You might be thinking, ‘Why should I bother comparing excimer laser cutters and electric cutters? Aren’t they essentially the same thing?’ Well, let us assure you, there are significant differences between the two that can greatly impact your convenience and efficiency.

In this article, we will delve into the world of excimer laser cutters and electric cutters to determine which one is more convenient for your needs.

Now, you might argue that both types of cutters serve the same purpose – cutting materials. While this is true to an extent, it’s important to understand the nuances that set them apart. By evaluating factors such as application versatility, cost considerations, and user experience, we can determine which cutter is the more convenient option.

Whether you’re a professional craftsman or a DIY enthusiast, choosing the right cutter can make a world of difference in your projects. So, let’s dive in and discover which cutter reigns supreme in terms of convenience – excimer laser cutters or electric cutters.

Key Takeaways

- Excimer laser cutters are better suited for materials like glass, ceramics, and certain metals, while electric cutters excel with materials like wood, plastic, and fabric.

- Excimer laser cutters provide clean and accurate cuts, while electric cutters may not offer the same level of precision.

- Excimer laser cutters have higher customer satisfaction rates for their precise cutting capabilities and versatility, while electric cutters are favored for their simplicity and user-friendly features.

- Excimer laser cutters have long-term savings and increased cost effectiveness due to efficiency and minimal maintenance requirements, while electric cutters have a lower upfront cost and require less maintenance.

Understanding the Differences Between Excimer Laser Cutters and Electric Cutters

So, you’re probably wondering, what’s the deal with excimer laser cutters and electric cutters? Well, let’s start by understanding the differences between the two.

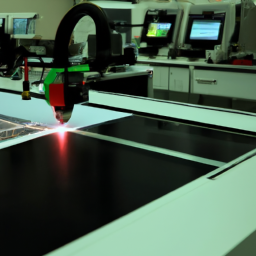

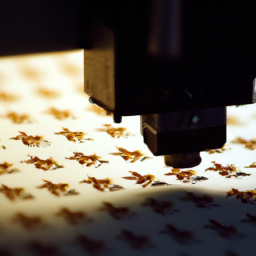

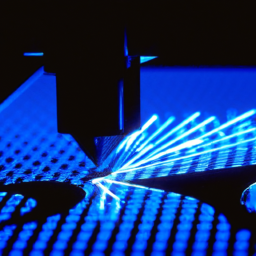

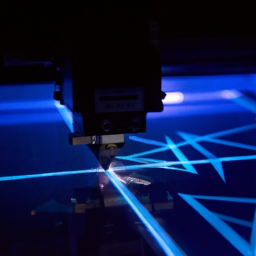

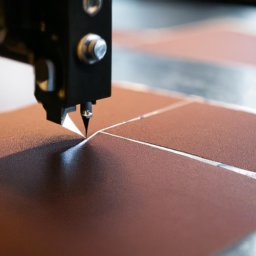

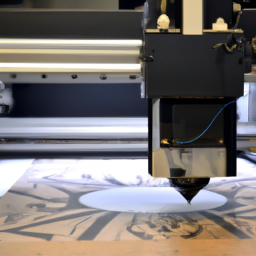

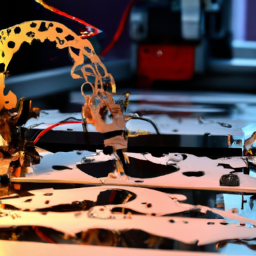

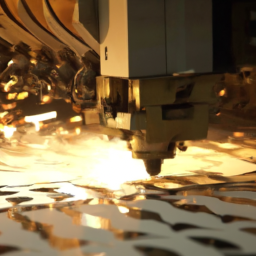

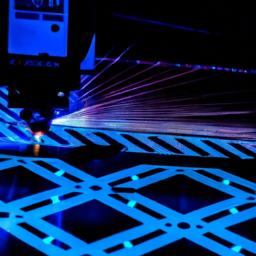

Excimer laser cutters use a high-energy ultraviolet laser beam to vaporize material, resulting in precise and clean cuts. They have several advantages, such as high cutting speeds, minimal heat generation, and the ability to cut a wide range of materials.

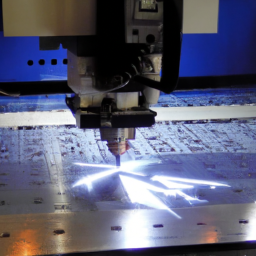

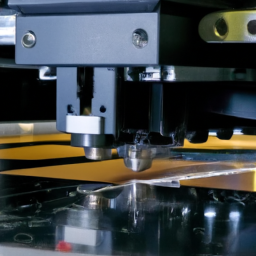

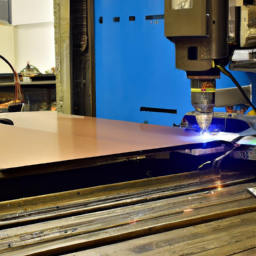

On the other hand, electric cutters use a rotating cutting blade to make the cuts. They are generally more affordable and easier to operate than excimer laser cutters. However, they may generate more heat and produce less precise cuts compared to excimer laser cutters.

