Imagine you are a skilled craftsman, standing before a vast forest of possibilities. In one hand, you hold a diode laser cutter, a precision instrument capable of etching intricate designs with impeccable accuracy. In the other, a vinyl cutter, a versatile tool adept at cutting through various materials with ease. As you ponder which path to take, the question arises: which one is best for your business?

In the world of modern technology, diode laser cutters and vinyl cutters have emerged as invaluable assets for businesses seeking to enhance their cutting capabilities. While both offer unique advantages, understanding their differences is crucial in making an informed decision.

This article will delve into the realms of diode laser cutters and vinyl cutters, exploring their cutting capabilities, costs, and maintenance considerations. By the end, you will be equipped with the knowledge to choose the right cutter that will propel your business to new heights of precision and efficiency.

So, let us embark on this journey, and uncover the perfect cutting tool for your business.

Key Takeaways

- Diode laser cutters are compact, cost-effective, and highly efficient, making them suitable for industries requiring high accuracy and professional-quality results.

- Vinyl cutters, on the other hand, are versatile and produce high-quality results, making them ideal for signage, vehicle graphics, apparel decoration, and custom decals.

- Diode laser cutters have a higher upfront cost and longer durability, while vinyl cutters have a lower initial cost but may require more frequent repairs and replacement parts.

- When choosing between diode laser cutters and vinyl cutters, factors such as business needs, volume of work, level of precision required, specific materials and applications, budgetary constraints, and return on investment should be considered. A detailed ROI analysis is important for making the best cutting tool choice for a sign-making business.

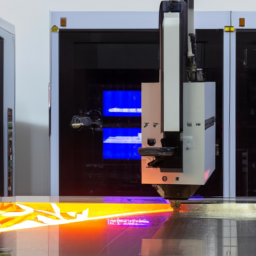

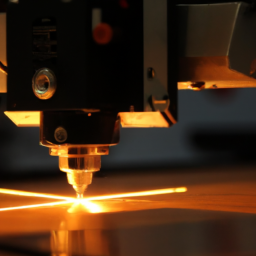

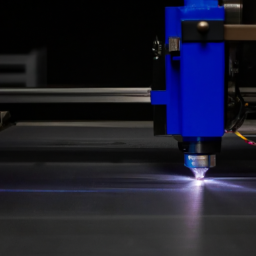

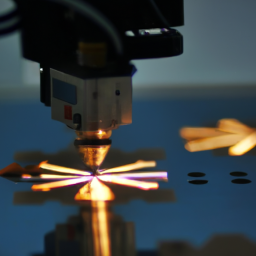

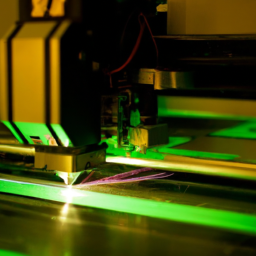

Understanding Diode Laser Cutters

If you’re looking for a laser cutter that’s versatile, easy to use, and perfect for intricate designs, then a diode laser cutter might just be the answer to your business needs.

Diode laser cutters are widely used in various industries due to their wide range of applications. They are commonly used for cutting materials such as wood, acrylic, leather, and fabric with precision and accuracy.

Diode laser technology utilizes a semiconductor diode as the laser source, which offers several advantages including compact size, low cost, and high energy efficiency. These cutters are capable of producing intricate designs with intricate details and smooth edges. They are also known for their fast cutting speed and low maintenance requirements.

With diode laser cutters, you can achieve professional-quality results for your business.

Now, let’s explore vinyl cutters and see if they can meet your needs.

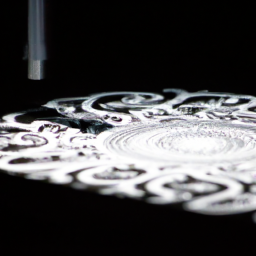

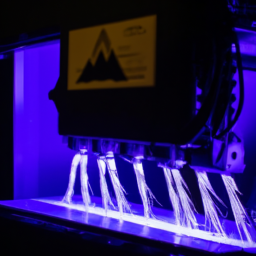

Exploring Vinyl Cutters

When it comes to vinyl cutters, it’s important to understand their key attributes and how they can benefit your business.

These machines are designed to precisely cut out shapes and letters from vinyl material, making them ideal for creating signs, decals, and stickers.

The advantages of vinyl cutters include their versatility, ease of use, and ability to produce high-quality results.

