Looking to cut through materials with precision and accuracy? Diode laser cutters and waterjets are two popular options in the world of cutting technology. Both offer unique advantages, but when it comes to precision, which one reigns supreme?

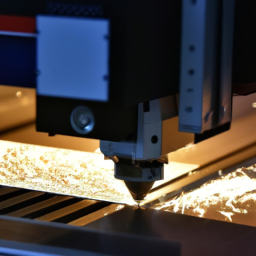

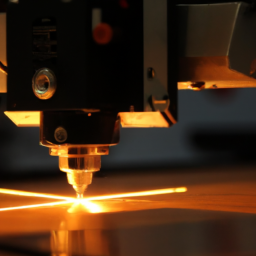

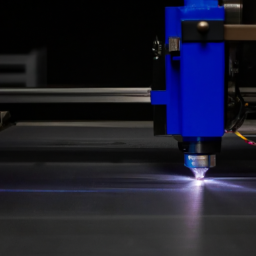

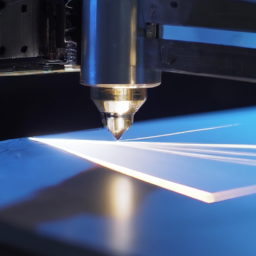

In the realm of diode laser cutters, a parallel beam of coherent light is emitted, allowing for precise cuts with minimal thermal distortion. On the other hand, waterjets utilize a high-pressure stream of water mixed with abrasive particles to cut through materials.

When it comes to precision, diode laser cutters have the upper hand. With their ability to achieve fine, intricate cuts, they are ideal for applications that require exact measurements. Waterjets, while versatile and capable of cutting through a wide range of materials, may not offer the same level of precision as diode laser cutters.

However, precision is not the only factor to consider when choosing between these two technologies. Factors such as material type, thickness, and cost must also be taken into account. So, whether you’re a hobbyist or a professional, understanding the differences between diode laser cutters and waterjets is crucial in making the right choice for your cutting needs.

Key Takeaways

- Diode laser cutters offer precise cuts with minimal thermal distortion.

- Diode laser cutters have better precision capabilities compared to waterjets.

- Diode laser cutters provide unparalleled precision and speed.

- Waterjets can cut through a wide range of materials with minimal heat affected zone.

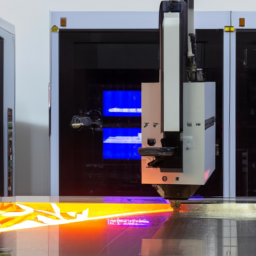

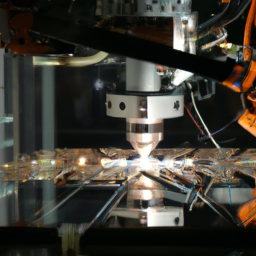

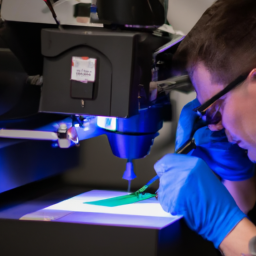

Understanding Diode Laser Cutters

If you want to truly understand the power and precision of diode laser cutters, you’ve got to see them in action – you won’t believe your eyes! These remarkable machines offer several advantages over traditional cutting methods.

First and foremost, diode laser cutters provide unparalleled precision, thanks to their concentrated beam of light that can accurately cut through a variety of materials. Additionally, their speed and efficiency make them ideal for high-volume production.

However, it’s important to consider the disadvantages as well. Diode laser cutters can be quite expensive to purchase and maintain, and they may not be suitable for cutting certain materials that are sensitive to heat.

Now that we’ve explored the benefits and limitations of diode laser cutters, let’s delve into the world of waterjet technology.

