Are you tired of spending hours on end trying to cut through various materials with traditional tools? Imagine a world where precision and efficiency are at your fingertips, where intricate designs can be effortlessly brought to life. In the realm of cutting technology, two powerhouses stand out: diode laser cutters and rotary cutters. These cutting-edge machines are revolutionizing industries across the board, providing unparalleled precision and speed.

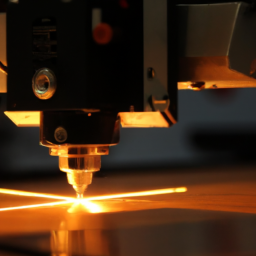

Picture a diode laser cutter, its focused beam of light slicing through materials like a hot knife through butter. Alternatively, envision a rotary cutter, its precise blades spinning at lightning speed, effortlessly gliding through even the toughest of substances. But which one reigns supreme in terms of efficiency?

In this article, we will delve into the intricacies of diode laser cutters and rotary cutters, exploring their applications and efficiency factors. By the end, you’ll have the knowledge to choose the perfect cutter for your needs. Get ready to experience the epitome of cutting technology.

Key Takeaways

- Diode laser cutters offer precision and speed, but struggle with thick materials and are expensive to purchase and maintain.

- Rotary cutters have spinning blades for precise cuts and faster cutting speeds, but may struggle with thicker materials and require a flat surface.

- Diode laser cutters are popular among DIY enthusiasts and hobbyists for affordability and ease of use, while rotary cutters are affordable and widely available.

- Diode laser cutters have industrial uses in automotive, aerospace, and electronics industries, while rotary cutters excel at cutting fabric, paper, and thin plastics.

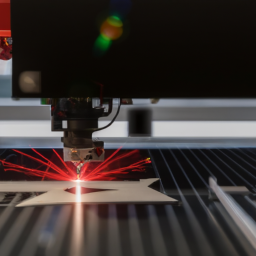

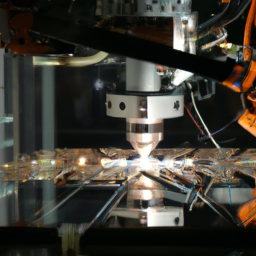

Overview of Diode Laser Cutters

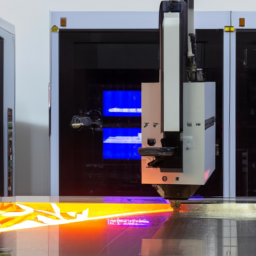

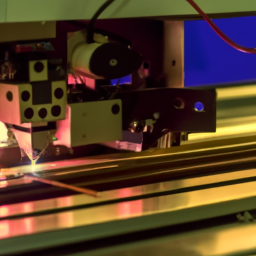

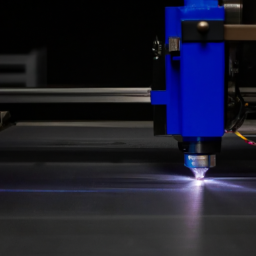

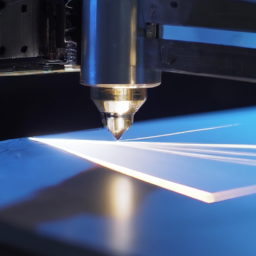

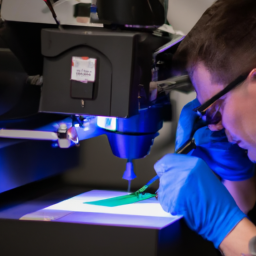

Diode laser cutters, with their precise and versatile capabilities, are revolutionizing the world of cutting technology. These cutters utilize a diode laser beam to cut through various materials with exceptional accuracy. One of the key advantages of diode laser cutters is their ability to make intricate and complex cuts with minimal material wastage.

They can effortlessly handle a wide range of materials, including wood, acrylic, fabric, and even metal. Additionally, diode laser cutters offer high cutting speeds, resulting in increased productivity. However, there are some limitations to consider. They’re not suitable for cutting thick materials, as the laser beam may struggle to penetrate them effectively. Moreover, diode laser cutters can be quite expensive to purchase and maintain.

Nonetheless, despite these limitations, diode laser cutters remain a popular choice for many industries.

Now, let’s delve into the overview of rotary cutters.

Overview of Rotary Cutters

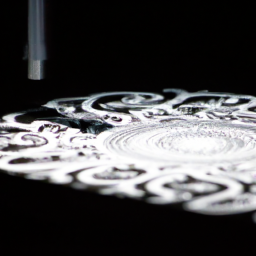

Comparing the two options, the rotary cutter swiftly glides through materials with a spinning motion, reminiscent of a sharp blade effortlessly slicing through butter. Its advantages include:

-

Versatility: The rotary cutter can handle a wide range of materials, such as fabric, paper, and thin plastics, making it suitable for various applications.

