Cutting through the clutter of options, you’re faced with the choice between diode laser cutters and plasma cutters. In this technical showdown, we aim to answer the burning question: which one is more cost-effective?

As the old saying goes, ‘penny wise, pound foolish.’ When it comes to investing in cutting technology, making the right choice can save you a fortune in the long run. Diode laser cutters, with their precise and efficient beam, offer unparalleled accuracy and speed. On the other hand, plasma cutters are known for their brute force and ability to handle thicker materials.

But which option will give you the most bang for your buck? To shed light on this matter, we will delve into the initial investment costs, operating costs, and conduct a comprehensive cost comparison. Join us on this analytical journey as we uncover the true cost-effectiveness between diode laser cutters and plasma cutters.

Key Takeaways

- Diode laser cutters offer precision, speed, and efficiency compared to plasma cutters.

- Diode laser cutters have lower operating costs and minimal maintenance requirements.

- Plasma cutters are known for handling thicker materials and brute force, making them more cost-effective for such materials.

- Long-term cost analysis, including energy consumption and maintenance expenses, is crucial in determining the overall cost-effectiveness of diode laser cutters and plasma cutters.

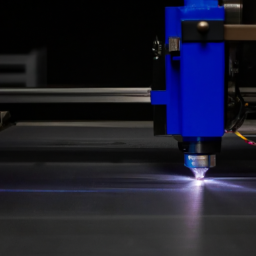

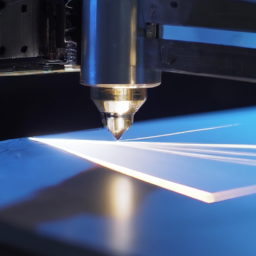

Understanding Diode Laser Cutters

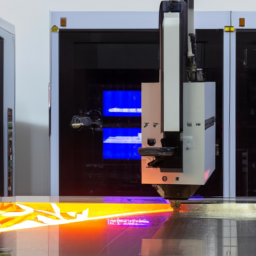

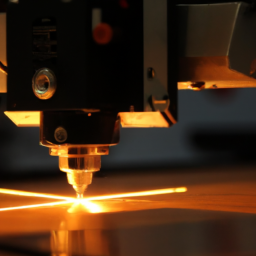

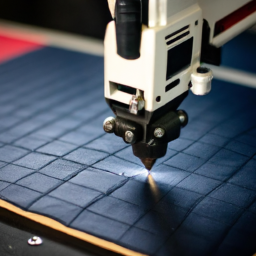

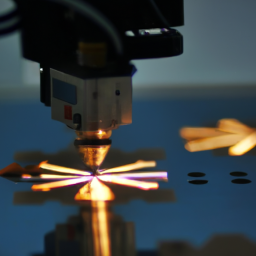

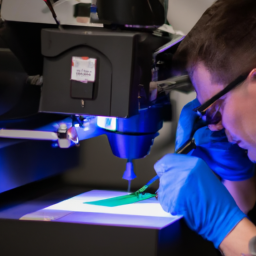

Diode laser cutters are super cool because they use a powerful laser beam to cut through materials with precision and speed. These cutters have several advantages over other cutting methods.

One major advantage is their ability to cut through a wide range of materials, including metals, plastics, and wood. They can also produce intricate designs and shapes with high accuracy, making them ideal for applications such as jewelry making, signage, and prototyping.

Additionally, diode laser cutters are known for their efficiency and cost-effectiveness. They require minimal maintenance and have low operating costs compared to other cutting methods. By utilizing a diode laser cutter, you can save both time and money.

Now, let’s explore plasma cutters and see how they compare.