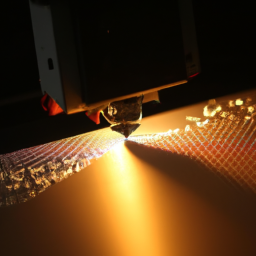

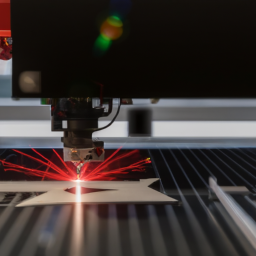

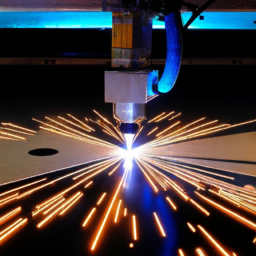

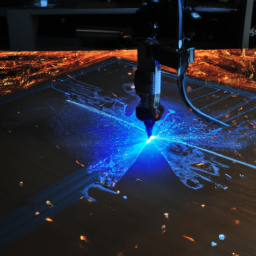

Exploring Waterjet Technology

Waterjet technology offers an impressive level of precision that can leave people in awe. With its advanced cutting capabilities, waterjet cutting has become a popular choice in various industries. Here are some advantages of waterjet technology:

-

Versatility: Waterjets can cut through a wide range of materials, including metals, composites, stone, glass, and even food products.

-

Minimal heat affected zone: Unlike other cutting methods, waterjets produce minimal heat during the cutting process, resulting in a small heat affected zone and reduced risk of material distortion.

-

No material limitations: Waterjets can cut thick materials without limitations, making it suitable for applications that require intricate designs and high precision.

-

Complex shapes: Waterjets can easily cut complex shapes, including sharp corners and tight curves, allowing for greater design flexibility.

-

Environmentally friendly: Waterjets use water and abrasive garnet as the cutting medium, making it an eco-friendly option compared to other cutting methods.

Waterjet technology’s precision capabilities make it a strong contender in the comparison against diode laser cutters.

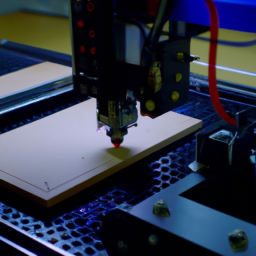

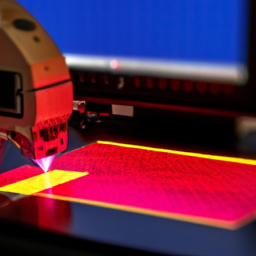

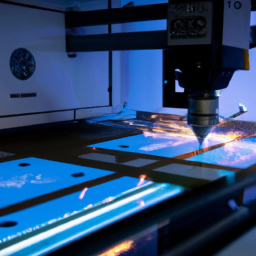

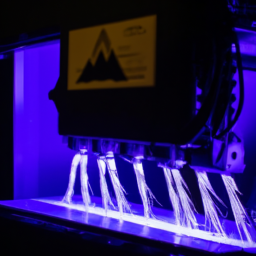

Precision Capabilities of Diode Laser Cutters

When it comes to diode laser cutters, you’ll find that they offer exceptional accuracy and repeatability. These machines are designed to cut with precision, ensuring that each cut is made exactly as desired.

Additionally, diode laser cutters are known for their impressive cutting speed, allowing for efficient production processes. Moreover, these cutters have the capability to cut through various thicknesses of materials, making them versatile and adaptable to different project requirements.

Accuracy and Repeatability

To achieve precision and consistency in your cuts, you can rely on diode laser cutters or waterjets. When it comes to accuracy and repeatability, diode laser cutters have an edge over waterjets.

Laser cutters use advanced measurement techniques and tolerance analysis to ensure precise cuts every time. The laser beam is controlled with high precision, allowing for accurate cuts with minimal error. Additionally, laser cutters have excellent repeatability, meaning that the same cut can be reproduced consistently. This level of precision and consistency is crucial in many industries, such as manufacturing and engineering.

Moving forward to the discussion on cutting speed and thickness, it is important to consider how these factors impact the overall performance of diode laser cutters and waterjets.