-

Precision: With its spinning motion, the rotary cutter provides precise cuts, allowing for intricate designs and clean edges.

-

Speed: Thanks to its continuous rotation, the rotary cutter can cut materials at a faster pace compared to other cutting methods.

However, the rotary cutter also has its limitations. It may struggle with thicker or tougher materials, and the spinning motion can result in some fraying or unraveling of fabric edges. Additionally, the rotary cutter requires a flat surface for optimal performance.

Considering these factors, let’s now delve into the efficiency aspects to consider when choosing between diode laser cutters and rotary cutters.

Efficiency Factors to Consider

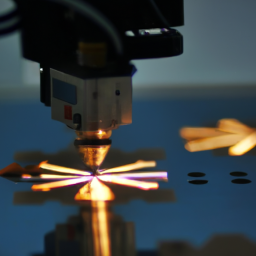

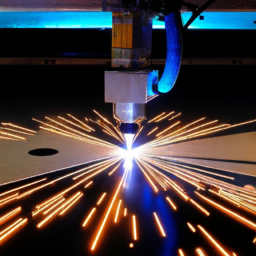

When considering efficiency factors, it’s important to look at the time-saving benefits and precision of each cutting option. In an efficiency comparison between diode laser cutters and rotary cutters, a cost effectiveness analysis is crucial.

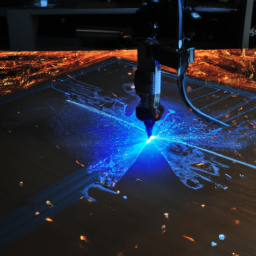

Diode laser cutters offer advantages such as faster cutting speeds and the ability to cut intricate designs with high accuracy. They utilize a focused laser beam to vaporize or melt material, resulting in clean and precise cuts.

Rotary cutters, on the other hand, use a spinning blade to cut through materials. While they are generally slower than diode laser cutters, they are still efficient for certain applications.

Transitioning into the subsequent section about ‘applications for diode laser cutters’, it is important to understand the efficiency factors in order to determine the most suitable cutting option for specific needs.

Applications for Diode Laser Cutters

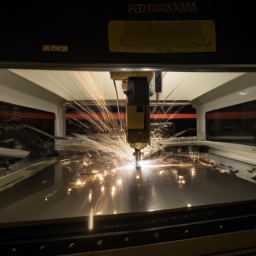

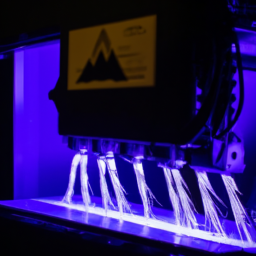

When considering the applications for diode laser cutters, it’s important to note their wide range of industrial uses.

These cutters are commonly employed in industries such as automotive, aerospace, and electronics for precise and efficient cutting of various materials.

Additionally, diode laser cutters have gained popularity among DIY enthusiasts and hobbyists due to their versatility and ease of use.

Lastly, these cutters have also found their place in the artistic and creative fields, offering artists the ability to intricately cut and engrave various materials to create unique and detailed artwork.

Industrial uses

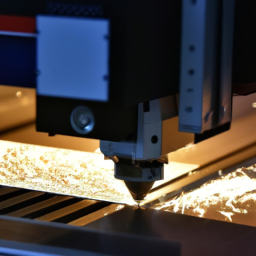

In the world of industrial applications, diode laser cutters outshine rotary cutters like a shooting star in the night sky. Their superior performance and cost effectiveness make them the go-to choice for many industrial users. Here are five reasons why diode laser cutters are widely used in the industrial sector:

-

Enhanced precision: Diode laser cutters offer unmatched accuracy, ensuring precise cuts even on complex materials.

-

Versatility: These cutters can handle a wide range of materials, including metals, plastics, and fabrics, making them suitable for various industrial applications.

-

Speed: Diode laser cutters are incredibly fast, enabling efficient production processes and high throughput.

-

Minimal maintenance: With fewer moving parts, diode laser cutters require minimal maintenance, reducing downtime and increasing productivity.

-

Cost savings: These cutters have lower operating costs compared to rotary cutters, thanks to their energy efficiency and longer lifespan.

Transitioning to the subsequent section about ‘diy and hobbyist uses’, diode laser cutters also find immense popularity among enthusiasts and hobbyists for their affordability and ease of use.

