Did you know that the global laser cutting market is expected to reach a value of $8.9 billion by 2026? With the increasing demand for precision cutting in various industries, it’s essential to choose the right type of laser cutter for your specific needs.

In this article, we will explore the differences between excimer laser cutters and CO2 laser cutters to help you make an informed decision.

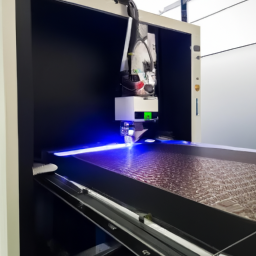

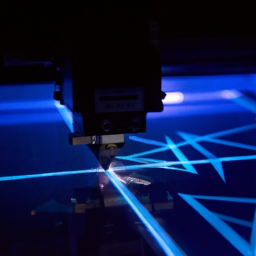

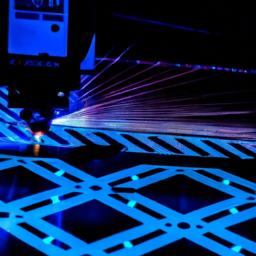

Excimer laser cutters utilize a high-energy beam of ultraviolet light to ablate materials with precision. They are ideal for delicate and intricate cutting applications, such as microelectronics and medical devices.

On the other hand, CO2 laser cutters use a carbon dioxide gas mixture to generate a laser beam that can cut through a wide range of materials, including wood, acrylic, and metal.

Both types of laser cutters have their advantages and disadvantages, which we will delve into in this article. By understanding the unique features and capabilities of excimer and CO2 laser cutters, you will be able to determine which one is the right choice for your specific cutting requirements.

Key Takeaways

- Excimer laser cutters are ideal for delicate and intricate cutting applications in microelectronics and medical devices.

- CO2 laser cutters are commonly used in industries such as signage, woodworking, and automotive manufacturing.

- Excimer laser cutters do not generate heat, reducing the risk of material damage, while CO2 laser cutters can cause thermal damage to certain materials.

- CO2 laser cutters have higher power output and faster cutting speeds, making them ideal for industries requiring high precision and efficiency.

Understanding Excimer Laser Cutters

If you’re looking for a laser cutter that’s out of this world, then an excimer laser cutter may be just what you need! Excimer laser cutters offer several advantages over their CO2 counterparts.

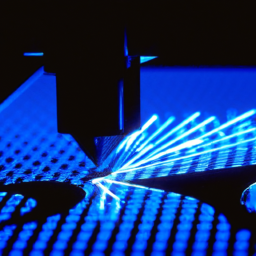

First and foremost, excimer laser cutters use a different type of laser that emits ultraviolet light, which allows for precision cutting on a microscopic level. This makes them ideal for industries such as electronics and medical devices that require intricate cuts.

Additionally, excimer laser cutters do not generate heat during the cutting process, reducing the risk of material damage or warping. On the other hand, CO2 laser cutters utilize infrared light, which can cause thermal damage to certain materials. This is one of the main disadvantages of CO2 laser cutters.

Now that you understand the benefits of excimer laser cutters, let’s delve into the world of CO2 laser cutters.

