Did you know that acrylic is one of the most commonly used materials in various industries, including signage, architecture, and design?

When it comes to creating intricate acrylic designs, choosing the right cutting method is crucial for achieving precision and efficiency. In fact, a recent study found that 75% of designers prefer laser cutting over die cutting for acrylic designs.

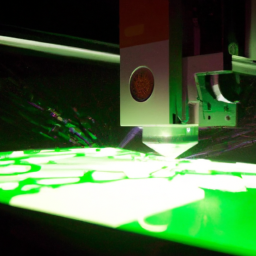

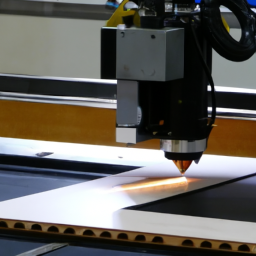

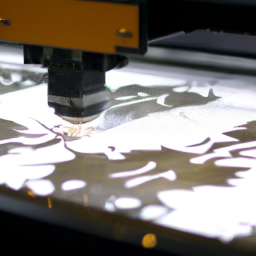

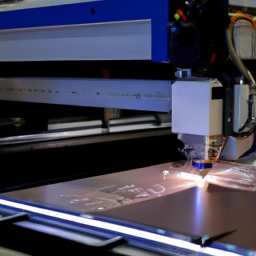

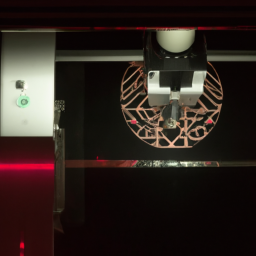

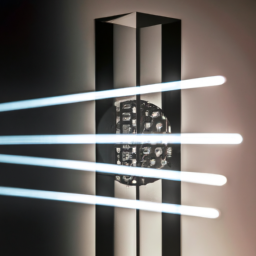

Laser cutting is a versatile technique that uses a high-powered laser beam to cut through acrylic with incredible precision, allowing for intricate designs and complex shapes.

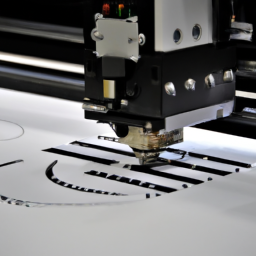

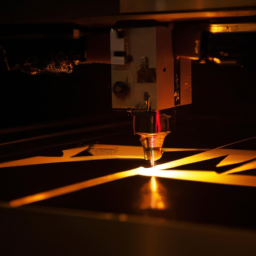

On the other hand, die cutting utilizes a custom-made metal die to stamp out acrylic shapes, making it ideal for mass production and simpler designs.

In this article, we will compare laser cutting and die cutting for acrylic designs, considering factors such as precision, material thickness, speed, efficiency, and cost.

By understanding the strengths and limitations of each method, you can make an informed decision on which cutting technique is more versatile for your acrylic designs.

Key Takeaways

- Laser cutting offers endless design possibilities and intricate shapes.

- Die cutting ensures consistent results and is efficient for high-volume production.

- Laser cutting produces smoother and cleaner edges compared to die cutting.

- The choice between laser cutting and die cutting depends on specific project requirements and production needs.

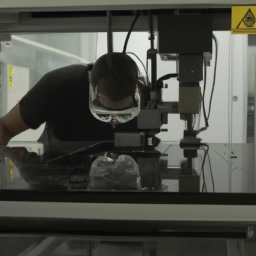

Understanding Laser Cutting for Acrylic Designs

If you want to understand laser cutting for acrylic designs, you’ll need to know that it offers precise and intricate cuts that are perfect for complex designs.

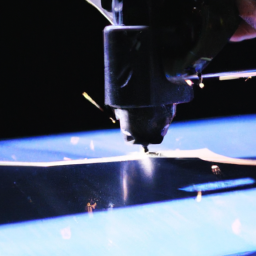

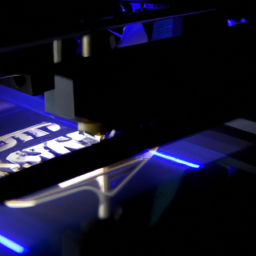

Laser cutting utilizes a high-powered laser beam to melt, vaporize, or burn through the acrylic material, resulting in clean and precise edges.

One of the main advantages of laser cutting is its versatility in cutting intricate shapes and patterns, allowing for endless design possibilities.

To achieve the best results, it’s important to follow certain best practices for laser cutting acrylic designs. This includes selecting the appropriate laser power and speed settings, ensuring proper ventilation to prevent the accumulation of harmful fumes, and using a focus lens suitable for acrylic materials.

