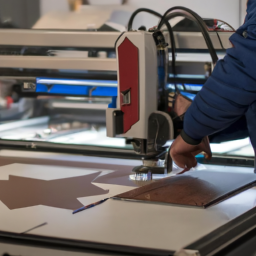

Picture this: you’re in your woodworking workshop, surrounded by the smell of fresh-cut wood and the hum of machinery. As you stand before your latest project, you’re faced with a crucial decision: laser cutting or electric cutting? Both techniques offer their own set of advantages and drawbacks, making it essential to choose the method that best suits your needs.

In the world of woodworking, precision and convenience are paramount, and your choice of cutting method can make all the difference. Laser cutting, with its remarkable accuracy and versatility, has gained popularity in recent years. However, electric cutting still holds its ground as a reliable and efficient option.

In this article, we will explore the differences between laser cutting and electric cutting in woodworking, weighing the benefits and drawbacks of each technique. By the end, you’ll have a clearer understanding of which method is more convenient for your woodworking projects.

So, let’s dive in and find the perfect cutting technique for you.

Key Takeaways

- Laser cutting offers high precision and clean cuts, making it suitable for projects that require intricate details.

- Electric cutting is versatile and safe, making it a good option for woodworkers of all skill levels.

- Laser cutting is more expensive and has limitations in cutting thick materials, while electric cutting lacks precision and can be noisy and vibrating.

- When choosing a cutting method, woodworkers should consider project requirements, budget, skill level, and safety precautions.

Differences Between Laser Cutting and Electric Cutting

Let’s dive into the differences between laser cutting and electric cutting, so we can figure out which one is easier to use in woodworking.

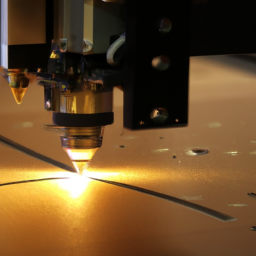

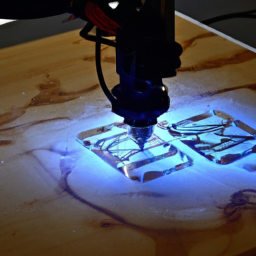

Laser cutting offers several advantages in woodworking. Firstly, it provides a high level of precision, allowing for intricate and detailed cuts. Additionally, laser cutting is capable of cutting through a wide range of materials, including wood, plastic, and metal.

On the other hand, electric cutting has its disadvantages. It often requires manual adjustment and can be time-consuming, especially when cutting complex designs. Moreover, electric cutting may leave rough edges and require additional finishing.

Transitioning into the subsequent section about the benefits of laser cutting in woodworking, it’s clear that laser cutting offers numerous advantages over electric cutting when it comes to convenience and efficiency in woodworking.

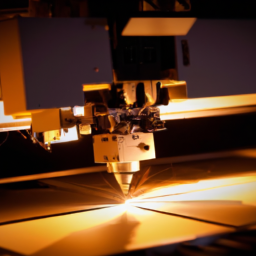

Benefits of Laser Cutting in Woodworking

Improve your woodworking experience with the efficient and user-friendly option of laser cutting. Laser cutting offers several advantages and applications in woodworking, making it a popular choice for many craftsmen. Here are four key benefits of laser cutting:

-

Precision: Laser cutting allows for precise and accurate cuts, resulting in clean edges and intricate designs.

-

Versatility: Laser cutting can be used on a variety of materials, including wood, acrylic, and MDF, offering flexibility in woodworking projects.

-

Time-saving: Laser cutting is a fast process, reducing production time and increasing efficiency in woodworking.

-

Customization: Laser cutting offers the ability to create intricate patterns and personalized designs, allowing woodworkers to add unique touches to their projects.

Transitioning to the subsequent section about the drawbacks of laser cutting in woodworking, it is important to consider the limitations and challenges that come with this technique.

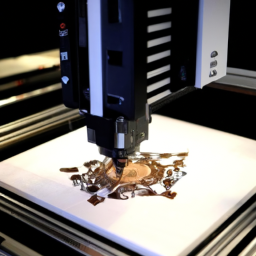

Drawbacks of Laser Cutting in Woodworking

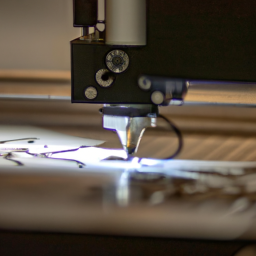

Consider the challenges you may face when using laser cutting in woodworking, as it may not always be the most suitable option for your projects. Laser cutting has its limitations in woodworking.

One major drawback is the inability to cut through thick materials efficiently. Laser cutting works best on thin to medium thickness wood, and it may struggle with thicker pieces.

Additionally, safety concerns arise with laser cutting. The intense heat generated by the laser can cause wood to catch fire, leading to potential hazards. Exposure to laser radiation can also be harmful if proper safety precautions are not taken.

Transitioning into the subsequent section about the benefits of electric cutting in woodworking, it is important to explore alternative methods that may offer more convenience and safety.

