Are you tired of the hassle and inefficiency of traditional metal cutting methods? Are you ready to take your metal fabrication business to the next level? Look no further! Choosing the right laser cutting machine is the game-changer you’ve been waiting for. With its precision, speed, and versatility, a laser cutting machine can revolutionize the way you work. But with so many options out there, how do you find the perfect fit for your business? Fear not, because we’ve got you covered.

In this article, we will guide you through the process of choosing the right laser cutting machine for your metal fabrication business. From assessing your business needs to evaluating machine features and specifications, we’ll provide you with the expert advice you need to make an informed decision. Get ready to transform your business with the power of laser cutting technology!

Key Takeaways

- Assess your business needs and consider factors such as production capacity, growth projections, and market analysis.

- Compare CO2 laser cutting machines and fiber laser cutting machines, considering their versatility, precision, cutting speed, and material compatibility.

- Set a budget by considering the size, power, capabilities, and long-term costs of maintenance and operation.

- Evaluate machine features and specifications, including high precision and accuracy, cutting speed and efficiency, software capabilities, compatibility with common file formats, and advanced features like nesting.

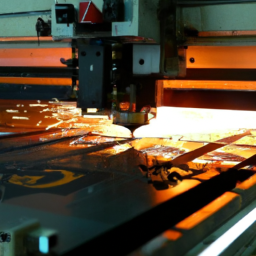

Assess Your Business Needs and Requirements

You’ll need to carefully evaluate your business needs and requirements in order to find the perfect laser cutting machine for your metal fabrication business.

Assessing your business needs involves considering factors such as your current production capacity, business growth projections, and market analysis. Are you looking to expand your operations and increase your output? Are you targeting specific industries or markets that require specialized cutting capabilities? Answering these questions will help you determine the size, power, and features necessary for your laser cutting machine.

Additionally, conducting a market analysis will give you insights into the demand for specific types of fabrication work, which can also influence your choice of machine.

Once you have a clear understanding of your business needs, you can proceed to the next step of researching different laser cutting technologies.

Research Different Laser Cutting Technologies

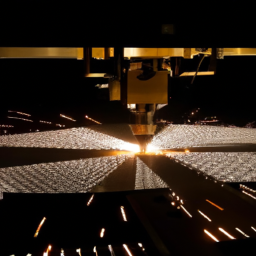

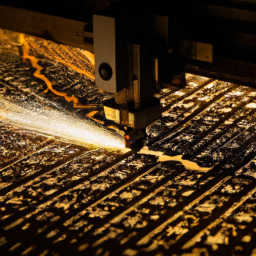

When researching different laser cutting technologies for your metal fabrication business, there are two main options to consider: CO2 laser cutting machines and fiber laser cutting machines.

CO2 laser cutting machines use a gas mixture to generate the laser beam, making them suitable for cutting non-metal materials such as wood, acrylic, and plastic.

On the other hand, fiber laser cutting machines use a solid-state laser source, which allows for faster cutting speeds and higher precision on metal materials.

It’s important to carefully consider the pros and cons of each technology to determine which one best meets your business needs and requirements.

Learn about CO2 laser cutting machines

CO2 laser cutting machines, also known as carbon dioxide laser cutting machines, are a popular choice for metal fabrication businesses due to their versatility and precision. These machines offer several advantages and have a wide range of applications in the industry. Here are three key points to consider:

-

High cutting speed: CO2 laser cutting machines can cut through metal at high speeds, reducing production time and increasing efficiency.

-

Read moreLaser Cutting Vs. Traditional Metal Fabrication Techniques: Which Is Best For Your Project?

Read moreLaser Cutting Vs. Traditional Metal Fabrication Techniques: Which Is Best For Your Project?Wide material compatibility: These machines can cut through a variety of materials, including stainless steel, aluminum, carbon steel, and more, making them suitable for a range of metal fabrication projects.

-

Excellent precision: CO2 laser cutting machines provide precise cuts with minimal heat-affected zones, ensuring clean edges and reducing the need for additional finishing processes.

Now that you’ve learned about CO2 laser cutting machines, let’s explore fiber laser cutting machines and their advantages in the next section.

