Imagine you are a metal fabricator, faced with the challenge of cutting intricate designs on various metal surfaces. You need a technique that is not only precise and efficient but also versatile enough to handle a wide range of projects. This is where the debate between laser cutting and die cutting comes into play.

Both methods have their merits, but which one is truly more versatile?

In the world of metal fabrication, versatility is key. It allows you to adapt to different design requirements and materials, ensuring that your end products are of the highest quality. Laser cutting, with its ability to cut through a variety of metals with precision and speed, has gained popularity in recent years.

On the other hand, die cutting, with its ability to produce consistent and repeatable cuts, has been a staple in the industry for decades.

In this article, we will explore the versatility of laser cutting and die cutting in metal fabrication. We will compare their strengths and weaknesses, consider the specific needs of metal fabricators, and provide real-life case studies and examples to help you make an informed decision.

So, let’s dive in and discover which cutting technique reigns supreme in the world of metal fabrication.

Key Takeaways

- Laser cutting offers precision, efficiency, and versatility in metal fabrication.

- Die cutting produces consistent and repeatable cuts, making it ideal for mass production.

- Laser cutting is more suitable for thinner materials and intricate cuts, while die cutting is better for thicker materials and high-volume production.

- Both laser cutting and die cutting are important and versatile techniques in metal fabrication, each with its own advantages and considerations.

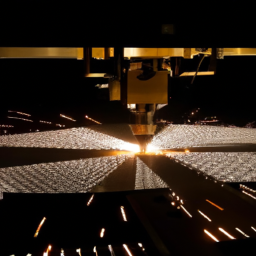

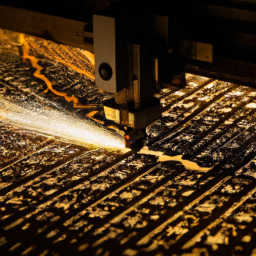

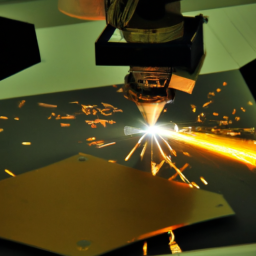

Overview of Laser Cutting Technique

Laser cutting allows you to precisely and efficiently cut metal using a high-powered laser beam. This technique offers several advantages, including a high level of precision, minimal material wastage, and the ability to cut complex shapes with ease.

With laser cutting, you can achieve clean and smooth edges without the need for additional post-processing. This makes it ideal for a wide range of applications, such as automotive manufacturing, aerospace industry, and architectural projects.

The versatility of laser cutting is further enhanced by its ability to cut various metals, including steel, aluminum, and copper.

Now, let’s move on to the overview of die cutting technique, which offers a different set of advantages and applications.

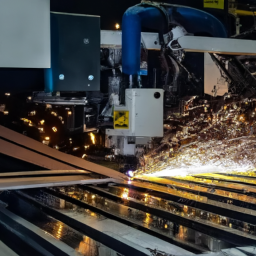

Overview of Die Cutting Technique

Die cutting is a highly efficient and speedy technique that is widely used in various industries. It allows for the production of large quantities of identical shapes with precision and accuracy.

By utilizing specialized dies, this method cuts through materials such as paper, fabric, and even metal, making it a versatile choice for mass production.

Efficiency and Speed

With lightning speed and precision, one method stands out as the ultimate champion in efficiency and speed in metal fabrication. Die cutting, with its streamlined process and advanced technology, offers significant advantages in improving productivity and cost effectiveness.

By utilizing customized dies, this technique allows for the quick and accurate production of metal parts in large quantities. The die cutting process involves the use of a press machine that cuts and shapes the metal using a die that is specifically designed for the desired shape. This method eliminates the need for manual labor and reduces production time, resulting in higher efficiency and cost savings.

However, when it comes to versatility, laser cutting takes the lead. It has the ability to produce large quantities of identical shapes, while also offering the flexibility to create intricate and complex designs.

Ability to Produce Large Quantities of Identical Shapes

Improve your metal fabrication process by utilizing a technique that effortlessly produces large quantities of identical shapes with lightning speed and precision. Laser cutting offers significant advantages over die cutting in this regard. While die cutting is limited by the need for physical dies and may require additional setup and adjustment time for each new shape, laser cutting can quickly and accurately cut identical shapes without the need for any physical tools. This makes laser cutting highly efficient and versatile for mass production. To further illustrate the advantages, consider the following comparison:

| Laser Cutting | Die Cutting | |

|---|---|---|

| Speed | Lightning fast | Slower due to setup |

| Setup Time | Minimal | Time-consuming |

| Flexibility | Highly adaptable | Limited by physical dies |

With laser cutting, you can easily produce large quantities of identical shapes, saving time and effort compared to die cutting. Now, let’s delve into a comparison of the overall versatility of these two metal fabrication techniques.

Comparison of Versatility

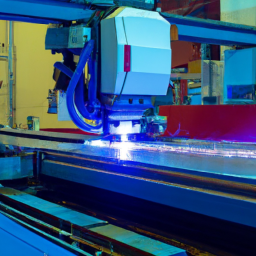

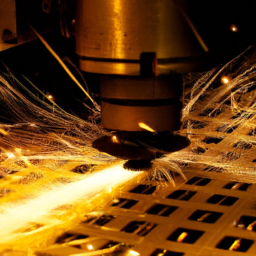

Discover the endless possibilities of laser cutting in metal fabrication, as it allows you to effortlessly create intricate designs. Laser cutting offers several advantages over die cutting, including the ability to cut complex shapes with high precision and accuracy.

