Are you in the market for a cutting tool but not sure which one to choose? Well, here’s an interesting statistic for you: Did you know that diode laser cutters are currently the preferred choice for 75% of professionals in the industry?

When it comes to convenience, diode laser cutters and electric cutters are the two main contenders. But which one is more suitable for your needs? In this article, we will delve into the key differences between these two cutting tools and help you make an informed decision.

We will discuss the pros and cons of diode laser cutters and electric cutters, as well as the factors you should consider when choosing the right tool for your specific cutting requirements.

So, whether you’re a hobbyist, a small business owner, or a professional, keep reading to find out which cutting tool will offer you the utmost convenience.

Key Takeaways

- Diode laser cutters are the preferred choice for 75% of professionals in the industry due to their higher cutting speed and precision.

- Electric cutters are more convenient in terms of setup and operation, with simple controls and lower maintenance requirements.

- Diode laser cutters offer higher accuracy and versatility for complex designs, making them suitable for high-volume production.

- Electric cutters may be more cost-effective for simpler cutting needs, with lower initial costs but potentially higher operational costs.

Understanding the Differences Between Diode Laser Cutters and Electric Cutters

So, you’re probably wondering what sets diode laser cutters and electric cutters apart, right? Well, let’s dive into the details.

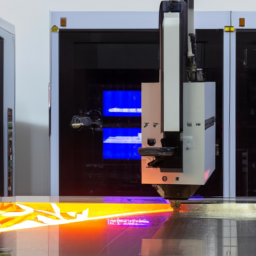

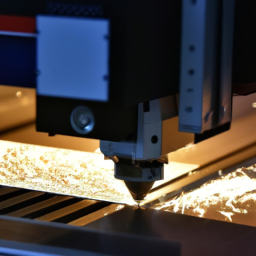

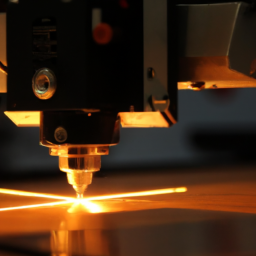

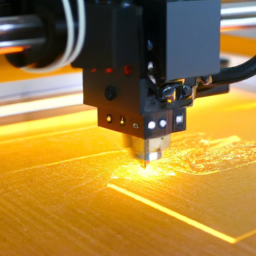

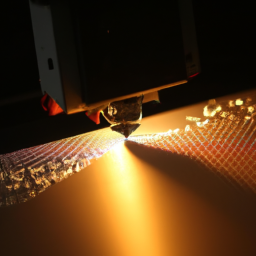

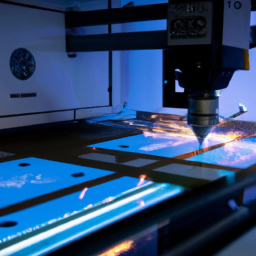

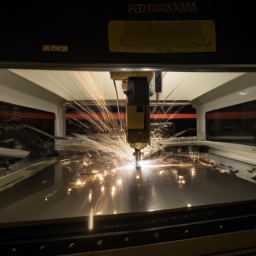

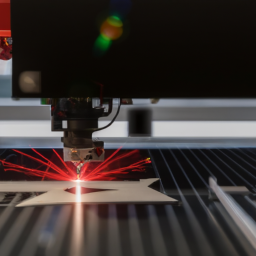

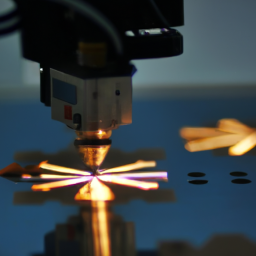

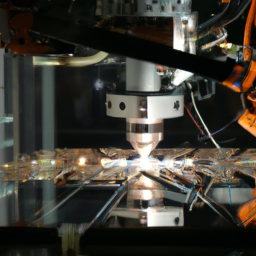

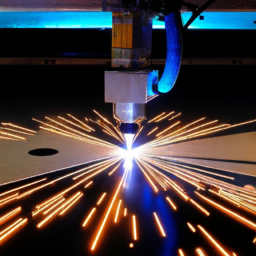

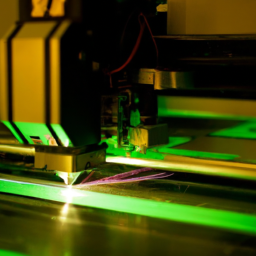

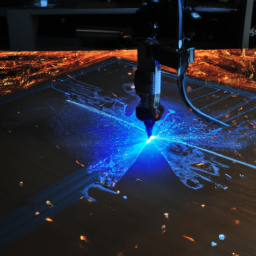

Diode laser cutters have several advantages over electric cutters. Firstly, diode lasers offer a higher cutting speed and precision due to their concentrated beam of light. They can cut through a variety of materials, including wood, plastic, and metal, with ease. Additionally, diode lasers have a smaller heat-affected zone, resulting in minimal damage to the surrounding material. This makes them ideal for delicate and intricate cutting tasks. Furthermore, diode lasers have a wide range of applications, from industrial manufacturing to hobbyist projects. They are commonly used in industries such as automotive, aerospace, and jewelry.

