As the saying goes, ‘You get what you pay for.’ When it comes to investing in machinery for your business, this adage holds true. Diode laser cutters and die cutters are two popular options that offer precise cutting capabilities, but which one is the better investment?

In this article, we will delve into the technicalities and compare the features of these machines to help you make an informed decision. Diode laser cutters are known for their versatility and precision. They use a laser beam to cut through various materials with utmost accuracy. On the other hand, die cutters utilize a die to cut materials into specific shapes. Both machines have their advantages and limitations, and it’s crucial to evaluate their capabilities based on your specific needs.

In addition to comparing features, we will also delve into the cost-effectiveness of each option. After all, the investment you make should not only meet your requirements but also bring long-term value to your business. So, join us as we analyze the pros and cons of diode laser cutters and die cutters, and help you determine which one is the better investment for your business.

Key Takeaways

- Diode laser cutters offer greater flexibility, precision, and accuracy compared to die cutters.

- Die cutters are better suited for simpler, repetitive cuts and are more efficient for high-volume production.

- Diode laser cutters are ideal for projects that require fine details and intricate designs.

- While diode laser cutters have a higher initial investment, they offer long-term savings in maintenance and operating costs.

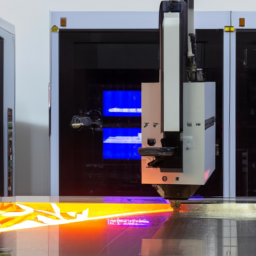

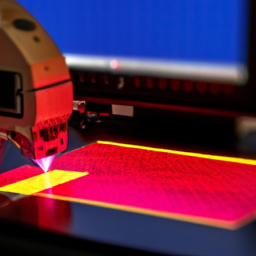

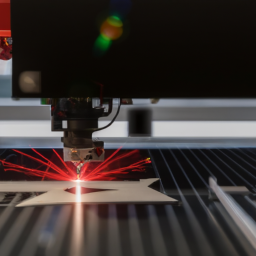

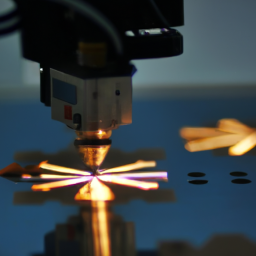

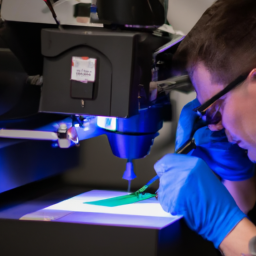

Understanding Diode Laser Cutters

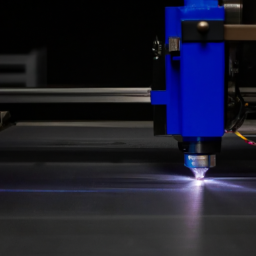

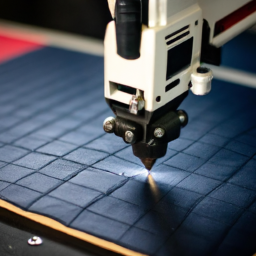

If you’re looking to add some serious cutting power to your workshop, diode laser cutters are the way to go! Diode laser cutters offer several advantages over traditional die cutters.

First and foremost, diode lasers are incredibly precise and can cut through a wide range of materials with ease. Whether you’re working with wood, acrylic, or even metal, a diode laser cutter will provide clean and accurate cuts every time.

Additionally, diode laser cutters have a much faster cutting speed compared to die cutters, saving you valuable time on your projects.

The applications of diode laser cutters are vast, from creating intricate designs for crafts and hobbies to producing precise cuts for industrial prototyping.

Now, let’s explore die cutters and see how they compare to diode laser cutters.

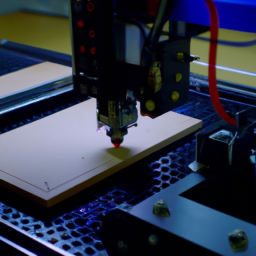

Exploring Die Cutters

When exploring die cutters, it’s important to understand how they work. Die cutters use a metal die to cut out shapes from various materials, such as paper or fabric, with precision and efficiency.

The benefits of using die cutters include their ability to produce consistent and uniform shapes, their high speed and accuracy, as well as their versatility in cutting a wide range of materials.

However, it’s important to note that die cutters have certain limitations. For example, they rely on a specific die for each shape, which can limit design flexibility. Additionally, die cutters are unable to cut intricate and complex shapes.

How Die Cutters Work

While you may think die cutters are a magical device that simply cuts through materials with ease, let me explain how they actually work.

