Imagine a surgeon delicately removing a tumor from a patient’s brain, using a tool that requires utmost precision. The tool must be able to cut through tissue without causing damage to surrounding areas.

It is in these moments that the choice between fiber laser cutters and waterjets becomes crucial. Fiber laser cutters and waterjets are two cutting technologies known for their precision and versatility. They have revolutionized various industries, from manufacturing to aerospace, enabling the creation of intricate designs with remarkable accuracy. But which one is more precise?

In the world of cutting, precision is everything. It can mean the difference between success and failure, between a flawless product and a costly mistake. This is why understanding the capabilities of fiber laser cutters and waterjets is essential.

In this article, we will delve into the intricacies of both technologies, exploring their strengths and limitations. Through a detailed comparison, we will determine which one reigns supreme in terms of precision. Whether you are a manufacturer, engineer, or simply curious about cutting-edge technology, join us as we explore the world of fiber laser cutters and waterjets, and uncover which one is truly more precise.

Key Takeaways

- Fiber laser cutters use laser beams focused to small spots for intricate cuts, offering high precision, speed, and versatility.

- Fiber laser cutters have minimal heat transfer, reducing warping or distortion, and can cut metals, plastics, and delicate fabrics.

- Waterjets can delicately carve through materials and create intricate designs on stone surfaces, with no heat-affected zone and no tool wear.

- Waterjets can cut metals, composites, stone, glass, and ceramics, allowing for precise and intricate cuts, even on delicate materials, while minimizing material waste.

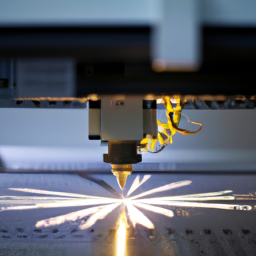

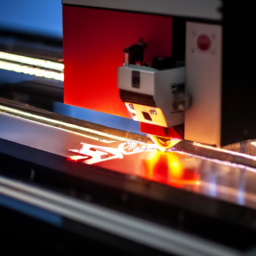

Understanding Fiber Laser Cutters

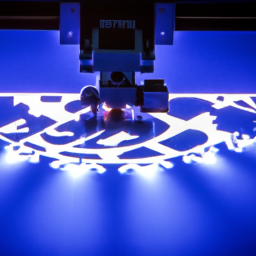

Fiber laser cutters are mind-blowingly precise, making your cutting dreams come true! These cutting-edge machines utilize fiber laser technology, which offers unparalleled precision and accuracy.

The laser cutting process starts with a high-powered laser beam that is directed onto the material you want to cut. The laser beam is focused to an incredibly small spot, allowing for intricate and precise cuts.

The fiber laser technology used in these cutters ensures minimal heat transfer to the surrounding material, reducing the risk of warping or distortion.

This precise cutting method is ideal for a wide range of materials, including metals, plastics, and even delicate fabrics.

With fiber laser cutters, you can achieve intricate designs and high-quality finishes with ease.

Understanding Waterjets

When it comes to precision, waterjets have a unique advantage due to their ability to delicately carve through materials. Waterjets are commonly used in the food industry for their ability to cut through various types of food products with minimal distortion or damage. The high-pressure water stream allows for precise cutting of delicate ingredients such as fruits, vegetables, and even proteins. Additionally, waterjets are highly beneficial in stone cutting applications. The powerful stream of water, combined with abrasive particles, can easily cut through hard materials like granite and marble with extreme precision. This makes waterjets an ideal choice for creating intricate designs or patterns on stone surfaces. Overall, waterjets offer unparalleled precision and versatility in various industries, making them a preferred choice for many applications.

| Pros of Waterjets in the Food Industry | Pros of Waterjets in Stone Cutting | ||

|---|---|---|---|

| Minimize distortion and damage to food | Precise cutting of hard materials | ||

| Ideal for cutting delicate ingredients | Ability to create intricate designs | ||

| Versatile in various food processing | Suitable for granite and marble | ||

| applications | surfaces | Can also be used for cutting through bone and tough meat. |

Precision Comparison: Fiber Laser Cutters vs. Waterjets

Looking to compare precision? Let’s delve into the world of fiber laser cutters and waterjets. When it comes to precision, both fiber laser cutters and waterjets have their advantages and limitations.

Advantages of Fiber Laser Cutters:

- High precision: Fiber laser cutters offer exceptional accuracy, with the ability to achieve intricate cuts and sharp edges.

- Speed: These machines operate at high speeds, allowing for quick and efficient cutting processes.

- Versatility: Fiber lasers can cut a wide range of materials, including metals, plastics, and composites.

Advantages of Waterjets:

- No heat-affected zone: Waterjets use a cold cutting process, eliminating the risk of heat damage to the material being cut.

