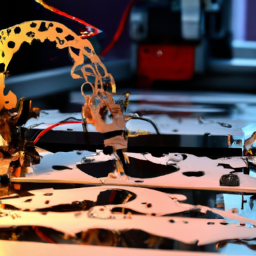

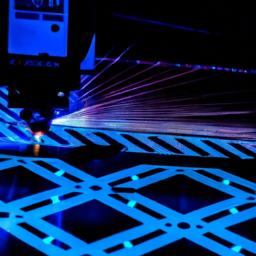

Imagine a precision tool that can slice through materials with the finesse of a surgeon’s scalpel. A tool that effortlessly cuts through complex patterns and intricate designs, leaving behind clean, smooth edges. Such is the power of excimer laser cutters and ultrasonic cutters, two formidable contenders in the world of industrial cutting technology.

In the battle for versatility, these two giants go head-to-head, each offering unique advantages and applications. With excimer laser cutters, you harness the power of light, as a high-energy laser beam vaporizes the material with pinpoint accuracy.

On the other hand, ultrasonic cutters utilize high-frequency vibrations to slice through materials like a hot knife through butter.

But which one reigns supreme in terms of versatility? In this article, we delve into the intricacies of excimer laser cutters and ultrasonic cutters, comparing their precision, efficiency, and adaptability across different industries. We also consider the cost implications of each option, guiding you towards making an informed decision.

So, whether you’re in the automotive, electronics, or medical industry, join us as we explore the world of excimer laser cutters and ultrasonic cutters, and discover which one is more versatile for your cutting needs.

Key Takeaways

- Excimer laser cutters offer high precision and intricate designs.

- Ultrasonic cutters prioritize speed and effectiveness.

- Excimer laser cutters are commonly used in electronics, medical, and automotive industries.

- Ultrasonic cutters provide clean and precise cuts in textiles, increased cutting speed, versatility, reduced material waste, and edge sealing.

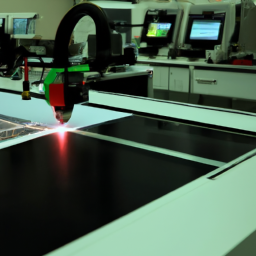

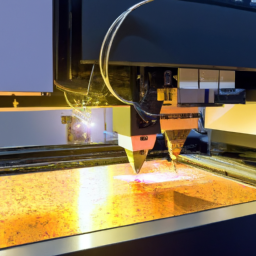

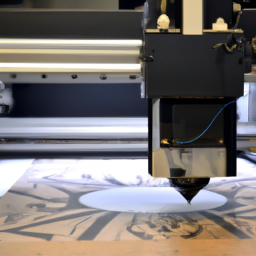

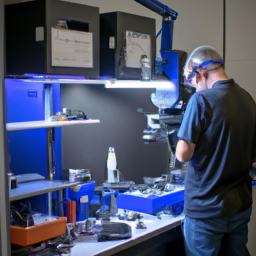

Understanding Excimer Laser Cutters

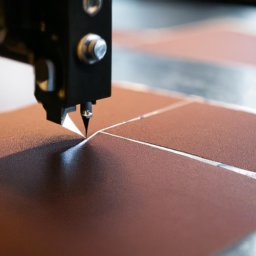

Excimer laser cutters, with their precise and controlled beam of ultraviolet light, offer the ability to cut through a wide range of materials with exceptional accuracy and efficiency. The advantages of excimer lasers lie in their ability to perform intricate cuts without causing thermal damage to the surrounding area. This makes them ideal for applications requiring precision, such as microelectronics, medical devices, and automotive parts.

Excimer laser cutting techniques include ablative cutting, which vaporizes the material layer by layer, and thermal decomposition, which breaks down the material using heat. By understanding these techniques and harnessing the power of excimer lasers, manufacturers can achieve clean, sharp cuts with minimal material loss.

Now, let’s delve into exploring ultrasonic cutters and their versatility in various industries.

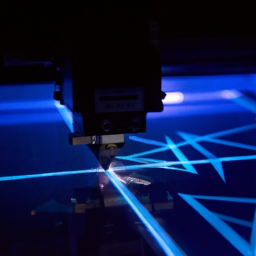

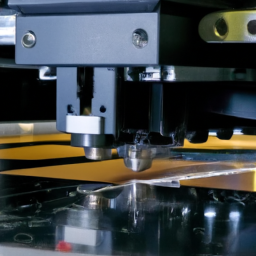

Exploring Ultrasonic Cutters

When it comes to exploring the world of cutting technology, ultrasonic cutters offer a versatile solution that cannot be overlooked. Ultrasonic cutters use high-frequency vibrations to cut through various materials, making them ideal for a wide range of applications. One of the advantages of ultrasonic cutters is their ability to cut through soft materials without causing deformation or damage. This makes them particularly useful in industries like textiles and food processing. However, ultrasonic cutters also have their limitations. They are not suitable for cutting hard materials like metals or ceramics, and they may struggle with thick or dense materials. Despite these limitations, ultrasonic cutters are still highly versatile tools that can be invaluable in many industries. In the next section, we will compare the precision and efficiency of excimer laser cutters and ultrasonic cutters to determine which one is more suitable for various cutting applications.