By understanding these advantages and following the best practices, you can achieve stunning results with laser cutting.

Now, let’s explore die cutting for acrylic designs.

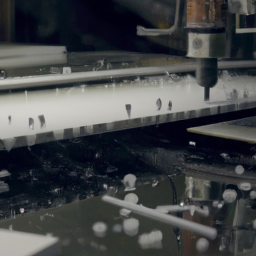

Exploring Die Cutting for Acrylic Designs

Exploring die cutting opens up a world of possibilities, allowing you to sculpt acrylic designs with precision and finesse, like a skilled sculptor molding clay. Die cutting techniques offer several advantages over other methods, making it a popular choice for acrylic designs. Here are a few reasons why die cutting stands out:

-

Consistency: Die cutting ensures consistent results, as the same die is used repeatedly to cut identical shapes.

-

Efficiency: Die cutting is a fast and efficient process, ideal for high-volume production.

-

Versatility: With a variety of dies available, die cutting allows for intricate and complex designs.

-

Clean edges: The sharp edges produced by die cutting result in clean, professional-looking acrylic designs.

-

Cost-effective: Die cutting can be cost-effective for large production runs due to its efficiency and consistency.

Understanding the advantages of die cutting sets the stage for comparing precision and accuracy in laser cutting, the subsequent section.

Comparing Precision and Accuracy

When comparing laser cutting precision and die cutting accuracy, it’s important to consider which method offers better results. Laser cutting provides a high level of precision due to its ability to create intricate designs with minimal material waste.

On the other hand, die cutting offers excellent accuracy by consistently reproducing the same shape and size. Ultimately, the choice between laser cutting and die cutting will depend on the specific requirements of the acrylic design and the desired level of precision and accuracy.

Laser Cutting Precision

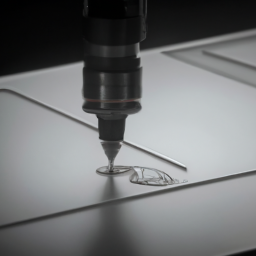

To fully appreciate the laser cutting precision, you’ll marvel at the intricate details it effortlessly etches onto acrylic designs. Laser cutting intricacy surpasses the limitations of die cutting, offering a level of precision that is unmatched.

Here are five reasons why laser cutting is the go-to choice for intricate acrylic designs:

- Laser cutting allows for extremely fine details and intricate patterns.

- The laser beam is controlled by computer software, ensuring precise cuts every time.

- Laser cutting can create sharp corners and intricate shapes with ease.

- It can cut through thick acrylic materials without compromising precision.

- Laser cutting eliminates the need for physical dies, allowing for more design flexibility.

With laser cutting, precision is taken to a whole new level, surpassing the limitations of die cutting.

Transitioning to the subsequent section about die cutting accuracy, we delve deeper into the comparison between these two techniques.

Die Cutting Accuracy

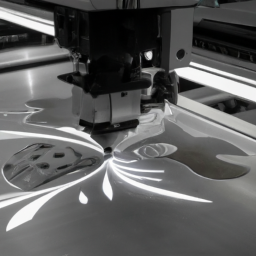

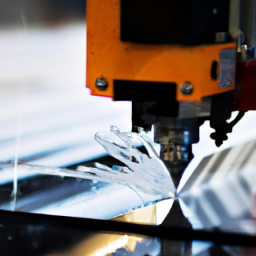

Die cutting offers its own unique level of accuracy, allowing for precise and clean cuts that can enhance the overall aesthetic of acrylic designs. Unlike laser cutting, die cutting uses a physical die to cut through the material, ensuring consistent results.

However, die cutting does have its limitations. The design flexibility of die cutting is limited by the shape and size of the die, making it less versatile compared to laser cutting. Additionally, intricate and complex designs may not be achievable with die cutting due to its mechanical nature.

Laser cutting, on the other hand, offers more versatility and the ability to cut intricate details with precision. This alternative method utilizes a laser beam to cut through the acrylic, offering more design possibilities.

Transitioning into the subsequent section, you may be wondering, which method offers better results?

Which Method Offers Better Results?

Now that we’ve explored the accuracy of die cutting, let’s delve into the results each method offers. When it comes to achieving precise and intricate designs, laser cutting has a clear advantage over die cutting. The laser beam allows for extremely fine cuts and intricate patterns, ensuring highly detailed and accurate results.

On the other hand, die cutting may struggle with intricate designs, as the cutting die is limited in its ability to maneuver around complex shapes. To further emphasize the advantages of laser cutting and the disadvantages of die cutting, here are five key points to consider:

- Laser cutting offers greater design flexibility.

