Are you ready to cut through the confusion and make an informed decision for your business? In the world of manufacturing, the choice between fiber laser cutters and CNC routers can be as sharp as a knife. But fear not, because we’re here to guide you through this cutting-edge dilemma. Like a skilled surgeon, we’ll dissect the advantages and drawbacks of each machine, allowing you to make a precise choice that suits your business needs.

Fiber laser cutters, with their intense beam of light, offer unparalleled precision and speed. On the other hand, CNC routers, like a versatile chisel, excel at shaping and carving materials with ease.

In this article, we’ll take a closer look at both options, comparing their cost, efficiency, precision, and versatility. By the time we’re done, you’ll have a clear understanding of which tool is the sharpest for your business.

So, let’s dive in and carve out the perfect choice for you!

Key Takeaways

- Fiber laser cutters offer unparalleled precision and speed compared to CNC routers.

- CNC routers excel at shaping and carving materials, particularly non-metal materials.

- Fiber laser cutters are more expensive to purchase and maintain, but can lead to increased productivity and cost savings in the long run.

- The choice between a fiber laser cutter and a CNC router should be based on the specific needs and requirements of the business, level of customization required, and preferences of customers.

Understanding Fiber Laser Cutters

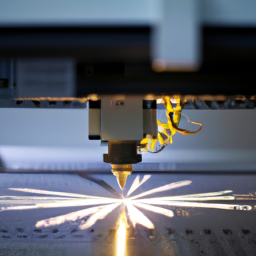

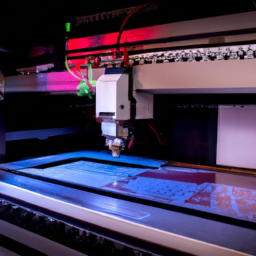

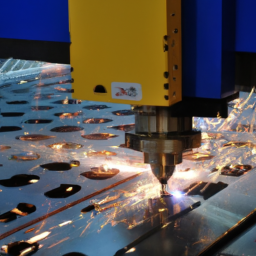

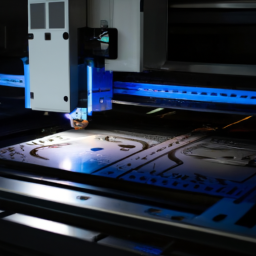

If you’re looking for a high-precision cutting solution, fiber laser cutters are the way to go. With their advanced fiber laser technology, these cutters offer numerous advantages over traditional cutting methods.

Fiber laser cutters use a high-powered laser beam to cut through a wide range of materials, including metal, plastic, and wood. The laser beam is transmitted through a fiber optic cable, which allows for precise and accurate cuts.

One of the main advantages of fiber laser cutters is their speed. They can cut through materials at a much faster rate compared to CNC routers, making them ideal for high-volume production. Additionally, fiber laser cutters have a smaller heat-affected zone, resulting in cleaner and more precise cuts.

However, it’s important to note that fiber laser cutters are typically more expensive than CNC routers and may require regular maintenance.

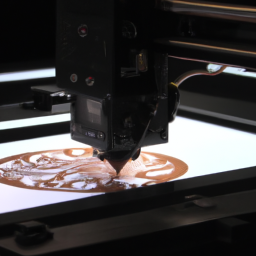

Exploring CNC Routers

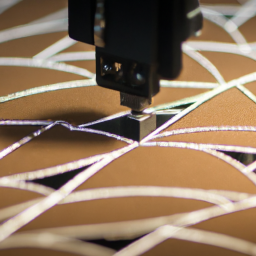

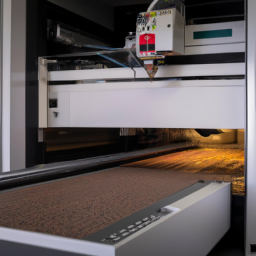

When it comes to functionality and applications, CNC routers offer a wide range of capabilities. These machines are capable of cutting and shaping various materials, including wood, plastics, and metals, with high precision and accuracy. Additionally, CNC routers can be used for a variety of applications, such as signage production, furniture manufacturing, and prototyping.

In terms of the types of materials they can cut, CNC routers are versatile machines that can handle a wide range of materials. They can cut through soft materials like foam and rubber, as well as harder materials like hardwood and aluminum. This flexibility makes CNC routers suitable for a variety of industries, including aerospace, automotive, and woodworking.

Like any technology, CNC routers have their pros and cons. On the positive side, these machines offer high precision and repeatability, allowing for consistent and accurate cuts. They also have a relatively low operating cost and can be programmed to automate the cutting process. However, CNC routers may have limitations when it comes to cutting thick or dense materials, and they require specialized software and training to operate effectively.

Functionality and Applications

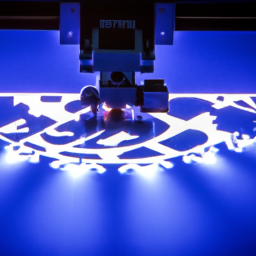

Imagine using a fiber laser cutter to effortlessly slice through metal materials, creating intricate designs and precise cuts for your business. Laser cutting technology offers several advantages over routing when it comes to functionality and applications. Here are four key points to consider:

-

Superior precision: Fiber laser cutters use a concentrated beam of light to cut materials with extreme accuracy, allowing for intricate designs and precise cuts that aren’t easily achievable with a CNC router.

