When it comes to precision in fabrication, every detail matters. That’s why choosing the right software for your cutting or milling needs is crucial. Laser cutter software and milling software both offer unique advantages, but which one is more precise?

In this article, we will delve into the intricacies of laser cutter software and milling software, comparing their precision and accuracy. By examining their capabilities, speed, efficiency, versatility, and flexibility, we will determine which software reigns supreme in the realm of precision.

Whether you are a hobbyist or a professional, understanding the differences between these two technologies can greatly impact the quality of your work. So, buckle up and get ready to dive into the world of laser cutter software and milling software to find out which one will take your precision to new heights.

Key Takeaways

- Laser cutter software offers high-resolution control of the laser beam and real-time monitoring of cutting parameters, making it suitable for projects prioritizing fine detail and smooth edges.

- Milling software offers high-precision control of the milling tool and the ability to import complex CAD models, making it more suitable for projects requiring precise material removal.

- Laser cutting is faster and more efficient than milling, offering exceptional accuracy and lower operating costs compared to milling machines.

- Laser cutting software is versatile and compatible with various materials, while milling software is ideal for harder materials.

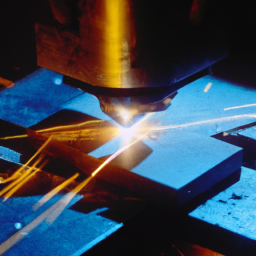

Understanding Laser Cutter Software

Do you want to understand laser cutter software and how it can help you achieve precise cuts?

Laser cutter software is a powerful tool that allows you to control the laser cutter with utmost precision. With laser cutting, you can achieve intricate designs and smooth edges that aren’t possible with milling software.

Laser cutting offers several advantages over milling. It can cut a wide range of materials, such as wood, plastic, and metal, with high accuracy and speed. It is widely used in various industries, including manufacturing, automotive, and electronics. It’s used for applications like prototyping, engraving, and signage.

By harnessing the capabilities of laser cutter software, you can achieve precise cuts that meet your exact specifications.

Now, let’s explore milling software and its unique features.

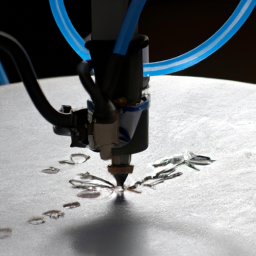

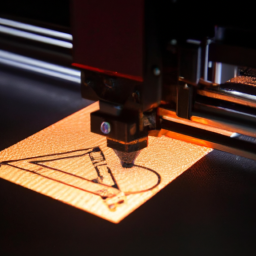

Exploring Milling Software

While exploring milling software, one user described it as a skilled sculptor carefully chiseling away at a block of wood, allowing for precise and intricate designs to come to life. Milling software offers a range of features that enable users to create complex shapes and detailed cuts with accuracy.

Some advantages of using milling software include:

- 3D Modeling: Milling software allows users to create 3D models of their designs, enabling them to visualize and refine their projects before production.

- Toolpath Optimization: The software optimizes toolpaths, reducing material waste and ensuring efficient cutting.

- Simulation: Users can simulate the milling process to identify potential issues and make necessary adjustments before cutting the actual material.

Milling software provides a high level of precision and control, enabling users to achieve intricate designs with accuracy.

In the subsequent section, we will compare the precision and accuracy of milling software with laser cutter software.

Comparing Precision and Accuracy

When it comes to precision in laser cutting, several factors come into play. These include the quality of the laser beam, the stability of the cutting platform, and the accuracy of the motion control system.

Similarly, in milling, precision is influenced by factors such as the rigidity of the milling machine, the sharpness of the cutting tool, and the accuracy of the positioning system.

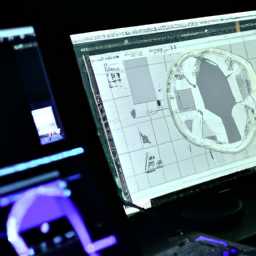

A comparative analysis of precision and accuracy between laser cutter software and milling software would involve examining the algorithms and calculations used in each software to ensure precise and accurate cutting or milling operations.