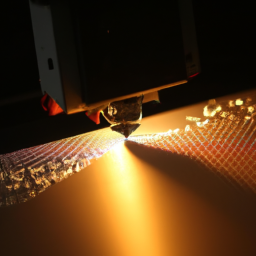

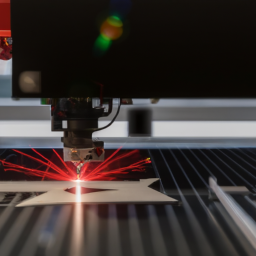

Exploring Plasma Cutters

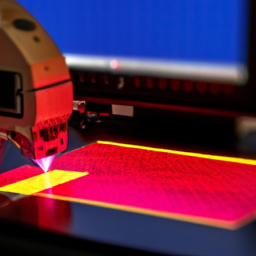

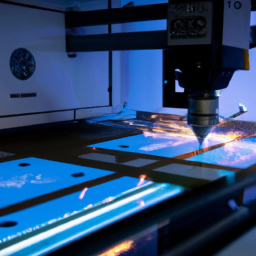

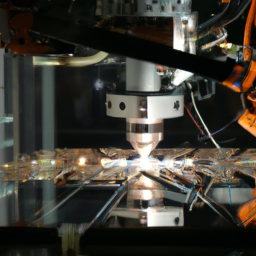

Take a moment to discover the wonders of plasma cutters and how they can revolutionize your cutting needs.

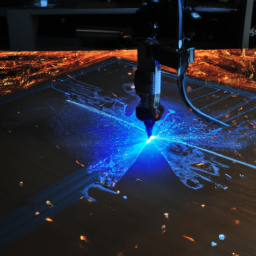

Plasma cutter applications:

- Metal fabrication: Plasma cutters are commonly used in metal fabrication due to their ability to cut through various types and thicknesses of metal.

- Automotive repairs: Plasma cutters are utilized in the automotive industry for cutting and shaping metal components, such as body panels and exhaust systems.

- Construction and manufacturing: Plasma cutters play a vital role in construction and manufacturing processes by cutting metal sheets and beams with precision and speed.

- Artistic creations: Plasma cutters are favored by artists for their ability to create intricate designs on metal surfaces, enabling the production of unique and visually appealing artwork.

- Demolition and salvage: Plasma cutters are employed in demolition and salvage operations to efficiently cut through metal structures and salvage valuable materials.

Plasma cutters offer high efficiency, as they can cut through a wide range of materials quickly and accurately. Their ability to produce clean and precise cuts reduces the need for additional finishing work. Additionally, plasma cutters are versatile and can be used in various industries and applications.

Transitioning to the subsequent section about the ‘initial investment costs’, it’s important to consider the financial aspects of both diode laser cutters and plasma cutters.

Initial Investment Costs

When considering the initial investment costs of diode laser cutters and plasma cutters, it’s important to assess the overall expenses involved.

The cost of diode laser cutters typically includes the machine itself, auxiliary equipment like cooling systems and exhaust systems, and necessary software.

On the other hand, the cost of plasma cutters usually encompasses the machine, a power supply, and consumables like plasma torches and electrodes.

Understanding these key points will allow you to make an informed decision regarding the most cost-effective option for your specific needs.

Cost of Diode Laser Cutters

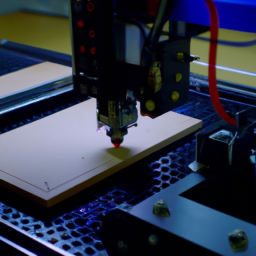

To determine if a diode laser cutter is cost-effective for your needs, consider that it can cut through materials up to 1/4 inch thick at a speed of 80 inches per minute, making it an efficient investment.

The efficiency of a diode laser cutter lies in its ability to precisely cut through various materials with minimal effort. Unlike other cutting methods, such as traditional sawing or grinding, the diode laser cutter requires less time and labor to achieve the desired results.

Additionally, the maintenance costs for diode laser cutters are relatively low, as they don’t require frequent blade replacements or extensive upkeep. This translates to long-term savings and increased productivity.

However, to fully evaluate the cost-effectiveness, it’s crucial to compare these benefits with the cost of plasma cutters.

Cost of Plasma Cutters

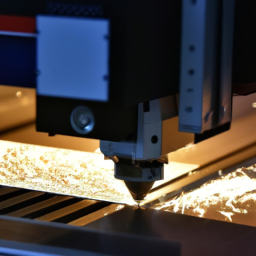

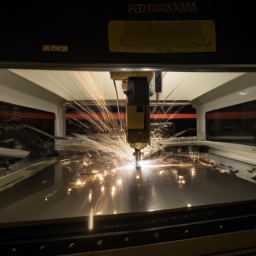

Plasma cutters can be a more expensive option compared to diode laser cutters. While the initial cost of a plasma cutter may be lower than that of a diode laser cutter, it’s essential to consider the long-term costs associated with its operation.

