Did you know that the global laser cutting market is projected to reach $6.72 billion by 2027? With such a significant growth potential, it’s crucial for businesses to invest in the right cutting technology.

Diode laser cutters and CNC routers are two popular options, each offering unique advantages. In this article, we will explore the differences between diode laser cutters and CNC routers to help you determine which one is better for your business.

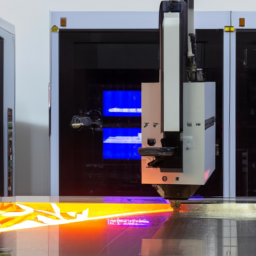

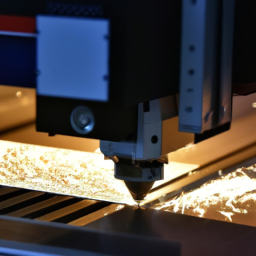

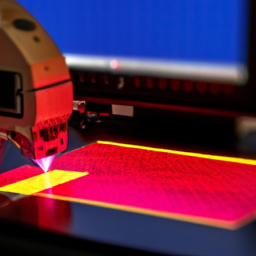

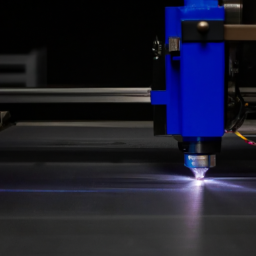

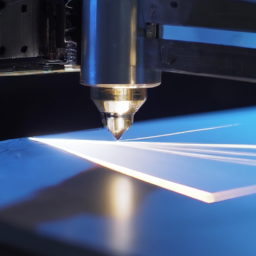

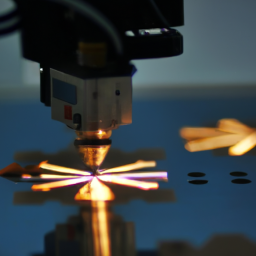

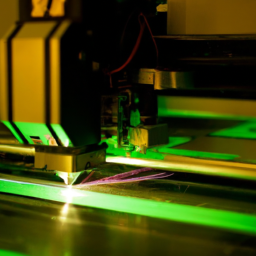

Diode laser cutters utilize a high-powered laser beam to cut through various materials, providing precise and intricate cuts. On the other hand, CNC routers use rotating cutting tools to carve and shape materials.

By comparing their cutting capabilities, cost and maintenance requirements, workflow, and efficiency, you can make an informed decision that aligns with your business needs. Whether you’re in the manufacturing, signage, or woodworking industry, understanding the pros and cons of these technologies is essential.

So, let’s dive in and discover which cutting option will elevate your business to new heights.

Key Takeaways

- Diode laser cutters offer high precision and cutting speed, making them ideal for small-scale production and intricate designs.

- Diode laser cutters are more affordable upfront compared to CNC routers and require less maintenance.

- CNC routers can handle larger workpieces and thicker materials, making them suitable for high-volume production.

- CNC routers have lower long-term sustainability costs and can produce intricate and detailed designs.

Understanding Diode Laser Cutters

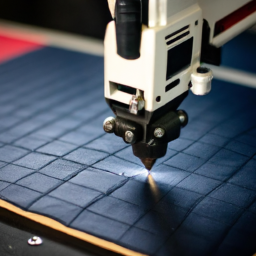

If you’re looking for a versatile and efficient tool for precision cutting, a diode laser cutter is exactly what you need. Diode laser cutters utilize a high-powered laser beam emitted from a diode to cut through various materials with incredible accuracy. One of the major advantages of diode lasers is their ability to cut through different types of materials, including wood, acrylic, fabric, and even metal.

This makes them suitable for a wide range of applications, such as signage production, jewelry making, and model building. Diode laser cutters offer clean and precise cuts, minimizing the need for post-processing. They also provide high cutting speeds, allowing for increased productivity.

Now, let’s explore CNC routers and see how they compare to diode laser cutters.

Exploring CNC Routers

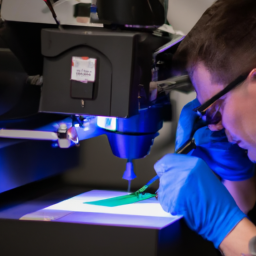

If you’re considering using CNC routers for your business, it’s important to understand how they work and the pros and cons they offer.