Die cutters use a sharp, custom-made die to cut precise shapes out of various materials. The die is placed on top of the material and then pressed down with force, resulting in a clean and accurate cut. This process is ideal for mass production as it can rapidly cut multiple identical shapes in a short amount of time.

However, die cutters have some disadvantages. They require a separate die for each unique shape, which can be costly and time-consuming to create. Additionally, die cutters are limited to cutting flat materials, making them less versatile compared to other cutting methods.

Despite these limitations, die cutters offer numerous benefits, which will be discussed in the subsequent section about the benefits of using die cutters.

Benefits of Using Die Cutters

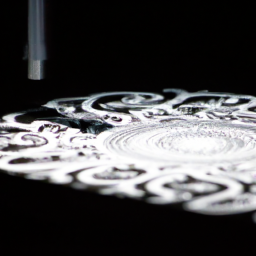

One of the advantages of using die cutters is their ability to quickly and accurately cut multiple identical shapes, saving time and ensuring consistent results. Die cutters are widely used in various industries such as packaging, printing, and automotive, where the need for precision and efficiency is paramount. These machines can handle a wide range of materials, including paper, cardboard, fabric, and even metal, making them versatile for different applications.

The ability to create intricate and complex designs is another benefit of using die cutters, allowing for the production of unique and attractive finished products. However, while die cutters offer many advantages, they also have their limitations. Transitioning into the subsequent section about the limitations of die cutters, it is important to consider their restricted flexibility and inability to handle materials that require more delicate cutting methods.

Limitations of Die Cutters

To fully understand the limitations of die cutters, you need to consider their restricted flexibility and inability to handle materials requiring more delicate cutting methods. Die cutters are designed to cut materials with a specific shape and size, making them less adaptable to cutting different designs or patterns.

Additionally, die cutters may struggle with intricate or detailed designs, as they’re not equipped to handle the precision required for such tasks. Furthermore, die cutters are limited in terms of the materials they can work with, often being limited to paper, cardboard, or thin plastic.

To overcome these limitations, alternative options such as diode laser cutters offer greater flexibility, precision, and the ability to work with a wider range of materials. This transition into the subsequent section about comparing features highlights the need to explore the benefits of diode laser cutters.

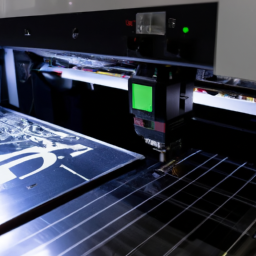

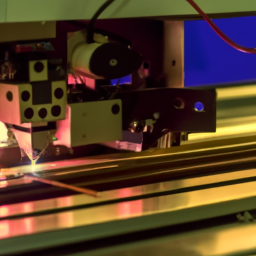

Comparing Features

When it comes to comparing features, diode laser cutters and die cutters offer distinct advantages for different types of projects.

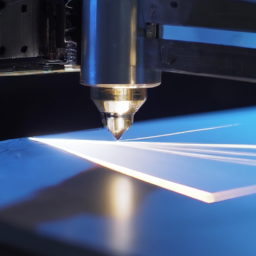

When comparing prices, die cutters tend to be more cost-effective upfront, as they have a lower initial investment. However, diode laser cutters offer long-term savings due to their lower maintenance and operating costs.

In terms of precision, diode laser cutters have the upper hand. They provide high levels of accuracy and can cut intricate designs with ease, making them ideal for projects that require fine details. Die cutters, on the other hand, may not offer the same level of precision and are better suited for simpler, repetitive cuts.

Evaluating capabilities, both types of cutters have their strengths and weaknesses, and choosing the right one depends on the specific needs of your project.

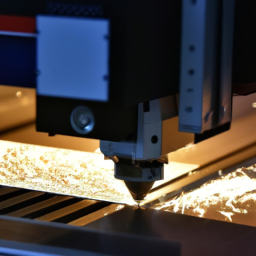

Evaluating Capabilities

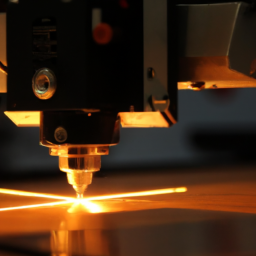

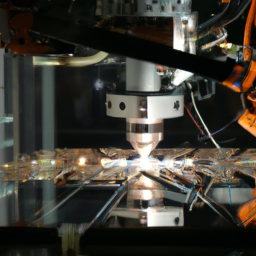

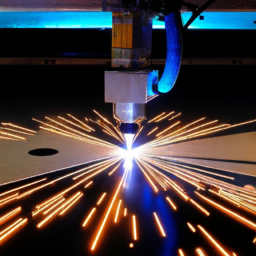

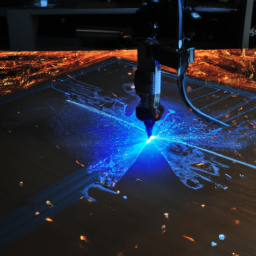

Now that we’ve compared the features of diode laser cutters and die cutters, let’s move on to evaluating their capabilities.

