and faster cutting speeds.

What are the key factors to consider when choosing between laser cutting software and waterjet cutter software?

When choosing between laser cutting software and waterjet cutter software, there are several key factors to consider.

Firstly, compatibility between the software and the machines is crucial to ensure smooth operation.

Additionally, the software’s ability to handle different materials, thicknesses, and complexities should be evaluated.

It is important to assess the software’s cutting speed, accuracy, and reliability.

Moreover, the availability of advanced features like nesting optimization and 3D modeling can greatly enhance efficiency and productivity.

Can laser cutting software handle complex shapes as effectively as waterjet cutter software?

When it comes to handling complex shapes, laser cutting software can hold its own against waterjet cutter software. With its advanced capabilities, laser cutting software can precisely cut intricate designs with ease.

However, it’s important to note that waterjet cutter software does have its advantages. Its ability to cut through a wider range of materials, including thick metals, gives it an edge in certain applications.

Nonetheless, laser cutting software remains a powerful tool for creating intricate and precise cuts.

Are there any integration issues when using laser cutting software with other design software programs?

When using laser cutting software with other design software programs, you may encounter integration challenges and compatibility concerns. These issues can arise due to differences in file formats, software versions, and communication protocols.

It’s crucial to ensure that the laser cutting software is compatible with the design software you’re using, and that they can seamlessly exchange data. Failure to address these integration issues can lead to errors, delays, and inefficient workflows.

Conclusion

In conclusion, when it comes to efficiency in design software for laser cutting versus waterjet cutter software, the choice depends on various factors.

Laser cutting software offers key features for precise cuts and intricate designs, while waterjet cutter software provides advantages in working with materials of varying thickness and types.

However, both options offer efficient workflows and integration with other software.

Ultimately, the decision should be based on the specific needs and requirements of your project.

Symbolically, like the intricate patterns created by laser cutting or the versatility of waterjet cutting, the right software choice can unlock endless possibilities for efficiency and cost-effectiveness in your design process.