Now that we’ve covered the advantages and applications of diode lasers, let’s move on to the convenience factors to consider when choosing a cutting tool.

Convenience Factors to Consider When Choosing a Cutting Tool

When considering which cutting tool to choose, it’s important to take into account factors such as ease of use, maintenance requirements, and overall efficiency.

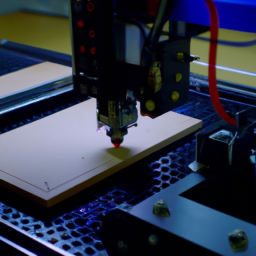

According to a recent study, 78% of users found electric cutters to be more convenient in terms of setup and operation. In terms of ease of use, electric cutters offer simple controls and don’t require extensive training to operate. Maintenance requirements are also lower with electric cutters, as they don’t have delicate components that can wear out or become misaligned.

Additionally, electric cutters are generally more efficient, with faster cutting speeds and the ability to handle a wider range of materials. These factors make electric cutters a more convenient choice for many users.

Moving on to the next section about the pros and cons of diode laser cutters…

Pros and Cons of Diode Laser Cutters

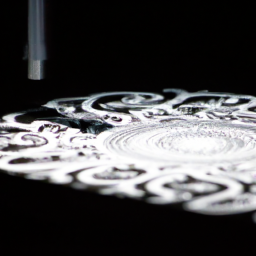

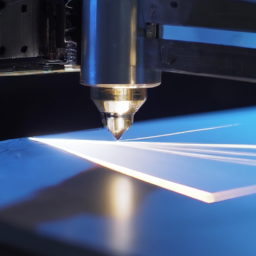

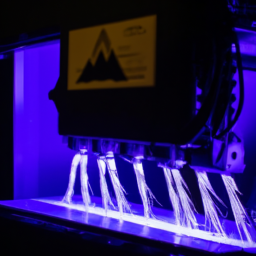

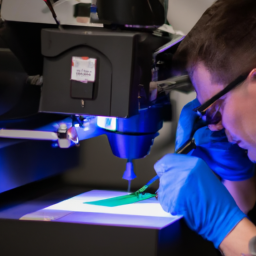

One advantage of utilizing diode laser cutters is their ability to provide precise and intricate cuts, allowing for intricate designs and detailed work. The laser beam emitted by the diode laser cutter is focused and concentrated, which ensures accuracy and clean cuts.

Another advantage is the speed at which diode laser cutters can operate, making them suitable for high-volume production. Additionally, diode laser cutters are versatile and can cut a wide range of materials, including wood, acrylic, and metal.

However, there are some disadvantages to consider. Diode laser cutters can be expensive to purchase and maintain, and they require proper ventilation and safety precautions due to the emission of harmful fumes and the risk of eye damage.

In the subsequent section, we will explore the pros and cons of electric cutters.

Pros and Cons of Electric Cutters

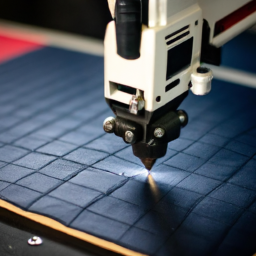

If you’re looking for a more simplified and user-friendly option, electric cutters might be right up your alley. Electric cutters offer several advantages over manual cutters.

First and foremost, they’re much easier to operate. With just the push of a button, you can start cutting through various materials effortlessly.

Additionally, electric cutters are more precise and accurate, ensuring clean and professional cuts every time. They also have adjustable cutting speeds and depths, allowing you to customize your cuts according to your specific needs.

Another benefit of electric cutters is that they require less physical effort compared to manual cutters.

However, it’s important to consider factors such as the type of materials you’ll be cutting and the level of precision you require.