-

Versatility: Laser cutting machines can work with a wide range of materials, including metals, plastics, and composites, making them suitable for various industries and applications.

-

Faster production: With high cutting speeds and minimal setup time, fiber laser cutters can significantly increase productivity and throughput compared to CNC routers.

-

Cleaner cuts: Laser cutting produces clean edges without the need for secondary processing, reducing the time and effort required for finishing operations.

When comparing capabilities, laser cutting is often the preferred choice for businesses that require high precision, versatility, speed, and clean cuts.

Types of Materials They Can Cut

Discover the sheer range of materials that can be effortlessly cut, leaving you in awe of the endless possibilities for your business.

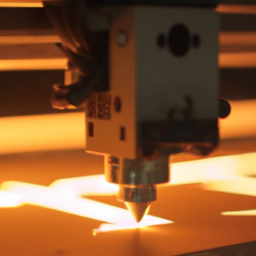

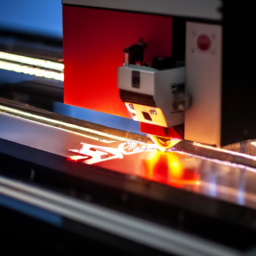

Fiber laser cutters and CNC routers offer an impressive array of laser cutting capabilities and material compatibility. Fiber laser cutters excel at cutting metal materials, such as stainless steel, aluminum, and brass. With their high power and precision, they can effortlessly slice through thick sheets of metal with intricate designs.

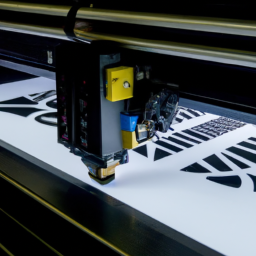

On the other hand, CNC routers are better suited for cutting non-metal materials, including wood, plastic, foam, and acrylic. They provide clean and precise cuts, making them ideal for signage production, woodworking, and prototyping.

Both machines offer versatile material compatibility, allowing you to explore various industries and expand your business horizons.

Pros and Cons

Although both options have their advantages and disadvantages, it’s important to consider that laser cutting can be up to 20% faster than traditional methods, saving your business valuable time.

Laser cutters offer numerous advantages, such as precise and intricate cuts, minimal material waste, and the ability to cut a wide range of materials, including metals, plastics, and wood. Additionally, they provide cleaner edges and require minimal post-processing.

On the other hand, laser cutters also have some drawbacks. They can be expensive to purchase and maintain, and the initial setup can be complex. Furthermore, they may not be suitable for cutting thick materials.

CNC routers, on the other hand, offer the advantage of versatility, as they can handle larger and thicker materials. However, they tend to be slower and may produce less precise cuts compared to laser cutters.

Consider Your Business Needs

To determine the best option for your business, assess your specific needs before making a decision between fiber laser cutters and CNC routers. Consider the level of customization options required for your projects. Fiber laser cutters excel at precise and intricate designs, making them ideal for industries like jewelry or electronics.

On the other hand, CNC routers are great for larger-scale projects that require engraving or carving on various materials like wood or plastic. Additionally, conduct a productivity analysis to understand your production requirements. Fiber laser cutters offer high-speed cutting capabilities, resulting in quicker production times.

CNC routers, on the other hand, are known for their versatility and can handle a wide range of materials and applications. By considering your business needs, you can choose the option that will optimize your production and efficiency.

Comparing Cost and Efficiency

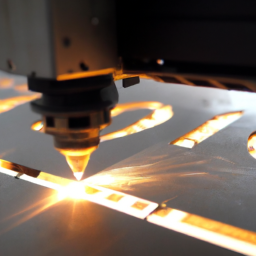

Save money and boost productivity by comparing the costs and efficiency of fiber laser cutters and CNC routers for your business. When considering the cost comparison, it’s important to evaluate the initial investment, maintenance costs, and operational expenses.

Fiber laser cutters are generally more expensive upfront due to their advanced technology, but they have lower maintenance costs and consume less power compared to CNC routers. In terms of efficiency analysis, fiber laser cutters offer higher cutting speeds, precision, and versatility, allowing for intricate designs and complex shapes.

CNC routers, on the other hand, are better suited for larger-scale projects and can handle a wider range of materials. Ultimately, the choice between fiber laser cutters and CNC routers depends on your business needs, budget, and the specific requirements of your projects.

- Fiber laser cutters: faster cutting speeds, precise cuts, versatile for intricate designs

- CNC routers: better for larger-scale projects, wide range of materials

- Lower maintenance costs for fiber laser cutters

- Fiber laser cutters consume less power

- Initial investment higher for fiber laser cutters, but long-term savings possible

Evaluating Precision and Versatility

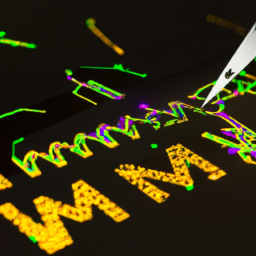

Boost your business’s productivity and expand your design capabilities with a highly precise and versatile tool for cutting and shaping materials. When evaluating accuracy, fiber laser cutters outperform CNC routers.