Laser cutting is versatile and can be used for a wide range of applications, such as creating custom parts, engraving logos or text, and even cutting through thick metal sheets. The laser beam is controlled by a computer, which means you can easily adjust the design and make changes on the fly.

On the other hand, die cutting is limited in its ability to produce intricate designs and is better suited for mass production of simple shapes.

When considering your metal fabrication needs, it is important to take into account the versatility and precision offered by laser cutting.

Considerations for Metal Fabrication Needs

Now that you understand the comparison of versatility between laser cutting and die cutting in metal fabrication, let’s dive into the considerations for your specific metal fabrication needs.

When deciding between these two methods, it is crucial to consider factors such as cost considerations and material thickness limitations. Here are three key points to keep in mind:

-

Cost considerations: Laser cutting generally requires a higher upfront investment due to the equipment and maintenance costs. On the other hand, die cutting may have lower initial costs but involves additional expenses for creating and maintaining the dies.

-

Material thickness limitations: Laser cutting is ideal for thinner materials, typically up to 25mm, while die cutting is better suited for thicker materials that may exceed the capabilities of laser cutting.

-

Precision requirements: If your project demands intricate and precise cuts, laser cutting is the way to go. However, if you need repetitive, high-volume production, die cutting offers better efficiency.

As we move forward, let’s explore case studies and examples that showcase the real-world applications of these cutting methods.

Case Studies and Examples

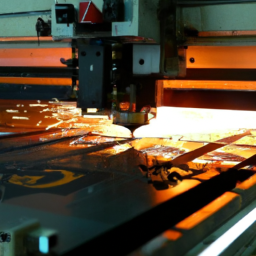

Let’s take a look at some real-world case studies and examples that highlight the practical applications of these cutting methods in metal fabrication.

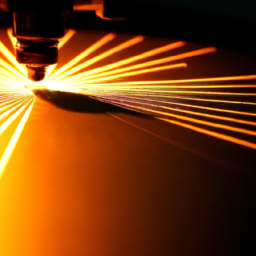

In a case study conducted by a manufacturing company, laser cutting was used to accurately cut intricate patterns on stainless steel sheets for architectural purposes. The precision of the laser cutting allowed for clean and precise cuts, resulting in a high-quality finished product.

Another example involves the use of die cutting in the automotive industry. A car parts manufacturer utilized die cutting to create custom gaskets for engine components. The die cutting process provided consistent and uniform cuts, ensuring a perfect fit for the gaskets.

These case studies demonstrate the versatility of both laser cutting and die cutting in various industries and highlight their importance in metal fabrication.

Frequently Asked Questions

What are some common applications for laser cutting in metal fabrication?

When it comes to metal fabrication, laser cutting offers numerous advantages over traditional cutting methods. Laser cutting is widely used for various applications in metal fabrication. It is used for creating intricate designs, precision cutting, and producing complex shapes and patterns. The advantages of laser cutting include high accuracy, minimal material waste, and the ability to work with a wide range of materials. It’s a versatile and efficient method that has revolutionized the metal fabrication industry.

How does die cutting compare to laser cutting in terms of precision?

Laser cutting offers significant advantages over die cutting in terms of precision. With laser cutting, you can achieve intricate and complex designs with extremely tight tolerances. The laser beam is highly focused and can cut with exceptional accuracy, resulting in clean and precise edges.

In contrast, die cutting relies on physical force and may have limitations in achieving the same level of precision. Laser cutting’s superior precision makes it the preferred choice for applications that require intricate designs and high accuracy.

Are there any limitations or restrictions to consider when using laser cutting for metal fabrication?

When it comes to using laser cutting for metal fabrication, there are a few limitations to consider. Laser cutting is not ideal for thicker materials and can struggle with reflective surfaces. However, it does offer several advantages over die cutting. Laser cutting allows for more intricate and complex designs, with greater precision and accuracy. Additionally, it’s a faster and more efficient process, making it a popular choice in many industries.

Can die cutting be used for complex shapes and designs, or is it more suitable for simpler designs?

Die cutting can be used for both simple and complex shapes and designs. The precision in die cutting allows for intricate patterns and details to be accurately reproduced. The complexity of designs that can be achieved with die cutting is determined by the capabilities of the cutting machine and the intricacy of the die.

However, die cutting may require additional setup time and cost for creating custom dies for complex designs.

What are some factors to consider when choosing between laser cutting and die cutting for a specific metal fabrication project?

When deciding between laser cutting and die cutting for a metal fabrication project, several factors should be considered.

Firstly, the cost effectiveness of each method is crucial. While laser cutting may have higher upfront costs, it can be more economical for large-scale productions.

Secondly, production speed is a key consideration. Laser cutting is generally faster than die cutting, making it suitable for projects with tight deadlines.

Carefully evaluating these factors will help determine the most suitable method for your specific metal fabrication project.

Conclusion

In conclusion, when it comes to metal fabrication, both laser cutting and die cutting offer their own unique advantages.

Laser cutting provides precise and intricate cuts, making it ideal for complex designs and small production runs.

On the other hand, die cutting is more cost-effective for large-scale production and can handle thicker materials.

Ultimately, the choice between the two techniques depends on your specific metal fabrication needs.

By carefully considering your requirements and examining case studies, you can make an informed decision that will ensure efficiency and quality in your metal fabrication processes.