Are you in search of the ultimate precision cutting tool? Look no further than the battle between excimer laser cutters and waterjets. These two powerhouses have been dominating the precision cutting industry, but which one reigns supreme when it comes to accuracy?

Excimer laser cutters and waterjets each have their own unique advantages, but it all boils down to one crucial factor: precision. In this article, we will delve into the technical aspects of both technologies and compare their precision levels.

By the end, you will have a clear understanding of which option is best suited to meet your needs. So, buckle up and get ready for a deep dive into the world of precision cutting.

Key Takeaways

- Excimer laser cutters offer micron-level accuracy, ensuring precise dimensions and smooth edges in medical applications and enabling the production of intricate microcircuits and delicate components in the electronics industry.

- Waterjets can achieve high precision levels with various factors like material type and nozzle size, making them versatile and cost-effective compared to excimer laser cutters.

- Excimer laser cutters are slower and more expensive compared to waterjets, but they have endless possibilities for innovation and creativity.

- Case studies and real-life examples provide valuable insights for decision-making when choosing between excimer laser cutters and waterjets, taking into consideration factors such as material type, required precision, speed, and cost.

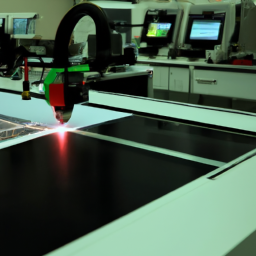

Overview of Excimer Laser Cutters

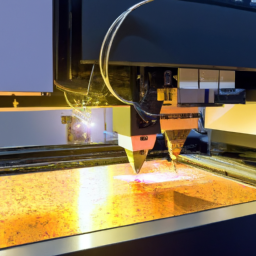

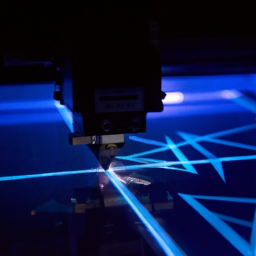

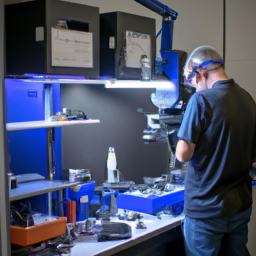

Excimer laser cutters are incredibly precise, making them the ultimate tool for achieving flawless and immaculate cuts. Utilizing excimer laser technology, these cutters use a high-energy beam of ultraviolet light to precisely ablate materials with minimal heat transfer. This allows for clean and accurate cuts, even on delicate materials.

The benefits of excimer lasers include their ability to cut with micron-level accuracy, producing sharp edges and intricate designs. They are also capable of cutting a wide range of materials, including metals, plastics, glass, and ceramics. Additionally, excimer laser cutters offer high precision and repeatability, ensuring consistent results with every cut.

As we transition into the subsequent section about the overview of waterjets, it is important to compare the precision and capabilities of these two cutting technologies.

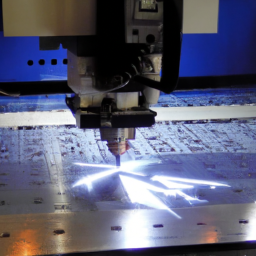

Overview of Waterjets

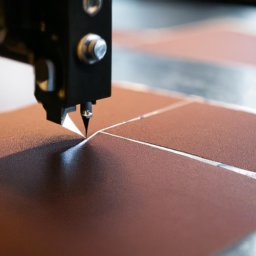

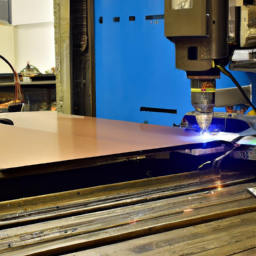

Waterjets are powerful tools used in various industries for cutting and shaping materials. They work by pressurizing water to high levels and then forcing it through a small nozzle, creating a focused stream of water that can cut through a wide range of materials.

This technology is widely used in industries such as aerospace, automotive, and manufacturing, where precision and versatility are crucial.

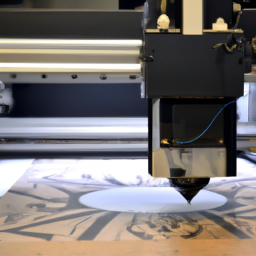

How waterjets work

Imagine yourself watching in awe as a powerful stream of water effortlessly slices through any material with astonishing precision. Waterjets, a versatile cutting tool, operate by pressurizing water to extreme levels and then propelling it through a small orifice.

The advantages of waterjets are numerous. Firstly, they can cut through almost any material, including metals, ceramics, and composites. Secondly, waterjets produce clean cuts without heat-affected zones, minimizing the risk of material distortion. Lastly, they offer the ability to cut intricate shapes with high precision.