Cutting Speed and Thickness

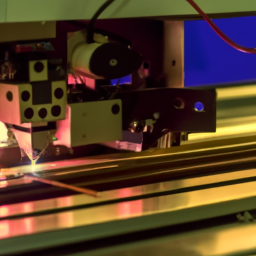

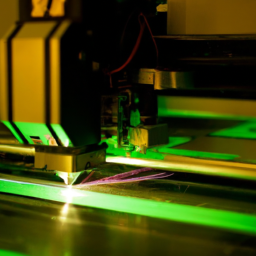

Imagine being able to cut through various materials quickly and effortlessly, while also having the ability to adjust the thickness of your cuts with ease. When it comes to cutting efficiency, diode laser cutters have a clear advantage over waterjets. Here’s why:

-

Speed: Diode laser cutters operate at high speeds, allowing for rapid material removal. This means you can complete your cutting tasks in a fraction of the time compared to waterjets.

-

Thickness: With diode laser cutters, you have precise control over the thickness of your cuts. You can easily adjust the laser power to cut through thin materials or make deeper cuts in thicker materials.

-

Material compatibility: Diode laser cutters are versatile and can cut through a wide range of materials, including metals, plastics, and woods. This makes them suitable for a variety of applications.

With their cutting efficiency and material compatibility, diode laser cutters offer a superior option for many cutting tasks. However, when it comes to precision capabilities, waterjets have their own strengths.

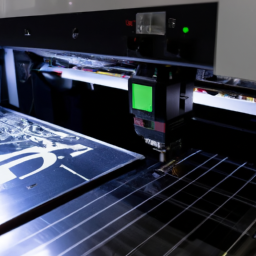

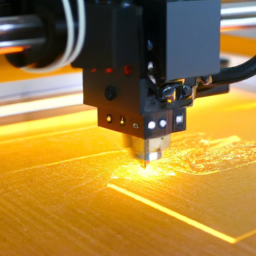

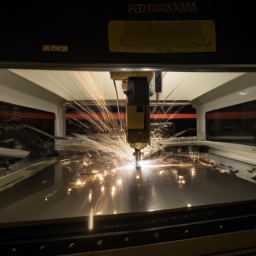

Precision Capabilities of Waterjets

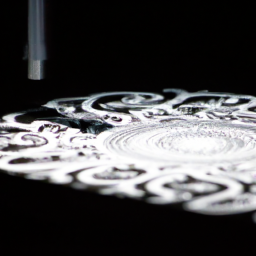

Waterjets are known for their high accuracy and repeatability, making them an excellent choice for precision cutting. With their advanced computer control systems, waterjets can consistently cut parts with tight tolerances, ensuring precise results every time.

Additionally, waterjets offer fast cutting speeds, allowing for efficient production and quick turnaround times. Furthermore, waterjets have the capability to cut through various thicknesses of materials, making them versatile and suitable for a wide range of applications.

Accuracy and Repeatability

The accuracy and repeatability of diode laser cutters are truly impressive, allowing for precise and consistent cuts every time. These machines employ advanced measurement techniques and error analysis to ensure the highest level of precision.

Laser cutters use a focused beam of light to melt and vaporize the material, resulting in clean and accurate cuts. The measurement techniques used include optical encoders, which provide precise feedback on the position of the laser head.

Error analysis is performed to identify and minimize any potential sources of error, ensuring that the cuts are accurate and repeatable. This level of precision is crucial for industries that require intricate and detailed cuts.

Moving forward, it is important to consider the cutting speed and thickness capabilities of diode laser cutters, as they play a significant role in determining the overall efficiency and effectiveness of the cutting process.

Cutting Speed and Thickness

Moving on to the current subtopic, let’s explore the cutting speed and thickness capabilities of diode laser cutters and waterjets.

When it comes to cutting speed, diode laser cutters have the upper hand. They can slice through materials at a rapid pace, making them ideal for projects with tight deadlines.

On the other hand, waterjets are known for their versatility in cutting a wide range of materials, regardless of their thickness. Whether it’s metal, stone, or even foam, waterjets can handle it all. This material compatibility makes them a popular choice for industries that require cutting various materials.