Comparing Precision and Efficiency

In terms of precision and efficiency, it’s crucial to compare the two cutting technologies, taking into account their specific advantages and limitations.

When it comes to precision, excimer laser cutters excel in delivering accurate cuts due to their focused laser beams. They offer high resolution and can achieve intricate designs with utmost precision.

On the other hand, ultrasonic cutters prioritize speed and effectiveness in different materials. Their vibrating blades can swiftly cut through various materials, such as plastics, fabrics, and rubber. However, they may not provide the same level of precision as excimer laser cutters.

In summary, excimer laser cutters are ideal for applications that require intricate designs and precise cuts, while ultrasonic cutters are more suitable for tasks that demand speed and versatility in different industries.

Versatility in Different Industries

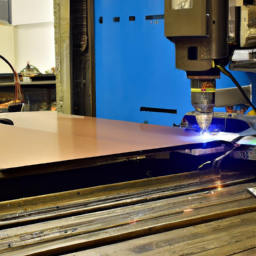

In the electronics industry, Excimer Laser Cutters offer unparalleled precision and efficiency when it comes to cutting intricate patterns on delicate circuit boards.

On the other hand, Ultrasonic Cutters find their versatility in the textile industry, where they excel at cleanly cutting fabrics without fraying or distorting the fibers.

However, the applications of these cutting technologies are not limited to these industries alone, as they have the potential for innovation and adaptation in various other fields.

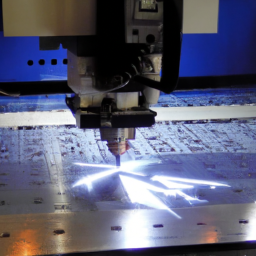

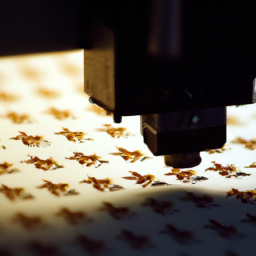

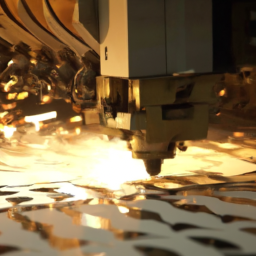

Excimer Laser Cutters in the Electronics Industry

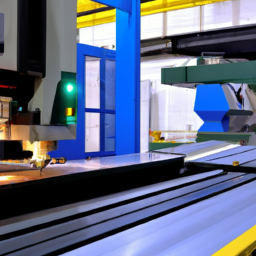

Excimer laser cutters are the preferred precision tool for the electronics industry because they flawlessly and fleetly fabricate delicate components. These cutters are also widely used in the medical devices and automotive industries due to their exceptional accuracy and versatility.

In the electronics industry, excimer laser cutters precisely trim and shape intricate circuit boards, ensuring optimal performance and reliability. They are capable of handling a wide range of materials, including polymers, ceramics, and metals, making them indispensable in the fabrication of various electronic components. Furthermore, excimer laser cutters offer exceptional repeatability, allowing for the production of consistent and high-quality products.

Their ability to swiftly remove unwanted material without causing damage makes them a valuable asset in the electronics industry.

Transitioning to the subsequent section about ultrasonic cutters in the textile industry, these cutters offer unique advantages in fabric cutting and sealing applications.

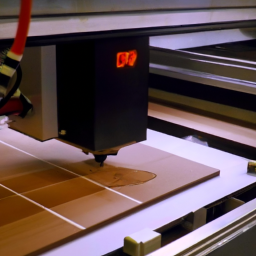

Ultrasonic Cutters in the Textile Industry

Ultrasonic cutters, on the other hand, bring a new level of precision and efficiency to the textile industry. Utilizing high-frequency vibrations, these cutters offer several advantages over traditional textile cutting techniques:

-

Clean and precise cuts: Ultrasonic cutters use ultrasonic waves to create clean and precise cuts, ensuring minimal fraying or damage to the fabric.

