Have you ever marveled at the intricate acrylic designs that adorn storefronts or interior decorations? They seem to effortlessly capture attention with their precision and elegance. But have you ever wondered how these designs are created?

Laser cutting and milling are two popular methods used to shape acrylic into stunning works of art, each with its own set of benefits and drawbacks. In this article, we will delve into the world of laser cutting and milling, comparing their precision levels to determine which method reigns supreme.

Imagine you are a sculptor, carefully chiseling away at a block of marble to reveal a masterpiece within. Similarly, both laser cutting and milling allow craftsmen to transform raw acrylic material into breathtaking designs. But which method offers the utmost precision?

Through an in-depth analysis of their techniques, we will uncover the intricacies of laser cutting and milling, exploring their precision capabilities and highlighting the factors to consider when creating acrylic designs. By examining real-life case studies and examples, we will help you make an informed decision and choose the right method for your next acrylic design project.

So, let’s dive into the world of laser cutting and milling to discover which one is truly more precise.

Key Takeaways

- Laser cutting uses a high-powered laser beam to shape acrylic, offering fine details, intricate patterns, and smooth edges.

- Milling involves removing material using rotary cutters, providing high precision and the ability to create complex shapes.

- Laser cutting is faster and more cost-effective for small-scale projects, while milling allows for more complex designs and three-dimensional shapes.

- Factors to consider when choosing between laser cutting and milling include acrylic thickness, design complexity, material suitability, and desired level of precision.

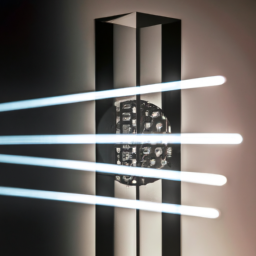

Understanding Laser Cutting

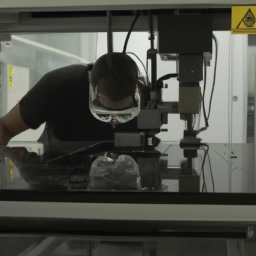

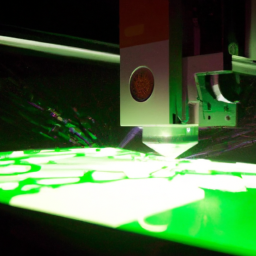

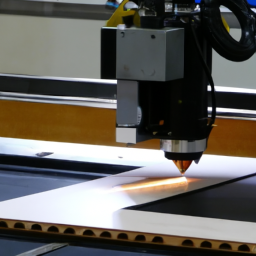

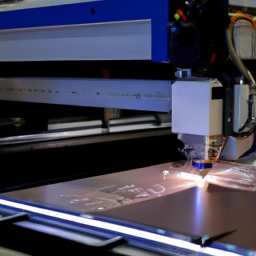

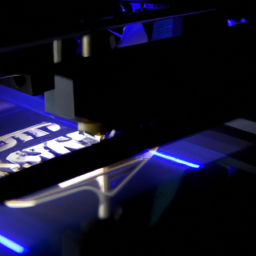

Laser cutting is a fantastic option for achieving precise and intricate designs in acrylic. Using laser cutting techniques, a high-powered laser beam is directed onto the surface of the acrylic, melting and vaporizing the material to create clean and precise cuts.

This process offers several advantages over other cutting methods. Firstly, laser cutting allows for extremely fine details, intricate patterns, and smooth edges that are difficult to achieve with other techniques. Additionally, the laser beam is non-contact, meaning there’s no physical force applied to the acrylic, reducing the risk of material damage.

Laser cutting also offers high levels of repeatability and accuracy, ensuring consistent results with every cut.

Now, let’s explore milling techniques to further understand the differences between these two methods.

Exploring Milling Techniques

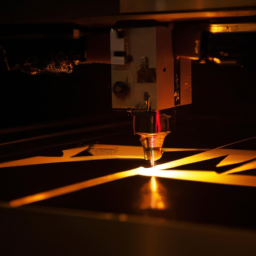

When it comes to milling techniques, it’s important to understand how it works.

Milling is a process that involves removing material from a workpiece using rotary cutters. This method offers several advantages, such as high precision and the ability to create complex shapes.

However, milling also has its limitations, including the potential for tool wear and the need for multiple setups.