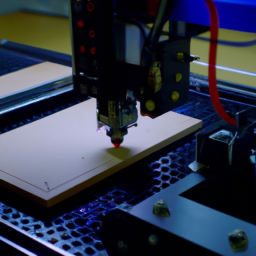

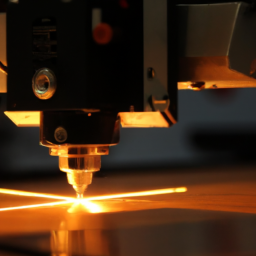

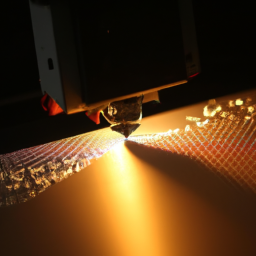

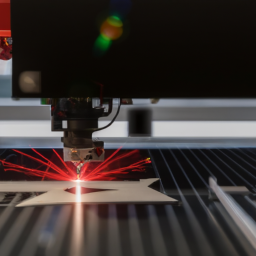

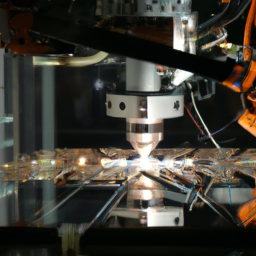

CNC routers are computer-controlled machines that use rotating cutting tools to shape and cut various materials. They offer precision and efficiency, allowing you to create intricate designs with ease.

However, they can be expensive to purchase and maintain, and may not be suitable for all types of materials.

How CNC Routers Work

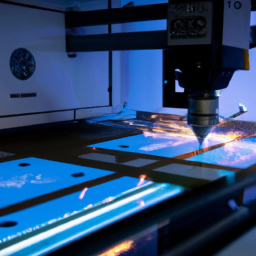

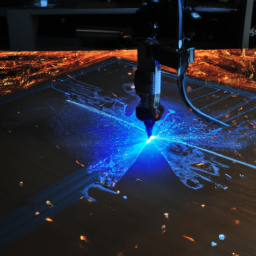

Although CNC routers may not possess the precision and finesse of diode laser cutters, they operate like skilled sculptors, meticulously carving out intricate designs from a solid block of material.

CNC routers offer several advantages, making them highly versatile and widely used in various industries. Their ability to work with a wide range of materials, such as wood, plastic, and metal, makes them suitable for applications in woodworking, sign-making, and prototyping.

CNC routers can cut, carve, shape, and engrave materials with high accuracy and repeatability, ensuring consistent quality in the final product. They can also handle larger workpieces and thicker materials compared to diode laser cutters.

However, CNC routers have their limitations, which we will explore in the subsequent section about the pros and cons of CNC routers.

Pros and Cons of CNC Routers

When considering whether to invest in a CNC router, it’s important to weigh the advantages and disadvantages to determine if it aligns with your specific business needs.

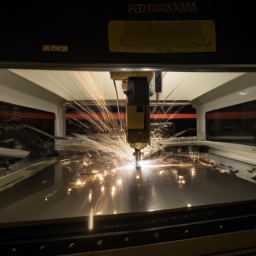

One major advantage of CNC routers is their versatility. They can work with a wide range of materials, including wood, plastic, and even metal, allowing for greater flexibility in your manufacturing processes. Additionally, CNC routers can produce highly intricate and detailed designs with precision and accuracy, resulting in high-quality finished products.

However, there are also some drawbacks to using CNC routers. They can be expensive to purchase and maintain, and they require a significant amount of space in your workshop. Furthermore, the setup and programming process can be complex and time-consuming.

Overall, CNC routers offer many advantages, but they also come with their own set of disadvantages.

Transitioning into the subsequent section about ‘comparing cutting capabilities,’ it’s important to consider how these advantages and disadvantages compare to diode laser cutters.

Comparing Cutting Capabilities

When comparing cutting capabilities between diode laser cutters and CNC routers, there are two key points to consider: precision and detail, and material compatibility.