Now, let’s delve into the factors to consider when choosing between diode laser cutters and waterjets, to ensure you make an informed decision for your specific needs.

Factors to Consider When Choosing Between Diode Laser Cutters and Waterjets

When it comes to choosing between diode laser cutters and waterjets, you’ll want to consider several factors.

One important factor to consider is the cost comparison between the two options. While diode laser cutters may have a higher upfront cost, they typically have lower maintenance requirements compared to waterjets. This is because diode laser cutters have fewer moving parts and do not require the same level of upkeep as waterjets, which often need regular maintenance and replacement of high-pressure seals and orifices.

Additionally, diode laser cutters have a longer lifespan and lower operating costs in terms of energy consumption. So, if cost and maintenance are key considerations for you, diode laser cutters may be the more suitable choice.

Frequently Asked Questions

What is the cost difference between diode laser cutters and waterjets?

The cost difference between diode laser cutters and waterjets depends on various factors, including the specific models and features desired. Generally, diode laser cutters tend to be more affordable than waterjets. However, it’s important to consider precision requirements when making a decision.

While diode laser cutters offer high precision for thinner materials, waterjets are more suitable for thicker materials and intricate designs. Therefore, the cost difference should be weighed against the required precision to determine the most suitable option.

Can diode laser cutters and waterjets cut through all types of materials?

Diode laser cutters and waterjets have different cutting powers and material compatibilities. Diode laser cutters are highly precise and can cut through a wide range of materials, including metals, plastics, and wood. They utilize a focused beam of light to melt or vaporize the material.

On the other hand, waterjets are versatile and can cut through almost any material with high accuracy. They use a high-pressure stream of water mixed with abrasive particles to erode the material.

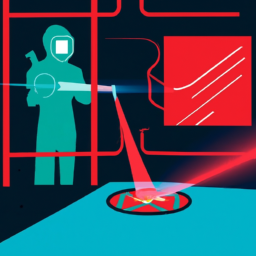

Are there any safety concerns associated with using diode laser cutters or waterjets?

When it comes to safety concerns, both diode laser cutters and waterjets have their advantages and limitations. Diode laser cutters can cause eye damage if proper safety precautions aren’t taken. Waterjets, on the other hand, can pose a risk of high-pressure water spray.

However, diode laser cutters offer advantages such as precision and speed, while waterjets excel at cutting thicker materials. It’s crucial to prioritize safety by ensuring proper training, protective gear, and adherence to safety guidelines when using either of these technologies.

How long does it take to set up and calibrate a diode laser cutter compared to a waterjet?

When comparing the setup time of a diode laser cutter to the calibration time of a waterjet, the diode laser cutter typically requires less time for setup. The process of setting up a diode laser cutter involves positioning the material, adjusting the laser power, and configuring the cutting parameters.

On the other hand, waterjet calibration involves aligning the nozzle, adjusting the water pressure, and fine-tuning the cutting speed.

Overall, diode laser cutters offer a quicker setup time compared to waterjets.

Can diode laser cutters and waterjets be used for both small-scale and large-scale projects?

For both small-scale and large-scale applications, diode laser cutters and waterjets can be used effectively. Diode laser cutters offer precise and intricate cuts, making them suitable for small-scale projects that require intricate designs.

On the other hand, waterjets provide versatility and can handle large-scale projects, cutting through thick materials effortlessly. Both options have their advantages and can be calibrated accordingly to meet the specific requirements of the project.

Conclusion

In conclusion, when it comes to precision, both diode laser cutters and waterjets have their strengths. Diode laser cutters offer exceptional accuracy and can create intricate designs with ease.

However, waterjets excel in cutting thicker materials with minimal heat-affected zones. Ultimately, the choice between the two will depend on the specific needs of your project.

Consider factors such as material type, thickness, and desired level of intricacy. By weighing these factors carefully, you can ensure the most precise and efficient cutting solution for your application.