Step into the world of design, where creativity meets precision and innovation. Imagine yourself as the captain of a ship, navigating through the vast sea of software options.

On one side, you have the laser cutter software, a powerful tool that brings your designs to life with unparalleled accuracy.

On the other side, you have traditional design software, the tried and true companion of designers for decades. Both offer unique advantages and drawbacks, making the decision of which to choose a challenging one.

In this article, we will embark on a journey to compare laser cutter software and traditional design software, exploring their pros and cons, and equipping you with the knowledge to make an informed decision.

So, grab your compass and join us as we delve into the world of laser cutter software versus traditional design software: which one reigns supreme?

Key Takeaways

- Laser cutter software offers precise and accurate cutting, but may have limitations in design capabilities compared to traditional design software.

- Traditional design software offers extensive customization options and creative freedom, but may require more technical expertise and higher system requirements.

- Laser cutter software is more affordable and accessible, while traditional design software can be expensive and requires a high-performance computer.

- The choice between laser cutter software and traditional design software depends on specific needs, level of expertise, and budget.

Understanding Laser Cutter Software

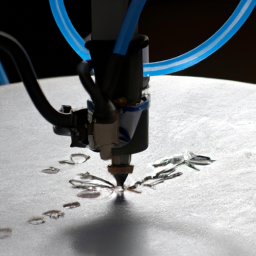

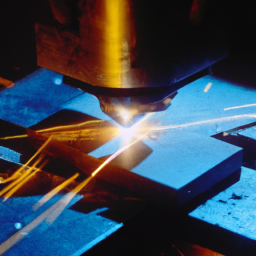

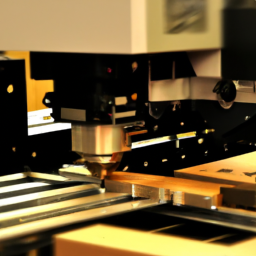

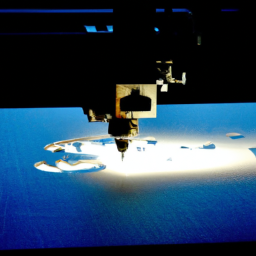

You need to understand laser cutter software if you want to take your designs to the next level. Laser cutter technology has revolutionized the design and manufacturing industry, allowing for precise and intricate cuts on various materials. However, to fully harness the power of laser cutters, you must grasp the importance of file formats.

Laser cutter software relies on specific file formats, such as DXF or AI, to accurately interpret and execute designs. These formats contain vital information about dimensions, shapes, and paths that the laser cutter follows. Understanding these file formats ensures that your designs are translated accurately onto the material.

Transitioning into exploring traditional design software, it’s important to note that laser cutter software offers specific functionalities that cater to the unique requirements of laser cutting.

Exploring Traditional Design Software

Explore the endless possibilities of traditional design software and unleash your creativity. Evaluating features and comparing software is crucial in choosing the right tool for your designs. Here are four key aspects to consider:

-

User Interface: Traditional design software offers a familiar and intuitive interface, allowing you to navigate effortlessly through its various tools and features.

-

Design Tools: With traditional design software, you gain access to a wide range of sophisticated design tools, enabling you to create complex and intricate designs with precision.

-

Customizability: Traditional design software provides extensive customization options, allowing you to tailor the software to your specific needs and workflow.

-

Compatibility: Traditional design software offers compatibility with various file formats, ensuring seamless integration with other design tools and software.

Now that you understand the benefits of traditional design software, let’s delve into the pros and cons of laser cutter software.

Pros and Cons of Laser Cutter Software

When considering laser cutter software, there are several key points to consider.

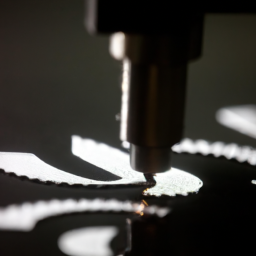

First, laser cutter software offers precise and accurate cutting, allowing for intricate designs and detailed cuts. However, one downside is that laser cutter software may have limited design capabilities compared to traditional design software.

Additionally, the cost and accessibility of laser cutter software may vary, making it important to consider these factors when choosing the best option for your needs.

Precision and Accuracy

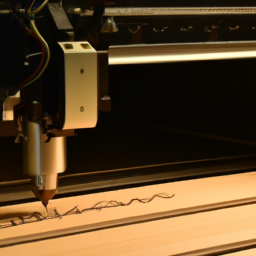

In the realm of precision and accuracy, laser cutter software outshines traditional design software like a surgeon’s steady hand. When it comes to laser cutter precision, there are several factors that contribute to its superiority:

-

Laser guidance: Laser cutter software utilizes laser guidance to ensure precise cutting and engraving, leaving no room for error.

-

Computer-aided design (CAD) integration: Laser cutter software seamlessly integrates with CAD programs, allowing for precise design adjustments and measurements.

