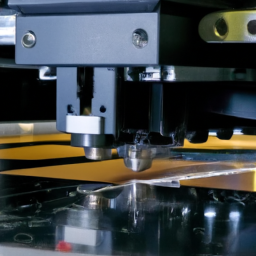

Did you know that excimer laser cutters are capable of achieving precision cuts with a tolerance of up to 0.001mm? These highly advanced machines are revolutionizing the world of cutting technology, providing unparalleled accuracy and efficiency.

In this article, you will gain a comprehensive understanding of the basics of excimer laser cutters.

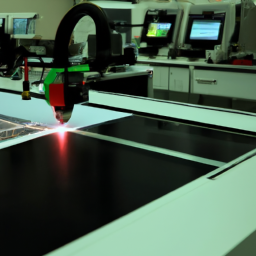

Excimer laser cutters operate on the principle of using a high-energy ultraviolet laser to vaporize material, resulting in clean and precise cuts. From medical devices and semiconductors to automotive parts and aerospace components, the applications of excimer laser cutters are vast and diverse.

The benefits of using excimer laser cutters are numerous, including minimal heat-affected zones, reduced material waste, and high processing speeds. However, choosing the right excimer laser cutter for your specific needs requires careful consideration of factors such as power output, spot size, and wavelength.

Safety and maintenance guidelines are also crucial to ensure the longevity and efficiency of these machines. Additionally, we will explore future trends and innovations in excimer laser cutting technology, giving you a glimpse into the exciting advancements that lie ahead.

So, buckle up and get ready to delve into the fascinating world of excimer laser cutters.

Key Takeaways

- Excimer laser cutters achieve precision cuts with a tolerance of up to 0.001mm.

- They offer minimal heat-affected zones, reduced material waste, and high processing speeds.

- Excimer laser cutters are versatile and can cut a wide range of materials including metals, plastics, ceramics, glass, and fabrics.

- Safety and maintenance guidelines are crucial for longevity, efficiency, and a safe working environment.

How Excimer Laser Cutters Work

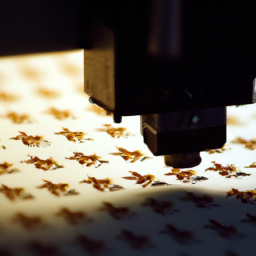

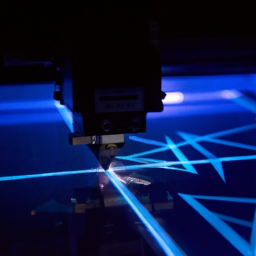

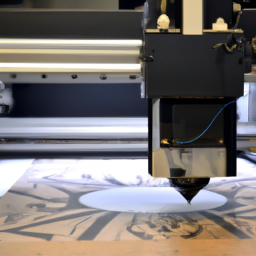

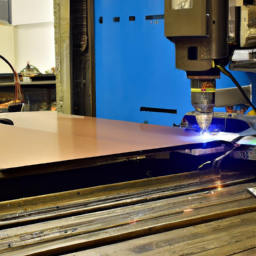

Imagine a tiny, powerful beam of light precisely slicing through materials like a surgeon’s scalpel – that’s how excimer laser cutters work. These cutting-edge machines utilize an excimer laser, which emits ultraviolet light pulses that are absorbed by a gas mixture inside the laser chamber. This absorption causes the gas molecules to become excited and subsequently release high-energy photons.

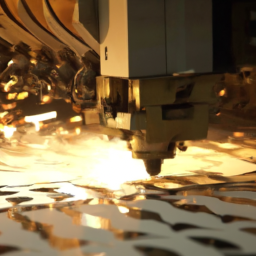

The resulting beam of light is then focused onto the material to be cut, where it vaporizes and melts the targeted area. Excimer laser cutters offer several advantages over other laser cutting methods. They produce extremely precise cuts with minimal heat-affected zones, resulting in high-quality edges and minimal material distortion. Additionally, their ability to cut a wide range of materials, including polymers, metals, ceramics, and composites, makes them highly versatile.

Transitioning into the subsequent section about applications of excimer laser cutters, let’s explore the various industries that benefit from this cutting-edge technology.

Applications of Excimer Laser Cutters

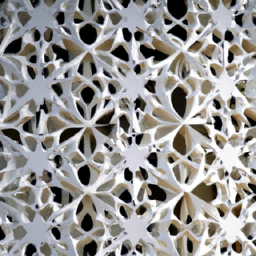

Discover the endless possibilities of utilizing these powerful machines to effortlessly create intricate designs and precise cuts for a wide range of applications.

