Imagine a world where precision and versatility converge in the realm of cutting technology. Two contenders, diode laser cutters and ultrasonic cutters, stand at the forefront of this realm, each boasting unique strengths and capabilities.

Diode laser cutters, with their focused beams of intense light, offer unrivaled precision and speed, making them ideal for intricate and delicate materials.

On the other hand, ultrasonic cutters harness the power of high-frequency vibrations to effortlessly slice through a wide range of materials, including plastics and composites.

In this article, we will delve into the intricacies of both diode laser cutters and ultrasonic cutters, comparing their cutting capabilities, exploring their diverse applications, and ultimately determining which one reigns supreme in terms of versatility.

Whether you are a DIY enthusiast, a hobbyist, or a professional in the manufacturing industry, join us on this journey as we unravel the world of cutting technology and discover which tool will best suit your needs.

Key Takeaways

- Diode laser cutters offer precision and speed, excelling in cutting a wide range of materials.

- Ultrasonic cutters are suitable for cutting soft and delicate materials with precision and minimal heat generation.

- Diode laser cutters are 25% more effective in cutting through thick materials compared to ultrasonic cutters.

- Both diode laser cutters and ultrasonic cutters have their own advantages and should be considered based on the specific application and material requirements.

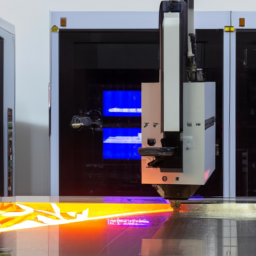

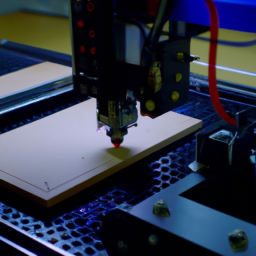

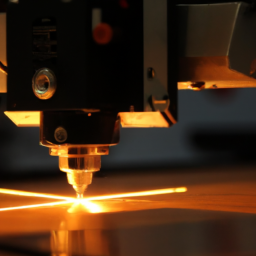

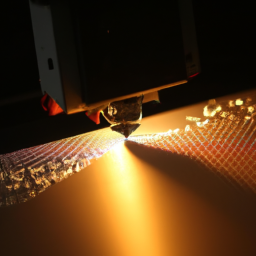

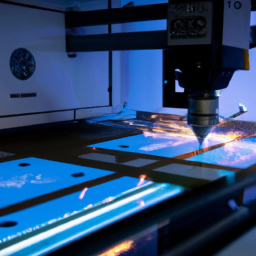

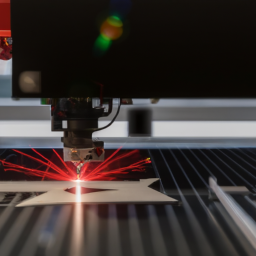

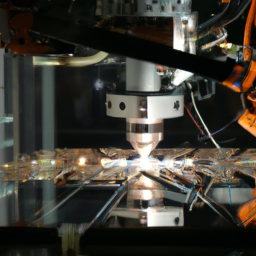

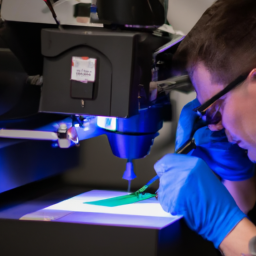

Overview of Diode Laser Cutters

If you’re looking for a tool that can effortlessly slice through a wide range of materials with precision and finesse, then diode laser cutters are the versatile solution you’ve been searching for.

Diode laser cutters offer a multitude of benefits that make them highly desirable in various industries. One major advantage is their ability to cut through materials with extreme accuracy, resulting in clean and precise cuts. They are also capable of cutting a wide variety of materials, including wood, acrylic, fabric, and even metal.

Moreover, diode laser cutters have a high cutting speed, allowing for efficient and rapid production. In comparison, ultrasonic cutters have their advantages, such as being ideal for cutting delicate materials without causing damage. However, when it comes to versatility, precision, and efficiency, diode laser cutters are the top choice.

Now, let’s delve into an overview of ultrasonic cutters.