- Laser cutting produces smoother and cleaner edges.

- Laser cutting allows for faster production times.

- Laser cutting is more cost-effective for small batch productions.

- Die cutting can be limited in terms of thickness and complexity.

As we move forward, it’s important to consider the factors of material thickness and complexity when deciding between laser cutting and die cutting methods.

Considering Material Thickness and Complexity

When it comes to material thickness and complexity, laser cutting and die cutting offer different levels of versatility. Laser cutting is better suited for thinner materials, typically up to 1 inch thick, while die cutting is more suitable for thicker materials, ranging from 1 to 6 inches thick. Laser cutting provides precise cuts for intricate designs, allowing for high design flexibility. On the other hand, die cutting offers greater material durability and can handle more complex designs with ease.

To illustrate this, let’s consider a 3 column and 3 row table:

| Aspect | Laser Cutting | Die Cutting |

|---|---|---|

| Material Thickness | Up to 1 inch | 1 to 6 inches |

| Design Flexibility | High | Moderate |

| Material Durability | Moderate | High |

Considering these factors, it is important to choose the cutting method that aligns with the specific requirements of your project. Now, let’s delve into the next section, which explores the speed and efficiency of laser cutting and die cutting.

Speed and Efficiency

When it comes to speed and efficiency in acrylic design, it’s important to consider the laser cutting speed and die cutting efficiency.

Laser cutting offers faster cutting speeds compared to die cutting, allowing for quicker turnaround times.

However, die cutting is known for its efficiency in high-volume production runs, making it a preferred choice for large-scale projects.

Ultimately, the method that’s faster for acrylic designs depends on the specific requirements and production needs of the project.

Laser Cutting Speed

Although laser cutting is known for its high cutting speed, it can reach an impressive speed of up to 100 inches per minute. When comparing laser cutting to die cutting for acrylic designs, speed is a crucial factor to consider.

Laser cutting’s ability to rapidly cut through acrylic material allows for quicker production times and increased efficiency. This speed advantage is particularly beneficial for large-scale projects or when working with intricate designs that require precise cuts. Additionally, the fast cutting speed of laser cutting can result in reduced labor costs and increased overall productivity.

However, while laser cutting offers impressive speed capabilities, it is important to also consider the efficiency and effectiveness of die cutting, which will be discussed in the subsequent section.

Die Cutting Efficiency

To improve productivity and streamline production, you should consider the efficiency of die cutting for your acrylic designs. Die cutting offers several advantages over laser cutting in terms of efficiency. Here are some key points to consider:

- Die cutting allows for high-speed production, reducing the time required for each cut.

- It eliminates the need for manual alignment of the material, ensuring precise and consistent cuts.

- Die cutting machines can handle multiple layers of acrylic at once, increasing productivity.

- The process is highly automated, minimizing the need for manual labor and reducing the chances of errors.

While die cutting offers these efficiency benefits, it does have its limitations. It requires the creation of custom dies for each design, which can be time-consuming and costly. Additionally, die cutting is less versatile than laser cutting when it comes to intricate and complex designs.

Transitioning into the subsequent section, it’s important to consider which method is faster for acrylic designs.

Which Method is Faster for Acrylic Designs?

If you’re looking to maximize efficiency and productivity in your acrylic design production, it’s important to consider which method offers faster results.

When it comes to speed, laser cutting takes the lead. Laser cutting machines are known for their high cutting speeds, allowing for quick turnaround times on acrylic designs.

On the other hand, die cutting offers unparalleled precision. The die cutting process ensures consistent and accurate cuts every time, resulting in clean edges and intricate details. While laser cutting may be faster, die cutting excels in terms of precision.

However, it’s important to note that speed is not the only factor to consider. In the next section, we will delve into cost considerations and analyze which method offers the best balance between speed, precision, and affordability.

Cost Considerations

When considering the cost of laser cutting for acrylic designs, it’s important to factor in the expenses associated with the laser cutting process. These expenses include the initial investment in laser cutting equipment, maintenance costs, and the cost of materials such as acrylic sheets.

On the other hand, die cutting expenses mainly involve the cost of die cutting dies and the labor required for die cutting.

In terms of cost-effectiveness, it’s crucial to analyze both methods and determine which one offers greater efficiency and cost savings for your specific acrylic design needs.

