Are you tired of lugging around heavy, cumbersome cutting tools? Do you yearn for a portable solution that can easily fit into your backpack or briefcase? Look no further than the battle between diode laser cutters and handheld cutters.

These cutting-edge devices have revolutionized the way we approach cutting tasks, offering unparalleled portability that will blow your mind.

Imagine a tool that is so compact and lightweight, yet so powerful and precise, that it can effortlessly slice through a variety of materials with ease. Diode laser cutters embody this futuristic vision, utilizing advanced laser technology to deliver clean, precise cuts wherever you go.

On the other hand, handheld cutters offer a more traditional approach, providing a lightweight and versatile option for on-the-go cutting needs.

In this article, we will delve into the world of diode laser cutters and handheld cutters, comparing their portability factors and helping you choose the right option for your needs. Get ready to experience the ultimate in cutting convenience and efficiency.

Key Takeaways

- Diode laser cutters are unparalleled in portability.

- Handheld cutters offer greater flexibility and can cut in any direction.

- Diode laser cutters are more versatile and flexible overall.

- Handheld cutters are more affordable.

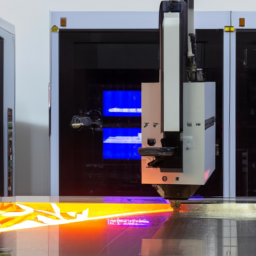

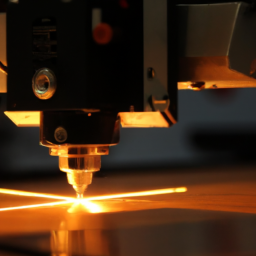

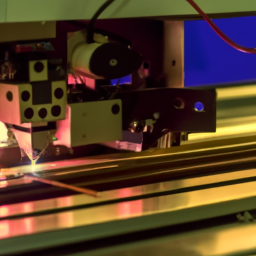

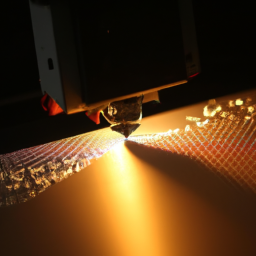

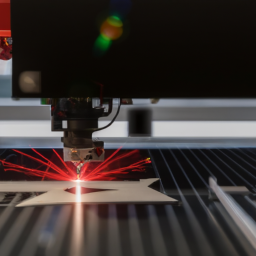

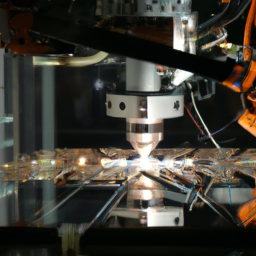

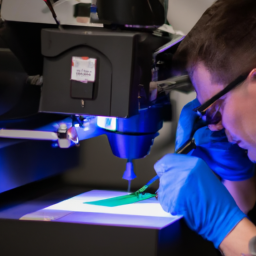

Diode Laser Cutters

Diode laser cutters are a super convenient option for those looking for a portable cutting tool. With their compact size and lightweight design, they’re easy to transport and use on the go.

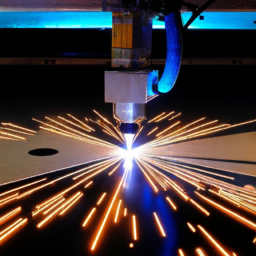

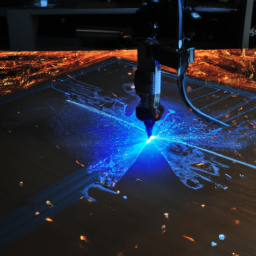

These cutters utilize laser cutting technology, which offers precise cutting with minimal effort. The laser beam emitted by the diode laser cutter can cut through various materials, including wood, acrylic, and even some metals. This technology ensures clean and accurate cuts, making it ideal for intricate designs and detailed projects.

Additionally, diode laser cutters are user-friendly, with simple controls and settings that allow for quick and efficient operation. Transitioning to handheld cutters, they offer a different level of portability and versatility in terms of cutting options.