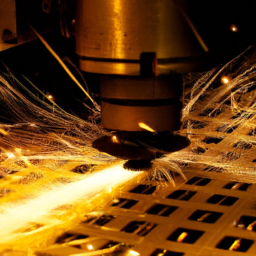

Explore fiber laser cutting machines

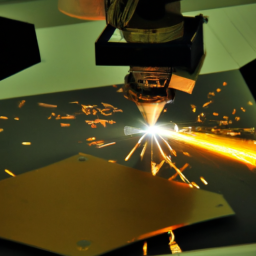

If you’re looking to take your precision and efficiency to new heights, fiber laser cutting machines are the way to go. These machines use a high-powered fiber laser to cut through various types of metal with incredible accuracy.

One of the main advantages of fiber laser cutting is its speed. It can cut through thick materials at a much faster rate compared to other cutting technologies. Additionally, fiber laser cutting machines have a smaller heat-affected zone, which minimizes distortion and allows for more intricate designs.

This technology is widely used in industries such as automotive, aerospace, and electronics. Whether you need to cut stainless steel, aluminum, or brass, fiber laser cutting machines can handle it all.

Now that you’ve explored the benefits of fiber laser cutting, it’s time to consider the pros and cons of each technology.

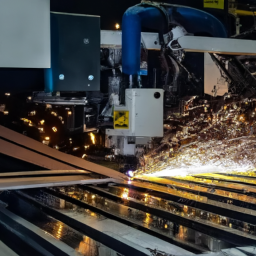

Consider the pros and cons of each technology

Now let’s weigh the pros and cons of each technology and figure out which one suits your needs best!

When considering laser cutting technology for your metal fabrication business, it’s crucial to understand the advantages and disadvantages of each option.

Fiber laser cutting machines offer numerous benefits, including high cutting speed, excellent precision, and low maintenance requirements. They are also suitable for cutting a wide range of materials, including reflective metals. However, fiber lasers tend to have a higher initial cost, and their cutting capabilities may be limited for thicker materials.

On the other hand, CO2 laser cutting machines are more affordable and can handle thicker materials with ease. However, they are generally slower and require more maintenance.

When choosing a laser cutting machine, consider factors such as your budget, material thickness requirements, and production volume. Transitioning into the subsequent section about ‘set a budget,’ it’s important to carefully consider all these factors to make an informed decision.

Set a Budget

When setting a budget for purchasing a laser cutting machine, it’s important to consider your specific needs and requirements. Determine the maximum amount you’re willing to invest in the machine, taking into account the size, power, and capabilities you require.

Additionally, don’t forget to factor in the long-term costs of maintenance and operation, as these can significantly impact your overall expenses.

Determine your budget for purchasing a laser cutting machine

To choose the right laser cutting machine for your metal fabrication business, you’ll need to determine your budget and consider the long-term cost savings it can provide, even though it may seem like a significant investment at first.

When determining your budget for purchasing a laser cutting machine, there are several buying considerations and cost analysis factors to keep in mind:

-

Initial investment: Consider the upfront cost of the machine and how it fits within your budget.

-

Operating costs: Evaluate the ongoing expenses such as electricity, gas, and consumables required for the machine’s operation.

-

Maintenance costs: Take into account the regular maintenance and repairs the machine may require and factor in the associated costs.

-

Training expenses: Consider the costs of training your staff to operate the laser cutting machine effectively.

-

Potential ROI: Analyze the potential return on investment by estimating the increased productivity and efficiency the machine can bring to your business.

By carefully considering these factors, you can make an informed decision about the budget for your laser cutting machine. Once you have determined your budget, the next step is to consider the long-term costs of maintenance and operation.

Consider the long-term costs of maintenance and operation

Considering the long-term costs of maintenance and operation is crucial in ensuring the sustainability and profitability of your metal fabrication enterprise. When choosing a laser cutting machine, it’s important to look beyond the initial purchase price and consider the cost-effective maintenance and operational efficiency of the machine.

