Did you know that laser cutters have become increasingly popular in recent years, with an estimated 10% increase in usage among industries? As technology continues to advance, the choice between laser cutter software and electric cutter software has become a crucial decision for many businesses.

In this article, we will explore the features and capabilities of both types of software, as well as the user experience they offer. We will also compare their cost and accessibility to help you determine which option is more convenient for your needs.

Whether you are a small business owner or an industry professional, understanding the differences between laser cutter software and electric cutter software is essential for making informed decisions and maximizing efficiency in your operations.

Let’s dive in and discover which option is the right fit for you.

Key Takeaways

- Laser cutter software offers precise cutting capabilities and intuitive controls.

- Laser cutter software enhances workflow efficiency and automation.

- Laser cutter software allows for seamless integration with popular design programs like Adobe Illustrator and AutoCAD.

- Having reliable training resources and customer support ensures users can maximize the potential of their cutting machines.

Features and Capabilities of Laser Cutter Software

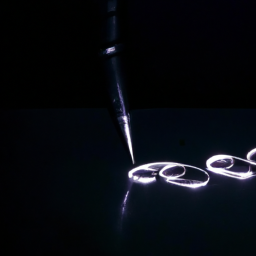

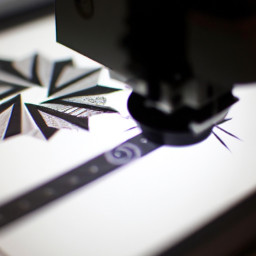

The laser cutter software allows you to easily design and create intricate patterns and shapes with just a few clicks. It offers a wide range of customization options, allowing you to adjust parameters such as speed, power, and focal length to achieve the desired cutting or engraving results.

Additionally, laser cutter software is compatible with various file formats, including vector graphics files like SVG and DXF. This means you can import designs from other software programs or create your own using popular design software like Adobe Illustrator or CorelDRAW.

With its user-friendly interface and robust features, laser cutter software provides a seamless and efficient workflow for designing and producing high-quality laser-cut projects. Transitioning to the next section, the user experience of laser cutter software is further enhanced by its intuitive controls and precise cutting capabilities.

User Experience of Laser Cutter Software

When using the laser cutter software, you’ll find the user experience to be intuitive and user-friendly. The laser cutter software is designed with laser cutter compatibility in mind, ensuring that it seamlessly integrates with the laser cutting machine.

The user interface is designed to be clean and easy to navigate, with clear icons and labels that make it simple to understand and operate. The software also offers a range of features to enhance the user experience, such as the ability to import and edit vector files, adjust laser power and speed, and preview designs before cutting.

With its user-friendly design and laser cutter compatibility, the laser cutter software ensures a smooth and efficient workflow.

Moving on to the features and capabilities of electric cutter software, you’ll find even more exciting possibilities for your cutting projects.

Features and Capabilities of Electric Cutter Software

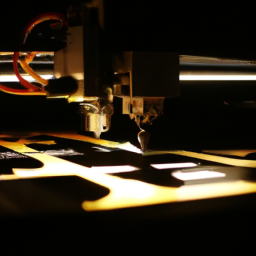

Electric cutter software offers a range of features and capabilities that enhance your cutting experience. Its versatility allows you to cut different materials with ease, providing you with a comprehensive cutting solution. With its cutting speed and efficiency, you can complete projects in less time without sacrificing precision.

Additionally, its integration with other design software streamlines your workflow, making it a convenient tool for all your cutting needs.

Versatility in Cutting Different Materials

With a laser cutter software, you can effortlessly cut a wide range of materials, making it a versatile tool for all your cutting needs. Laser cutting techniques allow for precise and intricate cuts, ensuring clean edges and minimal material waste. Additionally, laser cutters are compatible with various materials such as wood, acrylic, fabric, and even metals.

This versatility allows you to create a diverse range of products, from intricate designs to functional prototypes. Laser cutter software provides you with the ability to adjust settings such as speed and power, allowing for optimal cutting results depending on the material being used. Furthermore, the software enables you to easily switch between different cutting patterns and designs.

Transitioning to the subsequent section about cutting speed and efficiency, laser cutter software also excels in providing fast and efficient cutting capabilities.

Cutting Speed and Efficiency

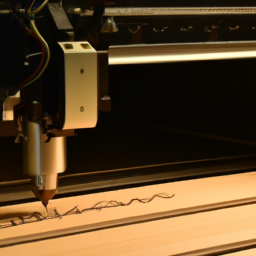

Get ready to experience lightning-fast cutting speeds and unparalleled efficiency with laser cutter software. The cutting quality achieved with laser cutter software is exceptional, ensuring precise and clean cuts every time. The software is designed to optimize the cutting process, allowing for smooth and efficient operation.

