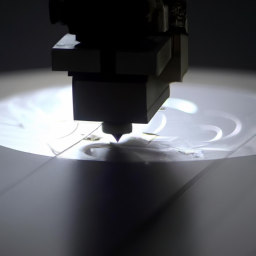

Looking to laser in on the perfect subtractive laser cutting machine for your business? Look no further! In this article, we’ll guide you through the process of choosing the right machine to meet your specific needs and requirements.

First and foremost, you must understand the unique needs of your business. What materials will you be working with? What are your production requirements and desired outcomes? Once you have a clear understanding of these factors, it’s time to research different machine types and brands.

Consider the capabilities and features of each machine. Does it offer the precision and speed you require? Can it handle the thickness and hardness of your materials?

Of course, budget is also an important consideration. Set a budget that aligns with your business goals and financial capabilities. Seek expert advice and consultations to ensure you make an informed decision.

Lastly, compare prices and request quotes from different suppliers. This will help you find the best value for your investment.

So, let’s dive in and find the perfect subtractive laser cutting machine to take your business to new heights!

Key Takeaways

- Understand the unique needs of your business before researching machines

- Research different machine types and brands

- Consider the machine’s capabilities and features

- Seek expert advice and consultations to make an informed decision

Understand Your Business Needs and Requirements

Before you dive into researching subtractive laser cutting machines, take a moment to understand what your business needs and requirements are.

To make an informed decision, it’s crucial to understand market trends and evaluate competitor offerings. Start by analyzing your production volume, material types, and desired level of precision.

Consider the size and weight of the materials you’ll be working with, as well as any future expansion plans. Additionally, assess the complexity of the designs you’ll be cutting and any specific features you require.

By understanding your business needs and requirements, you can narrow down your options and focus your research on the machines that best align with your goals. With this information in hand, you can confidently move forward and research different machine types and brands that’ll meet your specific needs.

Research Different Machine Types and Brands

Researching various machine types and brands can lead to finding the perfect subtractive laser cutting equipment for your company. When conducting your research, it’s important to read machine reviews and customer testimonials to gain insight into the performance and reliability of different machines. This will help you narrow down your options and make an informed decision.

Consider the following when researching:

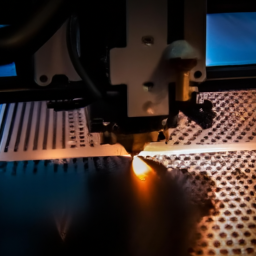

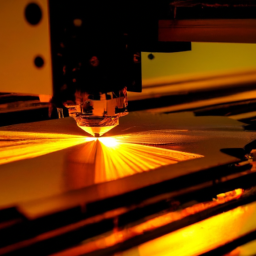

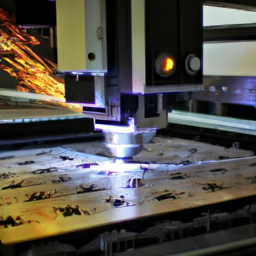

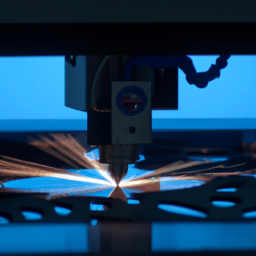

- Different machine types: Explore the range of laser cutting machines available in the market, such as CO2 lasers, fiber lasers, or hybrid lasers, to understand which one suits your specific business needs.

- Brand reputation: Look for well-established brands with a proven track record in manufacturing high-quality laser cutting machines.

- Machine features: Pay attention to the features and capabilities of each machine, such as cutting speed, precision, and software compatibility.

By thoroughly researching different machine types and brands, you can ensure that you choose a subtractive laser cutting machine that meets your business requirements and maximizes your productivity.

Now, let’s consider the machine’s capabilities and features in more detail.

