Are you in the market for a cutting machine but unsure of which software to choose? Look no further, as we delve into the world of laser cutter software and vinyl cutter software to determine which one is more versatile.

While both options have their merits, one theory holds true: laser cutter software offers a higher level of versatility compared to vinyl cutter software. In this article, we will provide an overview of both types of software, highlighting their key features and capabilities. We will also compare their precision and accuracy, as well as their compatibility with various materials. Additionally, we will discuss the ease of use and learning curve associated with each software.

By the end, you will have a clear understanding of which option best suits your needs, ensuring that you make an informed decision. So, let’s dive in and explore the world of laser cutter software versus vinyl cutter software.

Key Takeaways

- Laser cutter software offers more versatility compared to vinyl cutter software

- Laser cutter software provides faster cutting speeds and higher efficiency compared to vinyl cutters

- Vinyl cutter software is more affordable upfront and better for smaller-scale projects with limited budgets

- Laser cutter software has more potential for growth and versatility in the long run

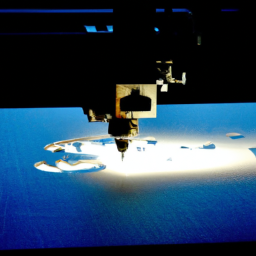

Overview of Laser Cutter Software

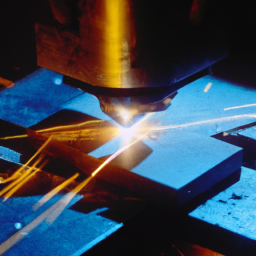

Laser cutter software is like having a creative wizard in your workshop, guiding you through the process of turning your designs into reality. With its advanced features and precise control, laser cutter software offers a multitude of benefits for users.

One of the key features is the ability to import various file formats, allowing you to work with different design software. Additionally, laser cutter software provides a wide range of customization options, such as adjusting cutting speed and power, which ensures accurate and intricate cuts.

Moreover, it offers the flexibility to work with a variety of materials, from wood and acrylic to fabric and metal. The benefits of laser cutting technology are numerous, including high precision, speed, and versatility.

Transitioning into the subsequent section about the ‘overview of vinyl cutter software,’ let’s explore how this software compares.

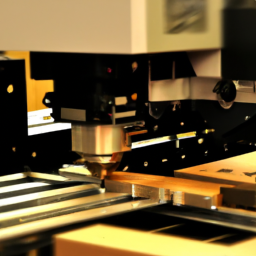

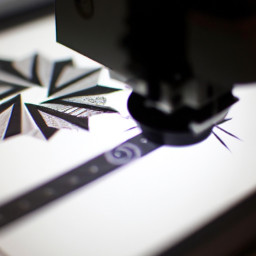

Overview of Vinyl Cutter Software

With vinyl cutter software, you have the power to effortlessly bring your creations to life, igniting a sense of artistic freedom. Here are some pros and cons of vinyl cutter software, as well as some common applications:

Pros:

- Vinyl cutter software is user-friendly and easy to learn, making it accessible to beginners.

- It allows for precise cutting, especially when working with intricate designs.

- Vinyl cutter software supports a wide range of materials, including adhesive vinyl, heat transfer vinyl, and cardstock.

Cons:

- One limitation of vinyl cutter software is that it primarily focuses on cutting, so it may not offer advanced design features like laser cutter software.

- It is also important to note that vinyl cutters may have size limitations, restricting the dimensions of your projects.

Common Applications:

- Vinyl cutter software is commonly used for creating custom decals, stickers, signage, and heat transfers for apparel.

As we move into the next section about the comparison of precision and accuracy, it’s important to consider the capabilities of both laser cutter software and vinyl cutter software.

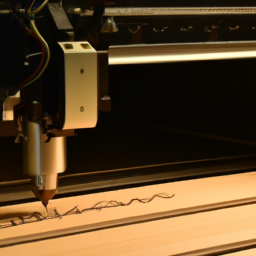

Comparison of Precision and Accuracy

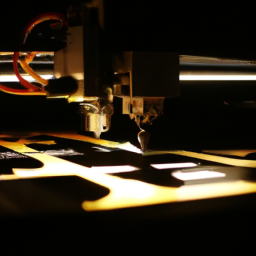

Imagine having the power to bring your artistic visions to life with incredible precision and accuracy, allowing you to create intricate designs that captivate and inspire. When comparing precision and accuracy between laser cutter software and vinyl cutter software, several factors come into play. Let’s take a closer look at the comparison of speed and efficiency as well as the comparison of cost and maintenance in the table below:

| Laser Cutter Software | Vinyl Cutter Software | |

|---|---|---|

| Speed and Efficiency | Laser cutters offer faster cutting speeds and higher efficiency due to their use of lasers. | Vinyl cutters have slower cutting speeds and lower efficiency since they rely on blade-based cutting. |

| Cost and Maintenance | Laser cutters tend to be more expensive upfront and require regular maintenance, including laser tube replacement. | Vinyl cutters are generally more affordable and have lower maintenance costs, mainly involving blade replacement. |

Considering these factors, laser cutter software excels in terms of speed, efficiency, and precision. However, it is essential to note that versatility in material compatibility is another key aspect to consider when choosing between the two options.