Opting for a machine that requires less frequent maintenance and has lower operational costs can significantly impact your bottom line in the long run. Look for machines that are designed with ease of maintenance in mind, with accessible parts and straightforward servicing procedures. Additionally, consider the energy efficiency of the machine, as this can also contribute to reducing operational costs.

By carefully evaluating the long-term costs of maintenance and operation, you can make an informed decision that’ll benefit your business in the years to come.

Moving on to the next section, let’s evaluate machine features and specifications.

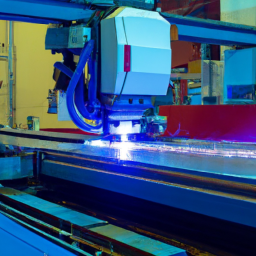

Evaluate Machine Features and Specifications

When evaluating machine features and specifications for a laser cutting machine, you should look for a machine that offers high precision and accuracy in its cutting capabilities. This is crucial for ensuring that your metal fabrication business produces high-quality products.

Additionally, consider the cutting speed and efficiency of the machine, as this will impact the productivity and turnaround time of your operations.

Lastly, assess the machine’s software capabilities and compatibility, as having advanced software can enhance the overall functionality and ease of use of the machine.

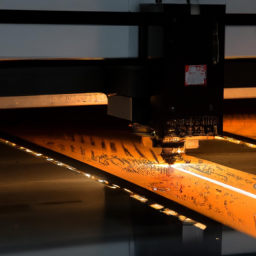

Look for a machine with high precision and accuracy

Look for a laser cutting machine that offers impeccable precision and accuracy, ensuring flawless results that will leave your customers in awe. When choosing a machine, it’s crucial to prioritize high power and durability.

Here are five key factors to consider:

-

Laser power: Opt for a machine with high power to achieve cleaner and more precise cuts.

-

Beam quality: Look for a machine that produces a consistent and focused laser beam for better accuracy.

-

Cutting speed: Consider a machine with fast cutting speeds to improve efficiency and productivity.

-

Positioning accuracy: Ensure the machine has a reliable positioning system to accurately place the laser beam.

-

Repeatability: Look for a machine with high repeatability to consistently produce the same accurate cuts.

Considering the cutting speed and efficiency of the machine is the next vital step in your quest for the perfect laser cutting machine for your metal fabrication business.

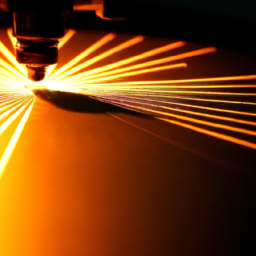

Consider the cutting speed and efficiency of the machine

Now that you understand the importance of high precision and accuracy in a laser cutting machine, it’s time to delve into another crucial aspect: cutting speed and efficiency.

When choosing a machine for your metal fabrication business, you need to consider how quickly and efficiently it can cut through different types of metal. Look for a laser cutting machine that offers fast cutting speeds without compromising on the quality of the cuts.

Additionally, machine durability is equally important to ensure continuous and reliable operation. Opt for a machine that is built with high-quality materials and components, as this will contribute to its longevity and ability to withstand the demands of your business.

With cutting precision and machine durability in mind, the next step is to assess the machine’s software capabilities and compatibility.

Assess the machine’s software capabilities and compatibility

To ensure a smooth operation, it’s important to assess how the machine’s software capabilities and compatibility align with your specific needs.

The machine’s compatibility refers to its ability to work with various software programs and file formats. It’s crucial to determine if the machine can read the files you commonly use in your metal fabrication business, such as DXF or DWG.

Additionally, consider the software capabilities of the machine. Does it have advanced features like nesting, which optimizes the use of material and reduces waste? Can it handle complex designs and intricate cuts?

Look for a machine that offers user-friendly software with a clear interface and comprehensive support. This will enable you to maximize the machine’s potential and streamline your workflow.

Moving forward, it’s essential to consider after-sales support and service to ensure long-term success.

Consider After-Sales Support and Service

When considering after-sales support and service for your laser cutting machine, it’s crucial to research the reputation and reliability of the manufacturer. Look for manufacturers that have a track record of providing excellent customer support and reliable machines.