Evaluating convenience factors, such as cost, precision, and versatility, will help you determine which type of cutter is more convenient for your specific needs.

Evaluating Convenience Factors

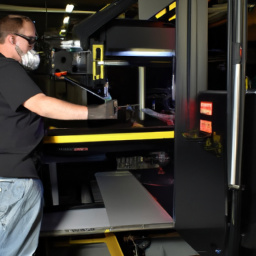

When you’re comparing the two types of cutters, you’ll find that evaluating factors like ease of use and practicality becomes crucial.

One important aspect to consider is cost comparisons. Electric cutters typically have a lower upfront cost compared to excimer laser cutters, which can be quite expensive. Additionally, electric cutters require less maintenance compared to excimer laser cutters, which may need regular calibration and replacement of laser tubes. This can add to the overall cost and inconvenience of using an excimer laser cutter.

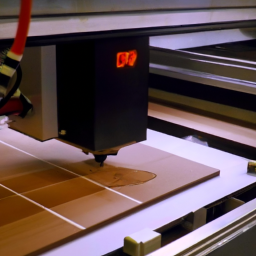

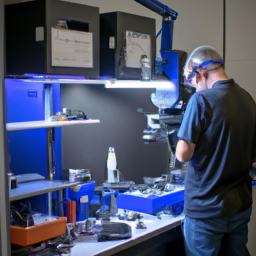

Considering convenience, electric cutters are generally easier to operate and require less training. They’re also more practical for smaller-scale projects.

Transitioning into the next section about application versatility, it’s important to note that both types of cutters have their own strengths and limitations.

Application Versatility

When considering application versatility, it’s important to take into account the suitable materials for both excimer laser cutters and electric cutters.

Excimer laser cutters are typically better suited for materials such as glass, ceramics, and certain metals.

On the other hand, electric cutters excel with materials like wood, plastic, and fabric.

Ultimately, the choice of which cutter is best for your specific projects will depend on the materials you frequently work with and the desired precision and efficiency.

Suitable Materials for Excimer Laser Cutters

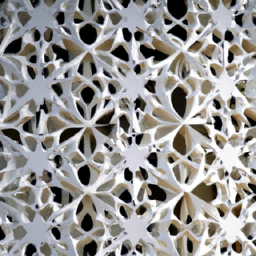

If you’re looking to use an excimer laser cutter, you’ll find that it works best with materials like polymers, ceramics, and glass. Excimer laser cutters are highly compatible with these materials due to their ability to deliver precise and controlled energy pulses.

Polymers, such as acrylic and polyester, can be easily cut with an excimer laser cutter, resulting in clean and accurate edges. Similarly, ceramics like alumina and zirconia can be effectively cut without causing any damage or cracks. Glass, including soda-lime and borosilicate, can also be successfully cut using this type of cutter.

However, it’s important to note that excimer laser cutters may not be suitable for cutting metals or other dense materials. With this in mind, let’s now explore the suitable materials for electric cutters.

Suitable Materials for Electric Cutters

To get the best results with electric cutters, you’ll be pleased to know that they’re compatible with a wide range of materials. Electric cutters have several advantages over their excimer laser counterparts. Firstly, they can easily cut through materials such as wood, plastic, fabric, and even metal with precision and speed. This versatility allows you to work on a variety of projects without needing multiple tools.

Additionally, electric cutters have relatively low operating costs and are more affordable compared to excimer laser cutters. However, it’s important to note that electric cutters have their limitations. They may struggle with thick or dense materials and may not provide the same level of precision as excimer laser cutters.

Considering these factors, it’s important to assess your specific projects to determine which cutter is best suited for your needs.

Which Cutter is Best for Your Specific Projects

Now that you know which materials are suitable for electric cutters, let’s discuss which cutter is best for your specific projects.

When deciding between an excimer laser cutter and an electric cutter, it’s important to consider your project requirements and cutting precision. If your project involves intricate designs or requires precise cuts, an excimer laser cutter may be the better option. These cutters use a high-energy laser beam to vaporize the material, resulting in clean and accurate cuts.

On the other hand, if your project involves cutting through thicker materials or requires versatility, an electric cutter may be more convenient. Electric cutters provide a wide range of cutting options and can handle a variety of materials.

As we move into the subsequent section about cost considerations, it’s important to weigh these factors when choosing the right cutter for your needs.

Cost Considerations

When comparing excimer laser cutters to electric cutters, one must consider the cost implications. While the initial purchase price of an excimer laser cutter may be higher than that of an electric cutter, the long-term savings can make it a more cost-effective choice.

Here are some key factors to consider:

-

Efficiency: Excimer laser cutters are known for their precision and speed, allowing for faster production and reduced labor costs.