Factors that contribute to precision in laser cutting

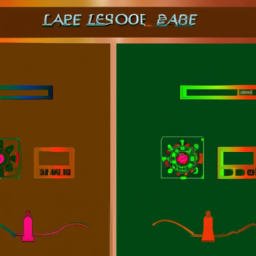

One key factor that contributes to precision in laser cutting is the use of high-quality optics. Laser cutting techniques rely on precise focusing of the laser beam to achieve accurate cuts. High-quality optics ensure that the laser beam remains focused and consistent, resulting in precise and clean cuts. Additionally, precision engineering plays a crucial role in laser cutting. The design and construction of the laser cutter itself must be precise to maintain accuracy throughout the cutting process. This includes aspects such as motion control systems, laser power stability, and beam delivery systems. To further illustrate the importance of these factors, consider the table below comparing the precision-related features of laser cutting software and milling software.

| Laser Cutting Software | Milling Software |

|---|---|

| High-resolution control of laser beam | High-precision control of milling tool |

| Real-time monitoring and adjustment of cutting parameters | Real-time monitoring and adjustment of milling parameters |

| Ability to import and manipulate complex vector files | Ability to import and manipulate complex CAD models |

| Laser power modulation for intricate cutting | Spindle speed control for various materials |

| Precision positioning of cutting path | Precision positioning of milling path |

These factors contribute to the precision of laser cutting. Moving forward, let’s explore the factors that contribute to precision in milling.

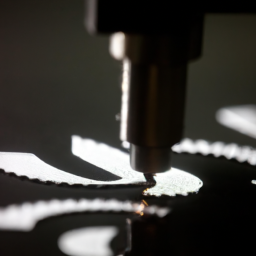

Factors that contribute to precision in milling

To achieve precision in milling, you can greatly benefit from using high-quality cutting tools that have been manufactured to tight tolerances, resulting in a deviation of less than 0.001 inches. Milling machine accuracy plays a crucial role in achieving precise machining.

The accuracy of the milling machine depends on various factors, including the rigidity of the machine structure, the quality of the spindle, and the precision of the linear motion system. Additionally, factors such as the stability of the workpiece and the cutting parameters used also contribute to precision in milling.

By carefully considering and optimizing these factors, you can ensure that your milling operations achieve the desired level of precision.

Transitioning to a comparative analysis of precision and accuracy between laser cutter software and milling software, it becomes evident that both have their unique capabilities and limitations.

A comparative analysis of precision and accuracy between laser cutter software and milling software

In comparing the precision and accuracy of laser cutter software and milling software, it’s fascinating to explore their distinct capabilities and limitations. When it comes to precision, both laser cutting and milling rely heavily on calibration. Ensuring that the machine is properly calibrated is crucial for achieving accurate results. However, laser cutting software tends to be more precise due to its ability to create finer details and intricate designs. On the other hand, milling software can sometimes struggle with achieving the same level of precision, especially when dealing with complex geometries. Additionally, the impact of software updates cannot be overlooked. Regular updates can enhance the precision of both laser cutting and milling software by optimizing algorithms and improving overall performance. As we delve into the next section on speed and efficiency considerations, it’s important to note how these factors also play a role in achieving precise results.

Speed and Efficiency Considerations

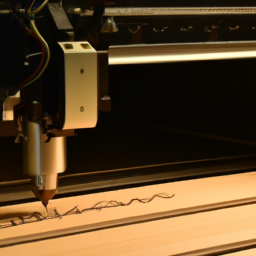

When it comes to speed and efficiency, laser cutter software definitely takes the cake. Laser cutters are known for their ability to quickly and accurately cut through various materials with precision. Here is a comparison of speed and efficiency between laser cutter software and milling software:

-

Speed: Laser cutters operate at high speeds, allowing for rapid cutting and engraving processes. In contrast, milling software requires more time due to the physical contact between the tool and the material.

-

Accuracy: Laser cutters offer exceptional accuracy, as they’re capable of achieving intricate designs and fine details. Milling software can also achieve high levels of accuracy, but it may require additional time for calibration and adjustments.

-

Cost-effectiveness: Laser cutters are generally more cost-effective as they require minimal maintenance and have lower operating costs compared to milling machines, which often require regular tool replacements and maintenance.

In terms of versatility and flexibility, laser cutter software offers a wide range of applications and is compatible with various materials, making it a valuable tool for different industries.

Versatility and Flexibility

When considering the versatility and flexibility of laser cutter software and milling software, it’s important to examine the applications and materials suitable for each process.

Laser cutting is well-suited for applications such as engraving, etching, and cutting thin materials like paper and fabric.

On the other hand, milling is ideal for working with harder materials like wood, metal, and plastic, allowing for intricate shaping and detailing.

By evaluating the capabilities of each software, you can determine which process will be most suitable for your specific needs and materials.

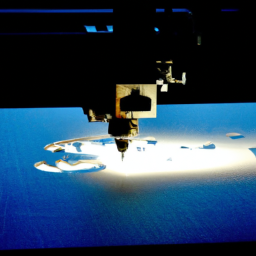

Applications and materials suitable for laser cutting

Discover the wide range of applications and materials you can effortlessly cut using a laser cutter. Laser cutting technology offers a multitude of applications for various industries, including signage, jewelry making, automotive, and even medical devices.