Excimer laser cutters are widely used in various medical applications due to their ability to precisely cut and shape different materials. They are commonly used in the fabrication of medical devices such as stents, catheters, and implants. The excimer laser’s high precision and accuracy make it ideal for creating intricate patterns and shapes on these medical devices.

Moreover, excimer laser cutters offer the advantage of precise material selection. This means that they can easily cut through delicate materials like polymers, ceramics, and metals without causing any damage. With their versatility and precision, excimer laser cutters have become an indispensable tool in the medical industry.

Transitioning to the next section, let’s explore the benefits of using excimer laser cutters.

Benefits of Using Excimer Laser Cutters

When it comes to excimer laser cutters, you can expect high precision and accuracy. These machines are designed to deliver precise cuts with minimal error, ensuring that your workpieces are cut to perfection.

Additionally, excimer laser cutters offer non-contact cutting, which means that there’s no physical contact between the laser and the material being cut, minimizing the risk of damage or contamination.

Lastly, excimer laser cutters are known for their versatility and flexibility. They can easily cut through a wide range of materials, including metals, plastics, and ceramics, making them suitable for various industries and applications.

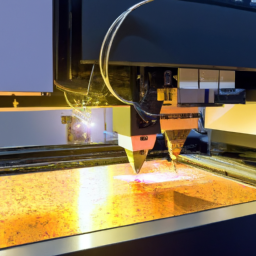

High Precision and Accuracy

With excimer laser cutters, can you imagine the level of precision and accuracy that can be achieved? These cutting-edge machines are designed to deliver high speed and cost efficiency, while ensuring the utmost precision in every cut. The laser technology used in excimer laser cutters allows for an incredibly narrow beam, resulting in clean and precise cuts with minimal heat-affected zones. With a positioning accuracy of up to ±0.001mm and a repeatability of ±0.001mm, these machines can consistently produce intricate and complex designs with unparalleled accuracy. Take a look at the table below to see the impressive precision and accuracy that can be achieved with excimer laser cutters.

| Accuracy | Positioning Accuracy | Repeatability |

|---|---|---|

| Excimer Laser | ±0.001mm | ±0.001mm |

| Traditional | ±0.01mm | ±0.02mm |

With such precision and accuracy, excimer laser cutters are ideal for non-contact cutting applications, where the material being cut is fragile or sensitive to heat.

Non-contact Cutting

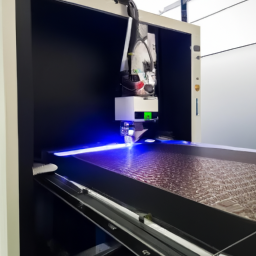

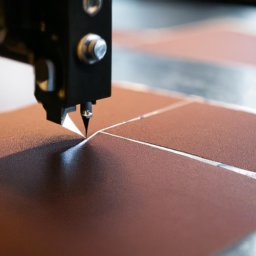

Imagine the precision and delicacy achieved through non-contact cutting, where materials are cut without direct physical contact, minimizing the risk of damage or distortion. Non-contact cutting is made possible by the use of excimer laser cutters, which utilize a high-energy, short-wavelength ultraviolet laser beam.

This advanced technology allows for a wide range of applications, including non-contact welding and laser marking.

Benefits of non-contact cutting include:

- Greater accuracy: The laser beam can cut with extreme precision, resulting in clean cuts and intricate designs.

- Enhanced safety: As there’s no physical contact, there’s a reduced risk of accidents or injuries.

- Minimal material waste: The focused laser beam ensures minimal material loss during the cutting process.

- Versatility: Non-contact cutting can be used on a variety of materials, including metals, plastics, glass, and ceramics.

With its non-contact cutting capabilities, excimer laser cutters offer a level of versatility and flexibility that traditional cutting methods can’t match.

Versatility and Flexibility

Now that you understand the concept of non-contact cutting, let’s delve into the versatility and flexibility of excimer laser cutters. These advanced machines are capable of performing a wide range of applications, making them an invaluable tool in various industries. With their precise and controlled laser beams, excimer laser cutters can easily cut through materials such as metals, plastics, ceramics, and even delicate materials like glass and fabrics. The versatility of these cutters allows for the creation of intricate designs, enabling manufacturers to produce complex and detailed products. Furthermore, the flexibility of excimer laser cutters allows for quick adjustments and modifications, making them highly efficient for prototyping and small-scale production. The benefits of this technology are endless, and it’s important to consider these factors when choosing the right excimer laser cutter for your needs. [Transition] Now let’s explore the factors that you should take into account when selecting an excimer laser cutter for your specific requirements.