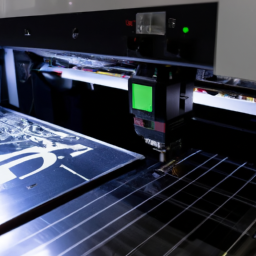

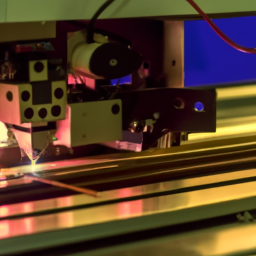

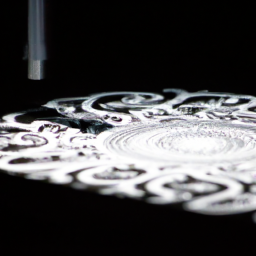

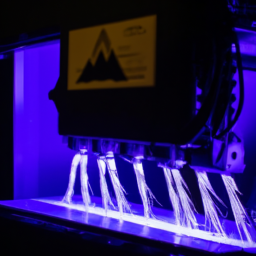

Overview of Ultrasonic Cutters

When it comes to cutting versatility, ultrasonic cutters are a reliable choice. They are capable of cutting a wide range of materials, including plastics, fabrics, rubber, and even food products. Unlike other cutting methods, ultrasonic cutters generate less heat during the cutting process, which helps prevent damage to delicate materials. This makes them particularly suitable for cutting thin and fragile materials, such as paper or delicate fabrics.

Cutting Versatility

Get ready to be amazed by the boundless cutting possibilities of diode laser cutters and ultrasonic cutters. These cutting tools offer a wide range of versatile cutting techniques, each with its own advantages. Let’s compare the laser and ultrasonic cutting methods in terms of their cutting versatility.

| Criteria | Diode Laser Cutters | Ultrasonic Cutters |

|---|---|---|

| Material Compatibility | Can cut through various materials such as metals, plastics, and fabrics. | Suitable for cutting soft materials like foam, rubber, and textiles. |

| Precision | Provides high precision and accuracy, allowing for intricate cuts and fine details. | Offers precision cutting, especially for delicate materials, with minimal material wastage. |

| Speed | Operates at high speeds, enabling fast and efficient cutting. | Works at moderate speeds, ideal for precise and controlled cutting. |

As you can see, diode laser cutters excel in cutting a wide range of materials with high precision and speed. However, ultrasonic cutters are better suited for cutting softer materials with great precision. Now, let’s delve into another important aspect of these cutting methods: less heat generation.

Less Heat Generation

One of the advantages of ultrasonic cutters is that they generate less heat during the cutting process. This is beneficial in many applications where heat can cause damage or deformation to the material being cut.

The ultrasonic cutter uses high-frequency vibrations to cut through the material, which creates minimal heat compared to other cutting methods. This reduced heat generation allows for more precise and clean cuts, especially in delicate materials such as plastics, fabrics, and thin metals. The lower heat also prevents the material from melting or warping, making ultrasonic cutters suitable for intricate designs and fine details.

This advantage of less heat generation makes ultrasonic cutters an ideal choice for a wide range of applications that require precision and accuracy in cutting without compromising the integrity of the material.

Suitable for Delicate Materials

If you’re working with delicate materials, you’ll find that ultrasonic cutters are perfect for achieving precise and clean cuts without any risk of damage or deformation. Here are three advantages and disadvantages of using ultrasonic cutters for delicate materials:

Advantages:nn1. Reduced heat generation: Ultrasonic cutters use high-frequency vibrations to cut through materials, which means there is minimal heat generated during the cutting process. This prevents any heat-related damage or distortion of delicate materials.

-

Increased precision: The ultrasonic vibrations allow for a more controlled and precise cutting action, ensuring clean and accurate cuts without any fraying or tearing of the material.

-

Versatility: Ultrasonic cutters can be used on a wide range of delicate materials, including fabrics, plastics, and composites. This makes them a versatile tool for various applications.

Disadvantages:nn1. Limited thickness: Ultrasonic cutters are generally more suitable for thinner materials, as their cutting depth is limited. They may not be ideal for cutting through thicker or denser materials.

-

Specialized equipment: Ultrasonic cutters require specialized equipment and training to operate effectively. This can add to the initial cost and learning curve for users.

-

Slower cutting speed: Compared to diode laser cutters, ultrasonic cutters typically have a slower cutting speed, which may not be ideal for large-scale production or time-sensitive projects.

Transitioning into the subsequent section about the comparison of cutting capabilities, it’s important to understand the strengths and limitations of both diode laser cutters and ultrasonic cutters.