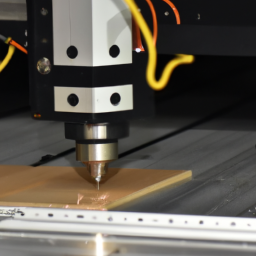

Benefits of Electric Cutting in Woodworking

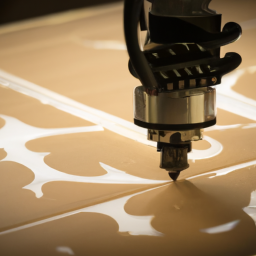

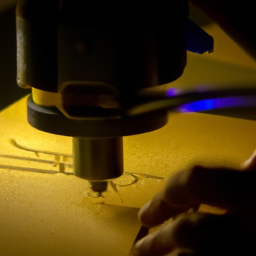

Explore the potential advantages of using electric cutting in woodworking to enhance your projects and make your work more efficient. Electric cutting offers a range of benefits that can significantly improve your woodworking experience. With its precise cutting capabilities and versatility, electric cutting allows for greater control and accuracy in shaping wood. It also offers a wide array of applications, from making intricate cuts for detailed designs to efficiently slicing through thick pieces of wood. Additionally, electric cutting is a safer alternative to other cutting methods, as it eliminates the risk of burns or fires associated with laser cutting. However, it is important to consider the drawbacks of electric cutting as well, such as the limitations in terms of materials and the potential for electrical hazards. Transitioning into the subsequent section about the drawbacks of electric cutting in woodworking, it is crucial to weigh these factors carefully before making a decision.

Drawbacks of Electric Cutting in Woodworking

Despite its advantages, electric cutting in woodworking has its drawbacks that can be frustrating and limiting for craftsmen.

One limitation of electric cutting is the lack of precision compared to laser cutting. Electric cutting tools, such as saws and routers, may produce rough edges that require additional sanding and finishing.

Safety concerns also arise with electric cutting, as improper handling can lead to accidents and injuries.

Additionally, electric cutting tools generate a significant amount of noise and vibration, which can be disruptive and uncomfortable during long hours of woodworking.

To choose the right cutting method for your woodworking projects, it’s essential to weigh the benefits and drawbacks of both laser cutting and electric cutting.

Transitioning into the subsequent section, it’s important to consider various factors to make an informed decision.

Choosing the Right Cutting Method for Your Woodworking Projects

When choosing the right cutting method for your woodworking projects, you’ll want to carefully evaluate the precision, safety, and comfort factors involved. Laser cutting and electric cutting are two popular options, each with their own pros and cons.

| Pros of Laser Cutting | Cons of Laser Cutting |

|---|---|

| High precision | Expensive |

| Versatile | Limited depth |

| Clean cuts | Safety concerns |

| Minimal material waste | Not suitable for all types of wood |

| Factors to consider when choosing between laser cutting and electric cutting |

|---|

| Project requirements |

| Budget limitations |

| Skill level and experience |

| Safety precautions |

Laser cutting offers high precision and versatility, resulting in clean cuts with minimal material waste. However, it can be expensive, has limited depth capabilities, and raises safety concerns. Additionally, laser cutting may not be suitable for all types of wood. Consider factors such as project requirements, budget limitations, skill level, and safety precautions when deciding between laser cutting and electric cutting methods in woodworking.

Frequently Asked Questions

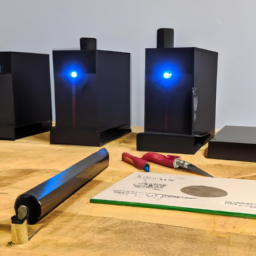

How much does a laser cutting machine cost?

When considering the cost of a laser cutting machine, several factors come into play. The price of a laser cutting machine can vary depending on its power, size, and capabilities.

On average, laser cutting machines can range from a few thousand dollars to over $100,000. It’s important to consider your specific needs and budget when choosing a laser cutting machine.

Factors such as material compatibility, precision, and production volume should also be taken into account.

Can laser cutting be used on all types of wood?

Laser cutting machines are incredibly versatile and can be used on a wide variety of wood types. From softwoods like pine and cedar to hardwoods like oak and mahogany, laser cutting can easily handle them all.

With its precise and controlled beam, the laser cutting machine can effortlessly cut through different wood thicknesses and shapes. So, no matter the type of wood you’re working with, a laser cutting machine is a reliable option for precise and efficient cuts.

How long does it take to learn how to use a laser cutting machine?

It typically takes a few weeks to a few months to become proficient in using a laser cutting machine. The learning curve involves understanding the machine’s software, safety precautions, and material settings. However, the benefits of laser cutting make the learning process worthwhile.

Laser cutting offers precision, versatility, and speed, allowing for intricate designs and efficient production. Additionally, the non-contact nature of laser cutting minimizes material waste and reduces the need for post-processing.

Is electric cutting safer than laser cutting?

Electric cutting is not necessarily safer than laser cutting, as both methods have their own safety considerations. However, laser cutting is more precise than electric cutting. In fact, studies have shown that laser cutting can achieve accuracy levels of up to 0.1mm.

Additionally, laser cutting can be more cost-effective in the long run due to its ability to cut intricate designs without the need for expensive tooling changes.

Can laser cutting machines be used for intricate designs?

Yes, laser cutting machines can be used for intricate designs. They offer precise and detailed cutting capabilities, allowing for complex patterns and shapes. However, it’s important to note the limitations of laser cutting for intricate designs. The thickness and type of material being cut can affect the intricacy that can be achieved. Additionally, the speed and power of the laser may also impact the level of detail.

Conclusion

In conclusion, when it comes to the battle between laser cutting and electric cutting in woodworking, the winner is clear.

Laser cutting shines like a bright beam of light, offering precise and intricate cuts that are sure to impress. However, it has its drawbacks, such as high costs and limited thickness capabilities.

On the other hand, electric cutting may not have the same wow factor, but it gets the job done efficiently and is more cost-effective.

Ultimately, the choice between these two methods depends on the specific needs and preferences of the woodworker.