Additionally, laser cutter software is compatible with a wide range of materials, giving you the flexibility to work with various materials without any compatibility issues. This compatibility ensures that you can achieve the desired cutting results regardless of the material you’re working with.

As we transition into the next section about integration with other design software, you’ll see how laser cutter software seamlessly integrates with other design tools, further enhancing your workflow and productivity.

Integration with Other Design Software

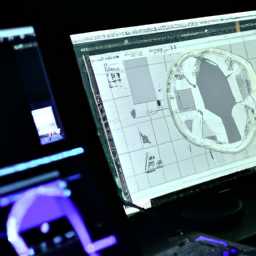

By seamlessly integrating with other design software, laser cutter software enhances your workflow and productivity, allowing for a seamless transfer of designs and a streamlined production process.

It offers compatibility with a wide range of 3D modeling software, such as AutoCAD and SolidWorks, enabling you to easily import and modify your designs for laser cutting.

Additionally, laser cutter software is also compatible with CNC machines, ensuring that your designs can be seamlessly transferred for further processing.

With this integration, you can effortlessly go from designing in your preferred software to cutting your materials with precision and accuracy. This level of compatibility and integration eliminates the need for manual file conversions or adjustments, saving you time and effort.

Now, let’s delve into the user experience of electric cutter software.

User Experience of Electric Cutter Software

When using electric cutter software, you’ll appreciate the ease of use and user-friendly interface. This allows for a seamless experience. The software ensures accuracy and precision in cutting, guaranteeing that your designs are executed with utmost precision.

Additionally, workflow efficiency and automation features streamline the cutting process. This saves you time and increases productivity.

Ease of Use and User-Friendly Interface

The laser cutter software’s intuitive interface effortlessly guides users through the design process, while the electric cutter software’s clunky and confusing interface only adds frustration to the already complex task. This stark contrast in ease of use greatly impacts the overall user experience. Here are five reasons why the laser cutter software proves to be more user-friendly:

- Streamlined navigation and clear menu options

- Intuitive drag-and-drop functionality

- Interactive tutorials and helpful tooltips for beginners

- Customizable workspace for personalized workflow

- Quick access to frequently used tools and settings.

This seamless user experience not only enhances ease of learning but also boosts customer satisfaction.

Moving forward, let’s explore the next subtopic: accuracy and precision in cutting.

Accuracy and Precision in Cutting

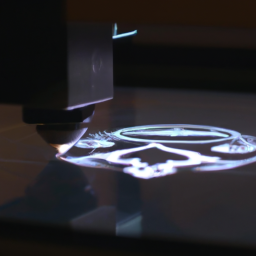

Achieving precise and accurate cuts is crucial for creating intricate designs that showcase your creativity and attention to detail.

When comparing laser cutter software and electric cutter software, both can deliver accurate and precise cuts. However, the impact of cutting techniques on material wastage differs.

Laser cutter software utilizes a focused beam of light to cut through materials, minimizing wastage. On the other hand, electric cutter software uses a physical blade, which may result in more material wastage due to the width of the blade.

Additionally, software updates are essential for maintaining accuracy and precision. Regular updates ensure that the cutting algorithms are optimized, reducing any potential errors or deviations.

As we delve into the subsequent section about workflow efficiency and automation, it is crucial to consider the impact of accuracy and precision on the overall efficiency of the cutting process.

Workflow Efficiency and Automation

Boost your productivity and unleash your creativity with an efficient and automated workflow. When it comes to workflow efficiency and automation, laser cutter software offers several advantages over electric cutter software. Laser cutter software allows for precise control over cutting parameters, such as speed and power, which can be adjusted based on the material being cut. This optimization of the workflow ensures that each cut is performed with the highest level of accuracy and precision. Additionally, laser cutter software often includes features that streamline processes, such as the ability to import and convert files, generate cutting paths automatically, and even integrate with design software. These automated features save time and reduce the risk of errors, making laser cutter software a convenient choice for users. Transitioning to the next section, let’s now delve into the comparison of cost and accessibility.

Comparison of Cost and Accessibility

When comparing the cost and accessibility of laser cutter software and electric cutter software, there are several key points to consider.

Firstly, the initial investment and maintenance costs differ between the two.

Secondly, the availability and affordability of software options also vary.

Lastly, the availability of training and support resources should be taken into account.

These factors play a crucial role in determining which software option is more convenient for users.