However, it’s also important to consider potential drawbacks such as the limitations on the types of materials that can be used and the initial investment required.

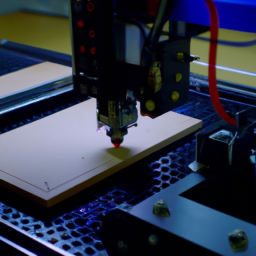

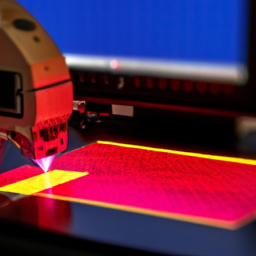

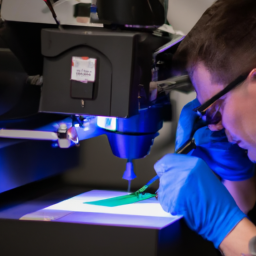

Introduction to Vinyl Cutters

To truly elevate your business and stand out from the competition, consider investing in a vinyl cutter for its precision and versatility.

With advanced features and a wide range of brands to choose from, a vinyl cutter can revolutionize your production process. Picture a sleek machine designed with a robust frame, equipped with a high-quality cutting blade that effortlessly slices through various materials.

Imagine the precise control you’ll have over intricate designs, thanks to the vinyl cutter’s intuitive software interface. Visualize the convenience of easily swapping out different blades for different materials, maximizing your productivity.

Furthermore, envision the seamless integration of the vinyl cutter into your workflow, allowing you to effortlessly produce custom decals, signage, and apparel.

By harnessing the power of a vinyl cutter, you’ll unlock endless possibilities for your business, boosting efficiency and expanding your creative capabilities.

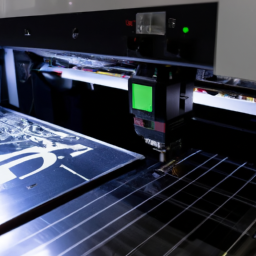

Uses and Advantages of Vinyl Cutters

Enhance your creative projects and streamline your production process with the versatility and precision of a vinyl cutter. Vinyl cutters are essential tools for various applications in the business industry. They are commonly used for signage, vehicle graphics, apparel decoration, and custom decals. With a vinyl cutter, you can achieve intricate designs and precise cuts on a wide range of materials such as vinyl, heat transfer material, and adhesive-backed film. Vinyl cutting offers numerous benefits, including cost-effectiveness, ease of use, and the ability to produce high-quality, professional-looking products.

To emphasize the advantages of vinyl cutting, consider the following table:

| Applications | Benefits |

|---|---|

| Signage | Clear, long-lasting |

| Vehicle Graphics | Customization, branding |

| Apparel Decoration | Creative, eye-catching |

| Custom Decals | Personalization |

While vinyl cutters offer significant advantages, it is important to consider potential drawbacks and factors before making a decision for your business.

Potential Drawbacks and Factors to Consider

Consider the potential drawbacks and factors to keep in mind as you weigh your options for incorporating vinyl cutting into your business strategy.

-

Limited materials: Vinyl cutters are primarily designed for cutting vinyl and similar materials. If your business requires cutting a wide range of materials, such as wood, acrylic, or fabric, a vinyl cutter may not be the best choice.

-

Precision limitations: While vinyl cutters are capable of producing intricate designs, they may not offer the same level of precision as diode laser cutters. Factors such as blade wear and material stretching can affect the accuracy of the cuts, which may be a concern for businesses that require high precision.

-

Time-consuming process: Vinyl cutting can be a time-consuming process, especially for complex designs. The setup, alignment, and weeding of the vinyl can take a significant amount of time, which may not be ideal for businesses with high production demands.

As you consider these potential drawbacks and factors to consider, it’s important to also evaluate the cutting capabilities of diode laser cutters to make an informed decision for your business.