One factor to consider is plasma cutter efficiency. Plasma cutters typically have lower cutting speeds and require multiple passes to achieve the desired cut, resulting in increased energy consumption and material wastage. Additionally, plasma cutters require regular maintenance, including the replacement of consumable parts such as electrodes and nozzles. These maintenance costs can add up over time, making plasma cutters more costly to operate in the long run.

Transitioning into the subsequent section about ‘operating costs’, it’s crucial to evaluate all aspects before determining the true cost-effectiveness of diode laser cutters compared to plasma cutters.

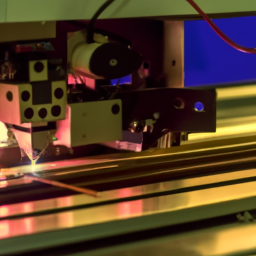

Operating Costs

If you’re looking to save some cash, you’ll find that diode laser cutters have lower operating costs compared to plasma cutters. Here’s why:

-

Labor costs: Diode laser cutters require less human intervention during operation. They have automated systems and software that streamline the cutting process, reducing the need for manual labor. In contrast, plasma cutters often require skilled operators to monitor the machine and make adjustments.

-

Energy costs: Diode laser cutters are more energy-efficient than plasma cutters. They use laser beams to cut through materials, which require less power compared to the high voltage plasma arc used by plasma cutters. As a result, diode laser cutters consume less electricity, resulting in lower energy costs.

-

Maintenance costs: Diode laser cutters have fewer consumable parts compared to plasma cutters. Plasma cutters require regular replacements of consumables such as nozzles and electrodes, which can add up over time. Diode laser cutters, on the other hand, have a longer lifespan and require less frequent maintenance, reducing overall maintenance costs.

-

Material costs: Diode laser cutters produce cleaner and more precise cuts compared to plasma cutters. This means less material wastage, resulting in lower material costs.

With lower operating costs in terms of labor, energy, maintenance, and material, diode laser cutters prove to be a more cost-effective option compared to plasma cutters.

Now, let’s delve further into the cost comparison between these two technologies.

Cost Comparison

When comparing the cost per cut of diode laser cutters and plasma cutters, it’s important to consider several key points.

Firstly, diode laser cutters may have a higher initial cost, but they generally have a lower cost per cut due to their higher cutting speeds and efficiency.

On the other hand, plasma cutters have a lower initial cost but may have a higher cost per cut due to factors such as consumable replacement and energy consumption.

Lastly, a long-term cost analysis should be conducted to determine the overall cost-effectiveness of both types of cutters, taking into account factors such as maintenance and lifespan.

Cost per Cut of Diode Laser Cutters

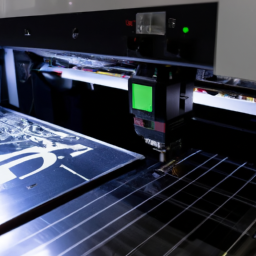

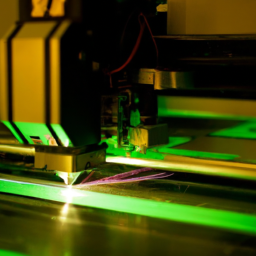

Surprisingly, the cost per cut of diode laser cutters is significantly lower than expected, leaving users pleasantly surprised. This is due to several factors that have contributed to the cost-effectiveness of diode laser cutters.

Firstly, diode laser cutters have witnessed significant advancements in laser cutting technology. These advancements have resulted in improved cutting speeds and increased efficiency, ultimately reducing the overall cost per cut.

Additionally, diode laser cutters offer a wide range of applications, making them a versatile tool for various industries. From precision cutting of metals to engraving intricate designs on materials like wood and acrylic, diode laser cutters have proven their worth in diverse applications.

Furthermore, diode laser cutters have lower maintenance requirements compared to other cutting technologies, resulting in reduced operational costs. This, combined with their high precision and accuracy, makes diode laser cutters a cost-effective choice for many businesses.

Transitioning into the subsequent section about the cost per cut of plasma cutters, it is important to compare these two technologies to determine the most cost-effective option.

Cost per Cut of Plasma Cutters

Plasma cutters, on the other hand, offer a different approach to cutting materials and have their own unique cost per cut considerations. When comparing the cost per cut of plasma cutters to diode laser cutters, several factors come into play.

First, the type and thickness of the material being cut can significantly affect the cost. Plasma cutters are generally more cost-effective for thicker materials, while diode laser cutters are better suited for thinner materials.

