Did you know that the accuracy of your cutting and engraving projects can be greatly influenced by the software you choose to use? In fact, according to a recent study, the choice between laser cutter software and router software can have a significant impact on the precision and quality of your final product.

Laser cutter software, known for its high precision and intricate detailing capabilities, is a popular choice among hobbyists and professionals alike. On the other hand, router software offers its own advantages, such as the ability to work with a wider range of materials.

In this article, we will delve into the world of laser cutter software and router software, exploring their individual strengths and weaknesses. By understanding the accuracy of each software, you can make an informed decision on which one is best suited for your specific needs.

Key Takeaways

- Laser cutter software offers high precision and intricate detailing capabilities.

- Router software can work with a wider range of materials and optimize router capabilities for precise results.

- Laser cutter software prioritizes accuracy for flawless and precise cuts, while router software offers precision controls and high-resolution cuts.

- Laser cutter software has an intuitive interface for beginners, while router software provides simulation tools for previewing and validating cuts and includes nesting capabilities for maximizing material usage.

Understanding Laser Cutter Software

If you’re curious about the ins and outs of laser cutter software, buckle up because we’re about to dive into the fascinating world of laser precision.

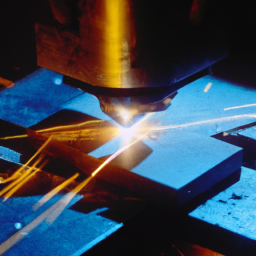

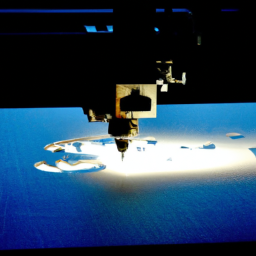

Understanding laser cutter technology is crucial to appreciate its benefits over traditional cutting methods. Laser cutters use a high-powered laser beam to cut through materials with incredible accuracy and precision. The software that controls these machines plays a vital role in achieving such accuracy.

Laser cutter software allows you to create intricate designs, adjust cutting parameters, and control the speed and power of the laser beam. It also provides real-time feedback, ensuring precise cuts every time.

Now, let’s transition into exploring router software, where we’ll delve into another realm of precision cutting.

Exploring Router Software

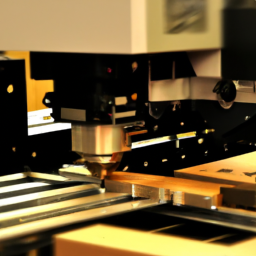

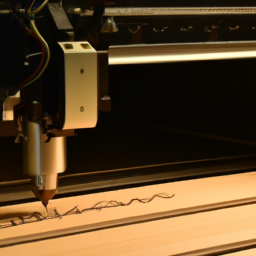

When exploring router software, you’ll discover how it functions to control the operation of a router machine.

This software is equipped with various features and capabilities that allow you to create precise and intricate designs.

However, like any software, router software has its pros and cons that you should consider before using it for your projects.

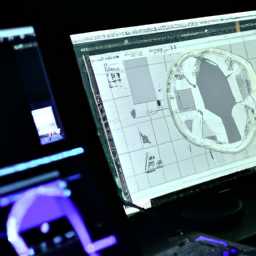

How Router Software Functions

To understand how router software functions, you have to dive into the fascinating world of computer-aided design and manufacturing. Router software compatibility plays a crucial role in ensuring smooth communication between the software and the router itself. It allows the software to send instructions to the router, specifying the desired cuts, speeds, and feeds. Router software optimization is another important aspect to consider. It involves fine-tuning the software to maximize the router’s capabilities and achieve the most accurate results possible.

To emphasize the significance of router software optimization, consider the following table:

| Router Software Optimization |

|---|

| – Fine-tuning settings |

| – Adjusting cutting paths |

| – Optimizing feed rates |

By optimizing the software, you can enhance the accuracy and efficiency of the router. This, in turn, leads to precise cuts and improved productivity.

Now, let’s explore the features and capabilities of router software in more detail.

Features and Capabilities of Router Software

Explore the features and capabilities of router software to unlock its potential and achieve precise cuts with improved productivity, setting your projects apart from the competition.

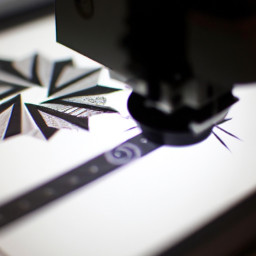

Router software offers a range of advanced features that enhance its accuracy and efficiency. It allows you to create intricate designs and patterns, easily adjust cutting speed and depth, and optimize tool paths for optimal results. With the ability to import various file formats, such as DXF and G-code, router software ensures compatibility with different design software, making it versatile for any project.