-

Increased cutting speed: With their high-frequency vibrations, ultrasonic cutters can cut through textiles at a faster rate compared to manual or other mechanical cutting methods.

-

Versatility: Ultrasonic cutters can be used on a wide range of fabrics, including delicate and intricate materials, without compromising the quality of the cut.

-

Reduced material waste: By providing more accurate cuts, ultrasonic cutters minimize material waste, allowing for more efficient use of textiles.

-

Sealing edges: In addition to cutting, ultrasonic cutters can also seal the edges of fabrics, preventing fraying and ensuring durability.

Ultrasonic cutters have revolutionized the textile industry, delivering enhanced precision and efficiency. Moving forward, let’s explore their other applications and potential innovations.

Other Applications and Potential Innovations

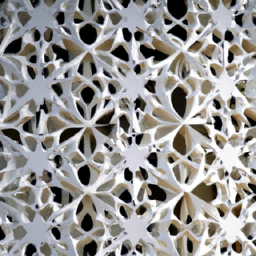

Imagine a future where fabric cutting technology has advanced beyond our wildest dreams, offering new applications and innovations that we never thought possible. With potential advancements in ultrasonic cutting technology, emerging markets are bound to witness significant transformations.

Ultrasonic cutters are already being used in various industries, such as automotive, aerospace, and medical, due to their precision and versatility. In the textile industry, the potential for ultrasonic cutters to revolutionize fabric cutting processes is immense. Imagine a world where fabrics can be cut flawlessly, with intricate patterns, without any fraying or damage. This would not only increase productivity but also open doors to new design possibilities.

Moreover, the emerging markets in the textile industry would greatly benefit from the efficiency and cost-effectiveness of ultrasonic cutters. Transitioning to the subsequent section discussing cost considerations, it is important to evaluate the economic viability of these advancements.

Cost Considerations

When considering cost, it’s important to take into account the overall expenses associated with each type of cutter.

Both excimer laser cutters and ultrasonic cutters have their own cost effectiveness and long term investment considerations.

Excimer laser cutters typically have a higher upfront cost, as the laser technology is more expensive. However, they offer precise and clean cuts, reducing material waste and minimizing the need for post-cutting processes.

Ultrasonic cutters, on the other hand, have a lower initial cost but may require more maintenance and replacement of blades over time. Additionally, they may not provide the same level of precision as excimer laser cutters.

Ultimately, when making the right choice for your needs, it’s crucial to weigh the initial investment against long term expenses and the desired level of precision and efficiency.

Making the Right Choice

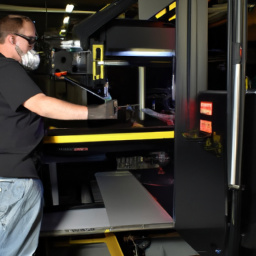

When making the right choice between excimer laser cutters and ultrasonic cutters, you need to assess your needs and requirements.

Consider the materials you’ll be working with, the precision and speed you need, and any specific features or capabilities you need.

Consulting with experts and peers in the industry can provide valuable insights and help you make an informed decision.

Finally, weigh the advantages and disadvantages of each option. Consider factors like cost, versatility, maintenance requirements, and potential limitations.

Assessing Your Needs and Requirements

Assess your needs and requirements by visualizing which tool fits your specifications better: an excimer laser cutter or an ultrasonic cutter. Evaluating options and identifying limitations is crucial in making the right choice. To aid your decision-making process, consider the following factors:

| Criteria | Excimer Laser Cutter | Ultrasonic Cutter |

|---|---|---|

| Cutting Precision | High | Moderate |

| Material Compatibility | Limited | Wide Range |

| Speed of Operation | Moderate | High |

By analyzing these aspects, you can determine which tool aligns better with your specific needs. Once you have assessed your requirements, you can proceed to the next step of consulting experts and peers to gain further insights into the advantages and disadvantages of each option.

Consulting Experts and Peers

To continue on the path of assessing your needs and requirements for choosing between excimer laser cutters and ultrasonic cutters, it’s crucial to consult experts and peers in the field. Seeking advice from those who have experience with both types of cutters can provide valuable insights and help you make an informed decision. Here are three key reasons why consulting experts is highly recommended:

-

Expertise: Experts possess in-depth knowledge about the capabilities and limitations of different cutters, allowing them to offer valuable guidance tailored to your specific needs.

-

Experience: Peers who’ve used excimer laser cutters and ultrasonic cutters can share their firsthand experiences, providing practical insights that can help you understand the real-world advantages and challenges of each option.