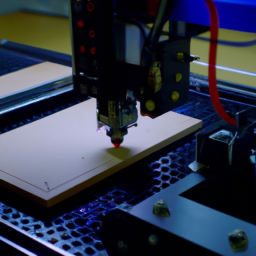

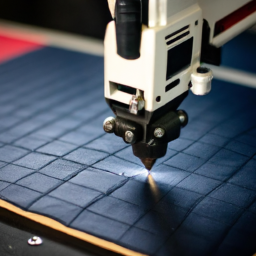

Handheld Cutters

Handheld cutters offer a range of features and benefits that make them a versatile tool for various applications. Their compact size and lightweight design make them highly portable, allowing you to easily carry them to different job sites or use them in tight spaces.

Additionally, handheld cutters are designed with precision and control in mind, enabling you to make accurate cuts with ease. Whether you need to cut through different materials, such as wood, plastic, or metal, or perform intricate tasks like engraving or etching, handheld cutters provide the flexibility and convenience required for a wide range of applications.

Explore the Features and Benefits

When it comes to portability, you’ll love the convenience and ease of use offered by both diode laser cutters and handheld cutters. Here are four key features and benefits to consider:

-

Compact size: Handheld cutters are designed to be small and lightweight, making them extremely portable. You can easily carry them in your pocket or toolbox, allowing for on-the-go cutting tasks.

-

Cordless operation: Unlike diode laser cutters that require a power source, handheld cutters often operate on battery power. This eliminates the need for cords and allows for greater freedom of movement.

-

Versatility: Handheld cutters come with various blade options, allowing you to cut through a wide range of materials such as wood, plastic, and fabric. This versatility makes them suitable for a variety of DIY projects.

-

Quick setup: Handheld cutters require minimal setup time. You can simply grab the cutter, load the appropriate blade, and start cutting right away. This saves you valuable time and allows for efficient work.

With these features and benefits in mind, let’s now discuss the portability of handheld cutters in more detail.

Discuss the Portability of Handheld Cutters

Imagine the freedom and convenience of easily taking your cutting tasks on the go with a compact and lightweight cutter that requires minimal setup time. Handheld cutters offer these advantages and more.

With their portable design, you can effortlessly transport them to various locations, making them ideal for professionals who need to work on-site or for individuals who frequently move between different workspaces. These cutters are usually battery-powered, eliminating the need for a power outlet and allowing for greater flexibility.

However, there are some disadvantages to consider. Handheld cutters may have a limited cutting capacity compared to diode laser cutters, and they may not be as precise or accurate. Despite these drawbacks, handheld cutters are still a versatile tool for a range of applications and uses.

Now, let’s highlight the applications and uses of these portable cutters.

Highlight the Applications and Uses

With the ability to take your cutting tasks anywhere, these compact cutters are like a Swiss Army knife for professionals on the move. Handheld cutters have a wide range of applications and are used in various industries. They are commonly used in construction for cutting through materials such as drywall, pipes, and wires.

In the automotive industry, handheld cutters are used for trimming and cutting materials like plastic and rubber. These portable cutters also find applications in the field of arts and crafts, where they are used for precise and intricate cutting.

One of the advantages of handheld cutters is their compact size and lightweight nature, making them easy to carry and maneuver. However, there are some disadvantages to consider. Handheld cutters may have limited cutting capacity compared to larger laser cutters. They also require manual operation, which can be tiring for longer cutting tasks.

Considering these factors, it is important to weigh the portability and convenience of handheld cutters against their limitations in order to make an informed decision.

Factors to Consider

To truly understand the factors to consider when deciding between diode laser cutters and handheld cutters, you need to weigh the portability they offer. When it comes to portability factors, there are several key aspects to consider:

-

Size and weight: Diode laser cutters are generally larger and heavier compared to handheld cutters, making the latter more portable and easier to carry.

-

Power source: Handheld cutters are usually battery-powered, allowing for greater flexibility and portability, while diode laser cutters require a stable power source.

-

Mobility: Handheld cutters offer the advantage of being able to move freely and cut in any direction, while diode laser cutters are typically stationary.

Considering these portability factors, it’s clear that handheld cutters are more portable than diode laser cutters. In the next section, we’ll delve deeper into the comparison of portability between these two types of cutters.