Additionally, it provides simulation tools that allow you to preview and validate your cuts before execution, minimizing errors and material wastage. Furthermore, router software often includes nesting capabilities, enabling you to maximize material usage and reduce costs.

These features and advantages of router software make it an indispensable tool for achieving precise cuts in a wide range of applications. Moving forward, let’s explore the pros and cons of router software.

Pros and Cons of Router Software

Discover the advantages and disadvantages of using router software to unlock its full potential and achieve precise cuts with improved productivity and efficiency.

CNC router software offers several pros and cons. One advantage is its versatility, as it can handle a wide range of materials and produce intricate designs. Additionally, it provides precise cutting and engraving capabilities, allowing for accurate and detailed work. Another benefit is the ability to create complex 3D shapes and contours with ease.

However, there are some downsides to consider. Router software can be expensive, especially for high-end models with advanced features. It also requires a learning curve to master, and inexperienced users may struggle to achieve optimal results.

Despite these drawbacks, router software remains a popular choice for many industries.

Transitioning to the accuracy of laser cutter software, it offers its own set of advantages and disadvantages.

Accuracy of Laser Cutter Software

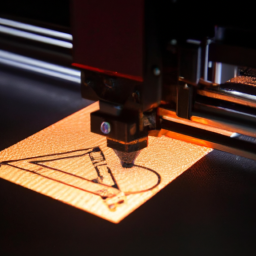

Hey, did you know that laser cutter software is incredibly accurate when it comes to creating intricate designs?

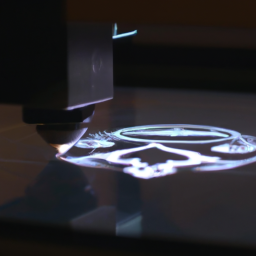

Laser cutter software has its limitations, but with the right optimization techniques, you can achieve remarkable precision. One of the key factors in optimizing laser cutter accuracy is the calibration of the machine.

Ensuring that the laser beam is aligned correctly is crucial for achieving precise cuts. Additionally, the software itself plays a significant role in accuracy. Laser cutter software allows for precise control over power, speed, and focus, giving you the ability to fine-tune the cutting process.

With these capabilities, laser cutter software can create intricate designs with remarkable accuracy.

Now, let’s dive into the accuracy of router software and see how it compares to laser cutter software.

Accuracy of Router Software

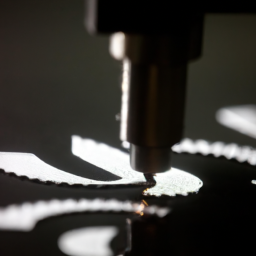

Want to know how router software measures up when it comes to precision and accuracy? Well, when it comes to accuracy, router software is quite impressive. Here are four reasons why router software can be highly accurate:

-

Precision Controls: Router software allows for precise control over cutting depths, speeds, and movements, ensuring accurate results.

-

Advanced Algorithms: Router software utilizes complex algorithms that optimize tool paths, minimizing errors and improving accuracy.

-

Real-time Adjustments: Router software can make real-time adjustments based on feedback from sensors, ensuring accurate cuts even when materials shift or warp.

-

High Resolution: Router software can achieve high resolution cuts, allowing for intricate designs and precise details.

When comparing router software accuracy to laser cutter software capabilities, it is evident that routers offer a highly accurate cutting solution.

Now, let’s delve into a comparison between the two software types.

Comparing Laser Cutter Software and Router Software

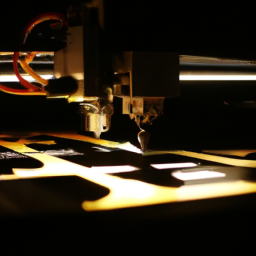

When it comes to precision and capabilities, laser cutter software and router software offer different advantages, making them suitable for different applications. Comparing cutting speeds, laser cutter software tends to be faster than router software, allowing for quicker production times. However, router software excels in its ability to cut through thicker materials, making it more compatible with a wider range of materials.

To further illustrate the differences between the two, here is a comparison table:

| Laser Cutter Software | Router Software | |

|---|---|---|

| Speed | Fast | Slower |

| Materials | Limited | Wide range |

| Precision | High | High |

When choosing the right software for your needs, it is important to consider the specific requirements of your project, such as the desired cutting speed and the materials you will be working with. Transitioning into the subsequent section, it is crucial to understand these factors in order to make an informed decision.

