Are you considering investing in a cutting machine for your business or personal use? If so, you may find yourself faced with a crucial decision: choosing between laser cutter software and CNC software. Both options offer their own unique advantages and applications, making it essential to understand which is the right fit for you.

Imagine you run a small woodworking business, and you need to create intricate designs on various materials. Laser cutter software can offer you precise and detailed cuts, perfect for delicate designs and complex patterns. On the other hand, CNC software provides versatility and accuracy, allowing you to perform a wide range of cutting tasks on different materials with ease.

In this article, we will delve into the world of laser cutter software and CNC software, exploring their applications, uses, and the factors to consider when making your decision. By the end, you will have the knowledge and insights needed to determine which option is best suited to meet your specific needs and requirements.

So let’s dive in and find the perfect cutting solution for you.

Key Takeaways

- Laser cutter software offers precise and detailed cuts, perfect for delicate designs and complex patterns.

- CNC software provides versatility and accuracy, allowing for a wide range of cutting tasks on different materials.

- Laser cutter software is beneficial for industries like manufacturing, automotive, and aerospace, while CNC software is ideal for woodworking and metalworking.

- Factors to consider when choosing between laser cutter software and CNC software include project requirements, precision needed, materials, budget, and compatibility with different machines.

Understanding Laser Cutter Software

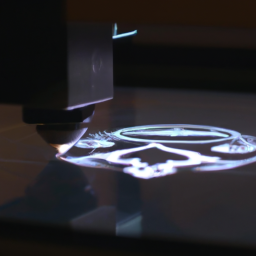

If you’re curious about laser cutter software and how it can enhance your projects, you’re in for a delightful surprise! Laser cutter software offers several advantages that can take your cutting and engraving tasks to the next level.

One of the key benefits is its precision, allowing you to achieve intricate designs with utmost accuracy. Additionally, laser cutter software often provides a wide range of common features, such as the ability to import various file formats, adjust cutting parameters, and preview designs before execution.

This software also enables you to optimize material usage, saving you time and money. Now that you understand the advantages and common features of laser cutter software, it’s time to delve into the world of CNC software and explore its capabilities.

Understanding CNC Software

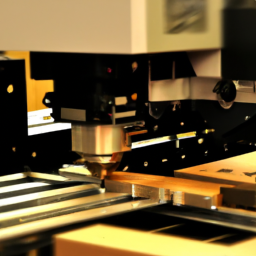

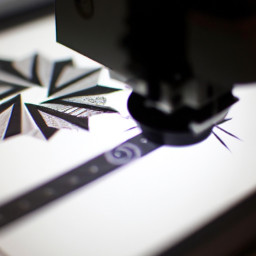

Explore the world of CNC software and discover the endless possibilities it offers for unleashing your creativity and bringing your designs to life. CNC software is a vital tool for controlling CNC machines, allowing you to program and execute complex machining operations with precision.

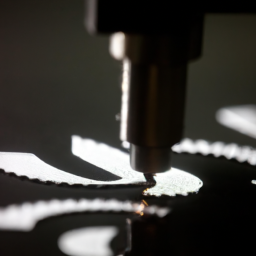

One of the key features of CNC software is its ability to generate toolpaths, which are the instructions that guide the machine’s movements. This software also provides advanced options for designing and editing your models, allowing you to create intricate and detailed designs.

However, it’s important to be aware of the limitations of CNC software. While it excels in machining operations, it may not be as versatile when it comes to other tasks such as graphic design or vector editing.

Transitioning into the subsequent section about the application and uses of laser cutter software, you’ll find that understanding the capabilities of both CNC and laser cutter software can help you choose the right tool for your specific needs.