How milling works

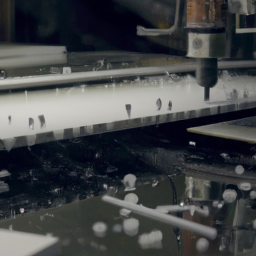

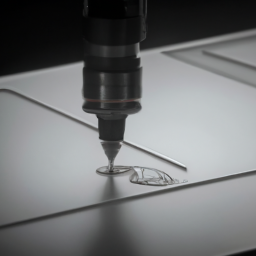

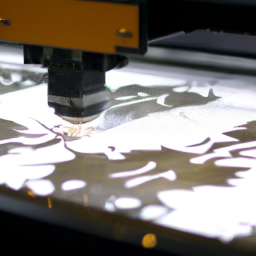

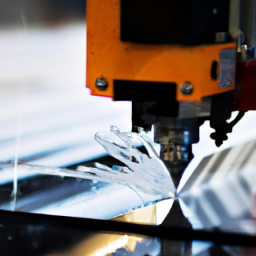

To achieve precise results when milling acrylic designs, you need to carefully program the machine and ensure accurate measurements are taken. The milling process involves using a rotating cutting tool to remove material from the workpiece. This can be done using a variety of techniques, such as face milling, end milling, or profile milling, depending on the desired outcome.

Milling applications for acrylic designs include creating intricate patterns, engraving text or logos, and producing complex shapes with smooth edges. The key to achieving precision lies in the programming of the machine, which determines the tool path and feed rate. Accurate measurements are also crucial to ensure that the desired dimensions are achieved.

By carefully controlling the milling process, you can achieve highly accurate results in your acrylic designs. This precision is one of the advantages of milling over laser cutting, as it allows for more intricate and detailed designs to be created.

Advantages of milling

Maximize your creativity and achieve stunning results with milling, the technique that offers unparalleled precision and the ability to create intricate and detailed designs in acrylic. Milling is a versatile process that can be used for a wide range of applications, including creating prototypes, producing custom parts, and engraving designs. It allows you to work with various materials, such as acrylic, wood, metal, and plastics, giving you the flexibility to bring your ideas to life.

To give you an idea of the capabilities of milling, here is a table showcasing some common milling applications and the materials they can be used on:

| Milling Application | Milling Materials |

|---|---|

| Prototyping | Acrylic, Metal, Plastics, Wood |

| Custom Part Production | Acrylic, Metal, Plastics, Wood |

| Engraving | Acrylic, Metal, Plastics, Wood |

Milling provides precise control over the cutting process, allowing you to achieve intricate details and complex geometries in your acrylic designs. However, it is important to consider the limitations of milling, which we will discuss in the next section.

Limitations of milling

Although milling offers precise control over the cutting process, there are certain limitations to consider. These limitations include:

-

Material selection: Milling isn’t suitable for all materials, especially those that are brittle or heat-sensitive. It may cause the material to crack or deform, compromising the precision of the final product.

-

Tool wear: As the milling tool is used repeatedly, it gradually wears down. This can lead to a decrease in precision over time, as the worn tool may not cut as accurately as a new one.

-

Time-consuming: Milling is a relatively slow process compared to laser cutting. It requires multiple passes and careful setup, which can be time-consuming, especially for complex designs.

Considering these limitations, it’s important to explore alternative methods that may offer better precision and efficiency. Transitioning into the subsequent section about the precision comparison, it becomes evident that laser cutting may be a viable alternative to overcome these limitations.

Precision Comparison

When comparing laser cutting to milling for acrylic designs, it’s important to consider the precision of each method. Precision comparison between these techniques has been extensively studied through various case studies.

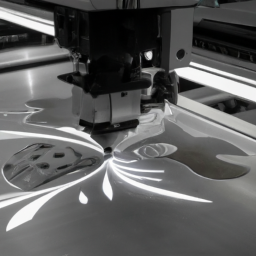

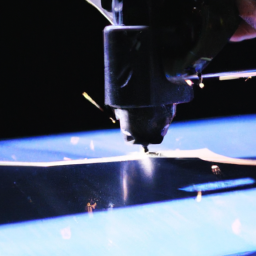

Laser cutting offers exceptional precision due to its ability to produce fine and intricate cuts with minimal material loss. The highly focused laser beam ensures a narrow kerf width, resulting in precise and clean edges.

On the other hand, milling can achieve high precision as well, but it is more dependent on the quality of the milling machine and tooling. Factors such as machine rigidity, spindle runout, and tool wear can affect the precision of the milled acrylic designs.

Considering the precision capabilities of both methods, it is crucial to explore other factors that should be taken into consideration for acrylic designs.

Considerations for Acrylic Designs

Now that we’ve discussed the precision comparison between laser cutting and milling, let’s consider some important factors when it comes to acrylic designs.

The thickness of the acrylic is a crucial consideration as it can affect the overall outcome of the design. Thicker acrylic may require more power and time for laser cutting, while milling can handle thicker materials with ease.

Additionally, the complexity of the design plays a significant role in deciding the best method. Laser cutting is well-suited for intricate and detailed designs due to its high precision, while milling is more suitable for less intricate designs.

By taking into account the acrylic thickness and design complexity, you can determine which method will provide the best precision for your specific project.

Transitioning into the next section, let’s explore some case studies and examples to further illustrate these points.