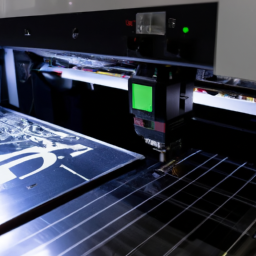

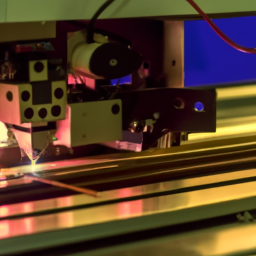

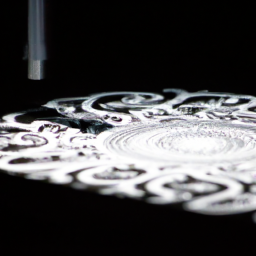

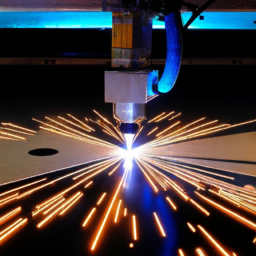

Diode laser cutters offer high precision and intricate detail due to their focused laser beams, allowing for precise cuts and intricate designs.

On the other hand, CNC routers excel in material compatibility as they can cut a wide range of materials such as wood, plastic, and metal, making them a versatile option for various industries.

Precision and Detail

If you want jaw-dropping precision and mind-blowing detail, a diode laser cutter is the way to go for your business. Here are three reasons why:

-

Laser cutting advantages: Diode laser cutters offer unparalleled precision due to their narrow beam width and high-powered laser. They can cut intricate designs with utmost accuracy, resulting in clean edges and sharp corners. Your products will have a professional finish that will impress your customers.

-

Router precision: While CNC routers are precise, they may not match the level of detail provided by diode laser cutters. The laser’s ability to focus on a small area allows for intricate patterns and delicate cuts that routers may struggle to achieve.

-

Material compatibility: Furthermore, diode laser cutters can work with a wide range of materials, including wood, acrylic, leather, and even metal. This versatility gives you the freedom to explore various industries and expand your business opportunities.

Transitioning into the next section on material compatibility, it’s important to consider the various materials you work with and how a diode laser cutter can handle them.

Material Compatibility

Explore the wide range of materials that can be effortlessly handled by a diode laser cutter and discover endless possibilities for your business.

When it comes to material compatibility, diode laser cutters have a clear advantage over CNC routers. While CNC routers are limited in the types of materials they can effectively cut, diode laser cutters can handle a diverse range of materials with ease.

Whether you need to cut through wood, acrylic, leather, fabric, or even metal, a diode laser cutter can deliver precise and clean cuts. This versatility allows you to expand your product offerings and cater to a wider customer base.

Considering the cost and maintenance, which we’ll discuss next, you’ll see that a diode laser cutter is a wise investment for your business.

Considering Cost and Maintenance

Although diode laser cutters and CNC routers both have their own costs and maintenance requirements, it’s important to weigh the pros and cons to determine which one is a better fit for your business.

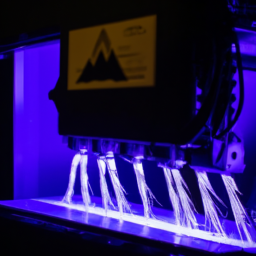

When it comes to cost effectiveness, diode laser cutters are generally more affordable upfront compared to CNC routers. However, CNC routers tend to have lower long-term sustainability costs as they require less frequent maintenance and have a longer lifespan.

Maintenance for diode laser cutters involves cleaning the lens and mirrors regularly, as well as replacing the laser tube periodically. On the other hand, CNC routers require occasional lubrication and tool replacement.

Considering the long-term sustainability and overall cost, CNC routers may be a more suitable option for businesses looking to minimize maintenance expenses.

Assessing workflow and efficiency is the next step to help determine the best choice for your business.

Assessing Workflow and Efficiency

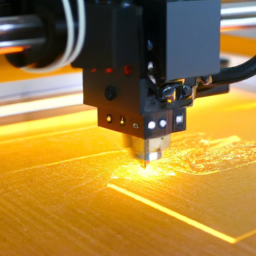

Assessing workflow and efficiency is crucial to determining the most effective solution for streamlining operations and maximizing productivity. When evaluating productivity, it’s important to consider how each machine can contribute to saving time and improving overall efficiency.