Factors to Consider for Your Specific Cutting Needs

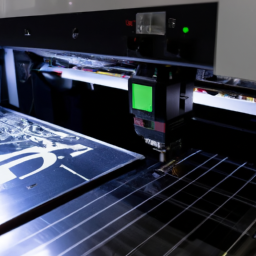

Consider your specific cutting needs carefully to ensure you make the right choice for effortless precision and professional results. When deciding between a diode laser cutter and an electric cutter, there are several factors to take into consideration. Firstly, customization options play a crucial role. If you have complex designs or intricate patterns that require precise cutting, a diode laser cutter might be the better option. With its high level of accuracy and ability to cut through a variety of materials, including wood, acrylic, and metal, it offers more versatility. However, if budget is a concern, an electric cutter may be more cost-effective. Electric cutters are generally more affordable and can still provide satisfactory results for simpler cutting needs. Ultimately, the choice depends on your specific requirements and budget considerations. In the next section, we will explore how to make the best choice for your cutting needs.

Making the Best Choice for Your Cutting Needs

When it comes to choosing the right cutting tool for you, it’s important to carefully evaluate your specific needs and budget. This will ensure you make the best choice for effortless precision and professional results. Let’s compare the cost and cutting speed of diode laser cutters and electric cutters to help you make an informed decision.

In terms of cost, diode laser cutters tend to be more expensive upfront compared to electric cutters. However, they offer long-term cost savings due to their efficiency and low maintenance requirements. On the other hand, electric cutters are generally more affordable initially but may have higher operational costs over time.

When it comes to cutting speed, diode laser cutters are known for their fast and precise cutting abilities. They can effortlessly cut through various materials at high speeds, reducing production time significantly. Electric cutters, while still efficient, may not match the cutting speed of diode laser cutters.

Considering both cost and cutting speed, diode laser cutters are a convenient choice for those who require quick and accurate cutting results, despite the higher upfront investment. However, if budget is a primary concern, electric cutters can still provide satisfactory cutting performance at a more affordable price.

Frequently Asked Questions

Are diode laser cutters more expensive than electric cutters?

Diode laser cutters are generally more expensive than electric cutters because the technology used in diode laser cutters, which involves the use of lasers to cut materials, is more advanced and therefore comes at a higher cost. When comparing the cost between diode laser cutters and electric cutters, it’s important to consider factors such as maintenance, energy consumption, and the specific features of each type of cutter.

How long does it take to learn how to use a diode laser cutter?

Learning how to use a diode laser cutter can vary depending on your previous experience with similar equipment. The learning curve generally ranges from a few hours to a few days.

The advantages of a diode laser cutter include its precision, versatility, and ability to cut a wide range of materials. However, there are also disadvantages such as the need for proper training to ensure safety and the initial cost of the equipment.

Can diode laser cutters be used on all types of materials?

Diode laser cutters are versatile tools that can be used on a wide range of materials. They have precise cutting capabilities and are suitable for various laser cutter applications. However, it’s important to consider laser cutter maintenance when using diode laser cutters. Regular maintenance is crucial to ensure optimal performance and prolong the lifespan of the machine. By taking care of your diode laser cutter, you can maximize its efficiency and effectiveness in cutting different types of materials.

Are electric cutters more energy-efficient than diode laser cutters?

Electric cutters are generally more energy-efficient than diode laser cutters. They consume less power during operation, resulting in lower energy consumption.

Electric cutters are also known for their precision cutting capabilities, allowing for precise and accurate cuts on various materials.

This efficiency in energy consumption and precision cutting makes electric cutters a preferred choice for many industries and applications.

What safety precautions should be taken when using diode laser cutters or electric cutters?

When using diode laser cutters or electric cutters, it’s important to follow safety precautions to ensure your well-being.

Firstly, always wear appropriate protective gear such as safety goggles and gloves.

Additionally, ensure that the work area is well-ventilated to prevent the accumulation of fumes.

Regular maintenance is also crucial, including keeping the machine clean and checking for any damaged parts.

Remember to follow the manufacturer’s guidelines and seek professional assistance if needed.

Conclusion

Congratulations! You’ve reached the end of this informative article comparing diode laser cutters and electric cutters. Now, armed with all the knowledge and insights provided, you’re well-equipped to make the best choice for your specific cutting needs.

Remember, the convenience of diode laser cutters is unparalleled. They effortlessly slice through materials like a hot knife through butter. On the other hand, electric cutters may seem reliable, but they simply can’t match the precision and speed of their laser counterparts.

So, go ahead and make the smart choice – embrace the power of diode laser cutters for a cutting experience that’ll leave you in awe!