With its precision and versatility, laser cutting can effortlessly handle materials such as acrylic, wood, leather, fabric, and metals like stainless steel and aluminum. The laser cutter’s focused beam allows for intricate and precise cuts, making it ideal for intricate designs, fine details, and complex shapes.

Laser cutting is highly efficient, producing clean and smooth edges without the need for additional finishing processes. Transitioning into the subsequent section about ‘applications and materials suitable for milling,’ you’ll find that while laser cutting excels in certain areas, milling software offers its own unique advantages.

Applications and materials suitable for milling

Milling technology offers a wide range of applications and materials that can be effortlessly handled with its precision and versatility. This includes metals like stainless steel and aluminum, as well as materials such as wood, plastic, and composites. The benefits of CNC machining are evident in its ability to produce highly accurate and intricate designs, making it suitable for industries such as aerospace, automotive, and prototyping.

When comparing milling to 3D printing, milling provides better surface finish and dimensional accuracy. It can create complex geometries with tight tolerances, making it ideal for producing functional parts and prototypes. Additionally, milling allows for the use of a wider range of materials, including metals, which are often required in industrial applications.

Evaluating the versatility and flexibility of laser cutter software and milling software, it becomes clear that both technologies have their strengths and limitations. However, the precision and wide range of materials that can be milled make it a preferred choice for many industries.

Evaluating the versatility and flexibility of laser cutter software and milling software

Now that we’ve explored the applications and materials suitable for milling, let’s shift our focus to evaluating the versatility and flexibility of laser cutter software and milling software.

When it comes to precision capabilities, both laser cutter software and milling software have their own strengths. Laser cutter software is known for its high precision in cutting intricate designs with smooth edges. On the other hand, milling software excels in precise material removal, allowing for more detailed and accurate carving.

To determine the ideal use cases for each software, it’s crucial to evaluate the specific requirements of your project. If you prioritize fine detail and smooth edges, laser cutter software may be the better choice. However, if precise material removal is your main concern, milling software would be more suitable.

By carefully assessing your needs, you can select the software that best aligns with your project goals.

Frequently Asked Questions

What are the main differences between laser cutter software and milling software?

Laser cutter software and milling software have distinct features. Laser cutter software emphasizes precision, offering features like vector engraving and raster engraving. It enables precise control over laser power and speed.

Milling software, on the other hand, excels in versatility and material compatibility. It supports a wide range of materials, including metals and plastics. Additionally, milling software allows for intricate 3D designs and offers advanced toolpath strategies, making it advantageous over laser cutter software in certain applications.

Can laser cutter software be used with milling machines, and vice versa?

Interchangeability and compatibility between laser cutter software and milling machines is possible, creating a harmonious union of precision. With the right software, these machines can seamlessly communicate and execute tasks, providing efficient and accurate results.

Laser cutter software can be adapted to milling machines and vice versa, allowing for a versatile workflow. The compatibility between these technologies expands the capabilities of both, unlocking a world of possibilities for precise fabrication.

Are there any limitations or specific requirements when using laser cutter software?

When using laser cutter software, there are certain limitations and specific requirements that need to be considered. The software may have limitations in terms of the types of materials it can cut or engrave, as well as the thickness of the material.

Additionally, specific requirements for laser cutting machines include proper ventilation and safety measures to prevent accidents. It’s crucial to adhere to these limitations and requirements to ensure optimal performance and safety when using laser cutter software.

How do precision and accuracy differ in laser cutting and milling processes?

Precision and accuracy play crucial roles in laser cutting and milling processes. Precision refers to the consistency and exactness of measurements and cuts, while accuracy refers to how closely the measurements and cuts align with the intended target.

In both laser cutting and milling, precision significantly affects the quality of the final products. Precise measurements ensure that the cuts are made accurately, resulting in products that meet the desired specifications.

What are some key factors to consider when choosing between laser cutter software and milling software?

When choosing between laser cutter software and milling software, there are several key factors to consider.

Firstly, consider the precision and accuracy required for your specific project. Laser cutting software offers high precision, especially for intricate designs, while milling software provides more versatility for complex shapes.

Additionally, consider the material you’ll be working with, as laser cutting is ideal for non-metal materials.

Finally, evaluate the cost and ease of use for each software, as well as the support and training available.

Conclusion

In conclusion, when it comes to precision, both laser cutter software and milling software have their strengths. Laser cutters offer unparalleled accuracy and detail, making them ideal for intricate designs.

On the other hand, milling software excels in producing precise and smooth finishes on a wider range of materials. However, it’s important to consider other factors such as speed, efficiency, versatility, and flexibility when choosing between the two.

Symbolically speaking, it’s like comparing a surgeon’s scalpel to a sculptor’s chisel – both are essential tools, but their effectiveness depends on the task at hand.