However, waterjets also have limitations. They’re slower compared to other cutting methods and may require additional time for setup and programming. Furthermore, the process can create a significant amount of noise and produce a large amount of waste material.

As we delve into the subsequent section about applications and industries that use waterjets, we’ll explore their extensive range of uses and the benefits they bring.

Applications and industries that use waterjets

One of the main reasons industries use waterjets is because they can cut through almost any material with precision and without heat-affected zones. This makes waterjets highly versatile and suitable for a wide range of applications across various industries.

For instance, in the aerospace industry, waterjets are used to cut complex shapes in materials like composites, aluminum, and titanium. In the automotive industry, waterjets are employed for trimming and shaping various components like dashboards and panels. The food industry also benefits from waterjets as they can precisely cut through products like meat and vegetables without causing damage.

Other industries that utilize waterjets include architecture, electronics, and manufacturing. Waterjets are highly sought after due to their ability to achieve intricate cuts with minimal material waste.

Transitioning to the subsequent section about the precision levels of excimer laser cutters, it is important to consider the various factors that contribute to their accuracy.

Precision Levels of Excimer Laser Cutters

To achieve the highest level of precision in your work, you must consider the capabilities of excimer laser cutters. Excimer laser cutting offers several advantages that make it a preferred choice for precise cutting applications.

The precision of excimer laser cutting is unparalleled due to the extremely small beam size and high power density. The laser beam can be focused to a spot size as small as a few micrometers, allowing for intricate and precise cuts. Additionally, the high power density ensures clean and precise cuts without any thermal damage to the surrounding material.

This level of precision is ideal for industries such as electronics, medical devices, and aerospace, where accuracy is of utmost importance.

Transitioning into the subsequent section about the precision levels of waterjets, it is important to compare the capabilities of both technologies to make an informed decision.

Precision Levels of Waterjets

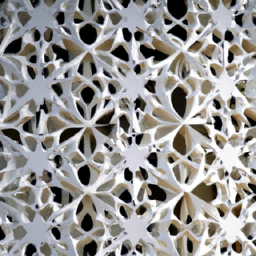

When it comes to achieving the highest level of precision in your work, you need to consider the capabilities of waterjets and how they can potentially exceed your expectations. Waterjets are known for their exceptional precision levels and cutting capabilities.

With waterjets, you can achieve intricate and detailed cuts with ease. The precision levels of waterjets are determined by various factors, including the type of material being cut and the size of the nozzle used. Waterjets can cut through a wide range of materials, including metals, composites, and even stone, with precision levels that are unmatched by other cutting methods.

The high-pressure water stream used in waterjets allows for precise and clean cuts, resulting in minimal material wastage.

Transitioning into the subsequent section about the comparison of precision levels, it is important to note the advantages of waterjets in terms of precision and cutting capabilities.

Comparison of Precision Levels

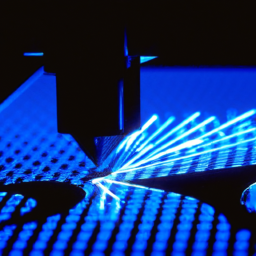

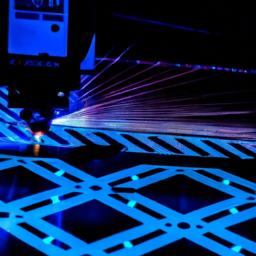

Get ready to be amazed by the comparison of precision levels between waterjets and other cutting methods! When it comes to precision, waterjets excel in several areas compared to other cutting technologies. Here are three key advantages of high precision cutting with waterjets:

-

Accuracy: Waterjets can achieve incredibly precise cuts, with tolerances as low as 0.1mm. This level of accuracy is crucial in industries where precision is paramount, such as aerospace and electronics.

-

Versatility: Waterjets can cut a wide range of materials, including metal, glass, ceramics, and composites, with consistent precision. This versatility makes waterjets a preferred choice for applications that require cutting different materials with high precision.

-

Minimal Heat Affected Zone (HAZ): Unlike other cutting methods, waterjets produce minimal heat during the cutting process. This reduces the risk of material distortion or warping, making waterjets ideal for delicate or heat-sensitive materials.

Considering the comparison with other cutting technologies, waterjets prove to be a top contender in terms of precision.

Now, let’s move on to choosing the right option for your needs.

Choosing the Right Option for Your Needs

When deciding between excimer laser cutters and waterjets, there are several factors to consider. These include the type of material being cut, desired precision levels, and budget constraints.

Additionally, examining case studies and real-life examples of successful applications for each technology can provide valuable insight into which option may be the best fit for your needs.