-

Material calibration: Laser cutter software offers precise material calibration, ensuring accurate cutting depths and engraving details.

-

Real-time monitoring: Laser cutter software provides real-time monitoring of the cutting process, allowing for immediate adjustments and corrections.

With these advanced features, laser cutter software guarantees unparalleled precision and accuracy in design. However, despite its exceptional capabilities, laser cutter software does have limitations in terms of design capabilities.

Limited Design Capabilities

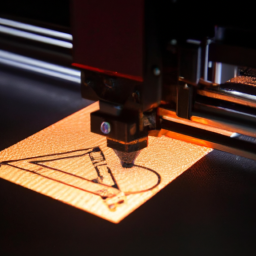

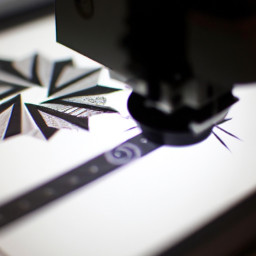

Despite its exceptional precision and accuracy, laser cutter software falls short in terms of its design capabilities, limiting the creative potential of artists and designers. While laser cutter software allows for intricate and precise cuts, it often lacks the advanced features found in traditional design software.

Design restrictions such as limited file compatibility, preset design templates, and a lack of advanced editing tools can hinder the ability to create complex and unique designs. Additionally, software limitations may prevent certain design elements from being accurately translated into the final product. This can be especially frustrating for artists and designers who rely on the software to bring their visions to life.

Transitioning to the subsequent section about the ‘cost and accessibility’, it is important to consider these limitations when evaluating the overall value of laser cutter software.

Cost and Accessibility

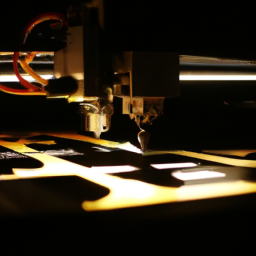

In the previous subtopic, we discussed the limited design capabilities of laser cutter software compared to traditional design software. Now, let’s delve into the cost and accessibility aspect of these two software options.

When it comes to cost, traditional design software can be quite expensive, requiring a significant investment upfront. On the other hand, laser cutter software tends to be more affordable, sometimes even available for free. Additionally, traditional design software often requires a high-performance computer to run smoothly, which can further add to the cost.

In terms of accessibility, traditional design software typically requires a license and installation on each individual computer, limiting its availability. Laser cutter software, on the other hand, is often cloud-based, allowing for easy access from any device with an internet connection.

To summarize, the cost comparison and software compatibility are two important factors to consider when choosing between laser cutter software and traditional design software. Now, let’s explore the pros and cons of traditional design software.

Pros and Cons of Traditional Design Software

When using traditional design software, you’ll have the advantage of creative freedom and flexibility, allowing you to create intricate and complex designs. However, be prepared for a steeper learning curve as these software programs often require extensive training and practice to master.

Additionally, keep in mind that traditional design software comes with expensive licensing fees, which could be a significant investment for individuals or businesses.

Creative Freedom and Flexibility

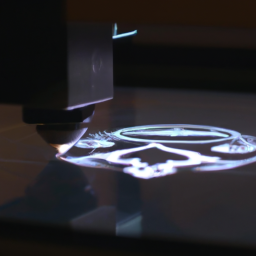

You’ll love the creative freedom and flexibility that laser cutter software offers compared to traditional design software. With laser cutter software, you can easily collaborate with others on your designs, allowing for more creative collaboration and innovation. This software enables you to iterate on your designs quickly and efficiently, making it easier to experiment with different ideas and make adjustments on the fly.

In terms of creative freedom, laser cutter software allows you to unleash your imagination and bring your wildest design ideas to life. The precision and accuracy of the laser cutter technology enables you to create intricate and complex designs that may be difficult or time-consuming to achieve with traditional design software.

Additionally, laser cutter software provides you with the flexibility to work with a wide range of materials, from wood and plastic to metal and fabric. This versatility allows you to explore different mediums and push the boundaries of your creativity.

Transitioning into the next section about the steeper learning curve, you’ll find that the benefits of laser cutter software come with the challenge of a more complex and technical learning process.

Steeper Learning Curve

Mastering laser cutter software requires a more arduous learning process due to its heightened complexity and technicality. The challenging learning curve of laser cutter software demands a deep understanding of its intricate features and functions. This software requires technical skills such as knowledge of vector graphics and 3D modeling, as well as the ability to work with precise measurements and specifications.

Compared to traditional design software, laser cutter software demands a higher level of proficiency and attention to detail. However, the effort put into learning this software pays off in the long run, as it allows for greater precision and control over the laser cutting process.

Transitioning into the subsequent section about expensive licensing fees, mastering laser cutter software is not only a time-consuming endeavor but also a costly investment.