Case Studies and Examples

Surprisingly, you may think that case studies and examples are just a bunch of boring stories, but they can actually provide valuable insights into the best methods for achieving precision in your acrylic projects. When it comes to comparing laser cutting and milling for acrylic designs, case studies offer real-life examples that highlight the advantages and limitations of each method.

Here are five key takeaways from these case studies:

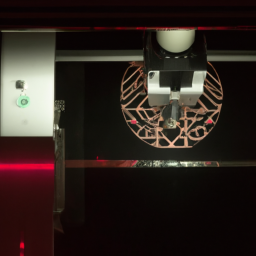

- Case study #1: Laser cutting proved more precise for intricate and detailed designs.

- Case study #2: Milling excelled in creating three-dimensional shapes with complex contours.

- Case study #3: Laser cutting resulted in smoother edges and minimal post-processing.

- Case study #4: Milling showcased superior accuracy for larger and thicker acrylic sheets.

- Case study #5: Laser cutting demonstrated faster production times and lower costs for small-scale projects.

These case study comparisons provide valuable insights into the strengths and weaknesses of laser cutting and milling for acrylic designs. Understanding these real-life examples can help you make the right choice for your specific project needs.

Now, let’s delve into the next section to explore the factors to consider when making your decision.

Making the Right Choice

Choosing the right method for your acrylic projects can be a challenging decision, but understanding the strengths and limitations of each option is crucial.

When weighing options between laser cutting and milling, material suitability is a key factor to consider. Laser cutting is highly precise and allows for intricate designs with smooth edges. It is suitable for thinner acrylic sheets and offers faster production times.

On the other hand, milling provides a higher level of precision and is better suited for thicker acrylic materials. It allows for more complex designs and offers the flexibility to create three-dimensional shapes. However, milling can be a slower process compared to laser cutting.

Ultimately, the choice between laser cutting and milling depends on the specific requirements of your acrylic project and the desired level of precision.

Frequently Asked Questions

What are the typical costs associated with laser cutting and milling acrylic designs?

The typical cost comparison between laser cutting and milling acrylic designs is influenced by several factors. According to recent data, laser cutting costs can range from $1 to $10 per minute, depending on the complexity of the design and the thickness of the acrylic.

Milling, on the other hand, is generally more expensive due to the high precision and labor-intensive nature of the process. Factors affecting cost include material waste, machine setup time, and the intricacy of the design.

Are there any limitations or restrictions when it comes to the size or thickness of acrylic that can be used with laser cutting and milling techniques?

When it comes to laser cutting acrylic, there are certain limitations to consider. The size of the acrylic sheet is an important factor as larger sheets may not fit within the laser cutting machine. Additionally, the thickness of the acrylic can impact the quality of the cut, as thicker sheets may require multiple passes to achieve the desired result.

On the other hand, milling techniques are more suitable for thick acrylic, as they can handle greater depths and provide precise results.

Can laser cutting or milling be used to create intricate or complex designs on acrylic?

When it comes to creating intricate or complex designs on acrylic, both laser cutting and milling can be used. Laser cutting offers the advantage of precise and clean cuts, allowing for intricate details. However, it has limitations in terms of depth and thickness. On the other hand, milling allows for greater flexibility in terms of size and thickness, but may not achieve the same level of precision as laser cutting.

So, it ultimately depends on the specific requirements of your design.

Are there any safety precautions or guidelines that need to be followed when working with laser cutting or milling techniques for acrylic?

When working with laser cutting or milling techniques for acrylic, it’s important to follow safety precautions to ensure a safe working environment. These precautions include proper ventilation requirements to minimize the inhalation of fumes and particles.

Additionally, proper equipment handling should be practiced to avoid accidents or injuries. Machine calibration is crucial to ensure precise cuts or milling, and material compatibility should be considered to prevent damage or deformities to the acrylic.

How does the choice between laser cutting and milling affect the overall production time of acrylic designs?

To reduce production time and optimize the manufacturing process of acrylic designs, the choice between laser cutting and milling plays a crucial role. Laser cutting offers faster and more precise results compared to milling. By utilizing a laser beam to cut through the acrylic material, the process is highly efficient and requires minimal setup time.

On the other hand, milling involves removing material through rotating cutting tools, which can be time-consuming and less precise. Therefore, laser cutting is the preferred method for reducing production time and maximizing efficiency in acrylic design manufacturing.

Conclusion

So, after carefully examining the precision of laser cutting versus milling for acrylic designs, it is clear that laser cutting emerges as the undisputed champion. Its accuracy is as sharp as a surgeon’s scalpel, leaving no room for error.

Milling, on the other hand, falls short in terms of achieving the same level of precision. When it comes to intricate acrylic designs, laser cutting is the way to go. Don’t settle for anything less than perfection, choose laser cutting for flawless results every time.