Consider the Machine’s Capabilities and Features

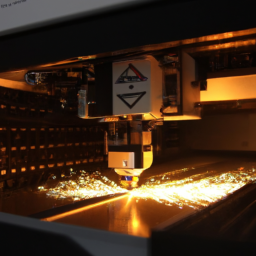

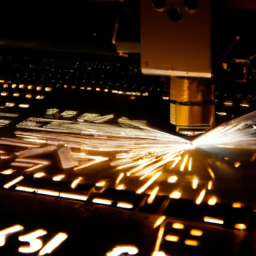

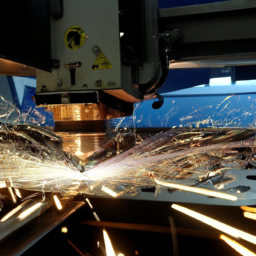

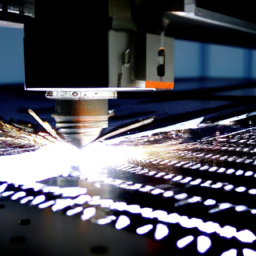

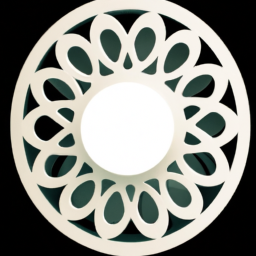

When considering the machine’s capabilities and features, you’ll be amazed by the precision and speed at which it effortlessly cuts through materials, like a skilled surgeon’s scalpel. The machine’s performance is a crucial factor to consider, as it determines how efficiently and accurately it can complete your cutting tasks.

Look for a machine that offers high cutting speeds and a wide range of compatible materials. Additionally, durability is another important aspect to keep in mind. You want a machine that can withstand heavy usage over time without compromising its performance. Look for a machine made from sturdy materials and with a solid construction.

With these capabilities and features in mind, you can now move on to setting a budget for your laser cutting machine purchase.

Set a Budget

Once you’ve got your heart set on a laser cutting machine, it’s time to figure out what kind of budget you can work with. Setting a budget is crucial for any business decision, and investing in a subtractive laser cutting machine is no exception.

Here’s a quick cost analysis to help you make an informed choice:

-

Initial Cost: Consider the upfront price of the machine, including installation and training fees.

-

Operating Costs: Factor in ongoing expenses like electricity, maintenance, and consumables.

-

Return on Investment: Calculate how long it will take for the machine to pay for itself through increased productivity and cost savings.

Understanding the financial implications of your decision is essential. Once you have set your budget and analyzed the costs, it’s time to seek expert advice and consultations to ensure you make the best choice for your business.

Seek Expert Advice and Consultations

To make an informed decision, it’s essential to consult with experts and seek their advice regarding the best options for your specific needs. Seeking expert advice allows you to tap into their wealth of knowledge and experience in the field of subtractive laser cutting machines.

These specialists can provide valuable insights on the latest technologies, features, and brands available in the market. They can guide you on the most suitable machine for your business, taking into consideration factors such as production volume, material types, and precision requirements.

Gathering information from experts will help you understand the capabilities and limitations of different machines, enabling you to make a well-informed choice. Once you have gathered all the necessary information, you can then proceed to compare prices and request quotes, ensuring you get the best deal for your investment.

Compare Prices and Request Quotes

When it comes to choosing the right subtractive laser cutting machine for your business, it’s important to compare prices and request quotes from different suppliers or manufacturers.

Make sure to consider any additional costs such as shipping or installation before making a decision.

Don’t be afraid to negotiate for the best deal and also take into account any warranties or after-sales support provided by the supplier.

Request quotes from different suppliers or manufacturers

Get quotes from various suppliers or manufacturers to ensure you find the perfect subtractive laser cutting machine for your business. When requesting quotes, consider two important factors: supplier reliability and warranty options.

You want to work with a reliable supplier who can provide high-quality machines and offer excellent customer service. Look for suppliers with positive reviews and a strong reputation in the industry.

Additionally, pay attention to the warranty options available for the laser cutting machine. A good warranty will give you peace of mind and protect your investment.

Once you have gathered quotes from different suppliers, you can compare prices and consider any additional costs such as shipping or installation.

Compare prices and consider any additional costs such as shipping or installation

Comparing prices and factoring in additional costs, such as shipping or installation, allows for a comprehensive evaluation of the overall investment involved in purchasing a subtractive laser cutting machine. When comparing prices, it’s important to consider the total cost, including any shipping costs that may be incurred. These costs can vary depending on the location of the supplier and the size and weight of the machine.

Additionally, installation expenses should be taken into account. Some suppliers may offer free installation, while others may charge a fee. By considering these costs, you can make an informed decision and ensure that you’re getting the best value for your money.

Transitioning into the next section, it’s also important to negotiate for the best deal and consider any warranties or after-sales support provided.