Additionally, inquire about warranty options and customer support services to ensure that you’ll have assistance if any issues arise.

Lastly, evaluate the availability of spare parts and maintenance services to ensure that you can keep your machine running smoothly and minimize downtime.

Research the reputation and reliability of the manufacturer

In your search for the perfect laser cutting machine for your metal fabrication business, don’t overlook the importance of investigating the manufacturer’s reputation and reliability – it’s like peering into the machine’s soul to ensure it’s built to withstand the test of time. When considering a laser cutting machine, it’s crucial to research the manufacturer’s reputation and reliability. This will give you a better understanding of the quality of their products and the level of support you can expect. To assist you in your evaluation, here is a table outlining some key factors to consider:

| Manufacturer Reputation | Reliability Assessment |

|---|---|

| Customer reviews | Equipment lifespan |

| Industry experience | Maintenance records |

| Certifications | Failure rate |

| Awards | Service response time |

| References | Spare parts availability |

By thoroughly researching the manufacturer’s reputation and reliability, you can make an informed decision about the laser cutting machine that best suits your business needs. As you move forward, it’s also important to inquire about warranty options and customer support services.

Inquire about warranty options and customer support services

Now that you’ve researched the reputation and reliability of the manufacturer, it’s important to inquire about warranty options and customer support services when choosing the right laser cutting machine for your metal fabrication business.

Warranty coverage is crucial in protecting your investment and ensuring the longevity of your machine. Make sure to ask about the duration of the warranty and what it covers, such as parts, labor, and repairs.

Additionally, inquire about the availability of customer support services, as prompt and reliable assistance is essential in minimizing downtime and maximizing productivity. By choosing a manufacturer that offers comprehensive warranty options and excellent customer support services, you can have peace of mind knowing that any issues or concerns will be addressed promptly and efficiently. This ensures not only your satisfaction as a customer but also the smooth operation of your metal fabrication business.

Transitioning into the subsequent section, it’s also important to evaluate the availability of spare parts and maintenance services.

Evaluate the availability of spare parts and maintenance services

Ensuring the smooth operation of your metal fabrication venture involves considering the availability of spare parts and maintenance services for your selected laser cutting machine. When choosing a laser cutting machine, it’s crucial to evaluate the availability of spare parts. Make sure that the manufacturer or supplier can provide you with the necessary replacement parts in a timely manner, as any delays can disrupt your production schedule.

Additionally, inquire about the maintenance services offered by the company. A reliable laser cutting machine should come with regular maintenance and servicing options to keep it in optimal condition. This will help extend the lifespan of the machine and minimize downtime.

By ensuring the availability of spare parts and maintenance services, you can avoid unnecessary disruptions to your metal fabrication business. Moving forward, it’s important to seek recommendations and read reviews to make an informed decision.

Seek Recommendations and Read Reviews

To choose the right laser cutting machine for your metal fabrication business, ask other professionals in the industry for recommendations. Their firsthand experience can provide valuable insights into the performance and reliability of different machines.

Additionally, reading online reviews and testimonials from customers can give you a broader perspective on the pros and cons of various options.

Lastly, attending trade shows and exhibitions allows you to see the machines in action and witness their capabilities firsthand, helping you make a more informed decision.

Ask for recommendations from other metal fabrication professionals

Consider reaching out to fellow metal fabrication professionals for their recommendations on the best laser cutting machine to use in your business. Who better to ask than those who are already in the industry and can provide valuable insights and advice? Seek feedback from experienced metal fabricators who have firsthand experience with different laser cutting machines. They can share their opinions on the performance, reliability, and overall satisfaction with the machines they’ve used.

Additionally, consider the potential impact on production efficiency. Metal fabrication professionals can offer insights into how different laser cutting machines have affected their productivity and workflow.

By gathering recommendations from other professionals, you can make a more informed decision on which machine would be the best fit for your specific needs.

Once you’ve gathered these recommendations, it’s important to read online reviews and testimonials from customers to further validate your decision.