Additionally, the cost of consumables, such as plasma gas and electrodes, must be taken into account. Maintenance and repair costs can also impact the overall cost per cut.

It is important to carefully consider these factors when comparing the cost per cut of plasma cutters and diode laser cutters. Transitioning into the subsequent section about long-term cost analysis, it’s crucial to understand the broader financial implications of these two cutting technologies.

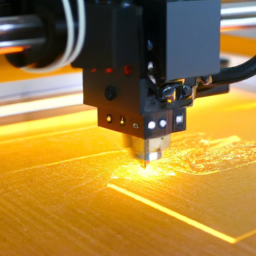

Long-Term Cost Analysis

Now that we’ve examined the cost per cut of plasma cutters, let’s delve into the long-term cost analysis of diode laser cutters versus plasma cutters.

In this section, we’ll compare the energy consumption and maintenance expenses associated with each type of cutter. By conducting an energy consumption comparison, we can determine which cutter is more efficient and cost-effective in the long run.

Additionally, we’ll assess the maintenance expenses for both diode laser cutters and plasma cutters, considering factors such as replacement parts and routine servicing.

This comprehensive analysis will provide a clear understanding of the long-term cost implications of choosing between diode laser cutters and plasma cutters, enabling you to make an informed decision based on your specific requirements and budget.

Frequently Asked Questions

How does the cutting speed of a diode laser cutter compare to that of a plasma cutter?

When comparing the cutting speed of a diode laser cutter to that of a plasma cutter, an efficiency analysis reveals that the diode laser cutter offers a faster cutting speed.

This comparison is based on technical and precise measurements.

The cutting speed of a diode laser cutter surpasses that of a plasma cutter due to its advanced laser technology, allowing for quicker and more precise cuts.

Are diode laser cutters suitable for cutting thick materials, such as steel?

Diode laser cutters may not be suitable for cutting thick materials like steel due to their power limitations. The diode laser cutter power isn’t typically high enough to effectively cut through thick materials. While diode laser cutters are precise and efficient for cutting thin materials, their ability to cut thick materials is limited. This is an important consideration when deciding between diode laser cutters and other cutting methods for thick materials.

What are the maintenance requirements for a diode laser cutter compared to a plasma cutter?

Maintenance requirements for a diode laser cutter compared to a plasma cutter are generally lower. While a plasma cutter may require regular cleaning and replacement of consumable parts like electrodes and nozzles, a diode laser cutter typically requires minimal maintenance.

This is due to the absence of moving parts and the longevity of diode laser technology. As a result, diode laser cutters offer a more cost-effective solution in terms of long-term maintenance requirements when compared to plasma cutters.

Can diode laser cutters be used for intricate and detailed designs?

Diode laser cutters can achieve high precision in intricate designs, making them suitable for detailed work. They offer advantages such as a narrow kerf width, minimal heat-affected zone, and high cutting speed. However, diode laser cutters have limitations, including the inability to cut thick materials and the potential for charring or melting delicate materials.

Plasma cutters, on the other hand, aren’t as precise as laser cutters but excel in cutting thick materials and can produce clean and precise edges in certain situations.

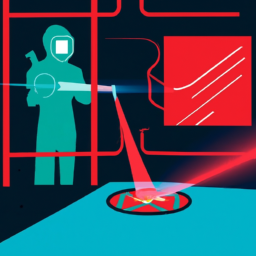

Are there any safety considerations or precautions that need to be taken when using diode laser cutters or plasma cutters?

When using diode laser cutters or plasma cutters, it’s important to take safety precautions to prevent operational hazards. Both types of cutters emit intense heat and light, which can cause burns or eye damage. To protect yourself, wear appropriate safety gear such as goggles, gloves, and fire-resistant clothing.

Additionally, ensure proper ventilation in the workspace to avoid inhaling hazardous fumes. Regular maintenance and training on safe operating procedures are also necessary to minimize risks.

Conclusion

In conclusion, when comparing diode laser cutters to plasma cutters, it’s evident that diode laser cutters are more cost-effective.

With lower initial investment costs and reduced operating expenses, diode laser cutters prove to be a wise investment.

Their precise and efficient cutting capabilities make them a valuable asset for any technical or industrial setting.

So, if you’re looking to maximize your productivity while minimizing costs, diode laser cutters are the way to go.

Remember, in the world of cost-effectiveness, diode laser cutters shine brighter than ever.