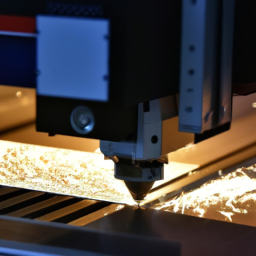

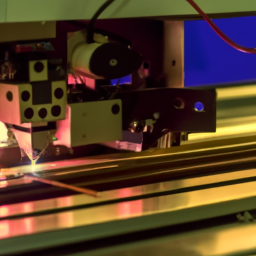

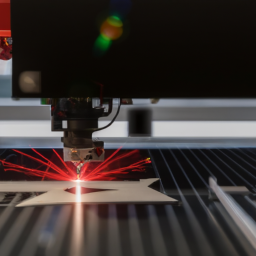

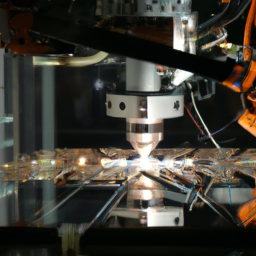

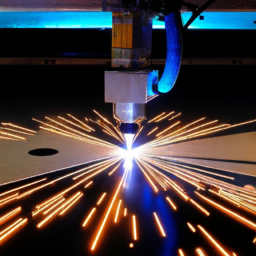

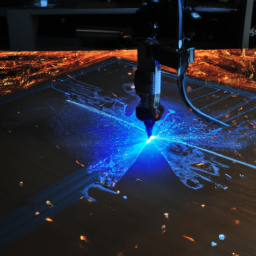

Comparing Cutting Capabilities

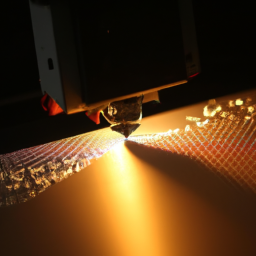

When it comes to comparing cutting capabilities, diode laser cutters and vinyl cutters each have their own unique strengths and applications.

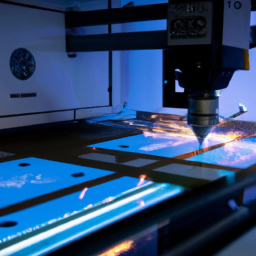

Diode laser cutters excel in cutting precision, offering an incredibly accurate and clean cut. They are capable of cutting intricate designs and detailed patterns with utmost precision, making them ideal for industries that require high levels of accuracy, such as electronics or medical device manufacturing.

On the other hand, vinyl cutters prioritize speed and efficiency. They can quickly cut through larger quantities of materials, making them a popular choice for businesses that focus on mass production or require fast turnaround times.

However, it’s important to consider the cost and maintenance considerations when choosing between these two options. Transitioning into the subsequent section, these factors play a crucial role in determining the overall suitability of diode laser cutters and vinyl cutters for your business.

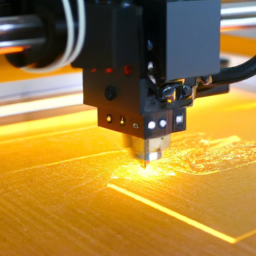

Cost and Maintenance Considerations

You don’t want to overlook the potential cost and maintenance hurdles that come with choosing between these two cutting options – it’s like navigating a winding road with unexpected tolls and potholes.

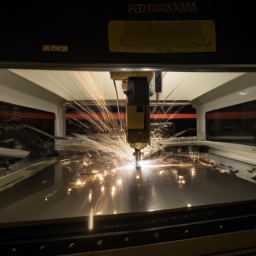

When considering the cost analysis, diode laser cutters generally have a higher upfront cost compared to vinyl cutters. However, they offer longer durability and require less maintenance in the long run.

Vinyl cutters, on the other hand, have a lower initial cost but may require more frequent repairs and replacement parts.

In terms of maintenance tips, regular cleaning and calibration are essential for both types of cutters to ensure optimal performance. Additionally, it is important to factor in the cost of consumables such as laser tubes or cutting blades.

Now that you have a better understanding of the cost and maintenance considerations, let’s delve into choosing the right cutter for your business.

Choosing the Right Cutter for Your Business

When choosing the right cutter for your business, it’s crucial to assess your business needs and objectives. This involves considering factors such as the volume of work, the level of precision required, and the specific materials and applications you work with.

Additionally, evaluating your budgetary constraints and return on investment is essential in making an informed decision that aligns with your financial goals.

Assessing Your Business Needs and Objectives

Consider the unique needs and goals of your business so that you can make the best choice between diode laser cutters and vinyl cutters.

To ensure business growth and meet market demand, it’s essential to assess which cutter aligns with your objectives.

Diode laser cutters offer precise and intricate cuts, making them ideal for businesses that work with complex designs and materials such as acrylic, wood, or metal.

On the other hand, vinyl cutters excel in creating professional-looking graphics and designs on adhesive vinyl, making them a popular choice for sign-making businesses.

Evaluating the materials and applications you work with will help you determine whether diode laser cutters or vinyl cutters are the best fit for your business.