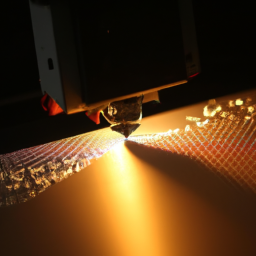

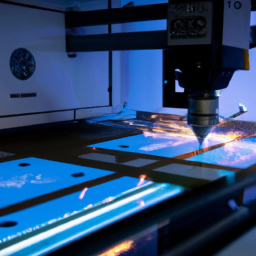

When it comes to precision, diode laser cutters offer a significant advantage. They use a focused laser beam to cut through material with extreme accuracy, allowing for intricate and detailed designs. On the other hand, die cutters rely on mechanical force to stamp out shapes, which may result in less precise cuts, especially for intricate patterns.

Speed is another important factor to consider. Diode laser cutters are known for their fast cutting speeds, as the laser beam can swiftly move across the material, reducing production time. Die cutters, on the other hand, may take longer to cut through materials, especially thicker ones that require more force.

Considering the precision and speed capabilities of both options, it’s clear that diode laser cutters have the edge in terms of efficiency and quality. However, the final aspect to consider is the cost-effectiveness, which we’ll explore next.

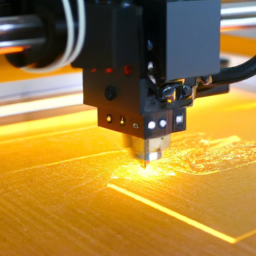

Considering Cost-effectiveness

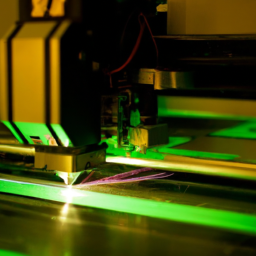

Consider the cost-effectiveness of these cutting options and make a wise investment for your business. When it comes to cost effectiveness, both diode laser cutters and die cutters have their advantages.

Diode laser cutters may initially seem more expensive due to their higher upfront cost, but they offer long-term savings through reduced maintenance and material waste. Their precision and versatility also allow for efficient production, increasing overall productivity and profitability.

On the other hand, die cutters have a lower initial cost, but their ongoing expenses can add up over time due to the need for frequent die replacements. It is important to carefully evaluate your business’s specific needs and projected usage to determine which option will provide the most cost-effective solution.

By considering cost effectiveness and long-term savings, you can make an informed decision that aligns with your business goals and maximizes profitability. Transitioning into the subsequent section, it is crucial to analyze other factors to make a well-rounded decision.

Making an Informed Decision

When making an informed decision between diode laser cutters and die cutters, there are three key points to consider.

First, assess your needs by evaluating the type and volume of materials you’ll be cutting, as well as any specific requirements or constraints you may have.

Second, weigh the pros and cons of each option, considering factors such as precision, speed, versatility, and maintenance costs.

Finally, consult experts and reviews to gather valuable insights and recommendations from those with experience in the field.

By following these steps, you can ensure that you make the best investment for your specific cutting needs.

Assessing Your Needs

Assessing one’s needs can help determine the most suitable investment between diode laser cutters and die cutters. When choosing between these options, it’s important to carefully evaluate your requirements.

Consider the following:

-

Material Types: Determine the range of materials you plan to work with. Diode laser cutters are versatile and can handle various materials such as wood, acrylic, and fabric. On the other hand, die cutters are better suited for cutting through thicker materials like leather and cardboard.

-

Cutting Precision: Evaluate the level of precision required for your projects. Diode laser cutters offer high precision and can create intricate designs with smooth edges. Die cutters, however, may not offer the same level of precision but are still suitable for simpler shapes and designs.

-

Cost and Maintenance: Take into account the initial investment and ongoing maintenance costs. Diode laser cutters tend to be more expensive upfront but require less frequent maintenance. Die cutters are generally more affordable but may require more regular maintenance and replacement of cutting dies.

By assessing your needs based on material types, cutting precision, and cost considerations, you can make an informed decision about which investment is the better choice for you.

Transitioning into the subsequent section about weighing the pros and cons, it’s important to consider all factors before finalizing your decision.

Weighing the Pros and Cons

Once you’ve carefully evaluated your needs and requirements, it’s time to weigh the pros and cons of each option to make an informed decision.