Factors to Consider When Choosing an Excimer Laser Cutter

When choosing an excimer laser cutter, there are several factors you should consider.

- Factors to consider:

- Safety precautions: The safety of operators and the surrounding environment should be the top priority. Look for features such as interlocks and safety sensors to prevent accidents.

- Power requirements: Different laser cutters have different power requirements. Ensure that the cutter you choose is compatible with your power supply.

- Cutting speed and precision: Consider the speed and precision required for your specific cutting applications. Look for a laser cutter that can meet your desired specifications.

Considering these factors will help you choose the right excimer laser cutter for your needs.

Now, let’s move on to discussing maintenance and safety guidelines for excimer laser cutters.

Maintenance and Safety Guidelines for Excimer Laser Cutters

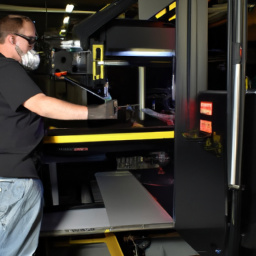

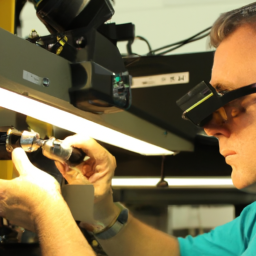

To ensure optimal performance and prevent accidents, it’s crucial to prioritize maintenance and follow safety guidelines when using an excimer laser cutter. Regular maintenance is necessary to keep the machine running smoothly and ensure accurate cuts.

This includes cleaning the optics regularly to remove any debris or contaminants that may affect the laser beam. It’s also important to check and calibrate the laser power and energy settings to ensure they’re within the recommended range.

When operating the laser cutter, it’s essential to wear appropriate personal protective equipment such as safety goggles and gloves. Additionally, a well-ventilated area should be used to prevent the accumulation of potentially harmful fumes.

By adhering to these maintenance guidelines and safety precautions, you can ensure the longevity of your excimer laser cutter and maintain a safe working environment.

Looking towards the future, there are exciting trends and innovations in excimer laser cutting technology that’ll continue to improve efficiency and precision.

Future Trends and Innovations in Excimer Laser Cutting Technology

In the future, you can expect to see advancements in laser beam delivery systems, which will improve the precision and efficiency of excimer laser cutting technology.

The integration of artificial intelligence and automation will also play a significant role, allowing for more streamlined and autonomous operation of excimer laser cutters.

Additionally, miniaturization and the development of portable excimer laser cutters will make this technology more accessible and versatile for various industries and applications.

Advancements in Laser Beam Delivery Systems

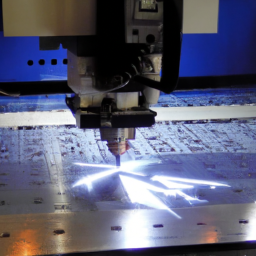

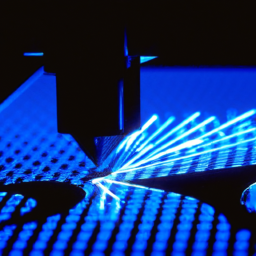

Imagine how much easier it would be to cut precise patterns with an excimer laser cutter if you had access to the latest advancements in laser beam delivery systems! Recent advancements in laser beam focusing have revolutionized the field of excimer laser cutting.

With improved focusing capabilities, these systems can now achieve even greater precision and accuracy in cutting various materials. Additionally, the development of new laser cutting materials has expanded the possibilities for excimer laser cutting applications. These materials are specifically designed to optimize the performance of laser beam delivery systems, resulting in cleaner and more efficient cuts.

As we move forward, the integration of artificial intelligence and automation will further enhance the capabilities of these laser cutters, allowing for even more precise and efficient cutting processes.

Integration of Artificial Intelligence and Automation

Now that we’ve discussed the advancements in laser beam delivery systems, let’s delve into the current subtopic of the integration of artificial intelligence (AI) and automation in excimer laser cutting technology.