Whether it’s a diode laser cutter or a CNC router, each machine has its own advantages. Diode laser cutters are known for their precision and speed, making them ideal for intricate designs and small-scale production. On the other hand, CNC routers are versatile and can handle larger materials, allowing for faster cutting and increased output.

Analyzing time-saving features such as automatic material handling, software integration, and tool changing capabilities is essential in making an informed decision. By carefully assessing workflow and efficiency, you can choose the right option for your business that will optimize productivity and meet your specific needs.

Choosing the Right Option for Your Business

When it comes to selecting the perfect solution for your business, you might want to consider flipping a coin, because clearly making an informed decision based on the specific needs of your business is overrated. However, if you prefer a more rational approach, there are several factors to consider when choosing between diode laser cutters and CNC routers.

Firstly, evaluate the long term benefits of each option for your business. Diode laser cutters offer precision and versatility, making them ideal for intricate designs and materials like acrylic and wood. On the other hand, CNC routers excel at handling larger projects and materials such as metal and foam.

Secondly, assess your workflow and efficiency requirements. Diode laser cutters are faster and require less maintenance, but CNC routers can handle high-volume production.

By carefully considering these factors, you can make an informed decision that aligns with the unique needs of your business.

Frequently Asked Questions

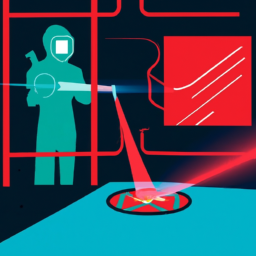

Are diode laser cutters safe to use in a business environment?

Diode laser cutters can be a safe option for use in a business environment. They offer several advantages, such as precise cutting, high-speed operation, and minimal material waste.

However, there are also some drawbacks to consider. Diode laser cutters are typically less powerful than CNC routers, limiting their ability to cut through thicker materials. Additionally, the cost-effectiveness of diode laser cutters versus CNC routers in a commercial setting depends on factors such as the volume and type of work being performed.

Can CNC routers be used to cut and engrave materials other than wood?

CNC routers are versatile machines that can cut and engrave a variety of materials beyond wood. In fact, a recent study found that CNC routers can handle alternative materials such as plastic, foam, acrylic, and even metals with precision and accuracy.

When compared to diode laser cutters, CNC routers offer a wider range of materials to work with, making them a suitable choice for businesses seeking versatility in their cutting and engraving processes.

How long does it typically take to learn how to operate a diode laser cutter?

The learning curve for operating a diode laser cutter can vary depending on your previous experience with similar equipment. However, with dedication and practice, one can acquire the necessary operating skills within a few weeks.

It involves understanding the machine’s software, safety protocols, material settings, and maintenance procedures. Familiarity with design software and knowledge of different materials can also enhance your proficiency.

Regular training and guidance can expedite the learning process, enabling you to efficiently utilize this technology for your business needs.

Are there any regulations or permits required for using CNC routers in a commercial setting?

Permit requirements and safety precautions must be considered when using CNC routers in a commercial setting. Before operating a CNC router, it’s important to determine if any permits or licenses are necessary.

These requirements may vary depending on your location and the type of work being done. Additionally, safety precautions should be followed to ensure the well-being of operators and bystanders. This includes wearing appropriate personal protective equipment and implementing safety protocols to prevent accidents.

What kind of maintenance is involved in owning a diode laser cutter or CNC router?

Maintenance requirements for owning a diode laser cutter or CNC router can be a walk in the park. Just kidding! These machines require regular maintenance to keep them in top shape.

For diode laser cutters, you’ll need to clean the lens frequently and ensure proper ventilation. Troubleshooting tips include checking for loose connections and adjusting the focal length.

CNC routers, on the other hand, may require cleaning the spindle, checking for worn-out bits, and lubricating the moving parts. Don’t forget to regularly calibrate and align both machines for optimal performance.

Conclusion

In conclusion, when it comes to deciding between diode laser cutters and CNC routers for your business, it’s crucial to weigh the cutting capabilities, cost, maintenance, workflow, and efficiency.

Both options have their advantages and disadvantages, and it’s essential to choose the right tool based on your specific needs.

Remember, ‘the devil is in the details,’ so thoroughly analyze your requirements, consider the intricacies of each machine, and make an informed decision that aligns with your business goals and objectives.