Negotiate for the best deal and consider any warranties or after-sales support provided

To ensure you get the best value for your investment, don’t forget to flex your negotiation skills and carefully consider the warranties and after-sales support offered by potential suppliers. Negotiating for the best deal is essential when purchasing a subtractive laser cutting machine. Use effective negotiation techniques to lower the price or to secure additional benefits, such as free shipping or installation. Additionally, pay close attention to the warranties provided by the supplier. A longer warranty period can provide you with peace of mind and save you money on potential repairs. Furthermore, consider the after-sales support offered. Good after-sales support ensures that any issues or concerns you may have with the machine will be addressed promptly. It is also a good idea to read customer reviews to gauge the supplier’s reputation for providing reliable after-sales service.

| Negotiation Techniques | Customer Reviews | Warranties | ||

|---|---|---|---|---|

| Start with a reasonable offer and be willing to compromise | Read customer reviews to gauge the supplier’s reliability | Consider the length and coverage of the warranty | ||

| Highlight your commitment to a long-term partnership | Look for positive feedback on after-sales support | Check if there are any limitations or exclusions in the warranty | ||

| Be prepared to walk away if the deal doesn’t meet your requirements | Consider both positive and negative reviews for a balanced perspective | Inquire about the process for filing warranty claims | Make sure to ask about the timeframe for resolving warranty claims and any associated costs. |

Frequently Asked Questions

How long does it typically take to learn how to operate a subtractive laser cutting machine?

Typically, it takes some time to learn how to operate a subtractive laser cutting machine. You’ll need to familiarize yourself with laser cutting techniques and understand the optimal cutting parameters for different materials.

It’s essential to receive proper training and practice regularly to become proficient. The learning curve may vary depending on your prior experience with similar equipment, but with dedication and hands-on experience, you can become skilled in operating a subtractive laser cutting machine.

What safety precautions should be taken when using a subtractive laser cutting machine?

When using a subtractive laser cutting machine, it’s crucial to follow safety guidelines and operating procedures. Start by wearing appropriate personal protective equipment, such as safety glasses and gloves.

Make sure to keep the work area clean and free from any flammable materials.

Familiarize yourself with emergency shutdown procedures in case of any accidents.

Additionally, always double-check the settings and alignment of the machine before starting any cutting operations.

Prioritize safety at all times.

Are there any maintenance or servicing requirements for subtractive laser cutting machines?

To keep your subtractive laser cutting machine in top shape, regular maintenance and servicing requirements are essential. This ensures optimal performance and prolongs the machine’s lifespan.

Maintenance tasks may include cleaning the machine, checking and replacing consumables like lenses and filters, and inspecting moving parts for wear and tear.

Servicing requirements often involve calibrating the machine, conducting software updates, and addressing any mechanical issues.

Following these maintenance and servicing requirements will keep your machine running smoothly and minimize downtime.

Can subtractive laser cutting machines be used for materials other than metal?

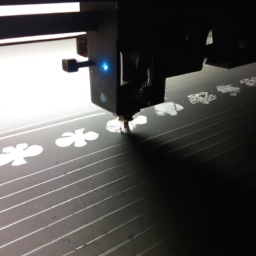

Yes, subtractive laser cutting machines can be used for materials other than metal. They’re versatile and can cut through a wide range of materials such as wood, plastic, acrylic, fabric, and more.

One of the advantages of using subtractive laser cutting over other cutting methods is its precision and accuracy. It allows for intricate and detailed cuts, making it ideal for various industries like signage, fashion, and furniture manufacturing.

Are there any additional costs or accessories that should be considered when purchasing a subtractive laser cutting machine?

When purchasing a subtractive laser cutting machine, it’s crucial to consider the additional costs and necessary accessories. These can include maintenance fees, replacement parts, and software upgrades. Keep in mind that these expenses can add up over time, so budget accordingly.

Additionally, essential accessories like safety glasses, ventilation systems, and material handling equipment should not be overlooked. Be prepared for these extra costs to ensure a smooth and successful laser cutting operation.

Conclusion

Now that you’ve explored the various aspects of choosing the right subtractive laser cutting machine for your business, it’s time to take action.

Consider the unique needs and requirements of your business, research different machine types and brands, and consult with experts in the field.

Remember, finding the perfect machine is like finding a needle in a haystack, but with careful consideration and expert guidance, you can cut through the clutter and uncover the gem that’ll make your business shine.