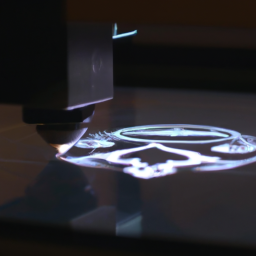

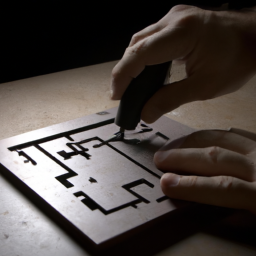

Versatility in Material Compatibility

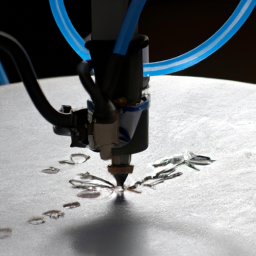

When it comes to material compatibility, the options available with laser cutter software and vinyl cutter software can bring your creative ideas to life in a variety of exciting ways.

Laser cutter software offers a wide range of possibilities when it comes to cutting capabilities. It can easily cut through materials such as wood, acrylic, leather, and even metal. The precision and power of a laser cutter make it a versatile tool for intricate designs and detailed cuts.

On the other hand, vinyl cutter software is specifically designed for working with vinyl materials. While it may not have the same range of cutting capabilities as a laser cutter, it excels in cutting vinyl with precision and accuracy.

Transitioning into the subsequent section about the ‘ease of use and learning curve’, both software options provide unique benefits that cater to different needs.

Ease of Use and Learning Curve

When it comes to ease of use, laser cutter software often offers a user-friendly interface that allows for intuitive navigation and operation. This makes it easier for users to quickly learn and navigate the software, resulting in a smoother workflow.

On the other hand, vinyl cutter software may have a steeper learning curve due to its more complex features and settings, requiring users to invest more time and effort into mastering the software.

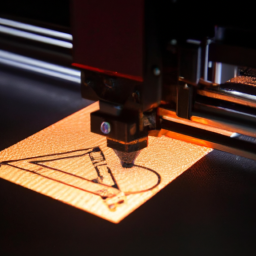

User-friendly interface of laser cutter software

The user-friendly interface of laser cutter software makes it a breeze to create intricate designs with just a few clicks. With its intuitive user interface design, even beginners can navigate through the software effortlessly. Here are three reasons why the user-friendly interface of laser cutter software is so appealing:

-

Customization options: Laser cutter software offers a wide range of customization options, allowing users to adjust settings such as power, speed, and depth. This level of control enables users to achieve precise and detailed cuts.

-

Drag-and-drop functionality: Laser cutter software often features a drag-and-drop functionality, making it easy to import designs and arrange them on the cutting bed. This saves time and eliminates the need for complex manual adjustments.

-

Visual preview: Laser cutter software provides a visual preview of the design before cutting, allowing users to identify any potential issues or make last-minute adjustments. This feature ensures accuracy and reduces material waste.

Transitioning to the subsequent section about the learning curve associated with vinyl cutter software, it’s important to consider the differences in usability and functionality.

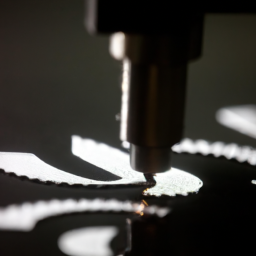

Learning curve associated with vinyl cutter software

Now that we’ve discussed the user-friendly interface of laser cutter software, let’s move on to the learning curve associated with vinyl cutter software.

While laser cutter software tends to be more intuitive and easier to navigate, vinyl cutter software can be a bit more complex for beginners. It may take some time and practice to become familiar with the various tools and features, as well as understanding the specifics of vinyl cutting.

However, once you get the hang of it, vinyl cutter software offers its own advantages. It’s specifically designed for vinyl cutting and offers a higher level of compatibility with different vinyl cutting machines. This means you can achieve more precise cuts and intricate designs.

Transitioning into the next section, it’s important to consider these factors when determining the best option for your needs.

Determining the Best Option for Your Needs

When determining the best option for your needs, it’s important to consider the specific requirements of your projects and the materials you’ll be working with.