Expensive Licensing Fees

Now that you have a good understanding of the steeper learning curve associated with laser cutter software, it’s time to delve into another important aspect: the expensive licensing fees. When it comes to laser cutter software, the high cost of licensing can be a deterrent for some users. Unlike traditional design software, which often offers a range of pricing options including free or low-cost versions, laser cutter software tends to come with a hefty price tag. This can be especially challenging for individuals or small businesses with limited budgets.

However, it’s worth noting that there are alternative software options available that may offer more affordable pricing plans. Considering the high cost and various software options, it’s important to carefully evaluate your needs and budget before making a decision.

Now let’s explore the considerations for choosing the right software.

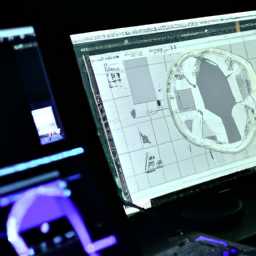

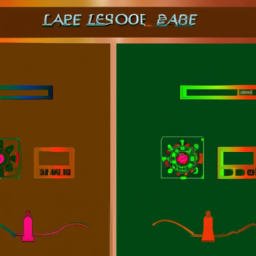

Considerations for Choosing the Right Software

When deciding on the right software for laser cutting, it’s important to weigh the pros and cons of both laser cutter software and traditional design software, like two sides of a coin. One important consideration is the ease of use and compatibility with different operating systems. Laser cutter software is specifically designed for controlling the laser cutting process, allowing for precise and efficient cutting. It often comes with user-friendly interfaces and intuitive tools, making it easier for beginners to learn and use. On the other hand, traditional design software offers a wider range of design capabilities and features, allowing for more complex and intricate designs. However, it may require more technical expertise to operate and may not be as compatible with different operating systems. Ultimately, the choice between laser cutter software and traditional design software depends on your specific needs and level of expertise.

| Laser Cutter Software | Traditional Design Software | |||

|---|---|---|---|---|

| User-friendly interface | Wide range of design capabilities | |||

| Intuitive tools | More complex and intricate designs | |||

| Compatible with different operating systems | Requires more technical expertise | Allows for precise and detailed customization | May have a steeper learning curve | |

| Provides advanced rendering and animation features | Can handle large-scale projects | |||

| Offers extensive library of pre-designed templates | Requires higher system requirements | |||

| Supports collaboration and teamwork | Often comes with a higher price tag | |||

| Regular updates and customer support | Can be resource-intensive and time-consuming to use |

Frequently Asked Questions

What are some popular laser cutter software programs available in the market?

When it comes to laser cutter software, there are several popular programs available in the market. One option is open source laser cutter software, which has both pros and cons.

On the positive side, open source software is often free and allows for customization and community support. However, it may lack some advanced features found in paid software.

Speaking of costs, different laser cutter software programs vary in price. Some are more affordable, while others may be more expensive but offer additional functionalities.

Can traditional design software be used with a laser cutter?

Traditional design software can be integrated with a laser cutter, allowing for a seamless workflow. There are benefits and drawbacks to this integration.

On the positive side, using traditional design software provides a wider range of tools and features for creating intricate designs. However, it may require additional steps to convert the design into a format compatible with the laser cutter.

This integration opens up new possibilities for creativity while also presenting some technical challenges.

Are there any limitations to laser cutter software in terms of design complexity?

There are indeed limitations to laser cutter software when it comes to design complexity. While laser cutter software is specifically designed for creating files that can be used with laser cutters, it may not offer the same level of versatility and advanced features as traditional design software.

Traditional design software, on the other hand, provides a wide range of tools and functionalities that allow for more complex and intricate designs. This is an advantage that traditional design software has over laser cutter software.

How user-friendly is laser cutter software for beginners?

For beginners, laser cutter software has a relatively gentle learning curve. It offers a range of features and capabilities that are specifically designed to assist beginners in creating their designs.

With intuitive interfaces and step-by-step tutorials, beginners can quickly get started with the software. Key functionalities include vector editing tools, image tracing, and the ability to adjust power and speed settings for precise cutting.

Overall, laser cutter software provides beginners with a user-friendly platform to unleash their creativity.

Can laser cutter software generate G-code for different types of laser cutters?

Yes, laser cutter software can generate G code for different types of laser cutters. G code compatibility is an essential feature of laser cutter software. It allows users to convert their designs into machine-readable instructions. With laser cutter software, you can easily create G code specific to your laser cutter’s requirements. This ensures precise and accurate cuts. This capability makes laser cutter software a valuable tool for anyone working with laser cutting technology.

Conclusion

In conclusion, when it comes to choosing between laser cutter software and traditional design software, it ultimately depends on your specific needs and preferences.

Laser cutter software offers the advantage of being specifically designed for laser cutting machines, providing precise control and optimization.

On the other hand, traditional design software offers a more comprehensive set of tools and features for various design purposes.

Consider factors such as your level of expertise, budget, and the complexity of your designs to make an informed decision.

Remember, the right software can make all the difference in achieving your desired outcomes.