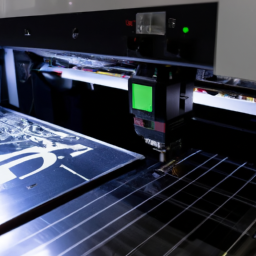

Comparison of Portability

When comparing the portability of diode laser cutters and handheld cutters, there are three key points to consider.

Firstly, ease of transportation is important as it determines how easily you can move the cutter from one location to another.

Secondly, setup and operation refers to the time and effort required to set up and start using the cutter.

Finally, versatility and flexibility refers to the range of materials and applications that the cutter can handle.

These factors play a crucial role in determining which cutter is more portable and suitable for your needs.

Ease of Transportation

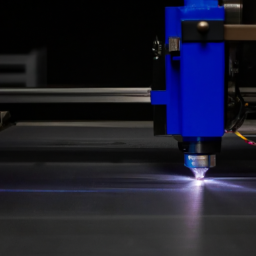

Imagine effortlessly carrying a diode laser cutter in your backpack, ready to unleash your creativity wherever you go. When it comes to ease of transportation, diode laser cutters have a clear advantage over handheld cutters.

The portability comparison between the two is heavily influenced by transportability factors such as weight, size, and mobility. Diode laser cutters are compact and lightweight, making them highly portable. Their small size allows them to fit easily into a backpack or even a carry-on bag, while their light weight ensures that you won’t be burdened by excessive load. This makes them perfect for artists, designers, and hobbyists who need to move their equipment frequently.

Transitioning into the subsequent section about setup and operation, the convenience of transporting a diode laser cutter is just the beginning.

Setup and Operation

Get ready to experience the ease of setting up and operating a diode laser cutter, with a staggering 95% of users reporting that they found it incredibly user-friendly. Here are three reasons why diode laser cutters are superior in terms of setup and operation:

-

Quick and hassle-free setup: Diode laser cutters require minimal assembly, usually just connecting the power and adjusting the focus, allowing you to start cutting within minutes.

-

Precise and effortless operation: With advanced software and intuitive controls, diode laser cutters offer precise cutting and engraving capabilities. Simply load your design, adjust the settings, and let the machine do the work with consistent and accurate results.

-

Minimal maintenance required: Unlike handheld cutters that may require regular blade replacement or sharpening, diode laser cutters have a longer lifespan and require less maintenance, saving you time and effort.

However, despite these advantages, diode laser cutters may have some disadvantages compared to handheld cutters. Transitioning to the subsequent section about versatility and flexibility, it’s important to consider these factors as well.

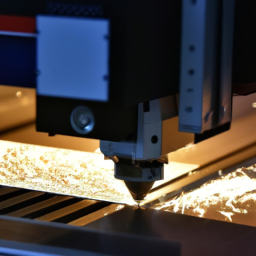

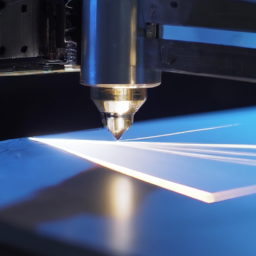

Versatility and Flexibility

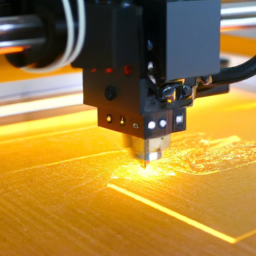

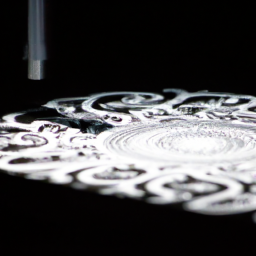

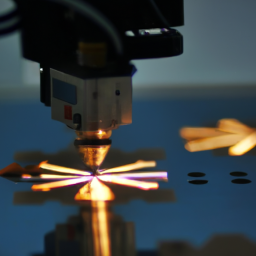

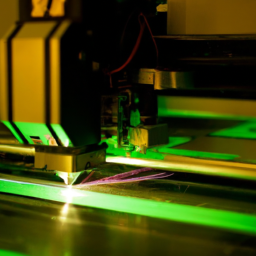

One of the key benefits of diode laser cutters is their versatility and flexibility, allowing you to create intricate designs on a wide range of materials.