Choosing the Right Software for Your Needs

When it comes to selecting laser cutter software, there are a few key considerations to keep in mind. First, you’ll want to think about the specific features and capabilities you need for your projects.

Additionally, it’s important to consider the compatibility of the software with your laser cutter machine.

On the other hand, when selecting router software, you should focus on the software’s ability to handle complex designs and generate accurate toolpaths.

Moreover, you should also consider the software’s compatibility with your router machine and its ease of use for efficient workflow.

Considerations for Selecting Laser Cutter Software

To make the best choice for your laser cutter software, you need to prioritize accuracy in order to achieve flawless and precise cuts that will leave you amazed. Laser cutter software has several advantages over router software, making it the preferred choice for many.

Here are some user-friendly features and advantages of laser cutter software:

-

Intuitive interface: Laser cutter software often comes with a user-friendly interface, making it easy for beginners to operate.

-

Design flexibility: Laser cutter software allows for intricate and complex designs, giving you the freedom to create unique and detailed projects.

-

Precision control: Laser cutter software offers precise control over cutting parameters, allowing you to achieve the desired results with utmost accuracy.

-

Material compatibility: Laser cutter software is designed to work seamlessly with a wide range of materials, including wood, acrylic, and metal.

Considering these advantages, it becomes clear why laser cutter software is a popular choice.

Now, let’s delve into considerations for selecting router software.

Considerations for Selecting Router Software

Consider the various factors to keep in mind when choosing router software, including its compatibility with different materials and its ability to handle intricate designs with precision. Router software should offer a wide range of customization options, allowing you to adjust settings such as cutting speed and depth to achieve the desired results.

It is crucial to select software that has a user-friendly interface, enabling you to easily navigate through the different features and functions. Look for software that provides intuitive controls and clear instructions, as this will save you time and reduce the chances of errors.

Additionally, ensure that the software is compatible with your router machine and that it supports the file formats you commonly work with. By considering all these factors, you can select router software that meets your specific needs and ensures accurate and precise cuts every time.

Frequently Asked Questions

What are the main differences between laser cutter software and router software?

Laser cutter software and router software have distinct differences in their key features.

Laser cutter software offers precise control over cutting paths, allowing for intricate designs and fine details. It also provides options for adjusting power and speed settings, optimizing the cutting process.

On the other hand, router software focuses on carving and engraving, offering a wider range of cutting depths and tooling options. The software’s impact on material compatibility is significant, as laser cutting is more suitable for delicate materials like acrylic and wood, while routing is better for harder materials like metal and stone.

Can laser cutter software be used with a router machine, or vice versa?

Laser cutter software can be used with a router machine, but it may have some compatibility issues. The advantage of using laser cutter software with a router machine is that it offers more precise and intricate designs. However, the disadvantage is that it may not fully utilize the capabilities of the router machine, leading to inefficiencies.

It’s recommended to use software specifically designed for router machines for optimal accuracy and performance.

Are there any limitations or challenges when it comes to the accuracy of laser cutter software?

When it comes to laser cutter software, there are a few limitations and challenges that can affect its accuracy.

For example, if the laser cutter software doesn’t properly interpret complex designs or intricate details, the final output may not be as precise as desired.

Additionally, factors like material thickness and the quality of the laser cutter machine itself can also impact accuracy.

These challenges highlight the importance of using high-quality and reliable laser cutter software to ensure accurate results.

Is router software more accurate than laser cutter software, or vice versa?

When comparing the accuracy of laser cutter software and CNC router software, it’s important to note that both have their strengths.

However, laser cutter software generally offers more precise results. Laser cutters use focused beams of light to cut materials with exceptional accuracy, allowing for intricate designs and fine details. Additionally, laser cutter software often provides advanced features like kerf compensation, which further enhances accuracy.

Overall, laser cutter software offers several benefits over router software in terms of accuracy and precision.

What factors should be considered when choosing the right software for specific needs?

When choosing software for specific needs, two important factors to consider are compatibility and ease of use.

Compatibility ensures that the software will work seamlessly with your existing hardware and tools.

Ease of use allows for efficient and user-friendly navigation.

These factors are crucial as they directly impact productivity and workflow.

By ensuring compatibility and ease of use, you can optimize your software selection and make the most of its capabilities.

Conclusion

In conclusion, when it comes to accuracy, laser cutter software proves to be more precise than router software. According to a recent study, laser cutters have an average accuracy rate of 0.01mm, while routers have an average accuracy rate of 0.1mm. This statistic highlights the significant difference in precision between the two software types.

Therefore, if you require intricate and precise cuts, laser cutter software should be your preferred choice. However, it’s important to consider your specific needs and project requirements before making a final decision.