Fiber laser cutters use a focused laser beam to cut through materials with extreme precision, resulting in clean and intricate cuts. On the other hand, CNC routers rely on rotating cutting tools, which may not achieve the same level of precision.

Additionally, fiber laser cutters offer a wide range of capabilities that surpass those of CNC routers. They can cut through a variety of materials, including metal, plastic, and wood, with ease. Moreover, fiber laser cutters can engrave detailed designs and create complex shapes, providing your business with endless possibilities for customization.

In conclusion, when comparing capabilities and evaluating accuracy, fiber laser cutters are the superior choice for your business.

Making the Right Choice

When making a decision, it’s important to consider the specific needs and requirements of your business. Choosing between fiber laser cutters and CNC routers can be a challenging task.

To help you make the right choice, here are a few factors to consider:

-

Cost-effective options: Fiber laser cutters are generally more expensive to purchase and maintain compared to CNC routers. However, they offer higher precision and faster cutting speeds, which can lead to increased productivity and cost savings in the long run.

-

Customer satisfaction: Both fiber laser cutters and CNC routers can deliver high-quality cuts and designs. However, fiber laser cutters are particularly suitable for detailed and intricate designs, while CNC routers excel at larger and more complex projects.

Assessing the specific needs and preferences of your customers can help guide your decision-making process.

By carefully evaluating the cost-effectiveness and customer satisfaction aspects, you can make an informed decision on whether a fiber laser cutter or a CNC router is the better choice for your business.

Frequently Asked Questions

How do fiber laser cutters and CNC routers differ in terms of their power and cutting capabilities?

Fiber laser cutters and CNC routers differ in terms of power and cutting capabilities. Fiber laser cutters use a high-powered laser beam to cut through materials, offering precise and fast cutting with minimal heat distortion.

On the other hand, CNC routers use rotating cutting tools to carve and shape materials, making them ideal for woodworking. CNC routers have the advantage of versatility and can work with a wide range of materials, while fiber laser cutters excel in precision cutting and are commonly used in industries like metal fabrication.

Can fiber laser cutters and CNC routers be used for the same materials and applications?

Fiber laser cutters and CNC routers can be used for a variety of materials and applications, but they have their own strengths and weaknesses.

Fiber laser cutters excel in cutting thin materials with high precision, while CNC routers are better suited for woodworking and cutting thicker materials.

However, when it comes to woodworking, CNC routers have some advantages over fiber laser cutters. They have the ability to create intricate designs and the option to use different types of cutting tools.

What are the maintenance requirements for fiber laser cutters and CNC routers?

Maintenance requirements for fiber laser cutters and CNC routers can vary depending on the specific model and usage.

For fiber laser cutters, regular maintenance includes cleaning the lenses, checking and adjusting the beam alignment, and inspecting and replacing worn parts. Troubleshooting tips may involve checking for loose connections, calibrating the laser power, and ensuring proper cooling.

As for CNC routers, maintenance typically involves lubricating the machine, cleaning the spindle, checking and replacing cutting tools, and inspecting the motors and belts for wear and tear. Troubleshooting tips may include recalibrating the machine, checking for loose connections, and ensuring proper voltage supply.

Are there any health and safety considerations when using fiber laser cutters or CNC routers?

When operating fiber laser cutters or CNC routers, it’s crucial to prioritize workplace safety. Both machines pose potential hazards that must be addressed. Safety precautions include wearing appropriate protective gear such as goggles, gloves, and ear protection.

Ensure the workspace is well-ventilated to prevent exposure to fumes or dust. Regular maintenance and inspections are necessary to keep the machines in optimal condition.

Implementing safety protocols and providing training to employees on machine operation and emergency procedures is essential for a safe working environment.

Can fiber laser cutters and CNC routers be easily integrated into existing production processes?

Integrating fiber laser cutters and CNC routers into existing production processes can present some challenges. One major consideration is the compatibility of the machines with your current workflow. This may require modifications to your production line or the implementation of additional software.

Additionally, there are cost implications associated with integrating these machines, including the initial investment, training, and maintenance. It’s essential to carefully assess these integration challenges and cost implications before making a decision.

Conclusion

In conclusion, after analyzing the characteristics of both fiber laser cutters and CNC routers, it’s evident that both machines have their own strengths and weaknesses.

However, when it comes to choosing the right option for your business, it ultimately depends on your specific needs and requirements.

While fiber laser cutters offer high precision and speed, CNC routers provide versatility and cost-effectiveness.

Therefore, it’s crucial to carefully evaluate your business needs and consider factors like cost, efficiency, precision, and versatility before making the final decision.

Remember, the right choice will greatly impact the success of your business in the long run.