Step into the world of cutting-edge technology, where sparks fly and precision reigns supreme. Picture yourself standing at the forefront of a battle between two formidable opponents: fiber laser cutters and plasma cutters. In this clash of titans, the question arises: which one is more cost-effective?

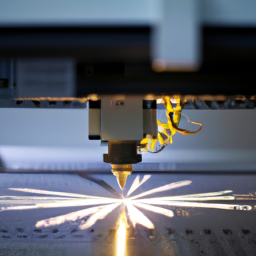

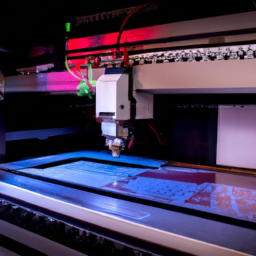

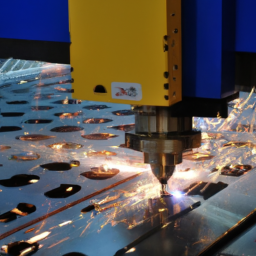

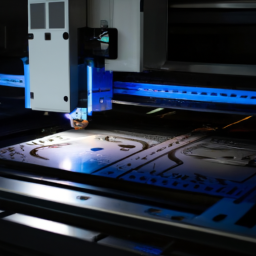

Fiber laser cutters, like a surgeon’s scalpel, slice through materials with unparalleled precision. These high-powered machines employ a concentrated beam of light, capable of etching intricate designs and delivering immaculate cuts.

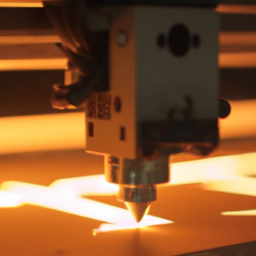

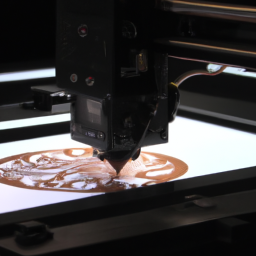

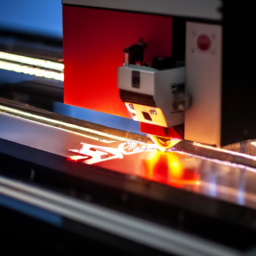

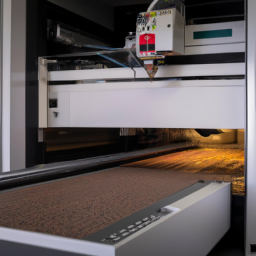

On the other hand, plasma cutters, akin to a fiery dragon’s breath, unleash a stream of superheated gas, melting away obstacles with brute force.

To make an informed decision, it is crucial to weigh the cost considerations. While fiber laser cutters may have a higher initial investment, their operational costs tend to be lower due to their energy efficiency. Plasma cutters, though comparatively affordable upfront, may incur higher expenses in terms of consumables and maintenance.

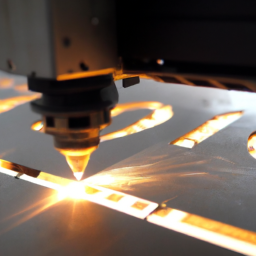

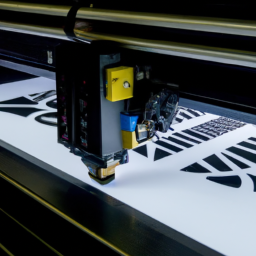

Beyond costs, cutting speed and precision play a pivotal role. Fiber laser cutters boast faster cutting speeds and finer details, ideal for intricate designs. Plasma cutters, while not as swift, excel in cutting thick materials with ease.

Material compatibility is yet another factor to consider. Fiber laser cutters triumph over plasma cutters when it comes to cutting reflective materials like brass and copper. However, plasma cutters exhibit their prowess when it comes to cutting thicker materials such as steel.

When it comes to choosing between fiber laser cutters and plasma cutters, it all boils down to understanding your unique needs and priorities. By delving into the intricacies of these two technologies, you can make an informed decision that strikes the perfect balance between cost, speed, precision, and material compatibility.

So, step into the arena of cost-effectiveness and let the battle begin!

Key Takeaways

- Fiber laser cutters offer unparalleled precision and faster cutting speeds, making them suitable for industries that prioritize speed and precision.

- Plasma cutters excel in cutting thick materials like steel and offer faster and more precise results, making them a cost-effective choice for industries that prioritize speed and precision.