This includes factors such as the size and complexity of the designs, as well as the type of material that’ll be cut or engraved.

Additionally, budget considerations play a significant role in choosing between a laser cutter and a vinyl cutter. You’ll need to assess the initial cost of the machine, as well as ongoing expenses such as maintenance, consumables, and software.

Lastly, it’s crucial to think about future scalability. If you anticipate your projects and production needs to grow over time, you should choose a machine that can accommodate this expansion and provide the necessary features and capabilities.

Consideration of project requirements and materials

Considering project requirements and materials, it’s like choosing between a Swiss Army knife and a precision scalpel – a laser cutter software offers a wide range of capabilities, while a vinyl cutter software is more specialized.

When deciding between the two, it is important to consider the complexity of your project and the limitations of the materials you will be working with.

Laser cutter software allows for intricate designs and can cut a variety of materials, including wood, acrylic, and metal. On the other hand, vinyl cutter software is best suited for simpler projects and limited to cutting vinyl materials.

Keep in mind that budget considerations and future scalability should also be taken into account, as laser cutter software may require a larger initial investment but offers more potential for growth and versatility in the long run.

Budget considerations and future scalability

If you’re looking to maximize your budget and future scalability, it’s important to carefully evaluate the long-term potential and growth opportunities of the available options.

When considering budget constraints, both laser cutter software and vinyl cutter software have their pros and cons. Laser cutter software tends to be more expensive upfront, as laser cutters themselves are generally pricier than vinyl cutters. However, laser cutter software can be a more cost-effective long-term investment due to its versatility and ability to work with a wider range of materials. Additionally, laser cutters offer the potential for future scalability, as they can handle more complex projects and larger volumes.

On the other hand, vinyl cutter software is typically more affordable upfront and may be a better fit for smaller-scale projects with limited budgets.

Ultimately, the decision between laser cutter software and vinyl cutter software will depend on your specific project requirements, budget, and long-term growth plans.

Frequently Asked Questions

Can laser cutter software be used with vinyl cutting machines?

Yes, laser cutter software can be used with vinyl cutting machines. While there may be compatibility limitations in vinyl cutter software, laser cutter software offers a more versatile solution. It allows you to design intricate patterns and details that can be cut with precision on both laser and vinyl machines. By using laser cutter software, you can maximize the capabilities of your vinyl cutting machine and achieve a wider range of creative possibilities.

Are there any limitations in material compatibility with vinyl cutter software?

Vinyl cutter software does have limitations in material compatibility. It is primarily designed for cutting vinyl materials, such as adhesive vinyl and heat transfer vinyl. While it can also cut other thin materials like paper and cardstock, it may struggle with thicker or more rigid materials.

On the other hand, laser cutting has the advantage of being able to cut a wide range of materials, including wood, acrylic, leather, and fabric. This makes laser cutting more versatile in terms of material compatibility.

What are the key differences in the learning curve between laser cutter software and vinyl cutter software?

When it comes to the learning curve, the key differences between laser cutter software and vinyl cutter software lie in their complexity and versatility.

Laser cutter software tends to have a steeper learning curve due to its advanced features and capabilities. On the other hand, vinyl cutter software is generally more user-friendly and intuitive, making it easier for beginners to grasp.

In terms of software compatibility, both types of software have their limitations, but laser cutter software often offers more options and flexibility.

How do precision and accuracy compare between laser cutter software and vinyl cutter software?

When comparing the precision and accuracy of laser cutter software and vinyl cutter software, it’s important to note that laser cutter software typically offers a higher level of precision and accuracy. This is due to the advanced technology and capabilities of laser cutters.

Laser cutter software allows for more intricate and precise designs, making it ideal for applications that require fine details and precise cuts. However, it’s also important to consider the versatility and adaptability of laser cutter software, as it may vary depending on the specific software being used.

Are there any specific features or functionalities that set laser cutter software apart from vinyl cutter software?

Laser cutter software offers several advantages over vinyl cutter software. It typically includes advanced features like 3D engraving, image tracing, and intricate design capabilities. Laser cutter software also allows for greater precision and accuracy, enabling users to create detailed and intricate designs.

On the other hand, vinyl cutter software has limitations in terms of the materials it can work with and the complexity of designs it can handle. Overall, laser cutter software provides more versatility and functionality compared to vinyl cutter software.

Conclusion

In conclusion, both laser cutter software and vinyl cutter software have their own unique advantages and versatility.

While laser cutter software offers unparalleled precision and accuracy, vinyl cutter software has its strengths in material compatibility and ease of use.

Ultimately, the best option for your needs depends on the specific projects you plan to undertake. So remember, "Don’t put all your eggs in one basket" and consider the diverse capabilities of both software options to maximize your creativity and productivity.