Application and Uses of Laser Cutter Software

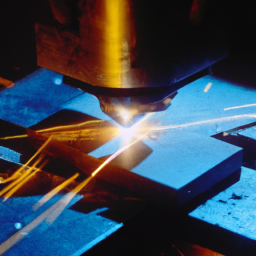

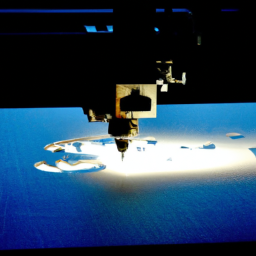

Laser cutter software has a wide range of applications across various industries. Industries such as manufacturing, automotive, and aerospace benefit from the precision and speed that laser cutter software offers.

With this software, you can create intricate designs and shapes, engrave logos or text on materials, and even cut through materials like wood, acrylic, and metal.

Examples of projects that can be done with laser cutter software include creating custom signage, prototyping parts, and fabricating intricate jewelry pieces.

Industries that benefit from laser cutter software

Discover the endless possibilities and precision that laser cutter software brings to industries like fashion, automotive, and architecture.

The automotive industry benefits greatly from laser cutter software due to its ability to create intricate and precise designs for car parts. This software allows for greater efficiency and accuracy in manufacturing processes, resulting in cost savings and improved quality control.

In the fashion industry, laser cutter software offers advantages such as the ability to cut intricate patterns and designs on various fabrics with precision and speed. This technology allows fashion designers to bring their creative visions to life in a more efficient and precise manner.

Examples of projects that can be done with laser cutter software include creating custom car parts and designing intricate fabric patterns for clothing.

Examples of projects that can be done with laser cutter software

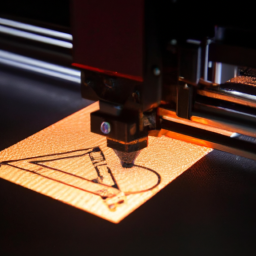

Get ready to unleash your creativity as you envision intricate jewelry designs and personalized home decor projects that come to life with the precision and speed of laser cutter software.

Laser cutter software applications offer a wide range of possibilities. You can create intricate patterns on various materials such as wood, acrylic, leather, and even metal.

You can design and cut custom jewelry pieces, including earrings, necklaces, and bracelets, with intricate details and precision.

Laser cutter software capabilities also extend to home decor projects like personalized signs, wall art, and even furniture.

The software allows you to easily import and convert designs, adjust settings for different materials, and execute precise cuts with ease.

With laser cutter software, the possibilities are endless for turning your creative visions into reality.

Transitioning into the subsequent section about ‘application and uses of CNC software’, you can explore even more possibilities for precision manufacturing and fabrication.

Application and Uses of CNC Software

CNC software allows users to effortlessly create intricate designs and carve them with precision, bringing their imagination to life. For woodworking enthusiasts, CNC software offers a wide range of tools and features specifically tailored to their craft. From designing intricate furniture pieces to carving detailed patterns into wood, CNC software for woodworking empowers users to create stunning and precise works of art.

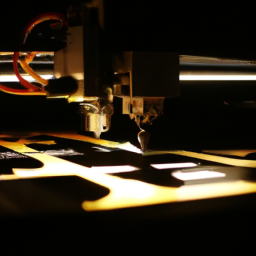

Similarly, CNC software for metal fabrication provides metalworkers with the tools and capabilities to cut, shape, and engrave metal materials with utmost accuracy. Whether it’s creating custom metal sculptures or intricate metal parts, CNC software for metal fabrication offers endless possibilities.

When choosing between laser cutter software and CNC software, factors such as material compatibility, project complexity, and desired level of precision should be taken into consideration. This ensures that you select the software that best suits your needs and helps you achieve your creative goals.

Factors to Consider When Choosing Between Laser Cutter Software and CNC Software

Now that you understand the various applications and uses of CNC software, it’s important to consider the factors that can help you make the right choice between laser cutter software and CNC software.

There are several considerations to keep in mind, such as the specific requirements of your project, the level of precision needed, the materials you plan to work with, and your budget constraints.

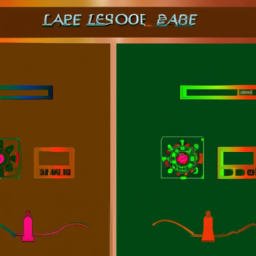

Laser cutter software offers the advantage of high precision and versatility, but it may come with a higher price tag and limited material compatibility. On the other hand, CNC software provides more flexibility and affordability, but it may not offer the same level of precision as laser cutter software.