- Fiber laser cutters have higher initial costs but lower operational costs, making them more cost-effective in the long run.

- Plasma cutters have lower upfront costs and can handle thicker materials, but they consume more energy and require regular electrode replacement. The right choice depends on specific needs and budget constraints.

Understanding Fiber Laser Cutters

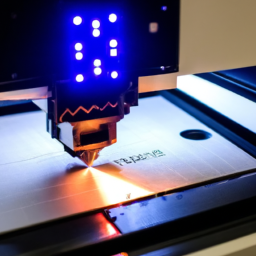

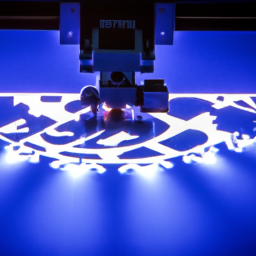

If you’re looking for a laser cutter that offers high precision and fast cutting speeds, then fiber laser cutters are the way to go. Fiber laser cutters utilize a high-powered laser beam that’s generated through the process of fiber optic amplification. This technology allows for a more concentrated and intense laser beam, resulting in cleaner and more accurate cuts.

One of the main advantages of fiber laser cutters is their ability to cut through a wide range of materials, including metals, plastics, and even reflective surfaces. They also offer a higher cutting speed compared to other types of laser cutters, which can significantly increase productivity and efficiency in a manufacturing setting.

Additionally, fiber laser cutters require less maintenance and have a longer lifespan compared to other laser cutting machines.

However, it’s important to note that fiber laser cutters do have some disadvantages. They tend to have a higher initial cost compared to plasma cutters, making them less accessible for smaller businesses or hobbyists. They also consume more energy, which can increase operational costs over time.

Despite these drawbacks, the precision, speed, and versatility of fiber laser cutters make them a cost-effective choice for many industries.

Exploring Plasma Cutters

When you’re considering options for cutting, take a moment to explore the world of plasma. Plasma cutter technology has been around for decades and offers several advantages over other cutting methods.

Plasma cutters can achieve cutting speeds up to 5 times faster than traditional methods. This is due to the high-temperature plasma arc that quickly melts through the material.

Plasma cutters can cut through a wide range of materials, including stainless steel, aluminum, and even non-ferrous metals. This versatility makes them suitable for various industries like automotive, construction, and manufacturing.

Plasma cutting produces clean, smooth edges with minimal heat-affected zones. This reduces the need for secondary processing and ensures a high-quality finished product.

Plasma cutters offer fast cutting speeds, versatility, and precision, making them a cost-effective choice for many industries.

Cost Considerations

To determine the most cost-effective option, you should carefully consider the various factors that contribute to the overall cost of using a plasma cutter. One important factor is the initial cost of the equipment. Plasma cutters tend to have a lower upfront cost compared to fiber laser cutters.

However, it is important to also consider the long-term savings. Fiber laser cutters have a higher initial cost but offer significant savings in terms of operating costs. They’re more energy-efficient and require less maintenance, resulting in lower electricity and maintenance expenses over time.

Additionally, fiber laser cutters have a longer lifespan, which means you won’t have to replace them as frequently.

Overall, while plasma cutters may have a lower initial cost, a cost comparison taking into account long-term savings shows that fiber laser cutters are more cost-effective.

Cutting Speed and Precision

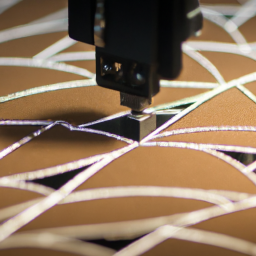

Cutting with a plasma cutter provides faster and more precise results compared to other options available. When it comes to cutting efficiency, plasma cutters have made significant strides due to technological advancements.

They are capable of cutting through a wide range of materials, including steel, aluminum, and stainless steel, with remarkable speed. The cutting speed of a plasma cutter is determined by the power output and the thickness of the material being cut. With higher power outputs, plasma cutters can achieve faster cutting speeds, making them a cost-effective option for industries that require high-volume cutting.

Additionally, plasma cutters offer exceptional precision, allowing for clean and accurate cuts, even on intricate designs. This level of precision reduces material waste and saves both time and money in the long run.

With their cutting efficiency and technological advancements, plasma cutters are a cost-effective choice for industries that prioritize speed and precision.