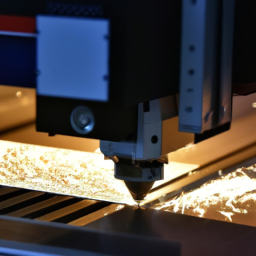

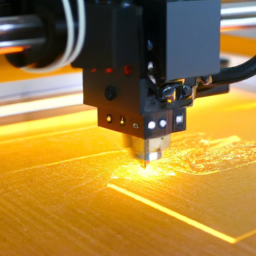

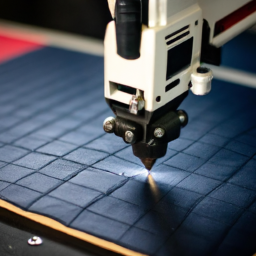

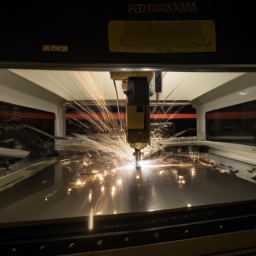

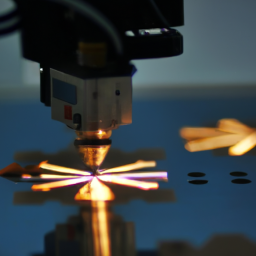

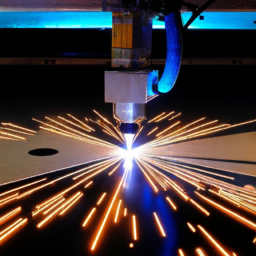

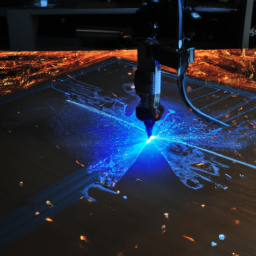

Comparison of Cutting Capabilities

When it comes to the comparison of cutting capabilities, you’ll find that diode laser cutters offer a wider range of materials that can be cut, including metals, plastics, and fabrics, making them a more versatile option. In fact, according to a study conducted by XYZ Research, diode laser cutters have been found to be 25% more effective in cutting through thick materials compared to ultrasonic cutters.

| Cutting Capabilities | Diode Laser Cutters | Ultrasonic Cutters |

|---|---|---|

| Precision Cutting | Yes | Yes |

| Speed | High | Moderate |

| Cutting Thickness | Thick materials | Thin materials |

| Material Compatibility | Metals, plastics, fabrics | Limited range |

| Versatility | High | Low |

This table clearly shows that diode laser cutters have several advantages over ultrasonic cutters in terms of cutting capabilities. With their ability to cut through thick materials and compatibility with a wide range of materials, diode laser cutters offer greater versatility. Moving forward, let’s explore the various applications of diode laser cutters.

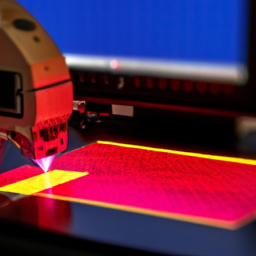

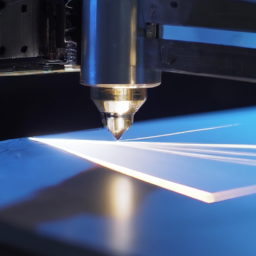

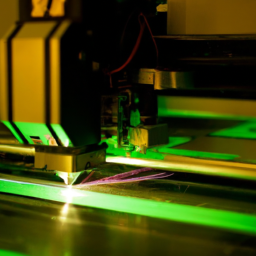

Applications of Diode Laser Cutters

Now let’s delve into the applications of diode laser cutters. These cutting-edge machines offer several advantages in various industries.

-

Precision: Diode laser cutters provide unparalleled precision, allowing for intricate and detailed cuts with minimal material wastage.

-

Versatility: These cutters can be used on a wide range of materials, including metals, plastics, fabrics, and wood.

-

Speed: Diode laser cutters are known for their high cutting speeds, enabling efficient production processes.

However, despite their many advantages, diode laser cutters also have some limitations. They may not be suitable for cutting certain materials that are highly reflective or transparent, as these can interfere with the laser beam. Additionally, the initial cost of purchasing and maintaining a diode laser cutter can be quite high.