DIY and hobbyist uses

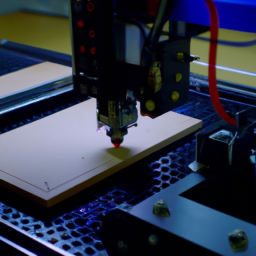

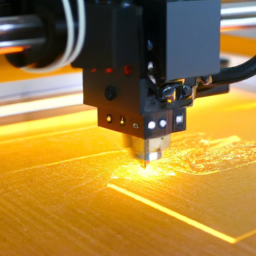

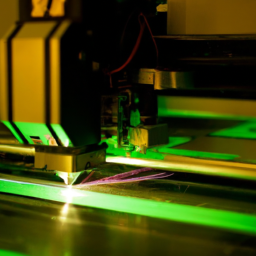

The world of DIY and hobbyist projects lights up with excitement when diode laser cutters make their appearance, offering an affordable and user-friendly tool for creative enthusiasts.

In the realm of DIY woodworking and crafting projects, diode laser cutters have proven to be a game-changer. With their precise cutting capabilities, these machines provide hobbyists with the ability to create intricate designs and patterns in a wide range of materials. Whether you’re working on a small wooden box or a delicate paper craft, a diode laser cutter can effortlessly bring your vision to life.

The versatility and accuracy of these machines make them a must-have for any DIY enthusiast.

Transitioning into the subsequent section about ‘artistic and creative uses’, diode laser cutters also open up a whole new world of possibilities for artistic expression and creative projects.

Artistic and creative uses

Let your imagination soar with the endless artistic possibilities that arise when using a diode laser cutter for your creative projects. A diode laser cutter opens up a world of artistic uses and creative applications. It offers precision and versatility, allowing you to create intricate designs on wood, acrylic, or even fabric. With ease, you can achieve precise cuts and engraving. The diode laser cutter is perfect for creating stunning customized jewelry, personalized home decor, or even intricate paper art. It works with various materials and offers a high level of accuracy, making it a valuable tool for artists and creatives alike.

Transitioning to the subsequent section, exploring the applications for rotary cutters, you’ll discover another tool that offers unique benefits for creative projects.

Applications for Rotary Cutters

When it comes to fabric and textile cutting, rotary cutters offer a precise and efficient solution. They allow you to easily cut through various types of fabric, ensuring clean edges and reducing fraying.

Additionally, rotary cutters are also a popular choice for paper and cardboard cutting, providing accurate and smooth cuts for various crafting and packaging needs.

Lastly, when it comes to leather and vinyl cutting, rotary cutters excel in their ability to slice through these materials with precision, making them a valuable tool in industries such as fashion and upholstery.

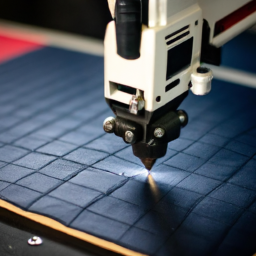

Fabric and textile cutting

Imagine how a diode laser cutter can effortlessly weave through fabric like a skilled tailor, while a rotary cutter struggles to cut through the layers, like a dull needle pushing through a stubborn fabric.

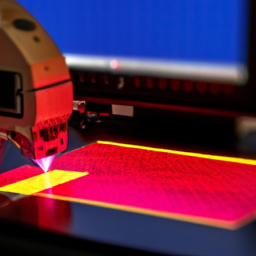

When it comes to fabric and textile cutting, diode laser cutters offer unparalleled precision and efficiency. The focused laser beam quickly cuts through various fabric types, including delicate materials, leaving clean edges without fraying. Unlike rotary cutters, which can snag or pull on the fabric, the laser cutter glides smoothly, ensuring precise and accurate cuts every time.

Additionally, the laser cutter can create intricate patterns and designs on fabric, enhancing its versatility for fabric and textile stitching and dyeing processes.

Now, let’s explore how diode laser cutters perform when it comes to paper and cardboard cutting.

Paper and cardboard cutting

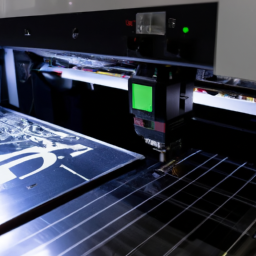

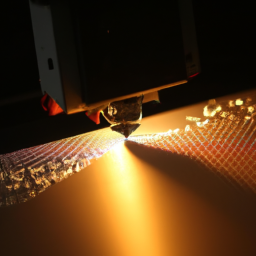

Paper and cardboard cutting with a diode laser cutter is a game-changer, effortlessly transforming mundane materials into intricate works of art. When comparing precision and accuracy in paper cutting techniques, the diode laser cutter reigns supreme. Its focused laser beam allows for intricate designs and clean cuts, ensuring minimal wastage.

The speed and versatility of the diode laser cutter also have a significant impact on cardboard cutting efficiency. With its ability to quickly cut through thick cardboard, it outperforms rotary cutters in terms of time and effort. Additionally, the diode laser cutter can effortlessly handle intricate designs and curves, providing a level of precision that rotary cutters simply cannot match.