- Versatility: Waterjets can cut through almost any material, including thick materials and reflective surfaces.

- No tool wear: Unlike fiber laser cutters, waterjets do not require sharpening or replacing cutting tools.

Limitations of Fiber Laser Cutters:

- Material limitations: Fiber lasers are not suitable for cutting highly reflective materials like copper or brass.

- Cost: These machines tend to be more expensive compared to waterjets.

- Maintenance: Fiber lasers require regular maintenance and alignment to ensure optimal performance.

Limitations of Waterjets:

- Slower cutting speed: Waterjets are generally slower compared to fiber lasers, especially when cutting thick materials.

- Kerf width: The width of the cut made by a waterjet can be wider compared to a fiber laser.

Both fiber laser cutters and waterjets offer precision in their own ways. Fiber laser cutters excel in accuracy, speed, and versatility, while waterjets offer the advantages of no heat-affected zone, versatility, and no tool wear. However, it’s important to consider the specific requirements of your project and the materials you will be working with when choosing between the two.

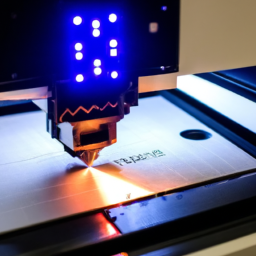

Applications of Fiber Laser Cutters

When it comes to metal cutting, fiber laser cutters offer unparalleled precision and accuracy. They are widely used in the automotive industry for cutting various metal components with intricate designs.

In the aerospace industry, fiber laser cutters play a crucial role in manufacturing aircraft parts with high precision requirements.

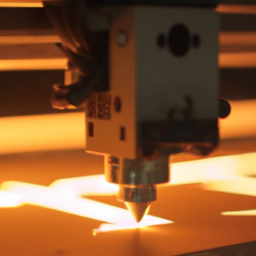

Metal Cutting

For precise metal cutting, you’ll find that fiber laser cutters are more accurate than waterjets. Fiber laser cutters excel in cutting metal with exceptional precision, making them the preferred choice in industries where accuracy is paramount.

These machines can effortlessly handle varying metal thicknesses, ensuring consistent and precise cuts throughout the process. The focused laser beam of a fiber laser cutter allows for intricate and detailed cutting, even on thin metals.

Additionally, fiber laser cutters offer high cutting speeds, enabling efficient production and reduced lead times. With their ability to cut through metals with utmost accuracy and efficiency, fiber laser cutters are the go-to choice for industries that demand precise metal cutting.

Automotive Industry

In the automotive industry, it’s clear that precise metal cutting is vital for manufacturing high-quality cars. When it comes to precision comparison, fiber laser cutters and waterjets are two popular options.

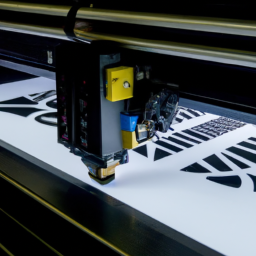

Fiber laser cutters use a high-powered laser beam to melt and vaporize the metal, resulting in a precise and clean cut. They offer a narrow kerf width and minimal heat-affected zone, making them ideal for intricate automotive parts.

On the other hand, waterjets use a high-pressure stream of water mixed with abrasive particles to cut through the metal. While they provide high precision, they may cause a wider kerf width and heat-affected zone compared to fiber laser cutters.

Ultimately, the choice between these two technologies depends on the specific requirements of the automotive industry, considering factors such as material type, thickness, and desired cut quality.

Aerospace Industry

The aerospace industry relies heavily on precise metal cutting techniques to manufacture high-quality aircraft, with advanced technologies offering efficient and accurate solutions. Did you know that the aerospace industry is projected to reach a market value of $511.7 billion by 2026?

- Fiber laser cutters and waterjets are widely used in aerospace manufacturing due to their precision engineering capabilities.

- Fiber laser cutters use a high-powered laser beam to cut through metal with incredible accuracy, producing clean and precise cuts.

- Waterjets, on the other hand, utilize a high-pressure stream of water mixed with abrasive particles to cut through various materials, including metals.

- Both technologies provide precise cutting results, allowing for the manufacturing of intricate components and parts for aircraft.

- The choice between fiber laser cutters and waterjets depends on the specific requirements of the aerospace project, such as material type, thickness, and desired finish.

The aerospace industry relies on advanced metal cutting technologies like fiber laser cutters and waterjets to achieve the precision and accuracy needed for manufacturing high-quality aircraft components.