When considering long-term investment, diode laser cutters offer several advantages. They have a longer lifespan compared to die cutters, requiring less frequent replacement and maintenance. Diode lasers also provide precise and intricate cuts, making them ideal for intricate designs and delicate materials.

On the other hand, die cutters are more efficient for high-volume production, as they can cut multiple layers of material simultaneously. They’re also more cost-effective for large-scale projects.

Analyzing efficiency, diode laser cutters are faster and have a shorter setup time, while die cutters require more time for preparation.

To ensure you make the right choice, consulting experts and reviews will provide valuable insights into the strengths and limitations of each option. As you move forward, it’s important to gather as much information as possible to guide your decision-making process.

Consulting Experts and Reviews

If you want to make a well-informed decision, it’s like navigating through a maze of options, and consulting experts and reviews can act as your compass, guiding you towards the right choice.

When it comes to choosing between diode laser cutters and die cutters, seeking advice from experts in the field and reading reviews can provide valuable insights. Here are four reasons why consulting experts and reading reviews are essential in making the right investment:

-

Expert Knowledge: Experts can provide in-depth knowledge about the capabilities, limitations, and performance of both diode laser cutters and die cutters.

-

Real-Life Experiences: Reading reviews allows you to learn from the experiences of others who have used either type of cutter, giving you a realistic perspective on their performance and reliability.

-

Comparison of Features: Experts and reviews can help you compare the features of diode laser cutters and die cutters, allowing you to make an informed decision based on your specific needs and requirements.

-

Cost-Effectiveness: By consulting experts and reading reviews, you can determine which option offers better cost-effectiveness in terms of initial investment, maintenance, and overall productivity.

By utilizing the expertise of professionals and the experiences of others, you can make a well-informed decision when choosing between diode laser cutters and die cutters.

Frequently Asked Questions

Can diode laser cutters be used on all types of materials?

Diode laser cutters offer numerous advantages when it comes to cutting different materials. They have the ability to work on a wide range of materials, including wood, acrylic, fabric, and even metals. This versatility is due to the high power and precision of diode lasers.

In comparison, die cutters are limited in terms of material versatility as they rely on physical cutting dies. Therefore, diode laser cutters are a superior option when it comes to working with various materials.

How does the speed of die cutters compare to diode laser cutters?

When comparing die cutter speed to diode laser cutters, it’s like comparing a race car to a bicycle.

Die cutters are known for their high-speed performance, allowing for rapid production. However, diode laser cutters offer several advantages over die cutters.

While they may not be as fast, diode laser cutters provide greater precision, versatility, and the ability to work with a wider range of materials. This makes them a valuable investment for industries requiring intricate and diverse cutting capabilities.

Are there any limitations to the size of materials that can be cut using a diode laser cutter?

The size of materials that can be cut using a diode laser cutter is limited. Diode laser cutters typically have a smaller cutting area compared to die cutters, which makes them less suitable for cutting larger materials. On the other hand, die cutters offer the benefit of being able to handle larger materials due to their larger cutting areas.

Therefore, if you need to cut larger materials, die cutters would be a better choice.

What are the main maintenance requirements for a die cutter?

To properly maintain a die cutter, there are several maintenance requirements and troubleshooting tips to keep in mind.

Regularly inspect the machine for any signs of wear or damage, and clean it thoroughly after each use.

Lubricate moving parts to ensure smooth operation.

In case of any issues, consult the user manual or contact the manufacturer for troubleshooting assistance.

Following these maintenance practices will help prolong the lifespan and optimize the performance of your die cutter.

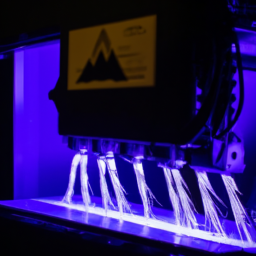

Can diode laser cutters be used for engraving or marking materials as well?

Yes, diode laser cutters can definitely be used for engraving or marking materials. In fact, they’re known for their versatility and wide range of applications. The advantages of using diode laser cutters include their high precision, speed, and ability to work with a variety of materials such as wood, acrylic, and metal. With their advanced technology and capabilities, diode laser cutters are an excellent choice for engraving or marking projects.

Conclusion

In conclusion, when it comes to investing in a cutting machine, considering the pros and cons of diode laser cutters and die cutters is crucial.

Both options offer unique features and capabilities that cater to different needs. However, it’s important to weigh these factors against the cost-effectiveness of each machine.

By carefully analyzing the specifications and considering your specific requirements, you can make an informed decision that suits your business needs. Remember, investing wisely in the right cutter can be a game-changer for your operations.