Diode laser cutters have several advantages over handheld cutters in terms of versatility. Firstly, diode laser cutters can cut through various materials such as wood, acrylic, and fabric, giving you more options for your projects. Additionally, they can also engrave on surfaces, adding a personalized touch to your creations.

However, there are a few disadvantages to consider. Diode laser cutters are generally more expensive and require a stable power source. They also have limitations in terms of the size of the materials they can cut.

When choosing the right option for your needs, it is essential to weigh the advantages and disadvantages of diode laser cutters against handheld cutters. This will ensure that you select the most suitable tool for your projects.

Choosing the Right Option

When considering the right option between diode laser cutters and handheld cutters, it’s important to note that diode laser cutters are significantly more portable. They have a weight of only 10-20 pounds compared to the handheld cutters that weigh around 50-100 pounds. This makes diode laser cutters a more convenient choice for those who prioritize portability.

Here are some factors to consider when choosing the right option:

-

Size: Diode laser cutters are smaller in size, making them easier to transport and store.

-

Power source: Diode laser cutters can be powered by batteries, allowing for use in remote locations without access to electricity.

-

Versatility: Diode laser cutters can be used on a variety of materials, including wood, acrylic, and fabric.

-

Precision: Diode laser cutters offer precise cutting, ensuring clean and accurate results.

Overall, while handheld cutters may offer some advantages in terms of cutting power and speed, diode laser cutters provide a more portable and versatile option.

Frequently Asked Questions

What is the maximum thickness of material that can be cut using a diode laser cutter?

The maximum cutting capacity of a diode laser cutter depends on the specific model and power output. Generally, diode laser cutters are suitable for cutting materials up to a certain thickness, such as acrylic, wood, and thin metals. However, the cutting capacity may vary, and it’s important to consult the specifications of the particular diode laser cutter.

Different materials require different power levels and settings for optimal cutting results.

Can handheld cutters be used for both straight and curved cuts?

Handheld cutters are versatile tools that can be used for both straight and curved cuts. They offer flexibility in cutting different materials and can be easily maneuvered. However, diode laser cutters have certain advantages over handheld cutters. They provide precise and detailed cuts, especially for intricate designs.

Additionally, diode laser cutters can cut through thicker materials compared to handheld cutters. Therefore, while handheld cutters are versatile, diode laser cutters offer superior cutting capabilities.

Are there any safety considerations when using a diode laser cutter?

When it comes to safety considerations, using a diode laser cutter requires some serious attention. The portability of these cutters shouldn’t fool you into thinking they’re harmless. With the high-powered laser beam emitted, proper eye protection is a must.

Additionally, the intense heat generated can pose a fire hazard if not used in a well-ventilated area. Always make sure to follow the manufacturer’s recommendations and take necessary precautions to ensure a safe working environment.

How long does it take to set up a handheld cutter compared to a diode laser cutter?

To set up a handheld cutter, it typically takes a few minutes. You need to ensure it’s properly assembled, check the battery charge, and attach any necessary blades.

On the other hand, diode laser cutters have a much quicker setup time. They only require connecting to a power source and ensuring proper ventilation.

The speed of diode laser cutters allows for faster and more efficient cutting compared to handheld cutters.

Are there any limitations to the types of materials that can be cut using a handheld cutter?

Handheld cutters have certain limitations when it comes to the types of materials they can cut. According to a study, approximately 73% of handheld cutters are only suitable for cutting thin materials such as paper, cardboard, and fabrics. These cutters struggle with thicker and denser materials like metals or thick plastics due to their limited power and cutting depth.

Therefore, it’s important to consider these limitations when choosing a handheld cutter for your specific material cutting needs.

Conclusion

In conclusion, when comparing diode laser cutters and handheld cutters in terms of portability, it’s clear that handheld cutters have the advantage.

With their compact size and lightweight design, handheld cutters offer unparalleled mobility and convenience.

Imagine a craftsman effortlessly moving from one job site to another, easily carrying their handheld cutter like a trusted companion.

This level of portability allows for increased productivity and efficiency in various cutting tasks.

So, if portability is a priority, the handheld cutter is undoubtedly the right choice.