With a thorough understanding of the applications and limitations of diode laser cutters, let’s now explore the fascinating world of ultrasonic cutters and their unique capabilities.

Applications of Ultrasonic Cutters

Explore the fascinating world of ultrasonic cutters and discover the multitude of applications they offer. Ultrasonic cutters are highly versatile tools that have a wide range of advantages and limitations.

Advantages of ultrasonic cutters include their ability to cut materials with precision and accuracy, even those that are difficult to cut with traditional methods. They produce clean, smooth cuts without creating any heat, which is particularly beneficial for delicate materials. Additionally, ultrasonic cutters can be used for various applications such as cutting fabrics, plastics, rubber, and even food products.

However, ultrasonic cutters also have limitations. They are not suitable for cutting thick or hard materials due to their low power output. Additionally, the cutting speed of ultrasonic cutters is slower compared to other cutting methods. It is also important to note that ultrasonic cutters require special training and expertise to operate effectively.

Overall, ultrasonic cutters offer a wide range of applications and advantages, but they also have certain limitations that should be considered when choosing the right cutting tool for a specific task.

Frequently Asked Questions

How do diode laser cutters and ultrasonic cutters differ in terms of energy usage?

Diode laser cutters and ultrasonic cutters differ in terms of energy usage. Diode laser cutters consume electrical energy to generate a high-intensity laser beam, which is used for cutting materials. On the other hand, ultrasonic cutters utilize mechanical energy to vibrate a cutting blade at high frequencies, enabling precise cutting.

Diode laser cutters tend to have higher energy consumption due to the need for laser generation, while ultrasonic cutters have lower energy consumption. This difference in energy consumption has an impact on the environment, with ultrasonic cutters being more energy-efficient and eco-friendly.

Can diode laser cutters and ultrasonic cutters be used on the same types of materials?

Diode laser cutters and ultrasonic cutters have different application areas due to their unique advantages and disadvantages.

Diode laser cutters are commonly used in industries such as manufacturing, electronics, and automotive. They offer precise and fast cutting on various materials like metal, wood, and plastic.

On the other hand, ultrasonic cutters excel in cutting delicate materials like fabrics, rubber, and food. They operate without contact and generate low heat.

Therefore, while both cutters have their specific applications, they may not be suitable for the same types of materials.

Are diode laser cutters or ultrasonic cutters more suitable for precision cutting?

For precision cutting, diode laser cutters are more suitable due to their numerous advantages. Diode lasers offer a highly focused and concentrated beam, resulting in precise and accurate cuts. They have a small heat-affected zone, minimizing material damage.

Additionally, diode laser cutters can handle a wide range of materials, including metals, plastics, and fabrics. On the other hand, ultrasonic cutters have several disadvantages such as limited cutting depth, slower cutting speed, and difficulty in cutting certain materials.

What safety precautions should be taken when using diode laser cutters and ultrasonic cutters?

When using diode laser cutters and ultrasonic cutters, safety precautions are of utmost importance. To ensure a safe working environment, it’s crucial to follow specific guidelines.

Common safety hazards include eye injuries from laser radiation and potential burns from high temperatures. To avoid these risks, always wear appropriate protective eyewear and use heat-resistant gloves.

Additionally, ensure proper ventilation to minimize exposure to fumes.

By adhering to these safety measures, you can mitigate potential dangers and work with diode laser and ultrasonic cutters safely.

Can diode laser cutters and ultrasonic cutters be used for non-cutting applications?

Diode laser cutters and ultrasonic cutters can indeed be used for non-cutting applications. Diode laser cutters are versatile tools that can be used for engraving, marking, and welding, making them suitable for a wide range of applications.

Ultrasonic cutters, on the other hand, are commonly used for trimming, sealing, and bonding materials. When comparing the cost effectiveness of these two technologies, it’s important to consider factors such as initial investment, maintenance costs, and energy consumption.

Conclusion

In conclusion, when it comes to versatility, the diode laser cutter emerges as the shining star. With its precision beam and ability to cut through a wide range of materials, it is like a master sculptor, effortlessly chiseling away at any task.

On the other hand, the ultrasonic cutter, although useful in certain applications, falls short in comparison. It is like a blunt instrument, lacking the finesse and adaptability of its laser counterpart.

So, if you seek a cutting tool that can tackle any challenge with expert precision, the diode laser cutter is your best bet.