Read online reviews and testimonials from customers

Check out online reviews and testimonials from customers to get a better understanding of the experiences and satisfaction levels with different laser cutting machines. Customer feedback is crucial when choosing the right laser cutting machine for your metal fabrication business. Online research allows you to gather valuable insights about the performance, reliability, and overall quality of various machines. By reading reviews and testimonials, you can learn from the experiences of other customers and make an informed decision.

To help you navigate through the vast amount of information available online, here is a table summarizing the key points from a selection of customer reviews:

| Reviewer | Laser Cutting Machine | Experience |

|---|---|---|

| John | Model A123 | Excellent |

| Sarah | Model B456 | Satisfactory |

| Mike | Model C789 | Disappointing |

By analyzing these reviews, you can identify patterns and trends, which will further assist you in selecting the most suitable laser cutting machine for your business needs.

Once you have gathered insights from customer feedback, it is time to move on to the next step: visiting trade shows and exhibitions to see the machines in action.

Visit trade shows and exhibitions to see the machines in action

After reading online reviews and testimonials from customers, you now have a better understanding of the performance and reliability of different laser cutting machines for your metal fabrication business.

However, it’s essential to see these machines in action before making a final decision. To gain more insights and stay up-to-date with the industry trends in laser cutting technology, visiting trade shows and exhibitions is highly recommended.

This allows you to witness the latest advancements firsthand and compare different models side by side. Additionally, you can interact with industry experts and manufacturers to learn about the best practices for optimizing laser cutting efficiency.

These events provide an invaluable opportunity to gather information and make an informed choice that aligns with your business requirements and goals.

Frequently Asked Questions

What safety measures should I take when using a laser cutting machine?

When operating a laser cutting machine, it’s crucial to prioritize safety to avoid accidents. Laser cutting machine safety measures include wearing appropriate protective gear, like safety glasses and gloves, to shield yourself from potential hazards.

Additionally, ensure that the work area is well-ventilated and free from flammable materials. Regularly inspect and maintain the machine to prevent malfunctions. By adhering to these laser cutting machine precautions, you can ensure a safe and productive working environment.

Are there any specific maintenance requirements for laser cutting machines?

Maintenance requirements for laser cutting machines include regular cleaning and inspection of the machine’s components. Common issues to watch out for include misalignment, worn-out parts, and debris buildup. Troubleshooting tips may involve adjusting settings, checking the power supply, or calibrating the laser beam.

Recommended cleaning products should be non-abrasive and suitable for the specific machine. Machine operators should receive proper training on maintenance procedures and safety protocols. Additional resources for training can be found through equipment manufacturers or industry associations.

How long does it typically take to learn how to operate a laser cutting machine?

The learning curve for operating a laser cutting machine varies depending on the individual’s experience and background. On average, it takes around 40 to 60 hours of training to become proficient in using a laser cutting machine.

However, this statistic is subject to change based on factors such as the complexity of the machine, the operator’s familiarity with similar equipment, and the level of hands-on practice provided during the training.

Can a laser cutting machine be used for materials other than metal?

Yes, a laser cutting machine can be used for materials other than metal. Some of the advantages of using a laser cutting machine for alternative materials include precise and clean cuts, reduced material waste, and the ability to work with a variety of materials.

However, there are also some disadvantages such as higher initial cost, limitations on the thickness of materials that can be cut, and potential for heat damage to certain materials.

Are there any environmental considerations when using a laser cutting machine?

When considering the environmental impact of using a laser cutting machine, it’s important to note that energy consumption plays a significant role. A single hour of laser cutting can consume as much electricity as an average household uses in a month. This staggering statistic highlights the immense power requirements of these machines.

Therefore, it’s crucial for metal fabrication businesses to carefully consider the energy efficiency and sustainability of the laser cutting machine they choose to minimize their environmental footprint.

Conclusion

In conclusion, choosing the right laser cutting machine for your metal fabrication business can be a daunting task. However, by assessing your needs, researching different technologies, setting a budget, evaluating machine features, and considering after-sales support, you can make an informed decision.

Remember, it’s like selecting the perfect tool from a well-stocked toolbox; each machine has its own unique capabilities and advantages. So, make sure to read reviews and seek recommendations to find the perfect fit for your business.

Happy cutting!