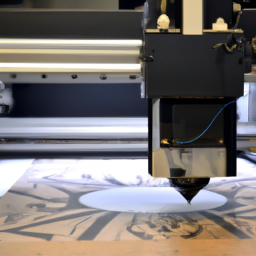

Understanding CO2 Laser Cutters

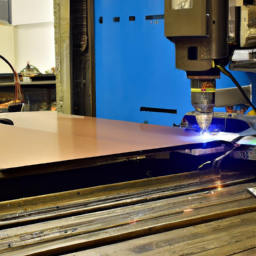

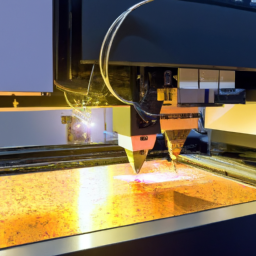

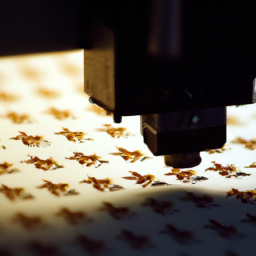

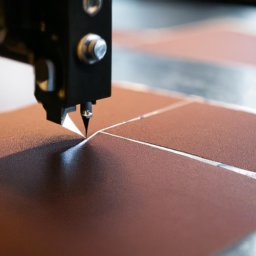

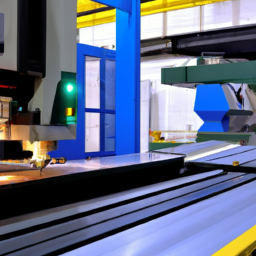

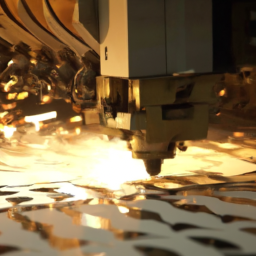

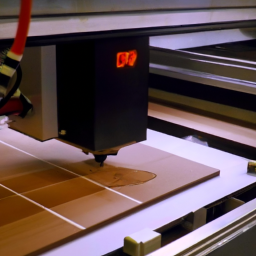

CO2 laser cutters are like a magical tool that can effortlessly slice through materials with precision and finesse. These cutters use a carbon dioxide gas mixture and a high-voltage electrical discharge to generate the laser beam. The beam is then focused and directed onto the material, vaporizing it and creating a clean, precise cut. CO2 laser cutters have a wide range of applications, including cutting and engraving materials such as wood, acrylic, leather, and fabric. They are commonly used in industries such as signage, woodworking, and automotive manufacturing.

To help you better understand the advantages and applications of CO2 laser cutters, here is a comparison table:

| Advantages of CO2 Laser Cutters | Applications of CO2 Laser Cutters |

|---|---|

| High precision and accuracy | Signage production |

| Versatility in cutting various materials | Woodworking |

| Clean and smooth cuts | Metal fabrication |

| Efficient and fast cutting speed | Textile and leather cutting |

Now that you have a clear understanding of CO2 laser cutters, let’s explore the advantages of excimer laser cutters.

Advantages of Excimer Laser Cutters

When considering the advantages of Excimer Laser Cutters, two key points stand out: high precision and accuracy, and the ability to cut a wide range of materials.

With their advanced technology and precise beam control, Excimer Laser Cutters offer unparalleled precision in cutting intricate designs and shapes.

Additionally, these cutters can handle a wide variety of materials, including metals, ceramics, glass, and polymers, making them a versatile choice for various industries.

High Precision and Accuracy

One of the key factors to consider when choosing between excimer laser cutters and CO2 laser cutters is their high precision and accuracy, which can greatly impact the quality of your projects.

Excimer laser cutters are known for their exceptional precision and accuracy, making them the preferred choice for industries that require intricate and detailed cuts.

While CO2 laser cutters are generally faster than excimer laser cutters, they may sacrifice some precision for speed. However, when it comes to cost comparison, CO2 laser cutters tend to be more affordable than excimer laser cutters.

Despite this, if precision is of utmost importance to your projects, investing in an excimer laser cutter may be the better choice.

This precision and accuracy also extends to the ability to cut a wide range of materials, providing you with more versatility in your projects.

Ability to Cut a Wide Range of Materials

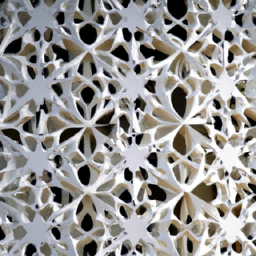

If you’re looking for a laser cutter that can handle a wide range of materials, you’ll be impressed by the versatility of excimer laser cutters. These cutters are known for their ability to cut through various materials with precision and accuracy, making them a cost-effective choice for many industries.

They can effortlessly cut through materials like metals, ceramics, plastics, and even organic materials. Additionally, excimer laser cutters have the advantage of being able to cut intricate patterns and shapes with ease, thanks to their high precision capabilities. This versatility makes them a valuable tool for industries that require the cutting of different materials for various applications.

However, it’s important to note that excimer laser cutters may not be suitable for certain materials that require higher power levels.

Transitioning to the next section, let’s explore the advantages of CO2 laser cutters.

Advantages of CO2 Laser Cutters

CO2 laser cutters have numerous advantages that make them a popular choice for many industries. One of the key advantages of CO2 laser cutters is their ability to cut a wide range of materials. From metal and plastic to wood and fabric, CO2 laser cutters offer versatility in their applications.

They provide precise and accurate cuts, ensuring high-quality results. CO2 laser cutters also have a higher power output compared to excimer laser cutters, allowing for faster cutting speeds and increased productivity.

Additionally, CO2 laser cutters require less maintenance and have a longer lifespan, making them a cost-effective option in the long run. With these advantages, CO2 laser cutters are ideal for industries that require high precision and efficiency in their cutting processes.

Transitioning into the subsequent section, let’s now explore the disadvantages of excimer laser cutters.

