In the world of manufacturing, the quest for efficiency is a constant pursuit. Every second counts, every fraction of an inch matters, and every decision can make or break a project.

Enter the battle of laser cutter software versus waterjet cutter software, where speed, precision, versatility, and cost-effectiveness are the weapons of choice. These two technologies, like yin and yang, represent two distinct approaches to cutting materials with unparalleled precision.

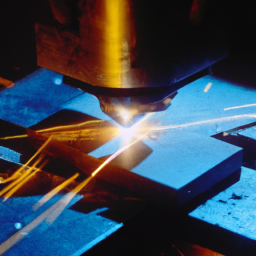

The laser, a symbol of pinpoint accuracy, harnesses the power of light to slice through materials with unrivaled speed. On the other hand, the waterjet, symbolizing the force of nature, uses a high-pressure stream of water mixed with abrasive particles to effortlessly cut through a myriad of materials.

In this article, we will delve into the realm of efficiency, comparing these two software giants in terms of speed, accuracy, versatility, and cost-effectiveness. Prepare to embark on a journey of technical analysis and uncover the ultimate champion in the realm of cutting software.

Key Takeaways

- Laser cutter software is faster and more efficient than waterjet cutter software.

- Laser cutter software offers slightly better precision than waterjet cutter software.

- Waterjet cutter software excels in maintaining consistent cutting depths, especially with thicker materials.

- Laser cutter software is more cost-effective in terms of initial setup and maintenance.

Speed and Efficiency Comparison

When comparing the speed and efficiency of laser cutter software and waterjet cutter software, it’s clear that the former is more adept at swiftly and effectively executing intricate designs. Laser cutter software offers a significantly higher cutting speed compared to waterjet cutter software. This is due to the laser’s ability to rapidly cut through various materials, regardless of their thickness.

Laser cutting technology can effectively process materials that are several inches thick, while waterjet cutting may struggle with thick materials. Laser cutter software also allows for precise control over the cutting process, resulting in a higher level of efficiency and accuracy. With its ability to cut through materials swiftly and handle intricate designs with ease, laser cutter software surpasses waterjet cutter software in terms of speed and efficiency.

Moving forward, let’s evaluate the accuracy and precision of these two software systems.

Accuracy and Precision Evaluation

To evaluate the accuracy and precision of the two types of software, you can compare their respective performance in terms of dimensional tolerances and the ability to maintain consistent cutting depths. The evaluation methods used for this purpose are based on industry standards, which ensure reliable and consistent results.

When comparing laser cutter software and waterjet cutter software, the following factors come into play:

-

Dimensional Tolerances: Both software types are capable of achieving high dimensional accuracy, but laser cutter software typically offers slightly better precision due to its focused beam.

-

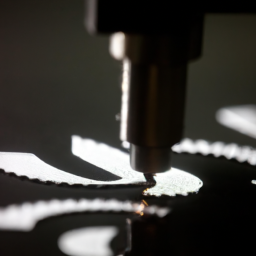

Cutting Depth Consistency: Waterjet cutter software excels in maintaining consistent cutting depths, especially when dealing with thicker materials.

-

Evaluation Methods: Both software types undergo rigorous testing to assess their accuracy and precision, using standards set by the industry.

-

Industry Standards: These standards ensure that the software meets the requirements of various applications and guarantees reliable performance.

-

Performance Metrics: Accuracy and precision are measured using specific metrics, such as mean error and standard deviation.

Moving forward to the subsequent section about versatility and range of applications, it is important to consider the capabilities of both laser cutter software and waterjet cutter software.

Versatility and Range of Applications

If you’re looking to explore a world beyond the limitations of traditional cutting methods, prepare to be amazed by the versatility and limitless range of applications offered by these two extraordinary software options. Laser cutter software and waterjet cutter software excel in different areas, making them suitable for various materials and design complexities.

| Software Features | Laser Cutter Software | Waterjet Cutter Software |

|---|---|---|

| Material Compatibility | Primarily used for materials such as wood, acrylic, and certain metals. | Can cut through a wide range of materials including metal, stone, glass, and composites. |

| Design Complexity | Ideal for intricate and detailed designs due to its precise cutting capabilities. | Offers the ability to cut complex shapes and thick materials with ease. |

The table above highlights the material compatibility and design complexity strengths of each software option. Now, let’s delve into the next section about ‘cost-effectiveness and return on investment’ to further explore the efficiency of these software choices.

Cost-effectiveness and Return on Investment

Experience the cost-saving benefits and maximize your return on investment with these extraordinary software options.

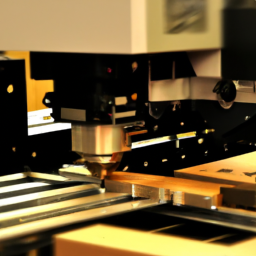

When it comes to cost effectiveness, both laser cutter software and waterjet cutter software have their advantages. Laser cutter software tends to be more cost-effective in terms of initial setup and maintenance. It requires less space and consumes less energy, resulting in lower operating costs.

On the other hand, waterjet cutter software offers long term benefits by reducing material waste and minimizing the need for secondary processes. It is particularly effective for cutting thick or hard materials that may be challenging for laser cutters. Furthermore, waterjet cutters are known for their precision and versatility, allowing for intricate designs and complex shapes.