Material Compatibility

Plasma cutters, like a skilled surgeon’s scalpel, seamlessly glide through a variety of materials with precision and ease. However, when it comes to material compatibility, fiber laser cutters have a distinct advantage.

While plasma cutters are versatile and can cut through materials like steel, aluminum, and stainless steel, they have limitations when it comes to certain materials. For example, plasma cutters struggle with cutting reflective materials like copper and brass, as well as materials with high thermal conductivity.

On the other hand, fiber laser cutters excel in cutting a wide range of materials, including those that pose challenges for plasma cutters. With their advanced technology, fiber laser cutters can perform a suitability analysis, determining the most effective cutting parameters for each material. This ensures high-quality cuts and minimizes material wastage, making fiber laser cutters more cost-effective in the long run.

Making the Right Choice

When making a decision between fiber laser cutters and plasma cutters, it’s important to consider factors beyond just the materials they can handle.

When weighing your options, it’s crucial to think about the long-term investment. Fiber laser cutters are known for their high precision and ability to cut a wide range of materials with excellent edge quality. They are also energy efficient and require minimal maintenance.

On the other hand, plasma cutters are more cost-effective upfront and can handle thicker materials. However, they may not provide the same level of accuracy and edge quality as fiber laser cutters. Additionally, plasma cutters consume more energy and require regular electrode replacement, which can add to the long-term costs.

Ultimately, making the right choice depends on your specific needs and budget constraints.

Frequently Asked Questions

Are there any safety precautions that need to be taken when operating a fiber laser cutter or plasma cutter?

When operating a fiber laser cutter or plasma cutter, it’s crucial to prioritize safety precautions to avoid common hazards. One such precaution is wearing appropriate personal protective equipment (PPE) like safety glasses and gloves to protect against sparks, fumes, and potential eye injuries.

Additionally, it’s important to ensure proper ventilation in the workspace to minimize the risk of inhaling harmful fumes.

By implementing these safety measures, you can safeguard yourself and others from potential accidents and maintain a secure working environment.

How do fiber laser cutters and plasma cutters compare in terms of maintenance requirements?

When comparing maintenance requirements, fiber laser cutters have lower maintenance costs compared to plasma cutters. Several factors affect the maintenance of laser cutters, including the type of laser technology used, the power output, and the quality of the cutting materials.

Fiber laser cutters generally require less maintenance due to their solid-state design and the absence of consumable parts like nozzles or electrodes. This translates to lower maintenance costs and reduced downtime, making fiber laser cutters a more cost-effective option.

Can fiber laser cutters or plasma cutters be used for cutting materials other than metal?

Fiber laser cutters and plasma cutters have other applications beyond cutting metal. Fiber laser cutters are ideal for non-metal materials like plastics and fabrics due to their high precision and ability to cut intricate designs. However, they may not be as cost-effective as plasma cutters for thicker non-metal materials.

Plasma cutters, on the other hand, are versatile and can cut a wide range of materials, including non-metals, but they may not provide the same level of precision as fiber laser cutters.

What is the typical lifespan of a fiber laser cutter or plasma cutter?

The typical lifespan of a fiber laser cutter depends on several factors, such as usage intensity, maintenance, and the quality of the machine. On average, a well-maintained fiber laser cutter can last up to 100,000 hours of operation.

In contrast, the lifespan of a plasma cutter is affected by factors like electrode wear and consumable replacement. Typically, a plasma cutter can last between 3,000 to 5,000 hours of operation before needing significant repairs or replacement.

How do fiber laser cutters and plasma cutters compare in terms of energy consumption?

When comparing fiber laser cutters and plasma cutters in terms of energy consumption, fiber laser cutters are known for their exceptional energy efficiency. They use a highly focused laser beam to cut through materials, resulting in minimal energy waste.

On the other hand, plasma cutters consume more energy due to the need for a high-temperature plasma arc. Additionally, fiber laser cutters boast faster cutting speeds, allowing for increased productivity and reduced energy usage per unit of material cut.

Conclusion

In conclusion, when it comes to cost-effectiveness, the fiber laser cutter emerges as the shining star. Its precision and cutting speed make it a superior choice for industries that value efficiency and productivity.

Symbolically, the fiber laser cutter represents progress and advancement, while the plasma cutter represents a more traditional approach. By embracing the latest technology, companies can stay ahead of the curve and achieve greater success in their operations.

The data supports this notion, as fiber laser cutters offer a higher return on investment and a brighter future for businesses.