AI has revolutionized manufacturing processes, and its integration in excimer laser cutters has brought about significant improvements in precision, efficiency, and productivity. By leveraging AI algorithms, these machines can analyze complex data in real-time, enabling them to make intelligent decisions and adapt to changing conditions.

Additionally, automation plays a crucial role in medical applications of excimer laser cutters. It enables the machines to perform intricate procedures with minimal human intervention, ensuring accuracy and reducing the risk of errors.

As we transition to the next section, it’s important to explore the advancements in miniaturization and the development of portable excimer laser cutters.

Miniaturization and Portable Excimer Laser Cutters

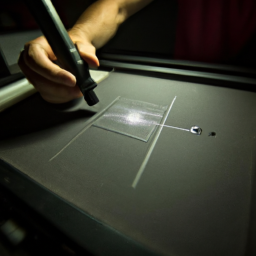

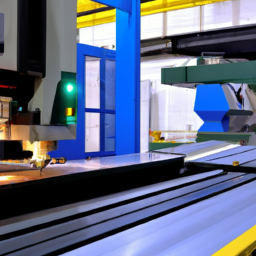

The remarkable trend towards miniaturization and the development of portable excimer laser cutting technology has sparked excitement and anticipation among industry professionals.

Advancements in miniaturized laser cutters have paved the way for more efficient and versatile applications in various fields.

Portable laser cutting technology offers convenience and flexibility, allowing professionals to bring the cutting-edge technology to different locations without compromising the precision and quality of the cutting process.

These miniaturized devices are designed to be compact and lightweight, making them easy to transport and operate.

Despite their smaller size, they still maintain high levels of accuracy and performance.

The integration of miniaturization and portability in excimer laser cutters has opened up new possibilities for industries such as electronics, medical, and automotive, where precise and intricate cutting is required.

Frequently Asked Questions

Are there any limitations or materials that cannot be cut using excimer laser cutters?

Excimer laser cutters may be powerful, but they have their limits. There are certain materials that simply can’t be tamed by their intense beams. From tough metals to heat-sensitive substances, these laser cutters have their Achilles’ heel. The limitations are due to the specific wavelength the excimer laser operates on, which restricts its ability to cut through certain materials. So while these cutters are incredibly precise and efficient, they’re not invincible.

Can excimer laser cutters be used for engraving or marking purposes as well?

Yes, excimer laser cutters can be used for engraving and marking purposes. With excimer laser engraving, the high-energy laser beam can remove material from the surface, creating precise and detailed designs.

Excimer laser marking, on the other hand, can create permanent marks by altering the surface properties of materials. Both processes offer a high level of accuracy and are commonly used in industries such as electronics, medical devices, and automotive.

What is the typical cost range of excimer laser cutters?

Excimer laser cutters, while being a significant investment, offer a range of benefits that justify their cost. The typical price range for these cutting-edge machines can vary depending on factors such as power, precision, and additional features.

However, considering the numerous applications of excimer laser cutters, including engraving and marking, their cost is justified. By utilizing the advantages of excimer laser cutters, such as their high precision and non-contact nature, you can achieve exceptional results in a wide range of industries.

Are there any specific training or certifications required to operate an excimer laser cutter?

To operate an excimer laser cutter, you must undergo specific training and meet certification requirements. This training ensures that you have the necessary knowledge and skills to safely and effectively operate the equipment. It covers topics such as laser safety protocols, machine operation, maintenance procedures, and troubleshooting techniques. Obtaining the required certifications validates your expertise and demonstrates your ability to handle the complexities of operating an excimer laser cutter.

Are there any environmental concerns associated with the use of excimer laser cutters?

When it comes to excimer laser cutters, it’s important to consider the environmental impact. These powerful machines can emit harmful gases and particulate matter, posing a risk to both human health and the environment.

That’s why it’s crucial to implement safety measures such as proper ventilation and filtration systems to minimize these emissions. By taking these precautions, you can ensure that the use of excimer laser cutters is both efficient and environmentally responsible.

Conclusion

In conclusion, excimer laser cutters are powerful tools that offer precise and efficient cutting solutions. By understanding the basics of how they work and the applications they can be used for, you can make an informed decision when choosing the right cutter for your needs.

Remember to consider factors such as power output and maintenance requirements. Following proper safety guidelines is crucial to ensure the longevity and effectiveness of your excimer laser cutter.

As technology continues to advance, we can expect exciting innovations in the field of excimer laser cutting. As the saying goes, "knowledge is power," so stay informed and explore the endless possibilities of excimer laser cutting technology.