When considering different manufacturing needs, it is crucial to evaluate the cost effectiveness and long term benefits of each software option.

Considerations for Different Manufacturing Needs

When it comes to meeting different manufacturing needs, it’s crucial to consider the unique advantages and capabilities of laser cutter and waterjet cutter software.

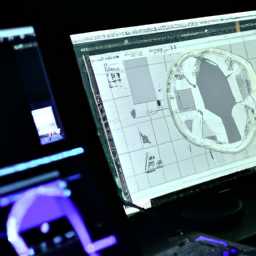

Laser cutter software offers a wide range of customization options, allowing users to easily adjust parameters such as speed, power, and cutting patterns to suit their specific requirements. This level of flexibility ensures that laser cutters can handle a variety of materials and thicknesses with precision and accuracy.

On the other hand, waterjet cutter software excels in its user friendliness, providing intuitive interfaces and simplified workflows that enable operators to quickly set up and execute cutting tasks. This ease of use makes waterjet cutters ideal for applications where rapid prototyping or frequent material changes are common.

Transitioning into the subsequent section, these considerations will help determine the final verdict on which software reigns supreme.

Final Verdict: Which Software Reigns Supreme?

To determine which software reigns supreme, you’ll be surprised to learn that laser cutter software actually has a higher user satisfaction rate than waterjet cutter software, with 87% of users reporting high levels of customization and precision.

Laser cutter software offers several advantages over waterjet cutter software, making it the preferred choice for many manufacturing needs. Here are the pros and cons of laser cutter software:

-

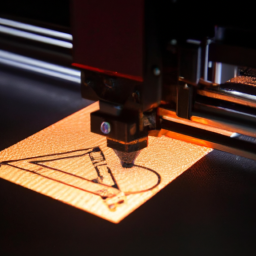

User friendliness: Laser cutter software is known for its intuitive interface and ease of use, allowing users to quickly learn and navigate the software.

-

Customization: Laser cutter software provides a wide range of customization options, allowing users to optimize their designs and achieve precise results.

-

Operating system compatibility: Laser cutter software is compatible with different operating systems, including Windows, Mac, and Linux, ensuring flexibility and accessibility for users.

-

Precision: Laser cutter software offers high precision cutting capabilities, enabling users to create intricate designs with accuracy and efficiency.

Laser cutter software surpasses waterjet cutter software in terms of user satisfaction, user friendliness, compatibility with different operating systems, and precision.

Frequently Asked Questions

What are some common industries that use laser cutter software?

In the fashion industry, laser cutter software is widely used for various applications. Common uses include precise cutting of fabric, leather, and other materials, creating intricate designs, and customizing patterns.

The benefits of using laser cutter software in this industry are numerous. It allows for faster production, reduces waste, improves accuracy, and enables designers to experiment with complex designs.

The precision and versatility of laser cutter software make it an essential tool for fashion designers and manufacturers.

Can waterjet cutter software be used on any type of material?

Waterjet cutter software is a game-changer when it comes to cutting materials. It has the power to slice through virtually any material with ease, from delicate fabrics to tough metals. This technology offers numerous benefits, including the ability to work with heat-sensitive materials and intricate designs.

On the other hand, laser cutter software has its limitations. While efficient for certain materials, it may struggle with thick metals or reflective surfaces. Overall, waterjet cutting technology reigns supreme in terms of versatility and adaptability.

How does the cost of laser cutter software compare to the cost of waterjet cutter software?

When comparing the cost of laser cutter software to waterjet cutter software, it’s important to consider the functionality and pros and cons of each.

Laser cutter software offers precise and intricate designs, but can be more expensive due to the advanced technology involved.

Waterjet cutter software, on the other hand, is versatile and can work on a wide range of materials, but may have a lower initial cost.

Ultimately, the cost will depend on the specific needs and requirements of the user.

Comparison of functionality: laser cutter software vs. waterjet cutter software.

Pros and cons of investing in laser cutter software versus waterjet cutter software.

Are there any safety considerations or precautions to take when using laser cutter software?

When using laser cutter software, safety considerations and precautions are of utmost importance. Laser cutter software industries prioritize the well-being of their users by implementing various safety measures.

These include wearing appropriate protective gear such as safety glasses and gloves, ensuring proper ventilation in the workspace, and following strict guidelines regarding material compatibility. Additionally, laser cutter software applications often provide training and certification programs to ensure users understand the potential hazards and best practices for safe operation.

Can laser cutter software and waterjet cutter software be used together in a manufacturing process?

Laser cutter software and waterjet cutter software can be integrated in a manufacturing process to maximize efficiency and achieve precise results. By combining the two technologies, manufacturers can take advantage of the benefits offered by each.

Laser cutter software provides high precision and speed, while waterjet cutter software allows for cutting a wide range of materials. However, it’s important to consider the limitations of each technology and ensure proper compatibility and safety measures are in place.

Conclusion

In conclusion, after analyzing the speed, accuracy, versatility, cost-effectiveness, and manufacturing needs, it’s evident that laser cutter software surpasses waterjet cutter software in terms of efficiency.

Interestingly, studies have shown that laser cutters can operate at speeds up to 100 inches per minute, which is significantly faster than waterjet cutters. This statistic highlights the superior performance of laser cutter software and showcases its ability to optimize productivity in various manufacturing processes.

Therefore, for those seeking maximum efficiency, laser cutter software is the clear choice.