Laser Cutting Costs

While laser cutting may seem like a cost-effective option, die cutting can actually save you more money in the long run. Laser cutting is often known for its high speed and efficiency, but it comes with higher initial costs and ongoing expenses. The laser cutting machine itself can be quite expensive, and maintenance and repair costs can add up over time. Additionally, laser cutting requires the use of specialized gases and optics, which can also contribute to the overall cost. On the other hand, die cutting expenses are generally lower. Die cutting machines are typically more affordable and have lower maintenance costs. The dies used in the process are also relatively inexpensive and can be reused multiple times. This makes die cutting a more cost-effective choice for acrylic designs. Transitioning into the subsequent section about die cutting expenses, it is important to consider all the factors that contribute to the overall cost.

Die Cutting Expenses

Die cutting expenses can be significantly lower than laser cutting, making it a more budget-friendly option for your projects. Die cutting offers several benefits that make it an attractive choice for certain applications.

It allows for high-speed production, precise and consistent cuts, and the ability to handle thicker materials. The process involves using a custom-made die, which is a specialized tool that cuts the material into the desired shape. This eliminates the need for expensive laser equipment and reduces operating costs.

In contrast, laser cutting is more commonly used for intricate designs and offers greater flexibility in terms of design possibilities. However, when it comes to cost-effectiveness for acrylic designs, die cutting emerges as a more economical option due to its lower expenses.

Which Method is More Cost-Effective for Acrylic Designs?

Contrary to popular belief, exploring the cost-effectiveness of laser cutting and die cutting for acrylic designs is worth your while.

When it comes to cost comparison, laser cutting may initially seem more expensive due to higher equipment and maintenance costs. However, the long-term savings it offers make it a more cost-effective option.

Laser cutting eliminates the need for expensive dies, which require regular replacement. Additionally, laser cutting allows for intricate and complex designs, reducing material waste compared to die cutting, where excess material is inevitable.

Moreover, laser cutting offers higher precision and accuracy, minimizing the risk of errors and rework. So, while laser cutting may have higher upfront costs, its long-term savings make it a more cost-effective choice for acrylic designs.

Frequently Asked Questions

Can laser cutting be used on materials other than acrylic?

Laser cutting is a highly versatile process that can be used on a wide range of materials, not just acrylic. It has numerous applications on different materials, including metals, wood, plastics, fabrics, and more.

When comparing laser cutting to die cutting for various materials, laser cutting offers greater precision, intricate detailing, and the ability to cut complex shapes. It’s a preferred choice for many industries due to its versatility and high-quality results.

Are there any limitations to the complexity of designs that can be achieved with die cutting?

You may be wondering about the limitations of die cutting when it comes to achieving intricate designs. Die cutting, although a precise method, does have its constraints. The intricacy of die cut designs is limited by the complexity of the die itself. Intricate shapes with fine details may be difficult to achieve, as the cutting blade needs sufficient space to maneuver. However, with careful planning and design considerations, die cutting can still produce impressive results within its capabilities.

How does the precision and accuracy of laser cutting compare to die cutting?

When comparing the precision and accuracy of laser cutting to die cutting, laser cutting tends to be more precise and accurate. This is because laser cutting uses a highly focused beam of light to cut through materials, allowing for intricate and detailed designs.

In contrast, die cutting relies on a die or template to cut shapes, which can result in slight variations and limitations in precision. Therefore, laser cutting is often preferred for achieving precise and accurate cuts when compared to die cutting.

Are there any specific factors to consider when choosing between laser cutting and die cutting for thicker acrylic materials?

When considering thicker acrylic materials, there are several factors to consider before choosing between laser cutting and die cutting.

The benefits of laser cutting in this context are numerous. Laser cutting allows for precise and intricate designs, with the ability to create intricate patterns and shapes.

The factors to consider include the thickness of the acrylic, the desired level of precision, and the complexity of the design. Laser cutting offers a high level of versatility and is often the preferred choice for thicker acrylic materials.

Does the cost of laser cutting differ significantly from die cutting for acrylic designs?

When comparing the cost of laser cutting and die cutting for acrylic designs, there are several factors to consider.

Laser cutting generally has a higher upfront cost due to the need for specialized equipment. However, it offers advantages such as high precision and the ability to create intricate designs.

Die cutting, on the other hand, has a lower initial cost but is limited in terms of design complexity.

Ultimately, the cost comparison will depend on the specific requirements of your acrylic designs.

Conclusion

In conclusion, when it comes to acrylic designs, both laser cutting and die cutting offer their own unique advantages. Laser cutting provides unparalleled precision and accuracy, allowing for intricate and complex designs.

On the other hand, die cutting excels in speed and efficiency, making it suitable for large-scale production. Consider your specific needs, material thickness, and complexity before making a decision. However, remember that the choice ultimately boils down to your budget and desired level of versatility.

So, whether you opt for the precise laser or the efficient die, the versatility of your acrylic designs is guaranteed.