Initial Investment and Maintenance Costs

To truly grasp the value of laser cutter software and electric cutter software, imagine yourself as a weary traveler faced with the choice of embarking on a treacherous mountain hike or taking a smooth and comfortable ride on a luxurious train. When it comes to the initial investment comparison, laser cutter software tends to be more expensive than electric cutter software. The cost of a laser cutter can range from a few thousand dollars to tens of thousands, while electric cutters are generally more affordable. However, it’s important to consider the long-term maintenance costs as well. Laser cutters often require regular servicing and replacement of parts, which can add to the overall expenses. On the other hand, electric cutters usually have lower maintenance costs. As shown in the table below, the initial investment for laser cutters may be higher, but the long-term maintenance costs for electric cutters can accumulate over time.

| Initial Investment | Long-term Maintenance Costs | |

|---|---|---|

| Laser Cutter | High | Moderate |

| Electric Cutter | Moderate | Low |

This comparison highlights the trade-off between the initial investment and long-term maintenance costs of laser cutter software and electric cutter software. Moving on to the next section about the availability and affordability of software, it is important to consider these factors when making a decision.

Availability and Affordability of Software

Imagine yourself searching for the perfect software to meet your needs, and consider the availability and affordability of options on the market. When comparing laser cutter software and electric cutter software, it’s important to evaluate their compatibility with different file formats and design software.

Laser cutter software generally offers more compatibility with various file formats, allowing for seamless integration with popular design programs like Adobe Illustrator and AutoCAD. On the other hand, electric cutter software may have limitations in terms of file format compatibility, restricting your options and potentially impacting the outcomes of your projects.

It’s crucial to choose software that can handle the file formats and design software you commonly use to ensure smooth workflow and accurate results. Transitioning into the next section about training and support resources, it’s also important to consider the availability of assistance to help you navigate any software-related challenges you may encounter.

Training and Support Resources

Now that we’ve discussed the availability and affordability of software for laser cutters and electric cutters, let’s move on to the next important aspect: training and support resources.

When it comes to operating sophisticated machinery like laser cutters and electric cutters, having access to comprehensive training resources is crucial. Laser cutter software often provides detailed tutorials, user manuals, and online forums where users can learn and troubleshoot. Similarly, electric cutter software offers training modules and step-by-step guides to assist users in mastering the software.

Additionally, both types of software typically offer customer support through email, phone, or live chat to address any technical issues or questions. Having reliable training resources and customer support ensures that users can maximize the potential of their cutting machines with confidence.

Here are the key resources available:

- Tutorial videos

- User manuals

- Online forums

- Training modules

Frequently Asked Questions

Can laser cutter software be used with electric cutters?

Did you know that laser cutter software can be used with electric cutters? This combination offers numerous advantages.

By using laser cutter software, you can take advantage of its advanced features such as precise cutting, intricate designs, and accurate measurements. When paired with electric cutters, you can further enhance your cutting capabilities, making the process more efficient and accurate.

This combination provides a powerful and convenient solution for all your cutting needs.

What are the recommended system requirements for laser cutter software?

To ensure optimal performance, it’s important to consider the recommended system requirements for laser cutter software.

These requirements vary depending on the specific software, but generally include a compatible operating system such as Windows, macOS, or Linux.

It’s crucial to check the software’s documentation or website for the exact system requirements, as well as any additional hardware or software dependencies.

Compatibility with different operating systems allows users to choose the platform that best suits their needs.

Are there any limitations to the size or thickness of materials that laser cutter software can handle?

The limitations of laser cutter software in terms of material size and thickness depend on the specific software and laser cutter being used. Some software may have restrictions on the maximum size of materials that can be processed, while others may have limitations on the thickness of the materials. It’s important to check the compatibility between the laser cutter software and the electric cutter to ensure that the software can handle the size and thickness of the materials you plan to work with.

Does electric cutter software require any specific hardware or tools?

To ensure electric cutter software compatibility, specific hardware or tools are necessary. These may include an electric cutter machine, a computer with the required software installed, and a stable internet connection for updates and support.

The advantages of electric cutter software lie in its precision, speed, and versatility. It allows for intricate designs, efficient cutting, and the ability to work with various materials. Electric cutter software offers a seamless and efficient cutting process, making it a convenient choice for many users.

Can electric cutter software be used with laser cutters?

Electric cutter software can be used with laser cutters, but there may be compatibility issues. While electric cutter software is specifically designed for electric cutters, it may not fully support the functionalities of a laser cutter.

Advantages of using electric cutter software with laser cutters include the ability to create intricate designs and precise cuts. However, a disadvantage is that certain features of the laser cutter may not be fully utilized, limiting its capabilities.

Conclusion

In conclusion, when considering the convenience of laser cutter software versus electric cutter software, it’s evident that both have their unique features and capabilities.

Laser cutter software offers precision and versatility, providing users with a seamless experience.

On the other hand, electric cutter software showcases efficiency and speed, ensuring quick and accurate results.

While laser cutter software may be more accessible in terms of cost, electric cutter software offers a wider range of applications.

Ultimately, the choice between the two depends on the specific needs and preferences of the user.