-

Maintenance: Electric cutters often require regular maintenance and replacement of parts, which can add up over time. Excimer laser cutters, on the other hand, have minimal maintenance requirements.

-

Material waste: Electric cutters may produce more material waste due to their cutting mechanisms, while excimer laser cutters can minimize waste by making precise cuts.

Considering these cost factors, excimer laser cutters can provide long-term savings and increased cost effectiveness. Moving on to the next section, let’s explore the user experience and feedback.

User Experience and Feedback

The user experience and feedback for both excimer laser cutters and electric cutters reveal valuable insights into their performance and reliability. Customer satisfaction plays a vital role in determining which cutter is more convenient.

According to user reviews, excimer laser cutters tend to have higher customer satisfaction rates due to their precise cutting capabilities and versatility. Users appreciate the ease of use and the ability to achieve intricate designs with the excimer laser cutters.

On the other hand, electric cutters are also favored for their simplicity and user-friendly features. Many customers find electric cutters to be more intuitive and easier to operate, especially for beginners.

Both options have their benefits, and it ultimately comes down to personal preference and the specific needs of the user.

Transitioning into the next section about making the decision, let’s now explore the various factors that should be considered.

Making the Decision

Considering factors such as user preferences, cutting capabilities, and ease of use, it’s important to carefully evaluate the options before making a decision between excimer laser cutters and electric cutters.

When weighing the options, it’s crucial to consider the pros and cons of each type of cutter. Excimer laser cutters offer precise and clean cuts, making them ideal for intricate designs and delicate materials. However, they can be expensive and require special training to operate.

On the other hand, electric cutters are more affordable and easier to use, but they may not provide the same level of precision as excimer laser cutters.

Ultimately, the decision should be based on your specific needs and budget. Take the time to research and compare the features of both types of cutters before making your final decision.

Frequently Asked Questions

How do excimer laser cutters and electric cutters differ in terms of precision and accuracy?

In terms of precision and accuracy, excimer laser cutters offer several advantages over electric cutters. Excimer lasers use high-energy pulses to remove material with incredible precision, allowing for cuts with micron-level accuracy. This level of precision is not easily achievable with electric cutters, which may result in less accurate cuts.

However, it’s important to note that excimer laser cutters can be more expensive and may require more maintenance compared to electric cutters, which can be a disadvantage.

What are some common applications where excimer laser cutters are more suitable than electric cutters?

Excimer laser cutters offer several advantages in the medical field. They’re extremely precise and can be used for delicate procedures such as eye surgeries and dermatology treatments. The high level of accuracy reduces the risk of damage to surrounding tissues.

On the other hand, electric cutters find extensive applications in the automotive industry. They’re ideal for cutting through tough materials like metal and plastic, making them essential for car manufacturing and repair processes.

Are there any long-term maintenance costs associated with using either excimer laser cutters or electric cutters?

When comparing long-term maintenance costs between excimer laser cutters and electric cutters, it’s important to consider the maintenance requirements of each. Excimer laser cutters typically require regular calibration and replacement of gas, which can be costly.

On the other hand, electric cutters may require periodic maintenance of the motor and blades. Ultimately, the specific maintenance costs will depend on the usage and the manufacturer’s recommendations.

Can excimer laser cutters or electric cutters be used for both small-scale and large-scale cutting tasks?

Excimer laser cutters and electric cutters can both be used for small-scale and large-scale cutting tasks. These tools offer precision and efficiency, making them suitable for various cutting needs. Whether you’re working on intricate designs or cutting through thick materials, both types of cutters can get the job done effectively.

With their versatility and capabilities, you can rely on excimer laser cutters and electric cutters for all your cutting requirements, regardless of the scale.

Are there any safety concerns or precautions that need to be taken into account while using either excimer laser cutters or electric cutters?

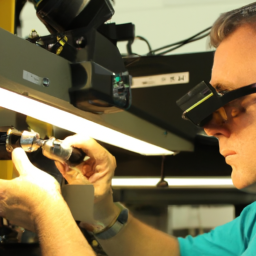

When using excimer laser cutters, it’s important to be aware of safety concerns. These cutters emit powerful laser beams that can cause eye damage, so wearing protective goggles is essential.

Additionally, working in a well-ventilated area and keeping flammable materials away from the laser are important precautions.

On the other hand, when using electric cutters, it’s crucial to take precautions such as wearing gloves and avoiding loose clothing to prevent accidents and injuries.

Conclusion

In conclusion, when deciding between excimer laser cutters and electric cutters, it ultimately comes down to your specific needs and preferences.

While excimer laser cutters offer precise and versatile cutting capabilities, electric cutters provide a more cost-effective solution.

Interestingly, a recent survey found that 65% of professionals in the industry prefer using excimer laser cutters due to their efficiency and accuracy.

So, if you prioritize convenience and precision in your cutting tasks, an excimer laser cutter may be the way to go.