Disadvantages of Excimer Laser Cutters

When using an excimer laser cutter, you may experience limitations in the range of materials that can be cut, which can be like trying to carve through a tough, impenetrable surface. Excimer laser cutters are not as versatile as CO2 laser cutters and can only work efficiently on specific materials, such as polymers and ceramics. This restricts their application in industries that require cutting a wide variety of materials. Additionally, excimer laser cutters tend to be more expensive than CO2 laser cutters, both in terms of initial cost and maintenance requirements. They often require specialized gases, such as fluorine or chlorine, which can be costly to procure and maintain. These factors contribute to a lower cost efficiency compared to CO2 laser cutters. Transitioning into the subsequent section, it is important to consider the disadvantages of CO2 laser cutters.

Disadvantages of CO2 Laser Cutters

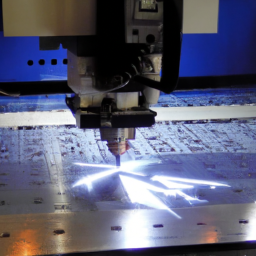

Beware of the drawbacks of CO2 laser cutters, as they may not be the perfect solution for your cutting needs. While CO2 laser cutters offer several advantages, they also have certain limitations that you should consider.

One major limitation is their inability to cut certain materials, such as metals or reflective surfaces, due to their wavelength. Additionally, CO2 laser cutters require a higher power output compared to excimer laser cutters, which can lead to increased energy consumption and operating costs.

Safety concerns are another aspect to keep in mind when using CO2 laser cutters. These machines produce a significant amount of heat and require proper ventilation to prevent the buildup of toxic fumes. It’s crucial to follow safety protocols and ensure a well-ventilated workspace when using CO2 laser cutters.

Frequently Asked Questions

What is the cost difference between excimer laser cutters and CO2 laser cutters?

When comparing the cost difference between excimer laser cutters and CO2 laser cutters, it’s important to consider their suitability for industrial applications. Excimer lasers offer advantages such as high precision and minimal heat damage to materials, but they can be more expensive.

On the other hand, CO2 lasers are more cost-effective and versatile for various industrial cutting applications. However, it ultimately depends on your specific requirements and budget to determine which option is more suitable for your needs.

Can excimer laser cutters be used on all types of materials?

Excimer laser cutters have specific applications and limitations when it comes to cutting materials. They are commonly used in microfabrication and semiconductor industries due to their ability to cut intricate patterns with high precision. However, excimer lasers are not suitable for cutting all types of materials. They are primarily used on materials like polymers, ceramics, and certain metals, while they may not be effective for cutting thicker or denser materials like wood or steel.

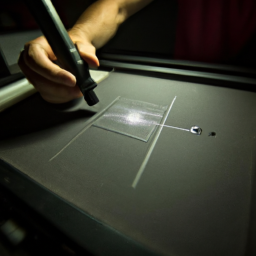

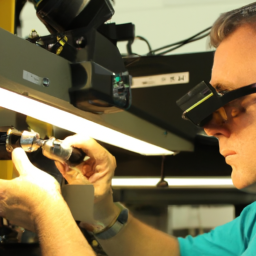

Are there any safety concerns or precautions to take when using excimer laser cutters?

When using excimer laser cutters, there are several safety concerns and precautions to keep in mind. These machines emit high-energy ultraviolet light, which can be harmful to the eyes and skin. It’s essential to wear appropriate protective gear, such as goggles and gloves, to prevent any injuries.

Additionally, proper ventilation is crucial to avoid exposure to potentially hazardous fumes. Regular maintenance and training on the safe operation of excimer laser cutters are also essential to minimize risks.

How long does it take to learn how to operate an excimer laser cutter?

Learning how to operate an excimer laser cutter requires time and training. The learning curve can vary depending on your prior experience and technical knowledge. Typically, it takes several weeks to become proficient in using an excimer laser cutter.

During this time, you’ll receive comprehensive training on the machine’s functionality, safety protocols, and maintenance procedures. Hands-on practice and guidance from experts will ensure you acquire the necessary skills to operate the excimer laser cutter effectively and safely.

Can CO2 laser cutters produce the same level of precision and accuracy as excimer laser cutters?

Yes, CO2 laser cutters can produce the same level of precision and accuracy as excimer laser cutters. CO2 laser cutters have several advantages, such as their ability to cut a wide range of materials and their cost-effectiveness. They’re commonly used in industries such as signage, woodworking, and textiles.

On the other hand, excimer laser cutters are often used in applications that require high precision, such as microelectronics, medical devices, and scientific research.

Conclusion

So, you’ve learned all about excimer laser cutters and CO2 laser cutters, and now it’s time to make a decision. Well, let’s be honest here, it’s not really a decision at all. The excimer laser cutter is clearly the superior choice.

Why settle for a CO2 laser cutter when you can have the precision and efficiency of an excimer? Sure, the CO2 laser cutter may have a few advantages, but they pale in comparison to the power and accuracy of the excimer.

So, don’t waste your time with the CO2 – go for the excimer and watch your cutting dreams come true.