It’s crucial to weigh the pros and cons of each option carefully to ensure that you choose the software that best suits your needs.

In the next section, we will delve deeper into the decision-making process, exploring the key factors to consider when deciding between laser cutter software and CNC software.

Making the Decision: Laser Cutter Software or CNC Software?

Imagine having the power to choose the perfect solution for your project, considering all the important factors that’ll guarantee you make the right decision.

When deciding between laser cutter software and CNC software, two crucial aspects to consider are cost comparison and compatibility with different machines.

In terms of cost, laser cutter software tends to be more expensive upfront compared to CNC software. Laser cutting machines require specialized software that can handle the intricacies of laser cutting, which can drive up the initial investment. On the other hand, CNC software is generally more affordable, making it a viable option for those with a limited budget.

Compatibility with different machines is another key factor to consider. Laser cutter software is designed specifically for laser cutting machines, ensuring optimal performance and precision. CNC software, on the other hand, is compatible with a wide range of machines, including laser cutters, routers, mills, and more. This flexibility allows for greater versatility and the ability to work with different types of materials.

Ultimately, the decision between laser cutter software and CNC software depends on your specific needs and budget. Consider the cost comparison and compatibility with different machines to make an informed choice that suits your project requirements.

Frequently Asked Questions

Can laser cutter software be used with any type of laser cutting machine?

When considering using laser cutter software with different types of laser cutting machines, there are several factors to consider. The pros of using laser cutter software include its ability to provide precise and intricate designs, as well as its user-friendly interface. However, the cons may arise if the software isn’t compatible with your specific machine, leading to issues in functionality and compatibility. Therefore, it’s crucial to research and ensure that the laser cutter software you choose is compatible with your specific machine.

What are some common file formats that can be used with CNC software?

When it comes to file compatibility, CNC software supports a wide range of common file formats. These include DXF, DWG, and STL. This allows you to easily import and work with files from various design software. The advantage of this is that it provides flexibility and compatibility with different CAD and design programs. However, one disadvantage is that some file formats may require additional software or plugins to convert them into a format compatible with CNC software.

How user-friendly is laser cutter software compared to CNC software?

You’ll be pleasantly surprised to know that laser cutter software is incredibly user-friendly compared to CNC software.

With laser cutter software, the user interface is intuitive and easy to navigate, making it a breeze to create precise designs.

However, there are a few drawbacks to consider. Laser cutter software may have limited functionality compared to CNC software, and it may not be suitable for complex projects.

The key difference lies in the user interface, with laser cutter software being more beginner-friendly.

Can CNC software be used for other applications besides cutting?

CNC software can be used for a wide range of applications besides cutting. It is capable of performing tasks such as drilling, milling, and engraving. One of the advantages of laser cutting over other techniques is its precision and ability to cut intricate designs. However, CNC software offers versatility and can be adapted for various purposes, making it a suitable choice for industries that require multifunctional capabilities.

Are there any limitations or restrictions when using laser cutter software or CNC software?

When it comes to laser cutter software and CNC software, there are limitations and restrictions to consider.

Laser cutter software often has limitations in terms of the types of materials it can work with, as well as the thickness and size of the materials.

On the other hand, CNC software offers a wider range of applications, including cutting, but also milling, drilling, and more.

It’s important to compare the software features for laser cutting and CNC machining to determine which is the right fit for your specific needs.

Conclusion

So, you’ve reached the end of this informative article comparing laser cutter software and CNC software.

Now it’s time to make a decision, my friend.

Do you want precision and finesse? Go for laser cutter software.

Do you prefer versatility and power? CNC software is your best bet.

But hey, no pressure! Just consider your application, uses, and the factors we discussed.

Ultimately, the choice is yours.

Good luck in your journey to becoming a master of fabrication!