Factors to consider when deciding between excimer laser cutters and waterjets

To make an informed decision between excimer laser cutters and waterjets, you should consider a few key factors. These factors include the material you will be cutting, the required precision, the speed of the cutting process, and the cost. Excimer laser cutters are highly precise and can cut through a variety of materials, including metals and plastics, with minimal heat affected zones. However, they can be slower and more expensive compared to waterjets. On the other hand, waterjets are versatile and can cut through a wide range of materials, including thick and hard materials. They are faster and more cost-effective, but may not offer the same level of precision as excimer laser cutters. Considering these factors will help you choose the right option for your needs. In the subsequent section, we will explore case studies and real-life examples of successful applications for each technology.

Case studies and real-life examples of successful applications for each technology

Discover how these powerful technologies have revolutionized industries and transformed the way we cut materials, unlocking endless possibilities for innovation and creativity.

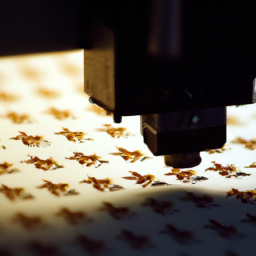

Excimer laser cutters have proven to be highly precise in a variety of applications. For example, in the medical field, excimer lasers have been used to accurately cut stents and catheters, ensuring precise dimensions and smooth edges. In the electronics industry, these lasers have enabled the production of intricate microcircuits and delicate components with minimal heat damage.

Waterjets, on the other hand, excel in cutting a wide range of materials, including metals, ceramics, and composites. They have been successfully employed in industries such as aerospace, where waterjets have been used to precisely cut complex shapes in aircraft components.

Case studies and real-life examples demonstrate the precision and versatility of both technologies, providing valuable insights for decision-making.

Frequently Asked Questions

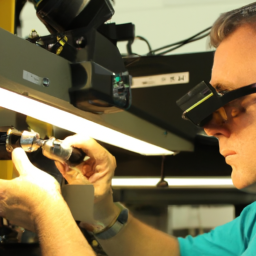

Are there any safety concerns or precautions to consider when using Excimer Laser Cutters or Waterjets?

When working with excimer laser cutters or waterjets, it’s essential to prioritize safety. There are several safety concerns and precautions to consider.

First, make sure to follow proper operating procedures and wear appropriate safety equipment, such as gloves and goggles.

Additionally, it’s crucial to receive proper training on how to use these machines safely.

By taking these precautions, you can minimize the risk of accidents and ensure a safe working environment.

What materials can be cut using Excimer Laser Cutters and Waterjets?

Excimer laser cutters offer several advantages over waterjets when it comes to cutting materials. They’re highly precise and can cut through various materials, including metals, ceramics, and polymers.

In contrast, waterjets have limitations when cutting certain materials, such as heat-sensitive substances and brittle materials. This is due to the high-pressure water stream used, which can cause thermal damage or breakage.

Therefore, excimer laser cutters are a preferred choice for their precision and versatility in material cutting.

How much maintenance is required for Excimer Laser Cutters and Waterjets?

When it comes to maintenance requirements, both excimer laser cutters and waterjets have their own benefits and drawbacks. Excimer laser cutters require regular cleaning and calibration to maintain their precision, but they have the advantage of being more precise in cutting delicate materials.

On the other hand, waterjets require routine checks and maintenance to ensure the proper functioning of the pump and nozzle, but they offer the flexibility of cutting a wide range of materials.

Can Excimer Laser Cutters and Waterjets be used for both small-scale and large-scale projects?

Excimer laser cutters and waterjets can indeed be used for both small-scale and large-scale projects. These technologies offer versatility in their application capabilities.

Excimer laser cutters are suitable for precise cutting in small-scale applications, while waterjets excel in large-scale projects due to their ability to handle thicker materials.

Both options provide reliable and efficient cutting solutions, allowing for a wide range of project sizes to be accomplished accurately and efficiently.

What is the average cost of Excimer Laser Cutters and Waterjets, and are there any additional expenses to consider?

When comparing the average cost of excimer laser cutters and waterjets, it’s important to consider hidden expenses. Excimer laser cutters typically have a higher average cost compared to waterjets. However, additional expenses such as maintenance, consumables, and training should also be taken into account.

These hidden expenses can significantly impact the overall cost of owning and operating either technology. Careful analysis and evaluation of these factors are crucial in making an informed decision.

Conclusion

So there you have it! After delving into the world of excimer laser cutters and waterjets, it’s clear that both options offer impressive precision levels. However, if you’re seeking absolute perfection, the excimer laser cutter is the way to go. Its laser technology allows for incredibly precise cuts, making it the ultimate choice for those who demand pixel-perfect accuracy.

While waterjets certainly hold their own in terms of precision, the excimer laser cutter takes it to a whole new level, like a superhero with a laser-sharp focus. Choose wisely and let your projects shine with unparalleled precision!