Transitioning into the subsequent section about leather and vinyl cutting, the diode laser cutter continues to showcase its superiority in various applications.

Leather and vinyl cutting

Moving on to leather and vinyl cutting, these materials require a different approach compared to paper and cardboard. When it comes to cutting leather and vinyl, precision is of utmost importance. The thickness of the material plays a crucial role in determining the cutting method to be used. Leather and vinyl can vary in thickness, ranging from thin to thick. Diode laser cutters are highly efficient when it comes to cutting through thin leather and vinyl, providing clean and precise cuts. On the other hand, rotary cutters excel at cutting through thicker leather and vinyl, where the added pressure and continuous motion of the blade are needed. To determine the ideal cutting method, it is essential to consider the thickness of the material and the desired precision. Choosing the right cutter for your needs will depend on these factors and more.

Choosing the Right Cutter for Your Needs

When deciding on the right cutter for your needs, envision the precise cuts of a diode laser and the versatility of a rotary cutter, both beckoning you to choose the tool that’ll bring your creative ideas to life. Consider the following factors:

-

Advantages of Rotary Cutters:

- Can easily cut through thick materials like leather and vinyl.

- Ideal for intricate designs and curves.

- Affordable and widely available.

- Can be used without electricity, making them portable.

-

Disadvantages of Diode Laser Cutters:

- Limited to cutting thin materials due to heat damage.

- Expensive and require regular maintenance.

- Require a power source for operation.

- Safety precautions must be taken to prevent eye damage from laser beams.

By weighing these factors, you can make an informed decision about which cutter is best suited for your specific needs and preferences.

Frequently Asked Questions

What is the maximum thickness of material that can be cut using a diode laser cutter?

The maximum thickness of material that can be cut using a diode laser cutter depends on multiple factors, such as the power of the laser and the type of material. Generally, diode laser cutters have cutting capabilities of up to 10mm for certain materials like acrylic and wood, while thinner materials like paper and fabric can be cut with even greater precision.

However, it’s important to note that the maximum thickness may vary depending on the specific diode laser cutter model and its specifications.

Can a rotary cutter be used on non-traditional materials like rubber or foam?

When it comes to cutting non-traditional materials like rubber or foam, using a rotary cutter does have its limitations. The blade of a rotary cutter may struggle to make clean cuts on these materials, resulting in jagged edges and imprecise shapes. On the other hand, a diode laser cutter offers significant advantages. Its precise laser beam can effortlessly cut through rubber or foam, creating smooth and accurate cuts.

This makes the diode laser cutter a superior choice for working with such materials.

Are diode laser cutters more expensive to purchase and maintain compared to rotary cutters?

Diode laser cutters are significantly more expensive to purchase and maintain compared to rotary cutters. On average, a diode laser cutter can cost anywhere from $5,000 to $50,000, depending on the power and capabilities. Additionally, the maintenance costs can be quite high, with regular replacement of laser tubes and other components.

In contrast, rotary cutters are much more affordable and require minimal maintenance. Therefore, if cost is a major consideration, rotary cutters are a more budget-friendly option.

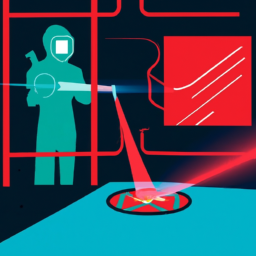

What safety precautions should be taken when operating a diode laser cutter?

When operating a diode laser cutter, it’s crucial to follow safety guidelines to prevent common accidents. Firstly, always wear appropriate protective gear, including safety glasses and gloves. Ensure that the work area is well-ventilated to prevent inhalation of fumes. Keep a fire extinguisher nearby and never leave the machine unattended while it’s running.

Additionally, avoid touching the laser beam and be cautious when handling hot materials. By adhering to these precautions, you can minimize the risk of accidents and ensure a safe working environment.

Can rotary cutters be used for intricate designs and detailed cuts?

Rotary cutters have advantages over diode laser cutters when it comes to intricate designs. They offer more flexibility and precision, allowing for intricate patterns and detailed cuts. However, rotary cutters have limitations in achieving the same level of detail as diode laser cutters. The laser technology of diode laser cutters enables them to create extremely fine and precise cuts that rotary cutters can’t match.

For achieving detailed cuts, diode laser cutters are the more efficient option.

Conclusion

In conclusion, when it comes to the efficiency of diode laser cutters versus rotary cutters, the former emerges as the frontrunner. With its precise and rapid cutting capabilities, diode laser cutters offer a streamlined solution for various applications.

While rotary cutters have their own merits, the efficiency factor tilts in favor of diode laser cutters. So, if you’re seeking the epitome of efficiency in your cutting endeavors, look no further than the diode laser cutter. It’s the cutting-edge choice that will elevate your productivity to new heights.