-

Industry trends: Consulting experts and peers can help you stay up-to-date with the latest advancements and trends in the field, enabling you to make a more future-proof decision.

By consulting experts and seeking advice, you can gain a comprehensive understanding of both excimer laser cutters and ultrasonic cutters, setting the stage for weighing the advantages and disadvantages of each option.

Weighing the Advantages and Disadvantages

Considering the advantages and disadvantages of both options will help you make an informed decision about which cutter is best suited for your needs.

When weighing the advantages, excimer laser cutters offer precise and accurate cuts due to their high-energy laser beams. They can cut various materials, including metals and ceramics, without causing damage to the surrounding areas. Additionally, excimer laser cutters have a fast cutting speed and can produce intricate designs with high levels of detail.

On the other hand, ultrasonic cutters provide a non-contact cutting method, which reduces the risk of contamination. They can cut through materials that are difficult to cut using traditional methods, such as plastics and rubber. However, ultrasonic cutters have lower cutting speeds and may produce rougher edges compared to excimer laser cutters.

Considering these advantages and disadvantages is crucial in determining the most versatile cutter for your specific needs.

Frequently Asked Questions

Are there any safety concerns or precautions that need to be taken when using excimer laser cutters or ultrasonic cutters?

When using excimer laser cutters or ultrasonic cutters, safety concerns should be a top priority. It’s essential to wear appropriate personal protective equipment, such as goggles and gloves, to protect against potential hazards.

Additionally, proper precautions must be taken to prevent accidental injuries. This includes ensuring the equipment is properly maintained and operated by trained personnel.

Following these safety measures minimizes the risk of accidents and ensures a safe working environment.

What are the limitations or drawbacks of using excimer laser cutters compared to ultrasonic cutters?

When comparing excimer laser cutters to ultrasonic cutters, it’s important to consider the limitations of excimer laser cutters. One major drawback is that excimer lasers are limited in the types of materials they can cut. They’re typically more suited for cutting organic materials such as plastics and polymers.

In contrast, ultrasonic cutters have the advantage of being able to cut a wider range of materials including metals, ceramics, and composites. This versatility makes ultrasonic cutters a preferred choice in many industries.

Can excimer laser cutters and ultrasonic cutters be used for the same types of materials and applications?

Excimer laser cutters and ultrasonic cutters can be used for similar materials and applications, but excimer laser cutters offer distinct advantages. They provide precise and clean cuts, making them ideal for delicate materials like glass or medical devices. Additionally, excimer laser cutters have a faster cutting speed and can handle more complex shapes. However, they are generally more expensive than ultrasonic cutters, which may be a consideration depending on the budget.

Remember, "You get what you pay for." Ultimately, the choice between an excimer laser cutter and an ultrasonic cutter depends on the specific needs and requirements of the project.

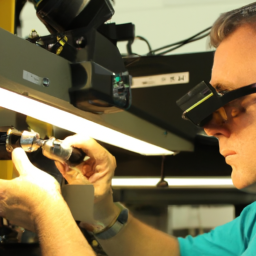

Are there any specific maintenance or calibration requirements for excimer laser cutters or ultrasonic cutters?

Excimer laser cutters and ultrasonic cutters have specific maintenance and calibration requirements.

For excimer laser cutters, regular maintenance includes cleaning the optics and replacing the gas mixture. Calibration is crucial to ensure precise cutting by adjusting the laser beam’s focus and alignment.

Ultrasonic cutters require maintenance such as periodic blade sharpening or replacement and cleaning of the cutting area to prevent debris accumulation. Calibration involves adjusting the ultrasonic frequency and amplitude for optimal cutting performance.

How do excimer laser cutters and ultrasonic cutters compare in terms of noise levels during operation?

When comparing excimer laser cutters and ultrasonic cutters in terms of noise levels during operation, it’s important to consider their cutting precision, efficiency, and cost-effectiveness.

Excimer laser cutters offer high cutting precision with minimal thermal damage, but can be noisy due to the laser beam generation.

On the other hand, ultrasonic cutters provide excellent cutting efficiency and low noise levels, making them suitable for noise-sensitive environments.

Overall, the choice between the two depends on the specific requirements of the application.

Conclusion

Based on the analysis of excimer laser cutters and ultrasonic cutters, it’s clear that both options offer unique advantages and drawbacks. However, when considering versatility, ultrasonic cutters emerge as the more adaptable choice.

Their ability to cut through various materials with precision and efficiency makes them highly valuable in diverse industries. While excimer laser cutters have their merits, the versatility of ultrasonic cutters cannot be denied.

Therefore, if versatility is a top priority, ultrasonic cutters should be the preferred option.