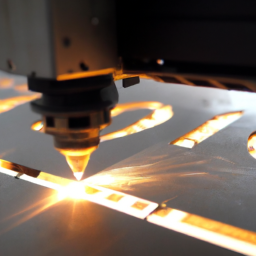

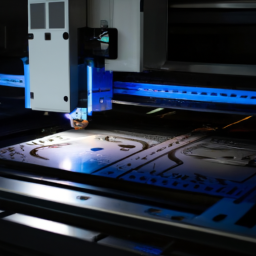

Applications of Waterjets

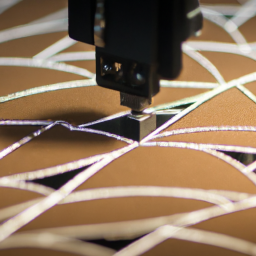

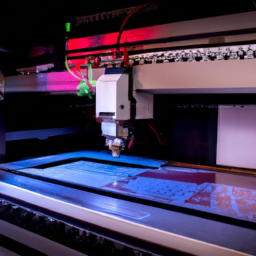

Waterjets offer a wide range of applications, making them a versatile tool for precision cutting. In the field of industrial manufacturing, waterjet cutting has become increasingly popular due to its ability to accurately cut a variety of materials.

The high-pressure water stream, combined with an abrasive substance, allows for precise and intricate cuts, even on delicate materials. Waterjets can easily handle materials such as metals, composites, stone, glass, and ceramics, making them ideal for applications in the aerospace industry.

With waterjet cutting, manufacturers can achieve intricate shapes and designs with minimal material waste. Additionally, the cold cutting process of waterjets eliminates any heat-affected zones, ensuring the integrity and quality of the materials being cut.

Overall, the versatility and precision of waterjet cutting make it a valuable tool in the industrial manufacturing sector.

Frequently Asked Questions

Can fiber laser cutters be used on all types of materials?

Fiber laser cutters offer numerous advantages but have limitations when it comes to the types of materials they can be used on. These cutters excel at precision cutting, providing clean and accurate results. However, they are most effective on materials such as metals, plastics, and composites.

Fiber laser cutters may struggle with materials that are highly reflective or transparent, as well as those that are thick or have uneven surfaces.

Are waterjets more suitable for cutting thicker materials compared to fiber laser cutters?

Waterjets are indeed more suitable for cutting thicker materials compared to fiber laser cutters. In fact, waterjets can cut through materials up to 8 inches thick with high precision.

However, when it comes to thin material cutting, fiber laser cutters have the advantage. They can achieve incredibly precise cuts on materials as thin as a human hair, making them ideal for delicate applications like electronics manufacturing.

The precision of waterjets for precision cutting and the advantages of fiber laser cutters in thin material cutting make them both valuable tools in different scenarios.

What are the maintenance requirements for fiber laser cutters and waterjets?

Maintenance requirements for fiber laser cutters and waterjets vary, but both technologies require regular upkeep to ensure optimal performance. Fiber laser cutters typically require periodic lens cleaning, alignment checks, and replacement of consumable parts such as nozzles and filters.

Waterjets, on the other hand, require regular inspection and maintenance of high-pressure components, such as seals and intensifier pumps.

Compared to other cutting technologies, fiber laser cutters generally have lower maintenance requirements and operating costs due to their simpler design and lack of abrasive materials.

Can fiber laser cutters and waterjets be used for 3D cutting or are they limited to 2D cutting?

Fiber laser cutters and waterjets are versatile tools that can be used for both 2D and 3D cutting. Fiber laser cutters have several advantages for 3D cutting, including their ability to make precise and intricate cuts on a variety of materials. They’re commonly used in industries such as automotive, aerospace, and jewelry manufacturing.

On the other hand, waterjets are also used in the manufacturing industry for 3D cutting applications, particularly for materials that are sensitive to heat or require high precision.

Are there any safety considerations or precautions that need to be taken when operating fiber laser cutters or waterjets?

When operating fiber laser cutters or waterjets, there are several safety considerations and operating precautions that need to be taken. Safety considerations include wearing appropriate protective gear, such as safety glasses and gloves, to prevent injuries from laser radiation or high-pressure water.

Operating precautions involve ensuring proper training and knowledge of the equipment, regular maintenance, and following safety protocols to minimize the risk of accidents or damage. Taking these precautions is crucial to ensure a safe working environment.

Conclusion

In conclusion, when it comes to precision, fiber laser cutters outshine waterjets. Their ability to produce intricate and accurate cuts with minimal kerf width sets them apart.

While waterjets offer versatility in cutting various materials, their precision falls short compared to fiber laser cutters.

So, if precision is your top priority, fiber laser cutters are the way to go. Remember, in the world of precision cutting, the devil is in the details, and fiber laser cutters are the masters of detail.