Evaluating the Materials and Applications You Work With

If your business revolves around intricate designs and working with a variety of materials, it’s crucial to assess the applications and materials you handle to determine the ideal cutting tool.

When evaluating efficiency, consider the speed and accuracy of the cutting process. Diode laser cutters offer high-speed cutting with precise detailing, making them ideal for intricate designs. Vinyl cutters, on the other hand, can handle a variety of materials but may not be as efficient when it comes to intricate designs.

Comparing versatility, diode laser cutters can work with a wide range of materials such as wood, acrylic, and fabric, while vinyl cutters are best suited for vinyl and heat transfer materials.

When considering budgetary constraints and return on investment, it’s essential to weigh the cost of each machine against the potential benefits it can bring to your business.

Transitioning into the subsequent section, you should also consider the financial aspect when making your decision.

Considering Budgetary Constraints and Return on Investment

To truly maximize your business’s potential, it’s crucial to carefully weigh the financial implications and potential returns of your investment in cutting tools. When considering budget limitations, it is important to conduct a thorough ROI analysis to determine which cutting tool is best for your business.

Diode laser cutters and vinyl cutters both have their own advantages and disadvantages in terms of cost and potential returns. Diode laser cutters tend to have a higher initial investment and maintenance costs, but they offer a wide range of applications and higher precision.

Vinyl cutters, on the other hand, have a lower initial investment and maintenance costs, but they are limited in terms of materials and applications. By conducting a detailed ROI analysis, you can determine which cutting tool will provide the best return on investment for your business.

Frequently Asked Questions

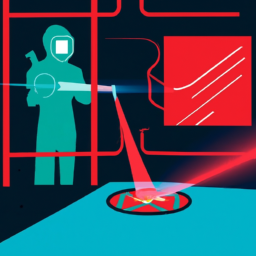

Are diode laser cutters safe to use in a business setting?

In a business setting, diode laser cutters are considered safe to use due to their advanced safety features and precise cutting capabilities.

One of the key benefits of using diode laser cutters is their ability to provide clean and accurate cuts, resulting in high-quality finished products.

Additionally, diode laser cutters offer a wide range of materials that can be cut, including wood, acrylic, and metal.

These features make diode laser cutters a valuable tool for businesses looking to enhance their productivity and efficiency.

Can vinyl cutters cut materials other than vinyl?

Vinyl cutters aren’t limited to cutting vinyl alone. With the right blade and settings, they can also cut various materials, including fabric.

However, diode laser cutters offer several benefits over vinyl cutters for fabric cutting. They provide precise and clean cuts, can cut intricate designs, and can seal the edges of fabric to prevent fraying. These advantages make diode laser cutters a more suitable choice for businesses working with fabric.

How often do diode laser cutters need to be recalibrated?

Recalibrating diode laser cutters is similar to adjusting the lens on a high-powered telescope. These machines require precise recalibration to maintain their cutting accuracy and efficiency. The recalibration frequency of diode laser cutters depends on factors such as usage, environmental conditions, and the specific model.

Regular maintenance is essential to ensure optimal performance and extend the lifespan of the cutter. It’s recommended to consult the manufacturer’s guidelines for specific recalibration frequency and maintenance requirements.

What is the average lifespan of a vinyl cutter?

The average lifespan of a vinyl cutter depends on various factors, such as usage, maintenance, and quality. However, on average, a well-maintained vinyl cutter can last anywhere from 3 to 7 years.

The maintenance cost of a vinyl cutter can vary, but generally, it includes blade replacement, occasional servicing, and regular cleaning.

In terms of cutting speed, diode laser cutters are generally faster than vinyl cutters, allowing for quicker production times.

Can diode laser cutters be used for engraving as well as cutting?

Yes, diode laser cutters can be used for both engraving and cutting. Diode laser engraving capabilities are impressive and can produce highly detailed and precise engravings. When comparing diode laser engraving to CO2 laser engraving, diode lasers offer advantages such as faster engraving speeds and the ability to engrave on a wider range of materials. However, CO2 lasers still excel in certain applications, such as engraving on organic materials like wood or leather.

Conclusion

Based on a thorough analysis of diode laser cutters and vinyl cutters, it’s clear that the choice ultimately depends on the specific needs and goals of your business. Diode laser cutters offer precision and versatility, making them ideal for intricate designs and a wide range of materials.

On the other hand, vinyl cutters are more cost-effective and efficient for smaller scale projects. By carefully considering your requirements and budget, you can make an informed decision that propels your business to new heights of success.